Method for comprehensively extracting and refining perilla oil

A technology of comprehensive extraction and perilla oil, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of complex refining process, complex process operation, large equipment investment, etc., to solve the problem of serious protein denaturation, The effect of less damage to active ingredients and improved oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

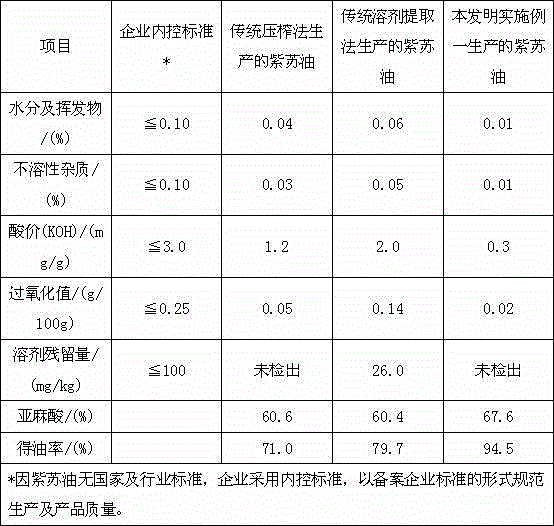

Examples

Embodiment 1

[0026] 1. Grinding perilla seeds: Take 500 kg perilla seeds that have been preliminarily dried to a moisture content of 15%-20%, and use a pulverizer to perform preliminary pulverization. The pulverizer is equipped with a 20-mesh sieve, and pulverized to obtain 20-mesh perilla seed powder;

[0027] 2. Twin-screw extrusion expansion: Put the crushed perilla seed powder in step 1 into a twin-screw extruder for expansion treatment. The control parameters of the expansion treatment are twin-screw speed 50r / min; the heating temperature is set to zone 1 50°C, 80°C in the second zone, and 110°C in the third zone; the hole diameter of the discharge mold is 14mm, and the rotary cutting frequency of the rotary cutting device of the extruder is set at 35HZ, and the material is cut into granular materials with a diameter of less than 20mm.

[0028] 3. Pulverization: pulverize the material puffed in step 2, and install a 20-mesh screen in the pulverizer, and pulverize to obtain a 20-mesh pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com