Preparation method of low-temperature curing water-based glass baking paint

A glass baking varnish, water-based technology, applied in the direction of coating, etc., can solve the problems of not meeting the process requirements, low energy consumption, and less selectivity, and achieve excellent scratch resistance and wear resistance, flexibility, high hardness, and film formation The effect of low curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

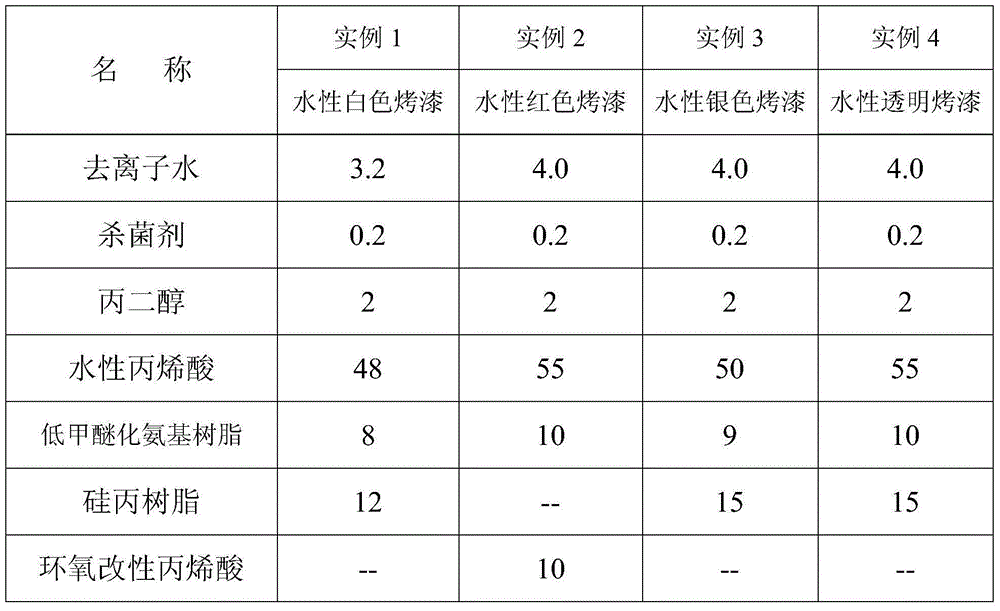

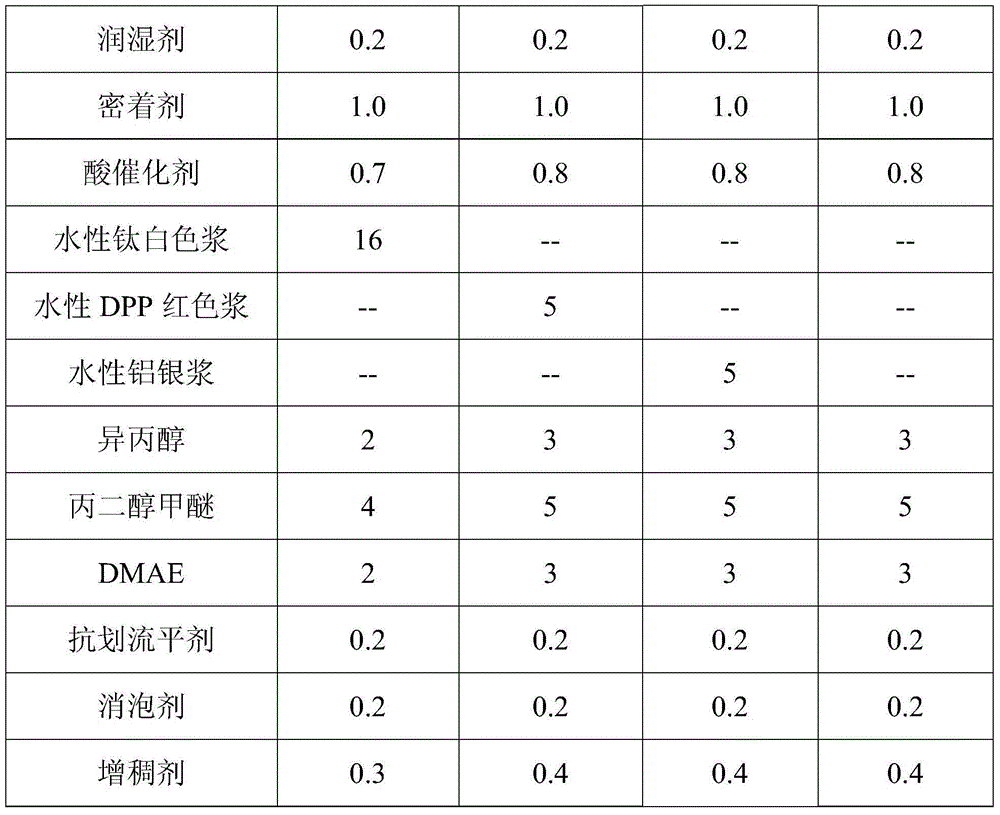

Examples

Embodiment 1

[0025] According to Example 1 in Table 1, the low-temperature curing water-based white glass baking varnish is mixed and stirred evenly with deionized water, wetting agent, and defoamer according to the formula weight ratio, and then add acrylic resin, amino resin, and hydroxyl resin, and then add film-forming aids, Acid catalyst, titanium white slurry, leveling agent, thickener, anti-settling agent, pH regulator are stirred evenly, water replenishment, defoaming, adjusted to the specified viscosity, filtered and packaged to prepare a low-temperature curing water-based white glass baking varnish.

Embodiment 2

[0027] Example 2 Refer to Example 1 for the preparation steps of low-temperature curing water-based red glass baking varnish.

Embodiment 3

[0029] Example 3 Refer to Example 1 for the preparation steps of low-temperature curing water-based silver glass baking varnish.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com