Woody molding, it's production system and production method

a production system and molding technology, applied in the field of wood-like molding products, can solve the problems of more expensive wine kept in the cylindrical main body than the actual price, and achieve the effects of improving moldability upon extrusion molding or the like, improving the percentage of re-use of wood waste material j, and good moldability upon forming the cylindrical main body by extrusion molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

case 1h

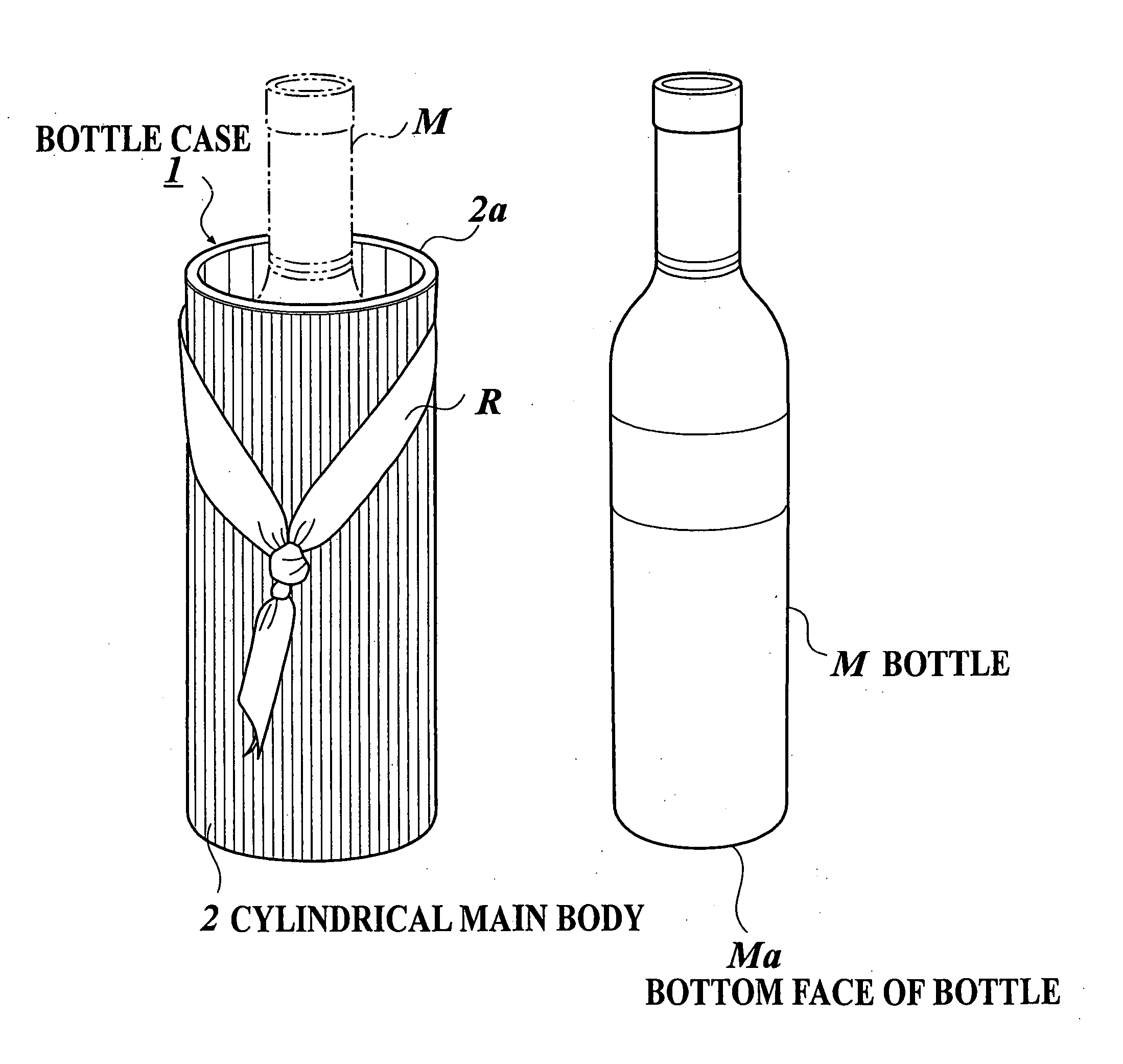

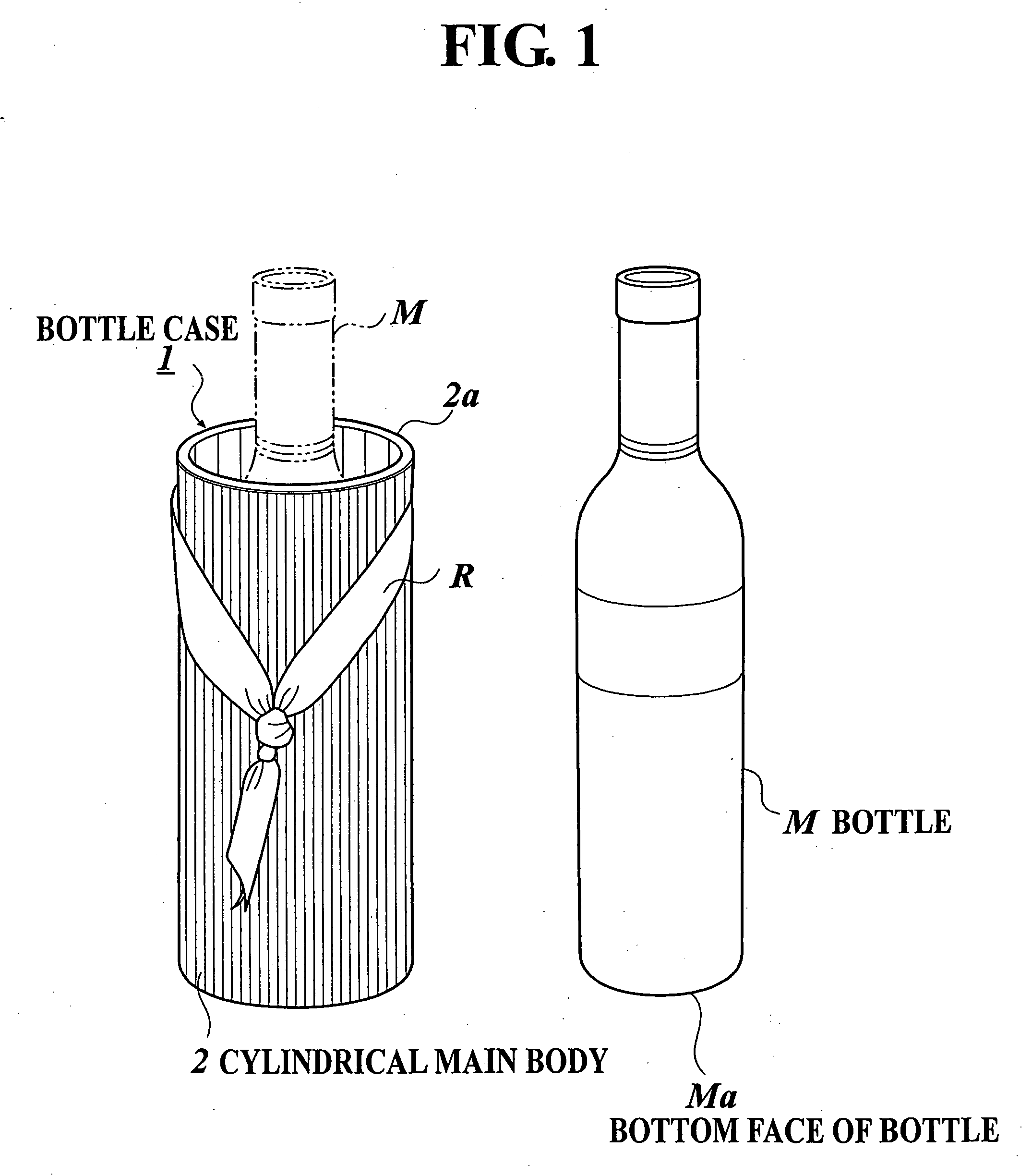

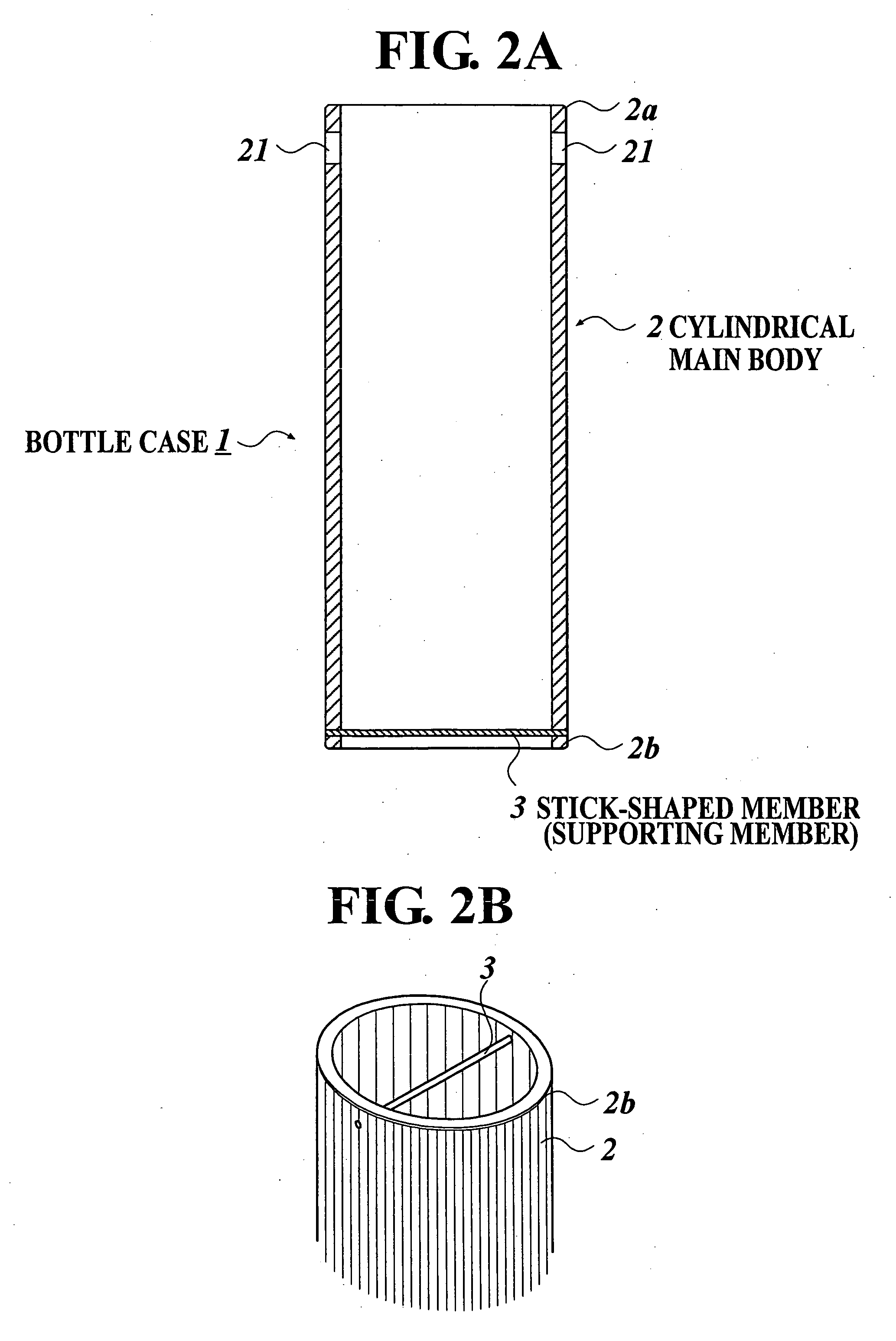

[0140] A bottle case 1H shown in FIG. 14A includes a cylindrical main body 2H, and a supporting member 3 (stick-shaped member) 3 to support the bottom face of a bottle when the bottle is inserted in the cylindrical main body 2H, and the like.

[0141] The cylindrical main body 2H includes opening portions 12 communicating with the inside thereof, which are formed by cutting out opposed central portions of the cylindrical main body 2H, in the same directions as those of the holes 21 provided in top end portions of the cylindrical main body. The opening portions 12 are vertically long. The stick-shaped member 3 is similar to that of the bottle case 1, and provided between the opposed portions at lower end portion of the cylindrical main body 2H.

case 1j

[0142] A bottle case 1J shown in FIG. 14B includes: a cylindrical main body 2J formed by cutting out (shown as cut-out portions 13, 13 in FIG. 13B) the top and bottom ends of the cylindrical main body 2 of the above-mentioned bottle case 1 into a circular arc shape when viewed from a side of the case; and a supporting member 3 to support the bottom face of a bottle inserted in the cylindrical main body 2J.

[0143] The stick-shaped member 3 is similar to that of the bottle case 1, and provided between the opposed portions at lower end portion of the cylindrical main body 2J above the cut-out portion 13 at the lower end of the cylindrical main body 2J.

case 1k

[0144] A bottle case 1K shown in FIG. 14C includes: a cylindrical main body 2K prepared by forming an opening portion 12 by cutting out a central portion of the cylindrical main body 2 as in a case of the cylindrical main body 2H of the bottle case 1H, and cutting out the top end of the cylindrical main body into a circular arc shape when viewed from a side of the case as in a case of the cylindrical main body 2J of the bottle case 1J; and the above-described supporting member (stick-shaped member) 3.

[0145] The stick-shaped member as the supporting member 3 is similar to that of the bottle case 1, and provided between the opposed portions at lower end portion of the cylindrical main body 2K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com