Patents

Literature

535 results about "Cellulose Powders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose (C6H10O5)n is refined wood pulp. It is a white, free-flowing powder. Chemically, it is an inert substance, is not degraded during digestion and has no appreciable absorption.

High-strength FeOOH desulfurizer and preparation method thereof

ActiveCN101584962AHigh mechanical strengthAvoid lostDispersed particle separationCarboxymethyl celluloseSulfur

The invention relates to a high-strength FeOOH desulfurizer, which consists of 50 to 95 weight percent of amorphous FeOOH, 0 to 45 weight percent of carrier and 5 to 50 weight percent of organic binder, wherein the carrier is one or more of aluminium oxide, diatomite, natural zeolite and catalytic cracking spent catalyst; and the organic binder is one or more of sodium carboxymethyl cellulose, sesbania powder and cellulose powder. The invention further discloses a preparation method for the desulfurizer on the basis. The FeOOH desulfurizer prepared by the preparation method has high sulfur capacity, high mechanical strength and wider applicable desulfurization range.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Solution containing cellulose dissolved in n-methylmorpholine-n-oxide and high tenacity lyocell multifilament using the same

ActiveUS20050154093A1Solidifying temperatureIncrease flexibilityNon-fibrous pulp additionMonocomponent cellulose artificial filamentLiquid stateLyocell

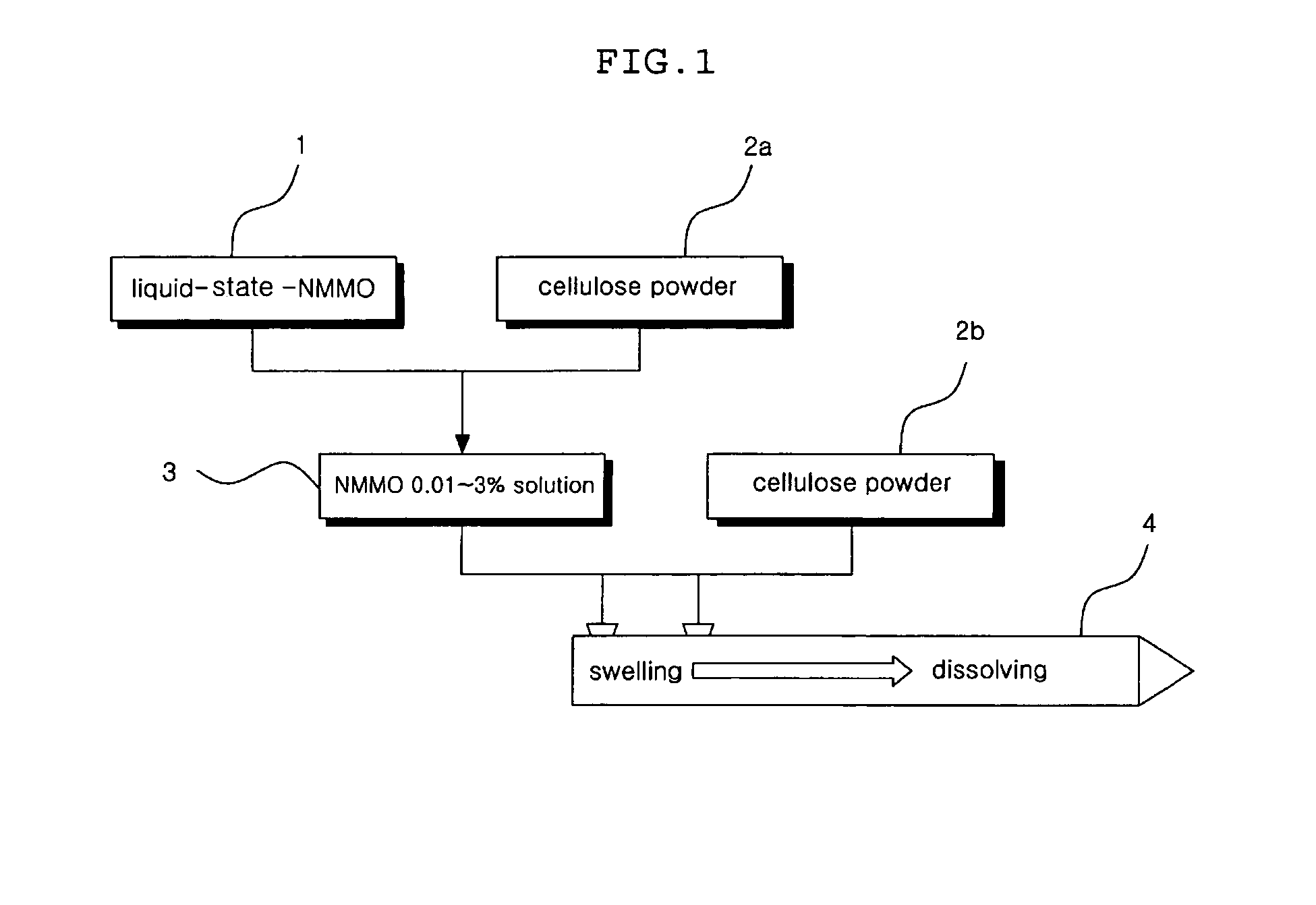

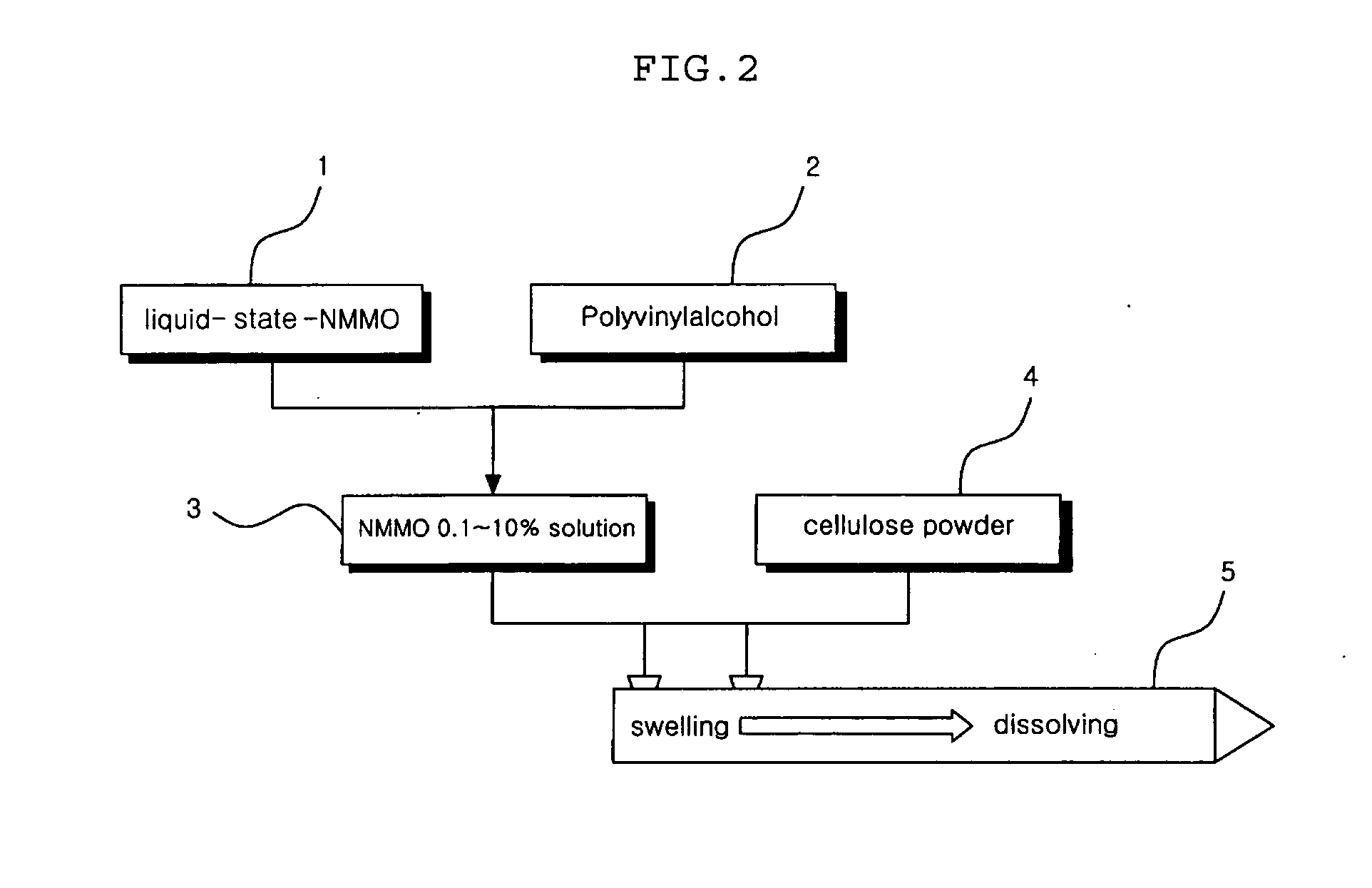

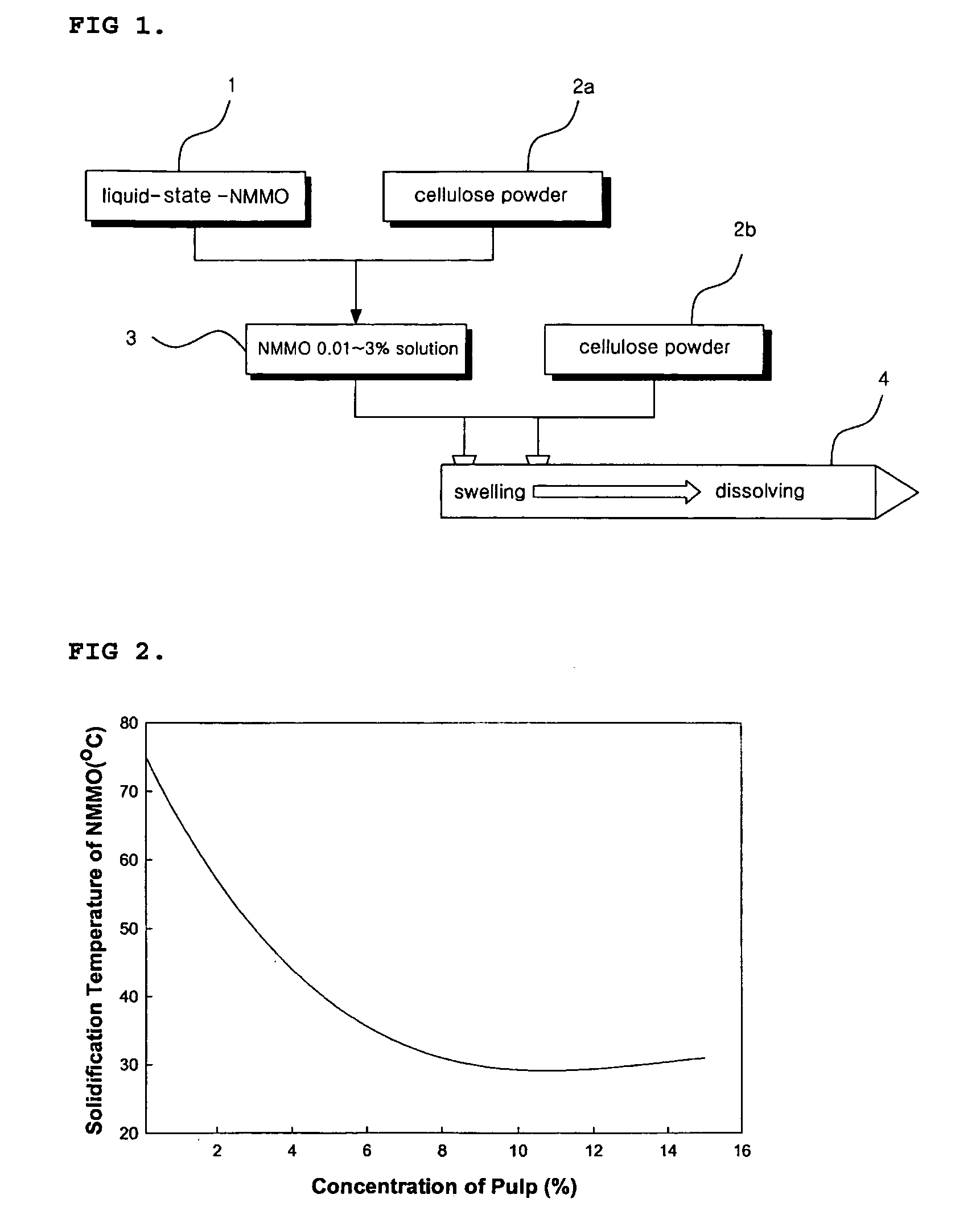

This invention relates to a method of preparing cellulose solution which is homogeneous at relatively low temperature, in which a small amount of cellulose powder or polyvinylalcohol is dissolved in the liquid-state, concentrated N-methylmorpholine-N-oxide (hereinafter, referred to as ‘NMMO’) so as to lower the solidifying temperature of NMMO, and then, the resulting solution and cellulose powder are fed into an extruder so as to be mixed, swollen and melted in the extruder.

Owner:HYOSUNG ADVANCED MATERIALS CORP

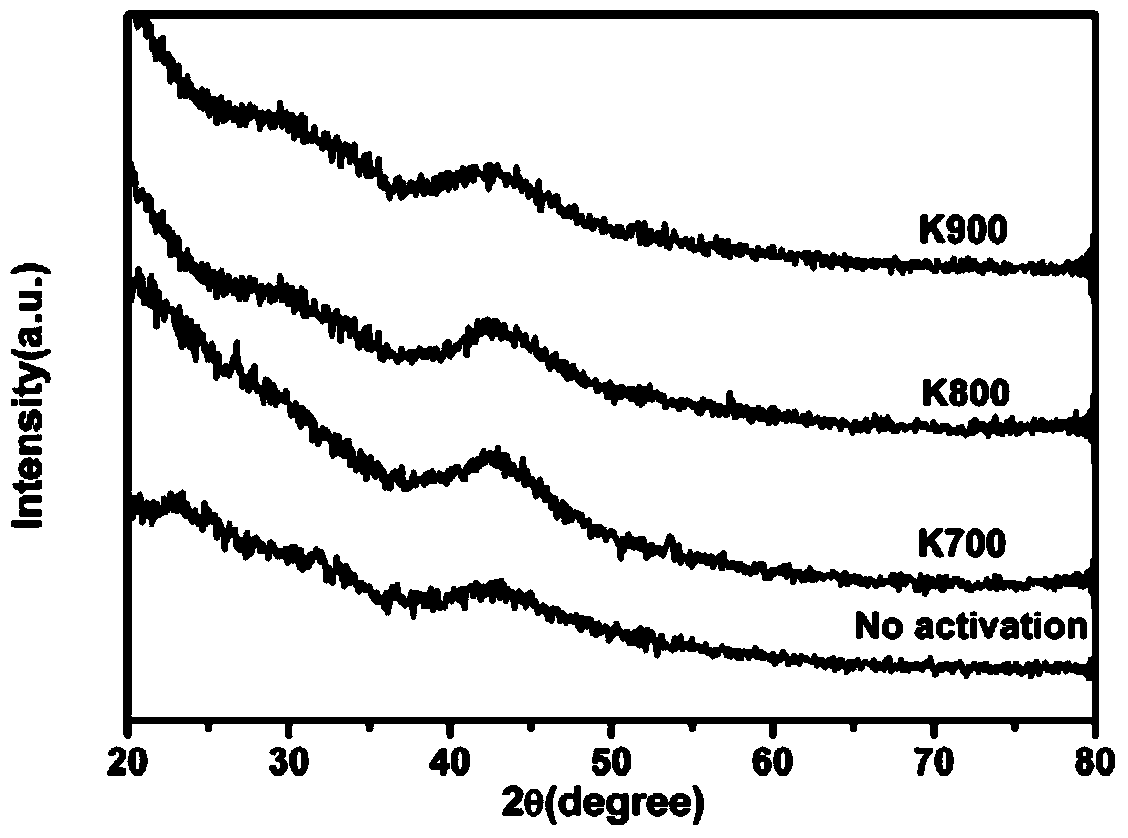

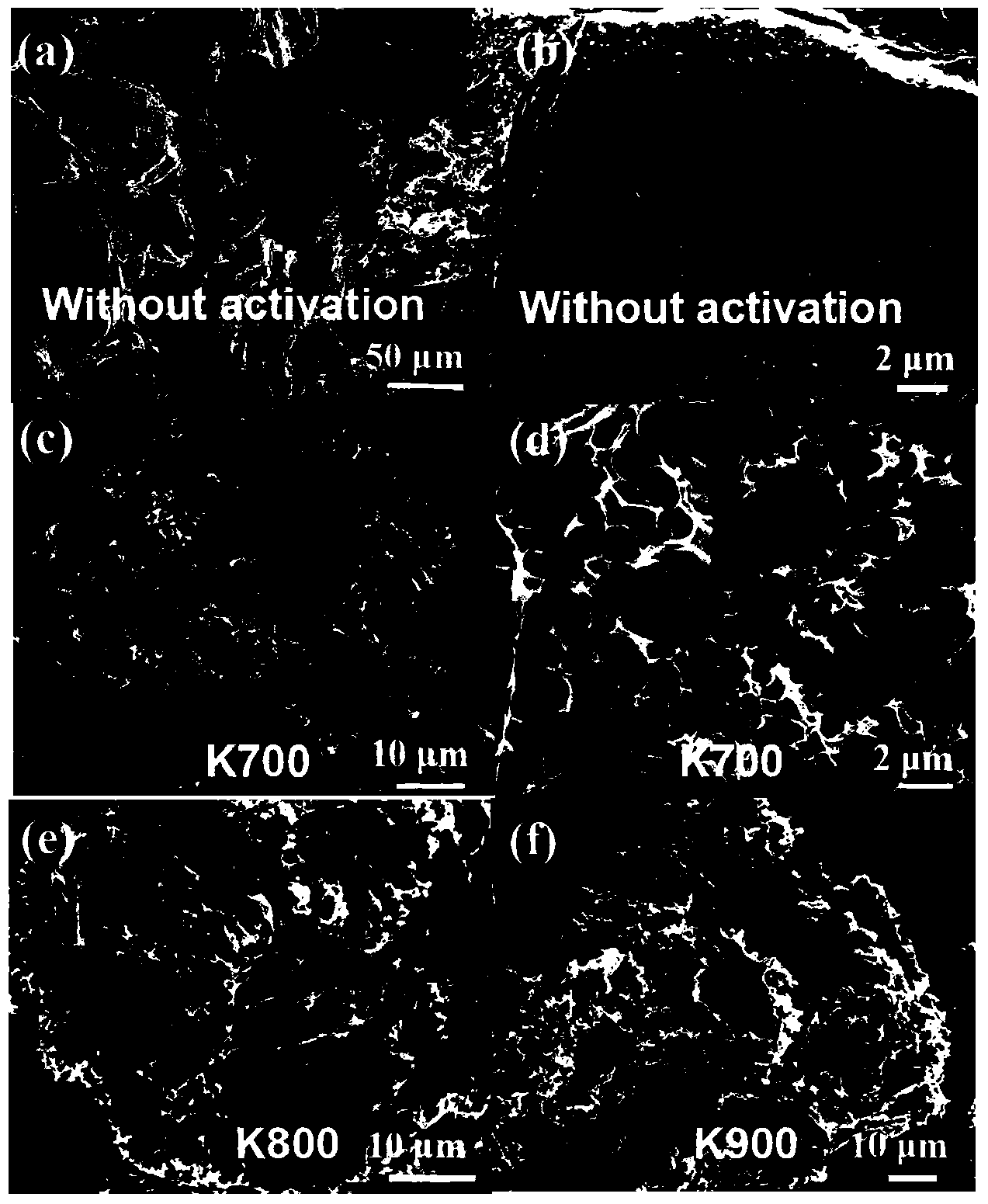

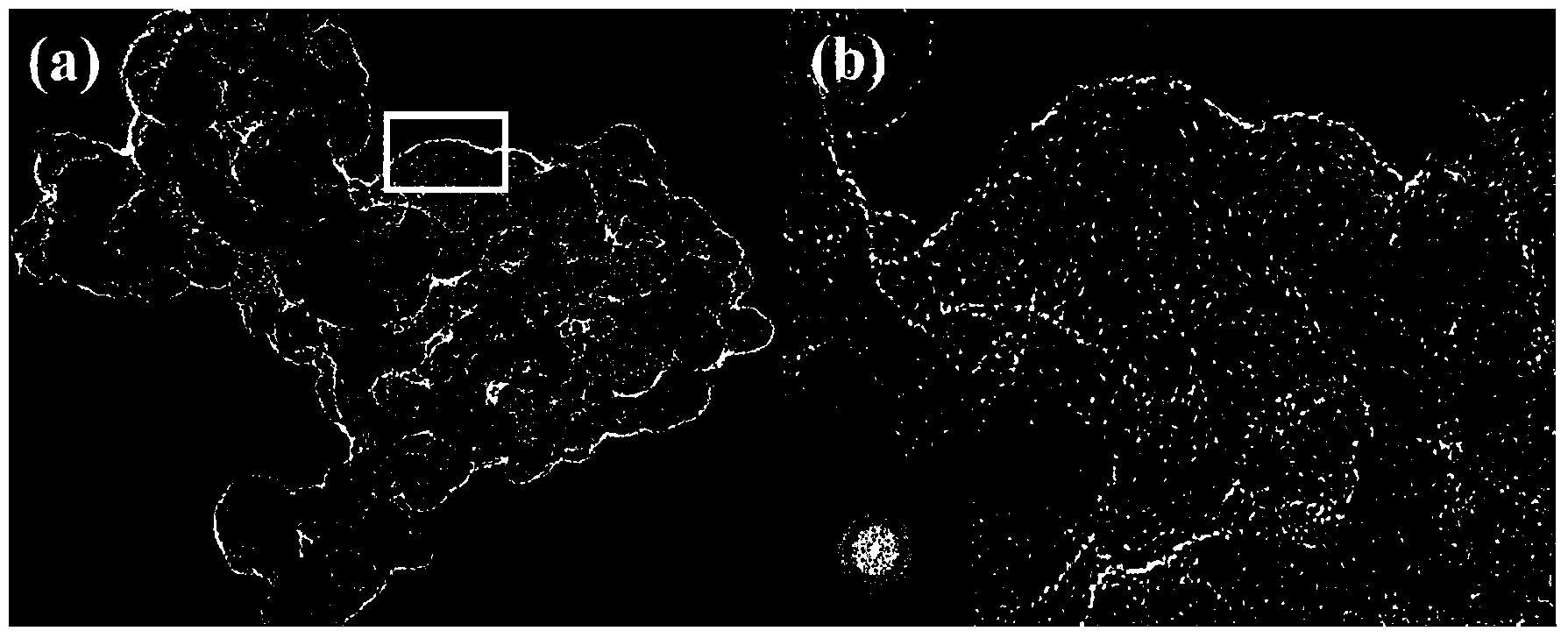

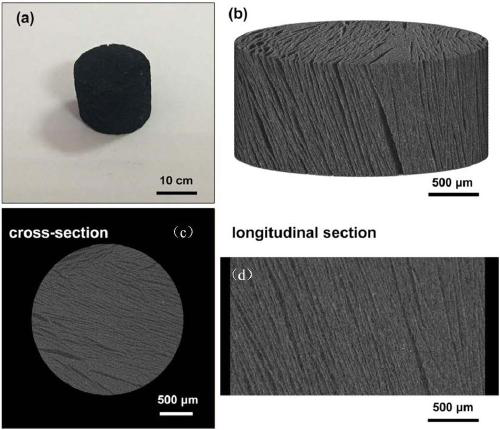

Method for preparing supercapacitor carbon aerogel by utilization of bagasse

ActiveCN103839699AImprove electrochemical performanceLow costHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceToxic industrial waste

The invention discloses a method for preparing supercapacitor carbon aerogel by the utilization of bagasse. The method includes the steps that the bagasse is used for preparing cellulose powder without xylogen and hemicellulose; the cellulose powder is used for preparing cellulose aerogel; the cellulose aerogel is carbonized to obtain carbon aerogel; the carbon aerogel is activated to obtain the supercapacitor carbon aerogel. According to the method, the industrial waste bagasse is used as raw materials, the requirements for sustainable development and environmental protection are met, and the cost of electrode materials is effectively lowered. The product prepared through the method is of a three-dimensional hierarchical pore structure; compared with a product obtained through a conventional method, the product prepared through the method is large in specific area and good in repeatability, and has higher specific capacitance and better cycling stability. The method is more suitable for preparing supercapacitor electrode materials and has wide development prospects.

Owner:SHANDONG UNIV

Water dispersible nanometer avicel, its prep.and colloid therefrom

The nanometer microcrystal cellulose powder is surface modified nanometer microcrystal cellulose with added hydrophilic colloid in the amount of 5-150 wt% of nanometer microcrystal cellulose and has grain size of 6.3-100 nanometers. During its preparation, hydrophilic colloid is dispersed homogeneously into water dispersed medium of surface modified nanometer microcrystal cellulose and the mixture is then dried and crushed. The nanometer microcrystal cellulose is easy to be water dispersed to form colloid, which is homogeneous and high in gluing strength and has the small size of microcrystal cellulose maintained, so that it has wide and unique application foreground in food production, medicine, papermaking, textile, new material preparation and other fields.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Cellulose powder

InactiveUS7939101B2High hardnessLess destructiveBiocideOrganic active ingredientsMetallurgySpecific volume

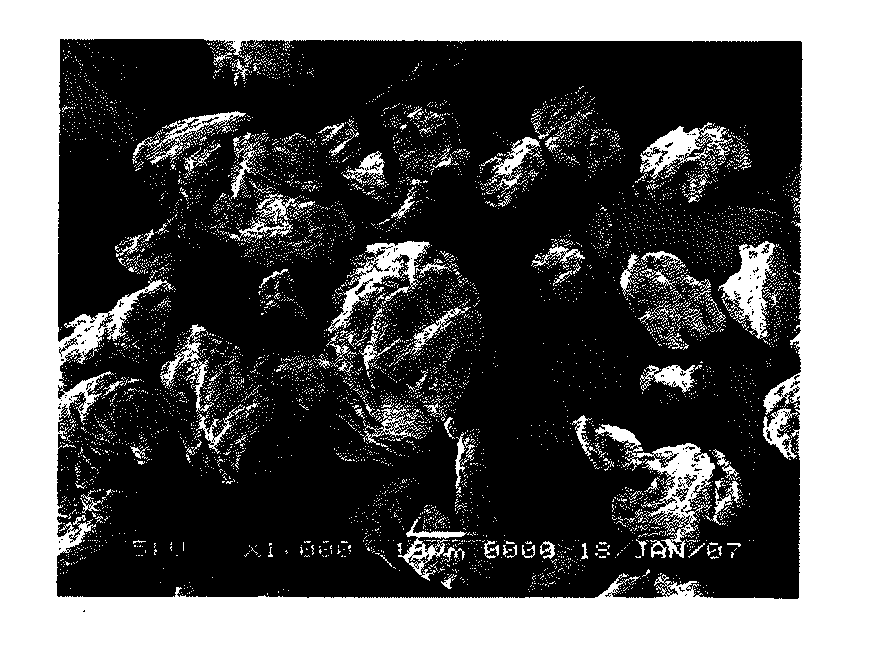

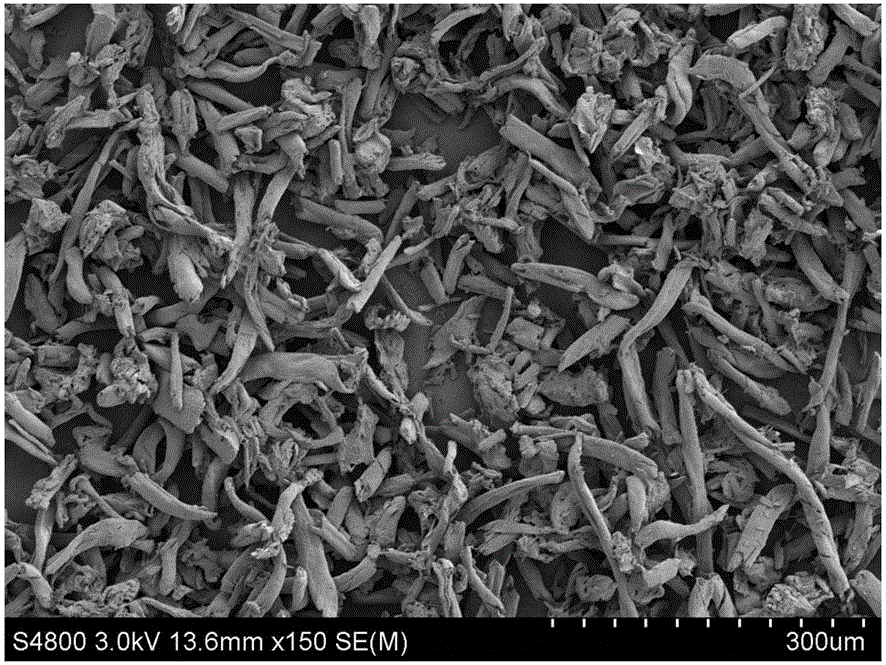

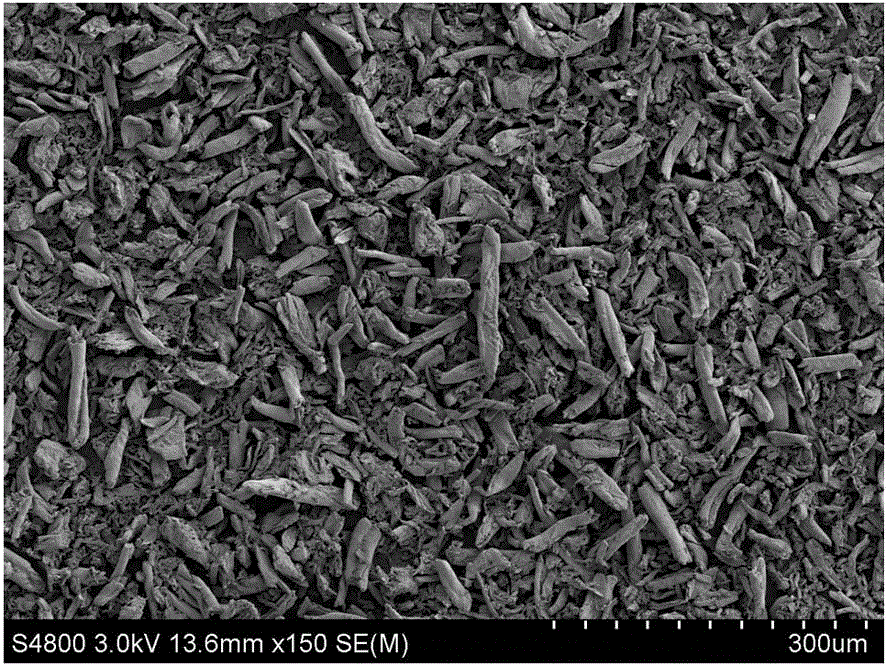

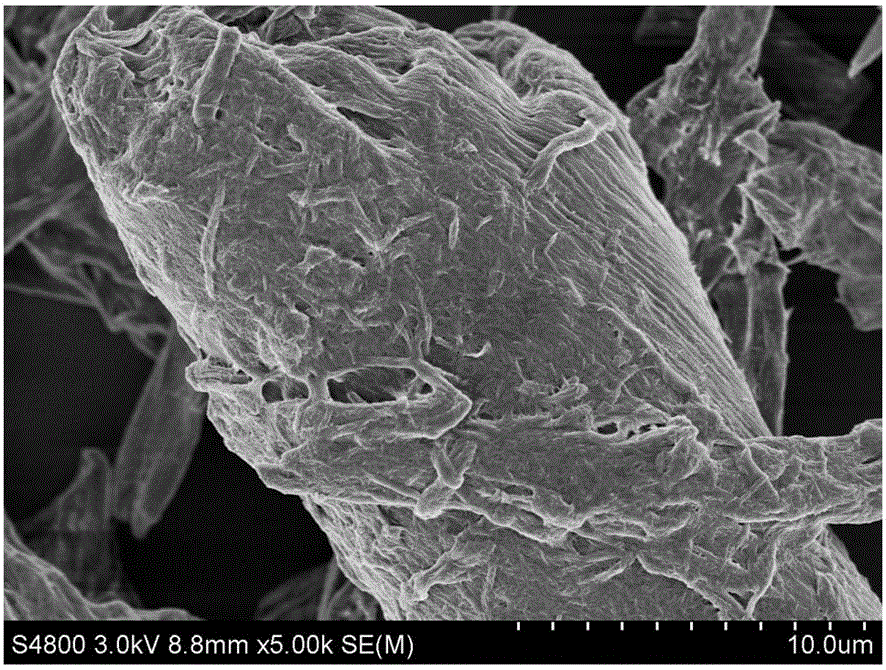

Cellulose powder having an especially excellent balance among moldability, fluidity and disintegrating property is provided. Cellulose powder having an average polymerization degree of 150-450, an average L / D (the ratio of the major axis to the minor axis) value of particles of 75 μm or less of 2.0-4.5, an average particle size of 20-250 μm, an apparent specific volume of 4.0-7.0 cm3 / g, an apparent tapping specific volume of 2.4-4.5 cm3 / g, and an angle of repose of 55° or less.

Owner:ASAHI KASEI CHEM CORP

Preparation method of MXene/cellulose composite aerogel

InactiveCN109679146AHigh strengthImprove conductivityMagnetic/electric field screeningPorosityFreeze-drying

The invention relates to the field of aerogel and electromagnetic absorbing materials, in particular to a preparation method of MXene / cellulose composite aerogel. The preparation method includes the steps that firstly, MAX phase ceramic powder is added into a mixed water solution of lithium fluoride, hydrochloric acid and hydrofluoric acid in a certain proportion for etching to obtain MXene nano-powder; a cellulose sol method is adopted, cellulose powder is added into a mixed water solution of sodium hydroxide and urea in a certain proportion, and a transparent cellulose mixed solution is prepared by cooling the mixture to -12 DEG C; the temperature is maintained, the MXene nano-powder is added into the cellulose mixed solution, and then the appropriate amount of epichlorohydrin is added to the mixture and the mixture is stirred thoroughly for chemical crosslinking; the temperature is raised, and the obtained homogeneous mixture is subjected to a gel reaction; and a gel product is frozen directionally and then freeze-dried to obtain the MXene / cellulose composite aerogel. The composite aerogel has the characteristics of low density, high porosity, good absorbing performance, wide absorbing frequency band and the like, and is convenient to use and suitable for large-scale application in the aerospace field.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for hydrolyzing lignocellulose

The invention discloses a method for hydrolyzing lignocellulose. Lignocellulose is pulverized into particles, and the particles are mixed with water to form even seriflux; the seriflux is preheated to60-150 DEG C by using ultrasonic waves or microwaves; the preheated even seriflux is quickly heated to 120-300 DEG C, solid acid is added and used as a catalyst, and stirring and catalytic reaction are simultaneously carried out for 15-300 minutes. The use of the ultrasonic waves or microwaves radiation in synergism with solid alkali for catalyzing and hydrolyzing the lignocellulose can greatly reduce the reaction time as well as energy consumption. The solid acid catalyst can be repeatedly used, is easily separated, and has the advantages of high mechanical strength, high durability, certainselectivity, relative singularity of catalytic hydrolyzate, high hydrolyzing efficiency and good market application prospect.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

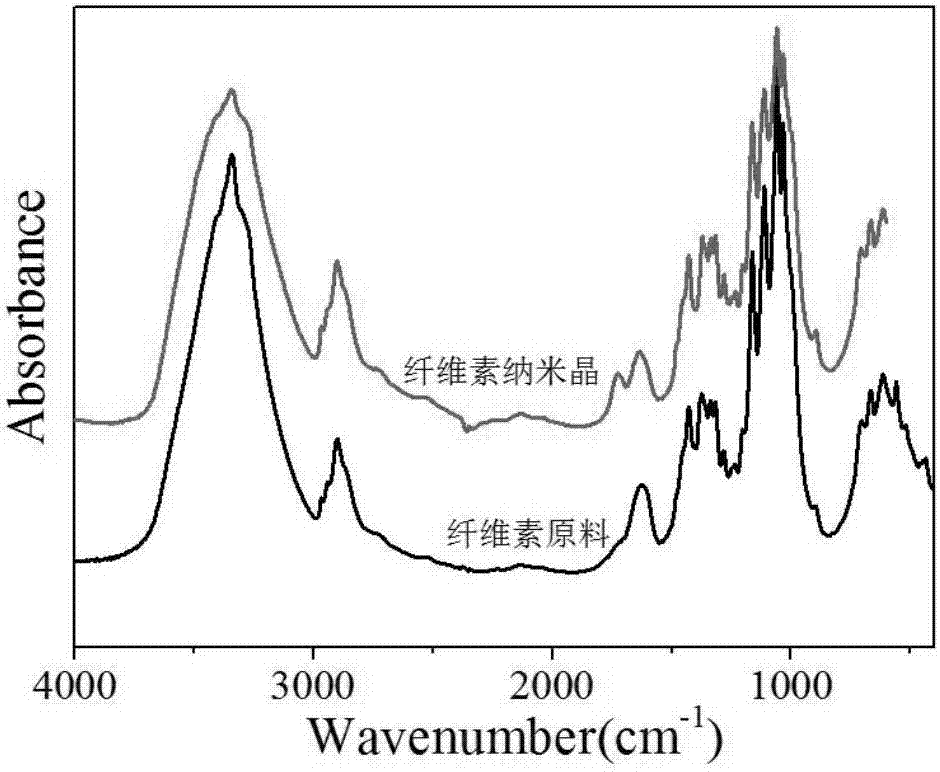

Preparation method of nano-cellulose

The invention discloses a preparation method of nano-cellulose, comprising the following steps of: firstly, swelling the raw material cellulose by aqueous alkali, soaking for a while, centrifugally separating out cellulose, and washing by deionized water till the filter liquor is neutral; dispersing the separated cellulose in water, adding sodium bromide, 2, 2, 6, 6-tetramethyl piperidine-1-oxide and sodium hypochlorite solution, carrying out an oxidation reaction under sonic oscillation, centrifugally separating after reaction, and carrying out freeze drying treatment on suspension liquid to obtain the nano-cellulose powder. Compared with the prior art, the preparation method is incompact in cellulose structure, can enlarge the unit cell distance, and can improve the reaction accessibility after the raw material cellulose is pretreated, so that the oxidation reaction efficiency can be improved, and the product yield can be obviously improved; the oxidation reaction conditions are mild, and are easy to control, and the product quality can not be influenced due to the fact that only a small quantity of sodium chloride and minute quantity of oxidizing agent are mixed in a reaction system after the reaction; and the sonic oscillation is adopted in the process of reaction, so that the oxidation reaction speed can be accelerated, and the reaction time can be obviously shortened.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Use of special screens in the preparation of cellulose powder

InactiveUS20090306364A1Sugar derivativesFats/resins/pitch/waxes removal in pulpChemistryCellulose Powders

Owner:DOW GLOBAL TECH LLC

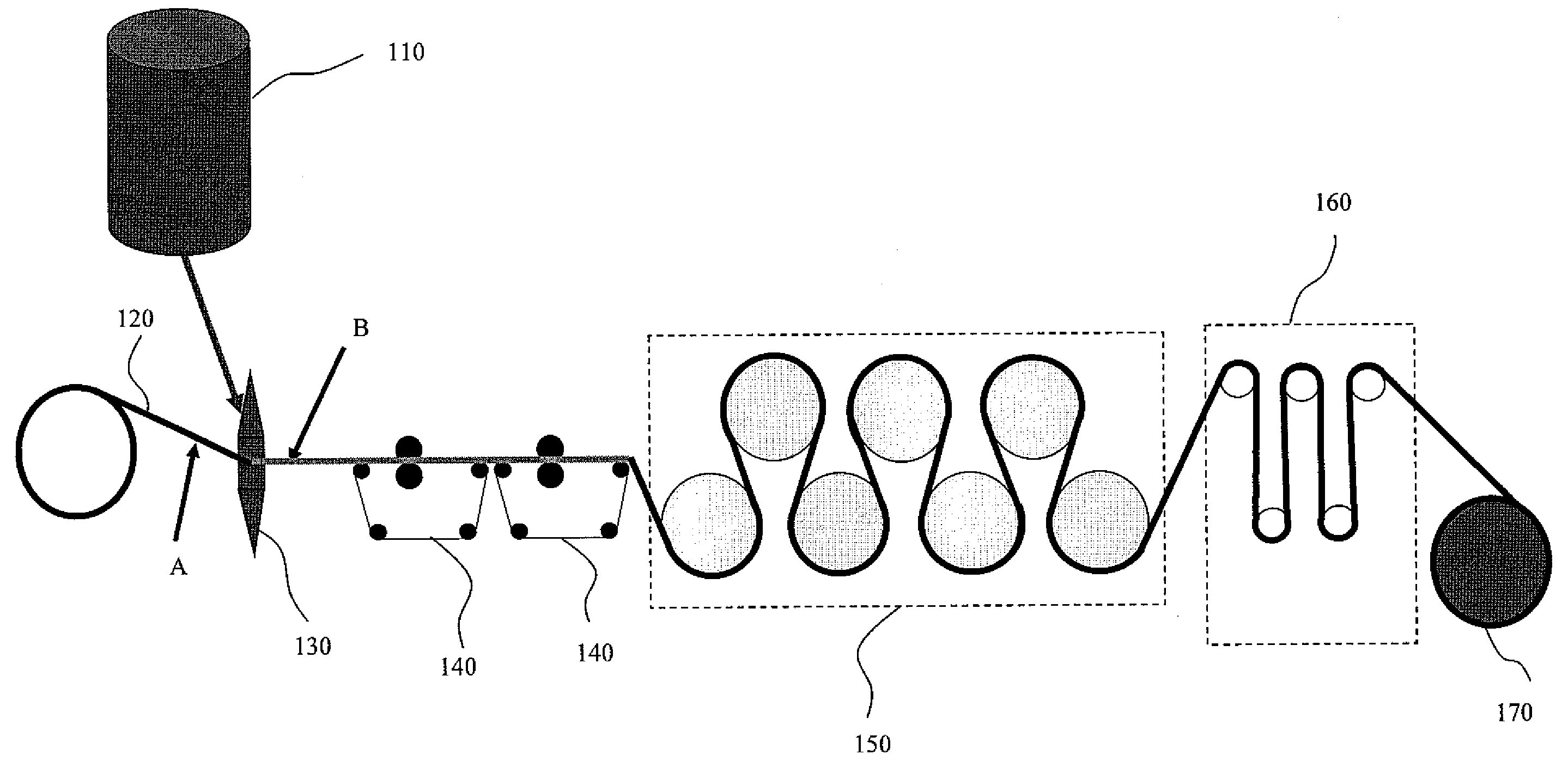

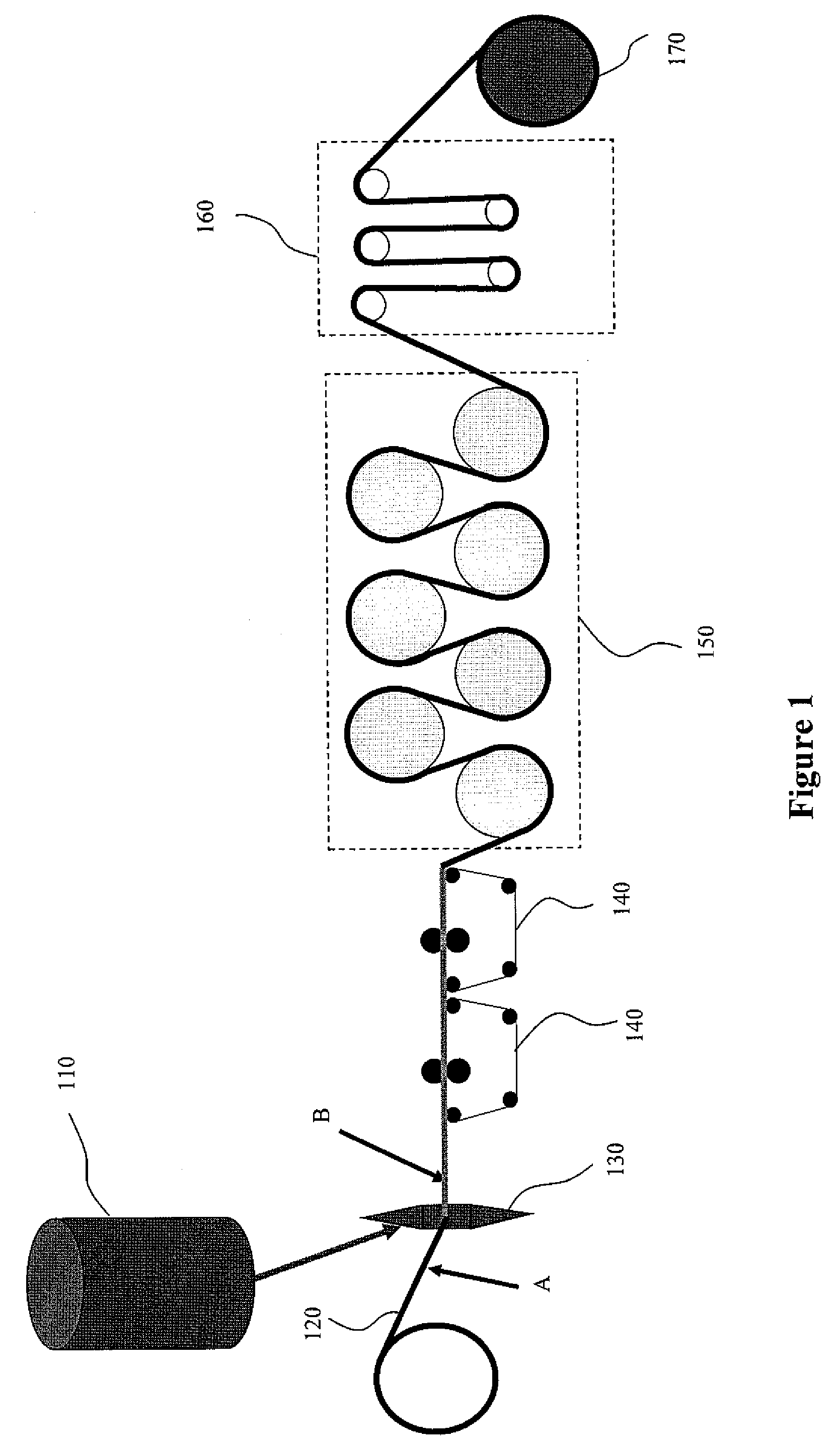

Cellulose dip cord produced from highly homogeneous cellulose solution and tire using the same

ActiveUS20050066646A1Smoothly swollenGood physical propertiesMonocomponent cellulose artificial filamentCellulosic plastic layered productsYarnPolymer science

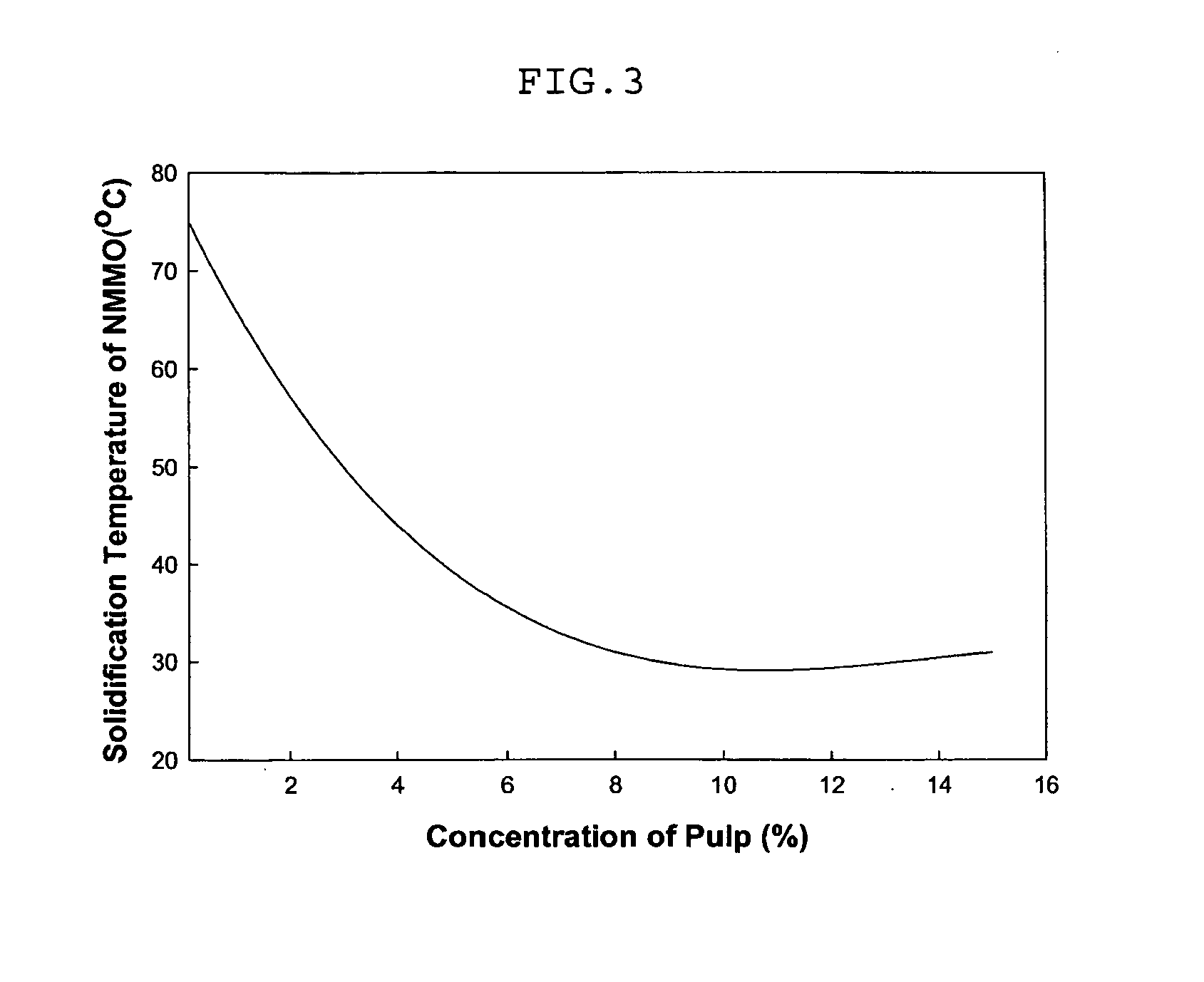

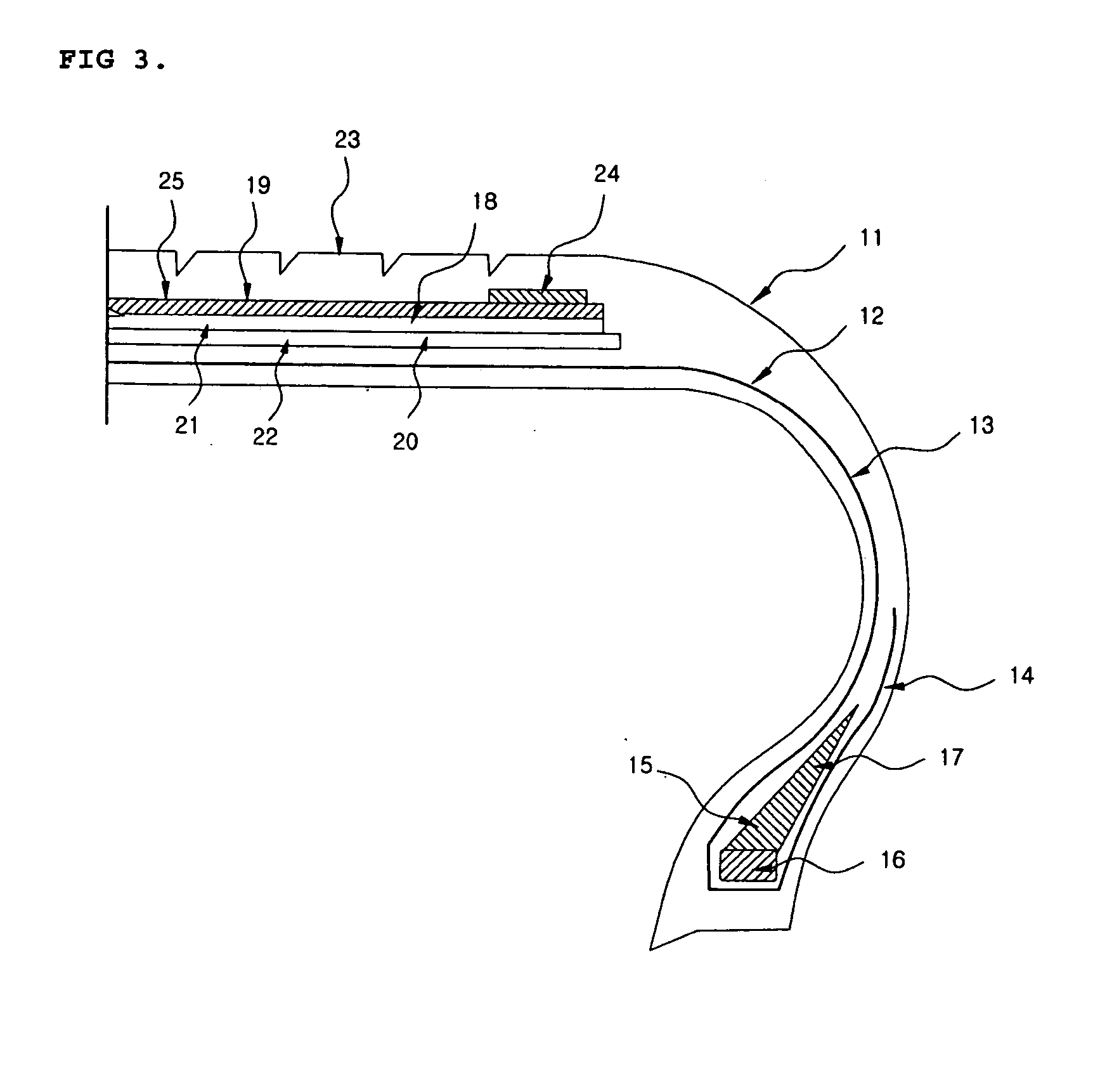

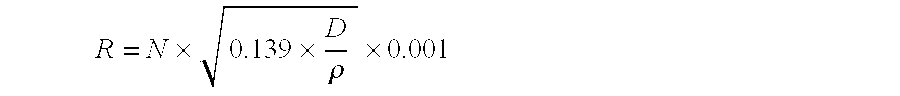

The present invention relates to a method for producing tire using high strength lyocell dip cord, and more particularity, to a lyocell dip cord and tire produced by a method comprising the steps of: (A) dissolving 0.01 to 3 wt % of cellulose powder in portions in concentrated liquid N-methylmorpholine N-oxide (NMMO) to prepare cellulose-containing NMMO solution; (B) feeding the NMMO solution and cellulose powder into an extruder having a screw to be subjected to dispersing, mixing, shearing, kneading, melting and measuring ability in the extruder to prepare a swollen and homogenized cellulose solution; (C) spinning the cellulose solution through a spinning nozzle, passing the spinning solution through an air gap to a coagulation bath and coagulating the spinning solution to obtain a multifilament; (D) subject the multifilament to water-wash, drying and oil-treatment, followed by winding; and (E) twisting the wound yarn with a twisting machine to prepare a greige cord, weaving the greige cord and dipping the woven cord in a dipping solution. According to the present invention, by lowering of solidification temperature of NMMO by dissolving a small amount of pulp in concentrated liquid NMMO, it is possible to prepare a homogeneous cellulose solution at a low temperature. Also, the lyocell dip cord prepared according to the present invention has excellent adhesion to rubber, tenacity and modulus. And, the tire in which the lyocell dip cord according to the present invention is applied to the carcass ply has excellent dimensional stability and handling stability.

Owner:HYOSUNG ADVANCED MATERIALS CORP

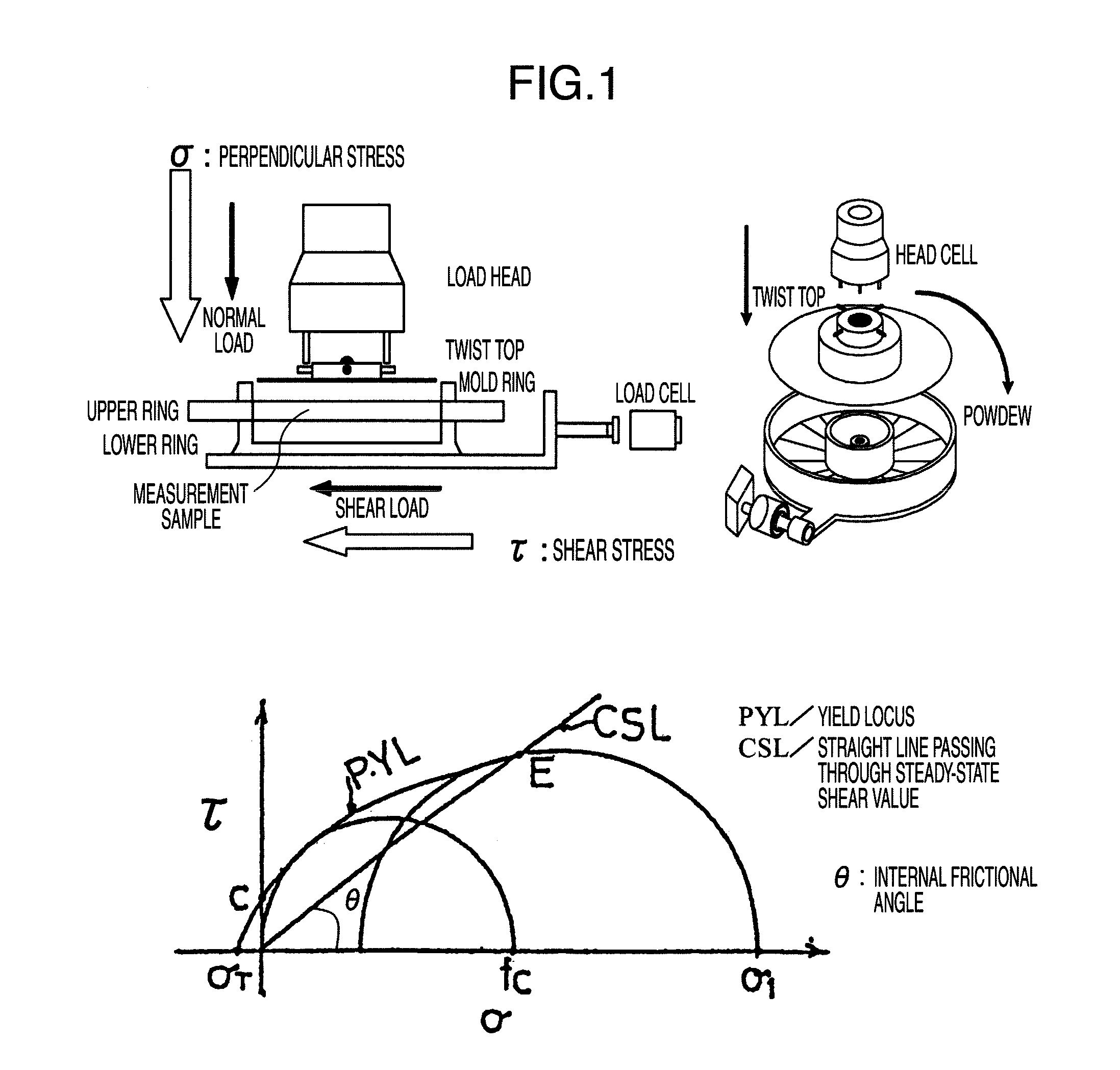

Cellulose powder having excellent segregation preventive effect, and compositions thereof

ActiveUS20110062630A1Easy to solveGood content uniformityOrganic active ingredientsCosmetic preparationsChemistryCellulose Powders

With regard to compositions derived from active ingredients and other additives in medical, food and industrial fields, there have been problems that the active ingredients cannot be uniformly mixed, and that the active ingredients become segregated and lose uniformity as the active ingredients undergo transport, input, and filling processes. There is provided a cellulose powder which improves the uniformity of compositions containing active ingredients or other additives to prevent segregation of the active ingredients, wherein the cellulose powder contains cellulose I type crystals, has an average particle diameter of less than 30 μm, a powder density of 0.1 to 0.45 g / cm3, a tapping density of 0.1 to 0.5 g / cm3, a repose angle of 35 to 50°, a specific surface of more than or equal to 0.1 m2 / g and less than 20 m2 / g, an internal friction angle of 36 to 42°, and is a cellulose powder including a secondary flocculation structure in which primary particles are flocculated.

Owner:ASAHI KASEI CHEM CORP

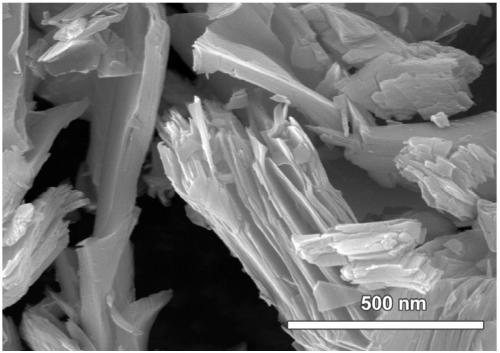

Method for preparing straw cellulose nano crystal whisker

InactiveCN104805722AReduce crystallinityReduce intensityPretreatment with alkaline reacting compoundsRaw material divisionHazardous substanceWhiskers

The invention provides a method for preparing straw cellulose nano crystal whisker. The method is characterized by comprising the steps: utilizing crop straws as raw materials, performing pretreatment and cellulose purifying treatment, mechanically grinding into straw cellulose powder; performing DMSO (Dimethylsulfoxide) treatment and TEMPO (Tetramethylpiperidine) oxidation treatment and stirring at high speed, thereby obtaining straw cellulose powder suspension liquid; performing centrifugal treatment, decentralized treatment and freezing and drying, thereby obtaining straw cellulose nano crystal whisker. The preparation process is simple and has high yield and low energy consumption; no toxic and harmful matters are discharged during production and the preparation process has a capability of large-scale promotion and application; utilized straws can be wastes of plant crops such as rice straws, wheat straws and oilseed rape straws; the raw material has wide source and cost is low; pollution to the environment is solved and additional value of straws is improved.

Owner:DONGHUA UNIV

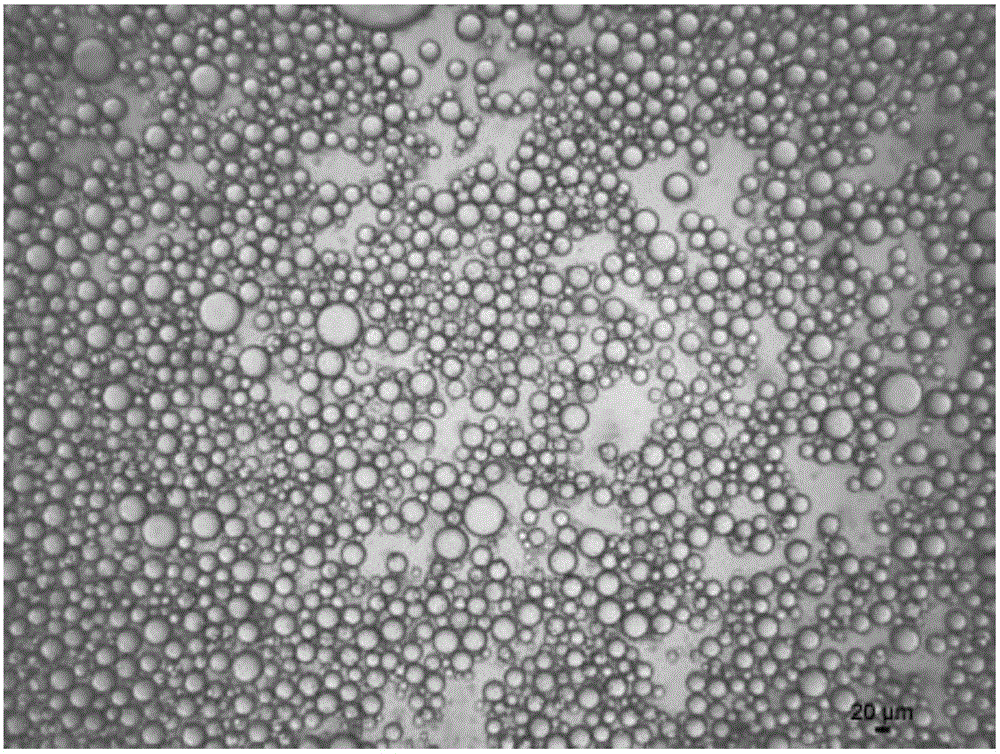

Method for preparing Pickering emulsion by utilizing modified nano-crystalline cellulose

The invention discloses a method for preparing Pickering emulsion by utilizing modified nano-crystalline cellulose. The method comprises the following steps: 1) taking the nano-crystalline cellulose modified with an amphiphilic segmented copolymer and grinding into powder, thereby acquiring the amphiphilic segmented copolymer modified nano-crystalline cellulose powder; 2) dispersing the amphiphilic segmented copolymer modified nano-crystalline cellulose powder acquired in the step 1) into deionized water, thereby forming modified nano-crystalline cellulose dispersion liquid; and 3) weighting an oily solvent, adding into the modified nano-crystalline cellulose dispersion liquid acquired in the step 2), and mixing and emulsifying, thereby forming stable Pickering emulsion. The method for preparing the Pickering emulsion by utilizing the modified nano-crystalline cellulose has the characteristics of less CNC dosage and low application cost.

Owner:SHAANXI UNIV OF SCI & TECH

Honeycomb heat accumulator made of silicon carbide-corundum composite materials

ActiveCN101798212ASimple compositionHigh refractorinessChemical industrySmall footprintPetrochemical

The invention relates to a honeycomb heat accumulator made of silicon carbide-corundum composite materials, which comprises the following main raw materials: 20-30wt% of silicon carbide powder, 4-8wt% of zirconia corundum powder, 20-30wt% of corundum powder, 15-20wt% of porzite powder, 15-30wt% of composition of kyanite, andalusite and sillimanite, 4-8wt% of kaolin and 2-5wt% of cellulose powder. The preparation method of the honeycomb heat accumulator comprises the following steps: adding the main raw materials into a ball mill for ball milling; adding stearic acid of which the weight is not greater than 1% of the total weight of the main raw materials for ball milling, and then, sieving to obtain a mixture; respectively adding tung oil of which the weight is not greater than 1% of the weight of the mixture and glycerol of which the weight is not greater than 1% of the weight of the mixture for mixing, aging and vacuum pugmill to form pug segments; carrying out extrusion forming in a mold, and drying; and insulating at the temperature of 1400-1450 DEG C for 4-8 hours, and then, calcining. The honeycomb heat accumulator of the invention has the characteristics of high fire resistance, good thermal shock resistance, strong corrosion resistance, large heat exchange area, small gas flow resistance, high heat accumulating efficiency, small floor space and long service life which can be more than two years, and is widely used for heat accumulating type heating furnaces of black and non-ferrous smelting, thermal power generation, petrochemical industry, ceramics, glass, machining, civil cookers and the like.

Owner:JIANGXI SHINCO ENVIRONMENTAL PROTECTION CO LTD

Recyclable desulfurizer and preparation method thereof and regeneration method

ActiveCN101898108AHigh sulfur capacityLoose structureOther chemical processesIron oxides/hydroxidesCarboxymethyl celluloseSulfur

The invention relates to a recyclable dry desulfurizer with high sulfur capacity. The desulfurizer contains not less than 88% of substances containing FeOOH and not less than 7% of organic binders, wherein the organic binder is one or more of sodium carboxymethyl cellulose, sesbania and cellulose powder. The invention further discloses a preparation method of the desulfurizer and a regeneration method of waste agents generated after the desulfurizer is used. The invention solves the following problems in the prior art: the dry-formed desulfurizer has low sulfur capacity, and after the dry-formed desulfurizer is used once, the waste agents can not be regenerated or the regeneration cost is high, so that great amount of waste agents are only buried, thus not only wasting the effective resources in the original desulfurizer but also leading to new environmental pollution problems.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Daily feed used for eupolyphoge sinensis culturing

The invention discloses a daily feed used for eupolyphoge sinensis culturing. The daily feed comprises a concentrated feed and a greenfeed. The concentrated feed is composed of following ingredients, by weight, 2 to 3 parts of yeast, 2 to 5 parts of beer yeast, 0.5 to 1 part of cane sugar, 65 to 75 parts of wheat bran, 5 to 7 parts of soya bean meal, 2 to 5 parts of concentrated soybean protein powder, 6 to 8 parts of corn powder, 0.02 to 0.04 part of ascorbic acid, 0.03 to 0.05 part of multivitamin, and 0.3 to 0.5 part of cellulose powder. The greenfeed is composed of following ingredients, by weight, 40 to 50 parts of pumpkin, 20 to 30 parts of black locust leaf, 10 to 20 parts of alniphyllum fortune, and 10 to 20 parts of Chinese cabbage. According to the daily feed, mixing feeding of the concentrated feed and the greenfeed is adopted, comprehensive nutritional demands of eupolyphoge sinensis are satisfied; yeast is added into the daily feed, so that dyspepsia of eupolyphoge sinensis is treated effectively, food consumption is increased, and eupolyphoge sinensis growth is promoted; appetite of eupolyphoge sinensis is promoted effectively by adding capsaicine into the daily feed at set intervals; and feed consumption of eupolyphoge sinensis is ensured.

Owner:桑金全

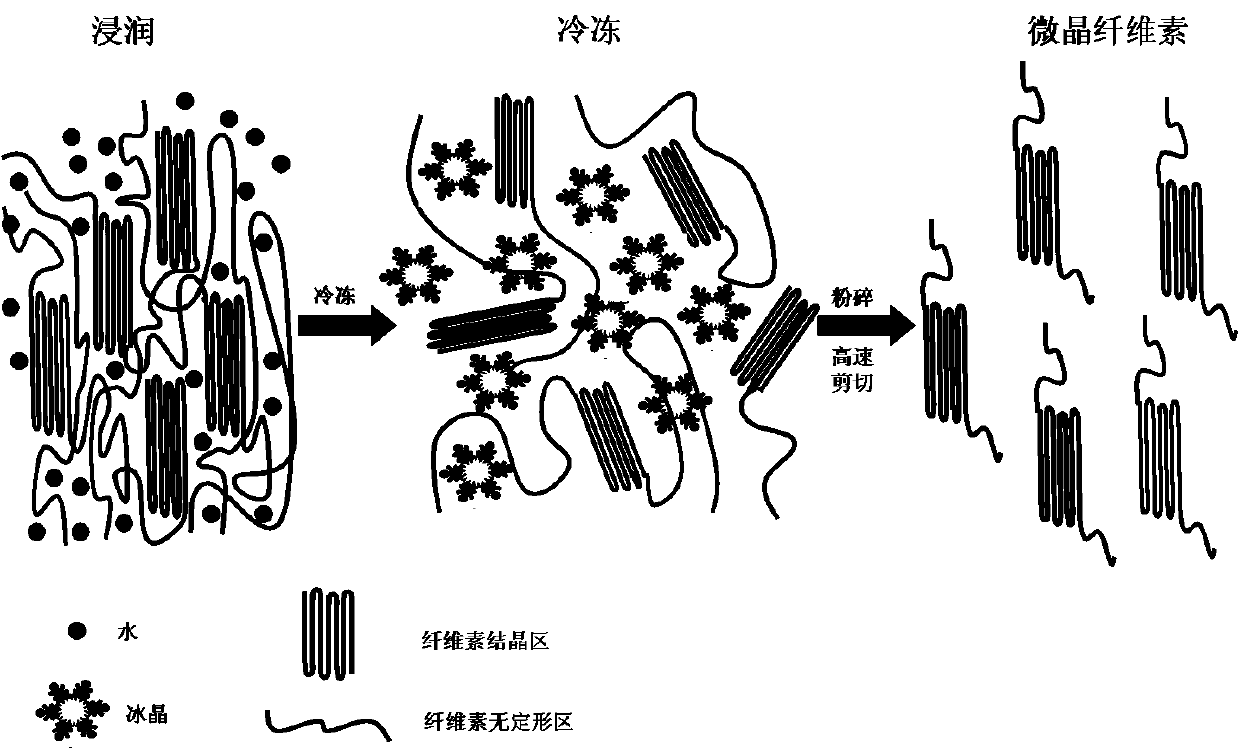

Method for preparing microcrystalline cellulose at low temperature

ActiveCN103726378AReduce the degree of polymerizationHigh crystallinityPulping with acid salts/anhydridesSolventHot Temperature

The invention relates to a method for preparing microcrystalline cellulose at low temperature. The method is characterized by comprising the following steps: (1) completely soaking the cellulose raw material in a soaking solvent, wherein the soaking solvent is water or an acid solution with mass percent concentration not over 15wt% or an oxide solution with mass percent concentration not over 5wt%; (2) freezing the cellulose raw material after the soaking treatment in the step (1), and grinding; (3) performing high-speed shear treatment on the cellulose powder obtained by the grinding in the step (2), and performing aftertreatment on the product after the high-speed shear treatment to obtain the microcrystalline cellulose. The method for preparing microcrystalline cellulose at low temperature provided by the invention can obtain microcrystalline cellulose with different polymerization degrees lower than 350 and relatively high crystallization degree; high-temperature treatment process can be avoided, the energy consumption is low, and the process is simple and green and environment-friendly.

Owner:HUBEI GEDIAN HUMANWELL PHARMA EXCIPENTS

Biomass resin and preparation method of fibre oriented shaving composite board

ActiveCN105368071AImprove secondary bonding performanceLow viscosityFlat articlesDomestic articlesPolymer scienceProtease preparation

The invention discloses biomass resin and a method for preparing a fibre oriented shaving composite board by using the biomass resin as an adhesive. The biomass resin is prepared from, by weight, 100 parts of water, 1-3.5 parts of a compound stabilizer, 5-50 parts of vegetable protein powder, 0.01-0.05 part of a protease additive, 2-10 parts of plant starch, 1-7 parts of modified plant cellulose powder, 0.01-0.05 part of a complex enzyme preparation, 0.1-5 parts of a molecular structure acylation modifier, 0.1-0.5 part of a cross-linking agent, 0.01-10 parts of a resin additive, 0.01-0.05 part of an antifoaming agent, 0.1-0.5 part of a preservative and 5-10 parts of a filler. In addition, the biomass resin is used as an adhesive to be applied in a preparation technology of a fibre oriented shaving composite board. Viscosity is reduced, solid content is raised, and secondary gluing performance after drying of the adhesive is enhanced.

Owner:郑州佰沃科技发展有限公司

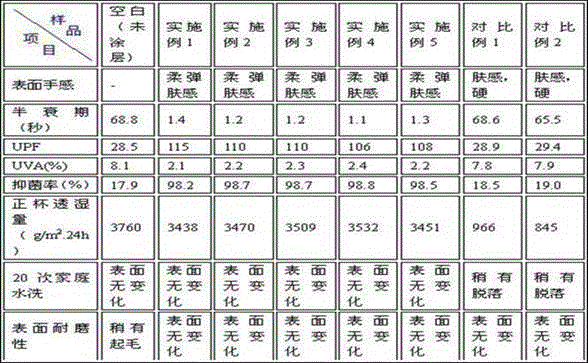

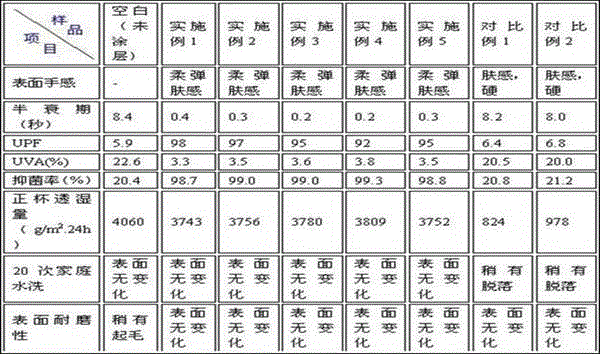

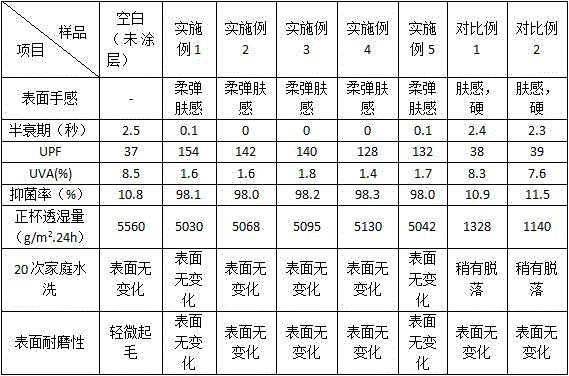

Antistatic, anti-ultraviolet, antibacterial, breathable, skin-touch waterborne polyurethane coating adhesive for textile and preparation method thereof

ActiveCN106436324AGuaranteed antistatic effectGuaranteed UV resistanceBiochemical fibre treatmentLight resistant fibresPolyesterPolymer science

The invention provides an antistatic, anti-ultraviolet, antibacterial, breathable, skin-touch waterborne polyurethane coating adhesive and a preparation method thereof. The coating adhesive is prepared from, by weight, 20-30 parts of deionized water, 0.5-3.0 parts of diisopropyl octadecanalkoxyl acetyl aluminum chelate, 5.0-15 parts of modified hemp lignocellulose powder, 3.0-5.0 parts of polyurethane elastic powder, 50-70 parts of polyurethane adhesive, 0.1-0.3 part of defoaming agent, 1.0-5.0 parts of associative polyurethane thickener, 2.0-5.0 parts of anti-static agent, 5.0-10 parts of organic silicon smooth handfeel agent, 2.0-5.0 parts of organic silicon anti-sticking agent and 1.0-3.0 parts of ultraviolet absorbent in a compounding mode. The coating adhesive is suitable for pure cotton, polyester, chinlon and various blended fabrics and good in wear resistance and washability.

Owner:LIAONING FIXED STAR FINE CHEM

Ecological type compound feed for juvenile Centropristis striata

InactiveCN101406262AWide variety of sourcesGuarantee the needs of breedingFood processingClimate change adaptationHerbal preparationsFish oil

The invention discloses centropristis striata linnaeus young fish ecotype mixed feed, which is characterized in that the mixed feed is prepared from the following components in weight percentage: 52.0 to 62.5 percent of fish meal, 1.0 to 6.0 percent of casein, 6.0 to 11.0 percent of wheat gluten, 13.0 to 25.0 percent of alfa-starch, 0 to 3.0 percent of fish oil, 0.5 to 7.0 percent of soybean oil, 0 to 17.0 percent of cellulose powder, 0. to 0.9 percent of mixing powder of a plurality of amino acids, 0.5 to 1.0 percent of composite vitamins, 0.8 to 1.2 percent of composite mineral salt, 0.01 to 0.05 percent of zymin, 0.1 to 0.6 percent of small peptide and 0.05 to 0.3 percent of compound traditional Chinese herbal preparation. Tests show that the centropristis striata linnaeus young fish fed by the mixed feed has the advantages of high feed intake, obvious food calling and high growth rate; and the weight is averagely increased by 24.50 to 69.62 percent, the survival rate is up to between 90.0 and 100 percent which is 85.0 percent higher than that of the comparative group, feed coefficient is up to between 1.20 and 1.84, and disease resistant capability is improved.

Owner:PUTIAN BIOENG INST

Etherification and oxidization method for preparing cellulose nano crystal whiskers

InactiveCN104805723AAchieve preparationIncrease added valuePretreatment with alkaline reacting compoundsRaw material divisionFiberMechanical crushing

The invention provides an etherification and oxidization method for preparing cellulose nano crystal whiskers. The etherification and oxidization method is characterized by comprising the following steps: taking plant fibers with low cellulose content as raw materials; carrying out pre-treatment, etherification treatment and alkali treatment; carrying out mechanical crushing to obtain plant cellulose powder; carrying out TEMPO oxidization treatment, and stirring at a high speed to obtain a plant cellulose powder suspension solution; and carrying out centrifugal treatment, dispersion treatment, freezing and drying to prepare the cellulose nano crystal whiskers. The etherification and oxidization method has a simple preparation process, high yield and low energy consumption; in a production process, no toxic and harmless substances are discharged, and the method has a large-scale popularization and application potential; the used plant fibers can be jutes, straws, cotton stalk peels and the like, and have a wide raw material source and low cost; the environmental pollution problem is solved and the addition value of the plant fibers is also improved.

Owner:DONGHUA UNIV

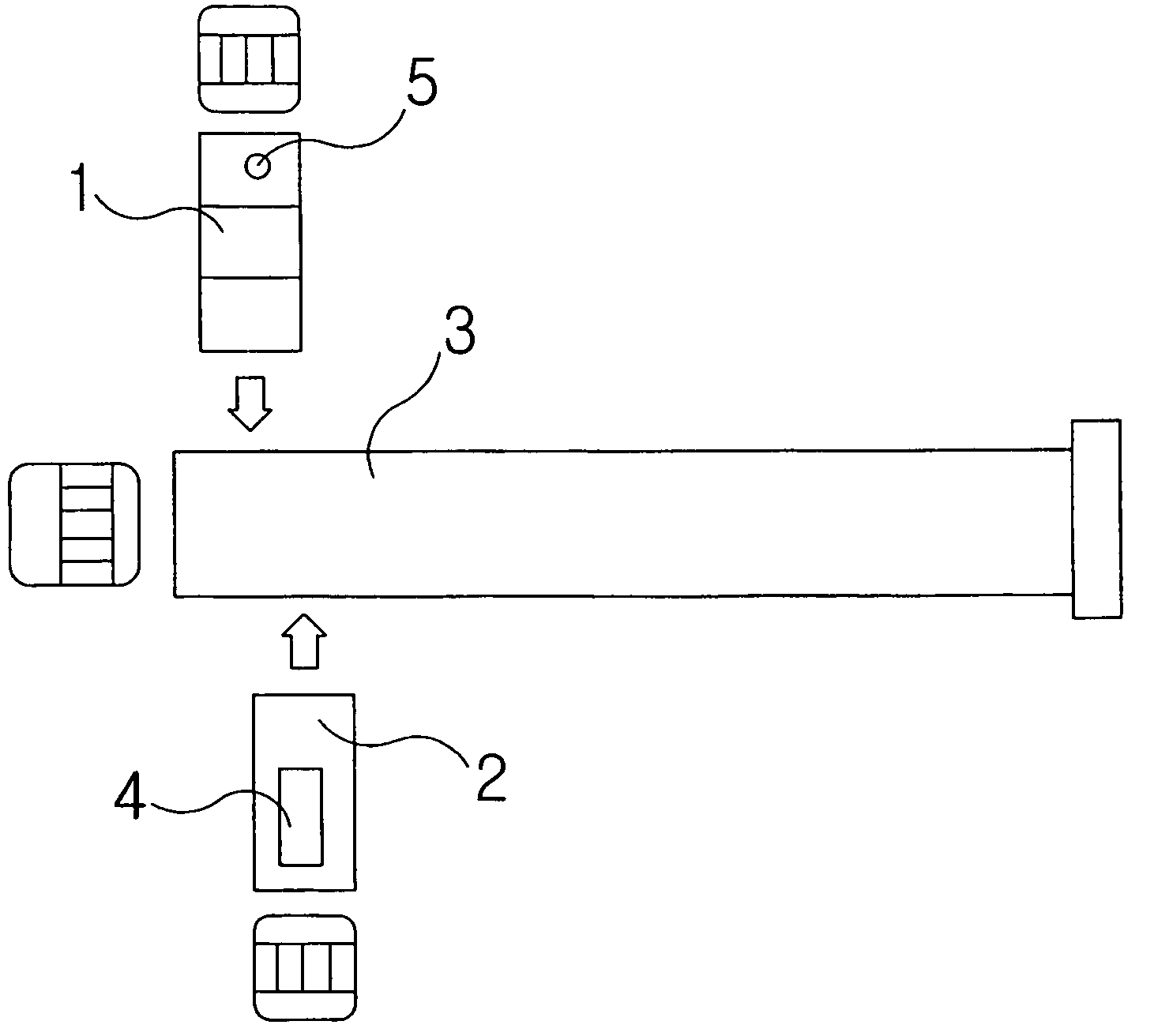

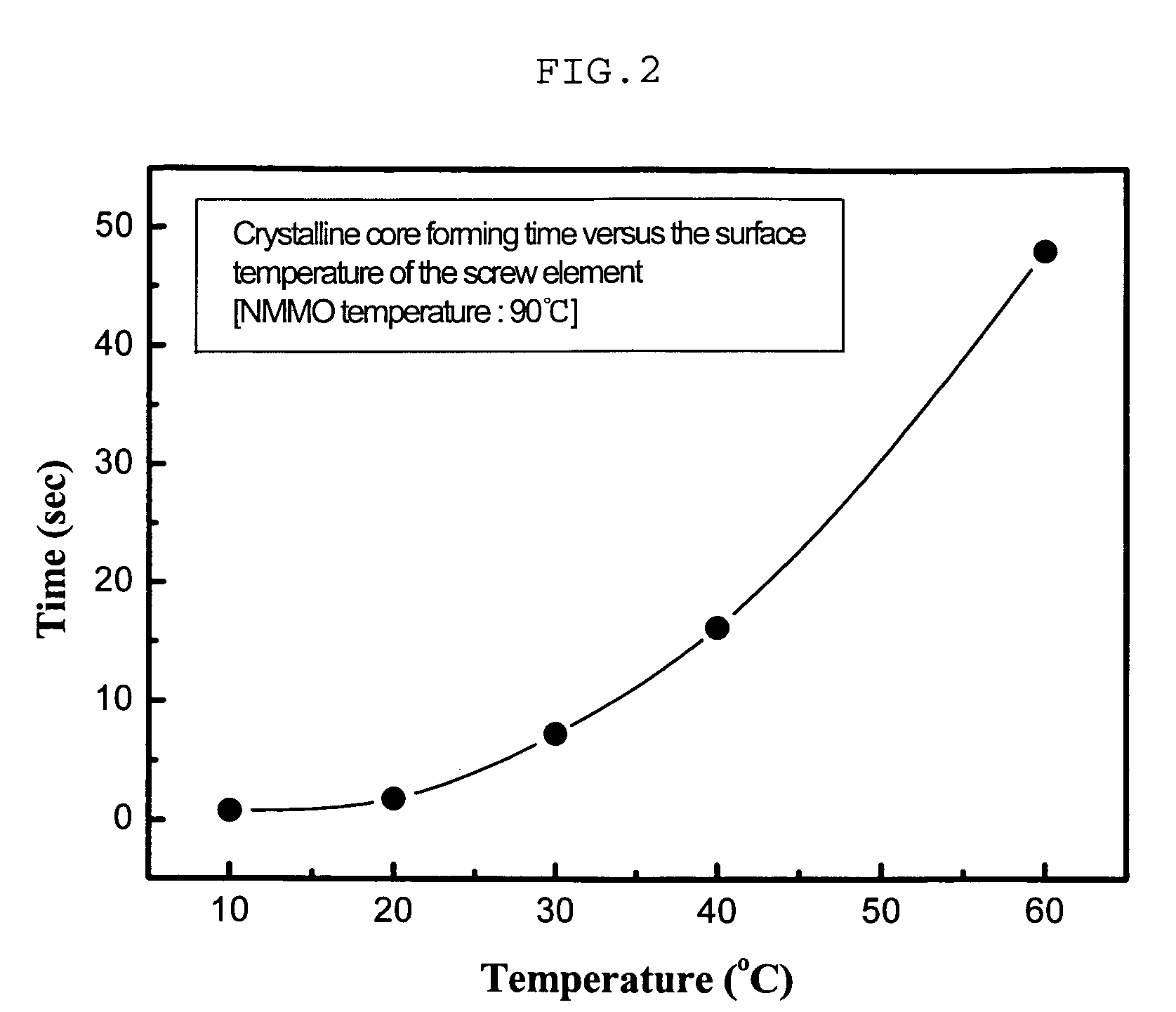

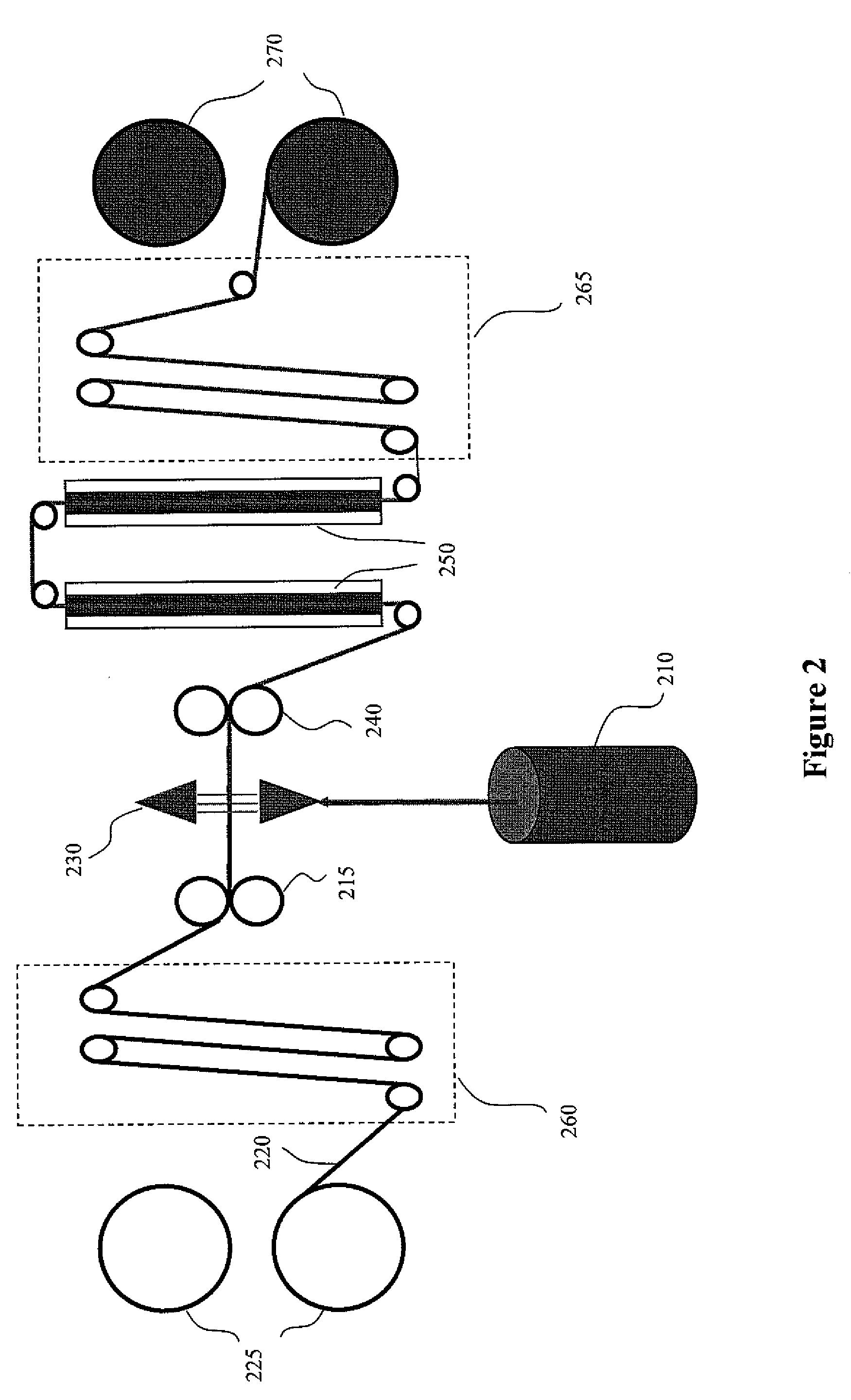

Jomogeneous celllulose solution and high tenacity lyocell multilament using the same

ActiveUS20050160939A1Minimize degradationImprove toughnessMonocomponent cellulose artificial filamentPneumatic tyre reinforcementsTO-18Liquid state

The present invention relates to a method for making highly homogenized cellulose solution, wherein the cellulose solution is obtained by obtaining a solidified N-methylmorphorine-N-oxide (hereinafter, referred to as ‘NMMO’) hydrates which is solidified a liquid-state NMMO hydrates comprising 10 to 18% by weight water by using a simple screw-type feeder and by controlling the temperature, feeding the solidified NMMO into a twin-screw type extruder continuously, obtaining a cellulose solution which is fully swelled in a few minutes by dispersing and mixing with cellulose powder in the twin-screw type extruder, and extruding a highly homogenized cellulose solution by feeding the obtained cellulose solution into a melting zone of the extruder to melting the cellulose solution in a few minutes by minimum heat and shear force.

Owner:HYOSUNG ADVANCED MATERIALS CORP

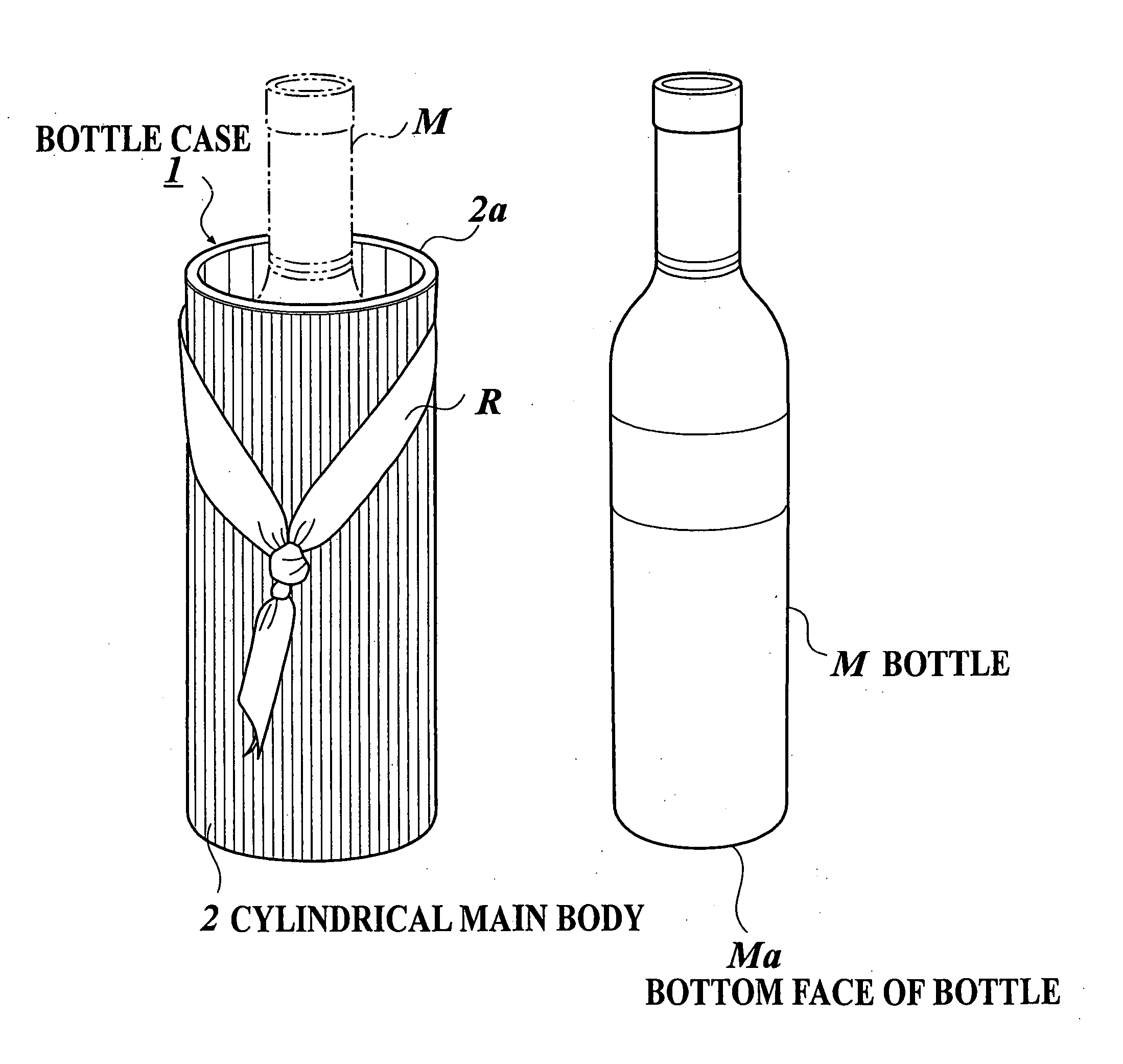

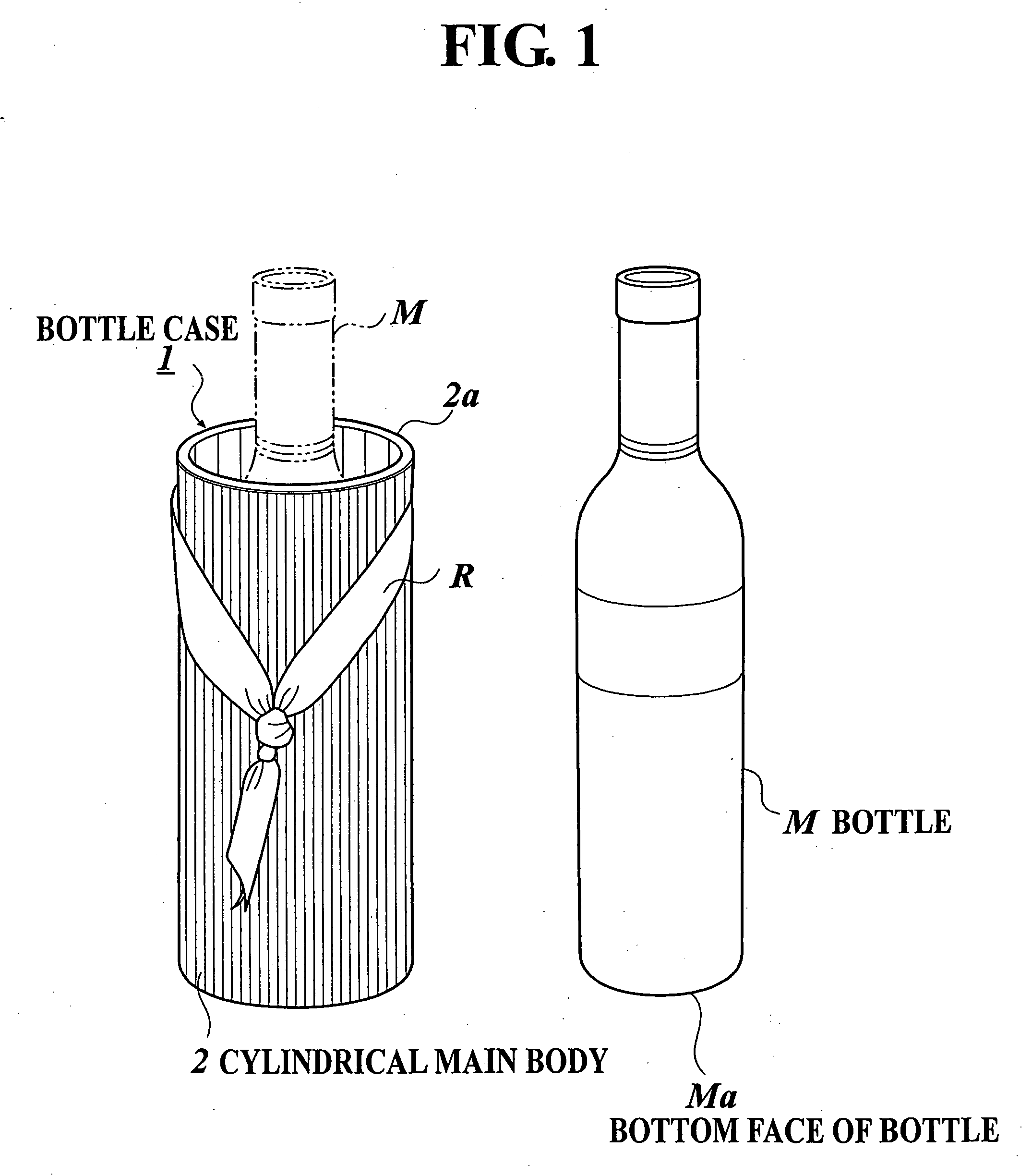

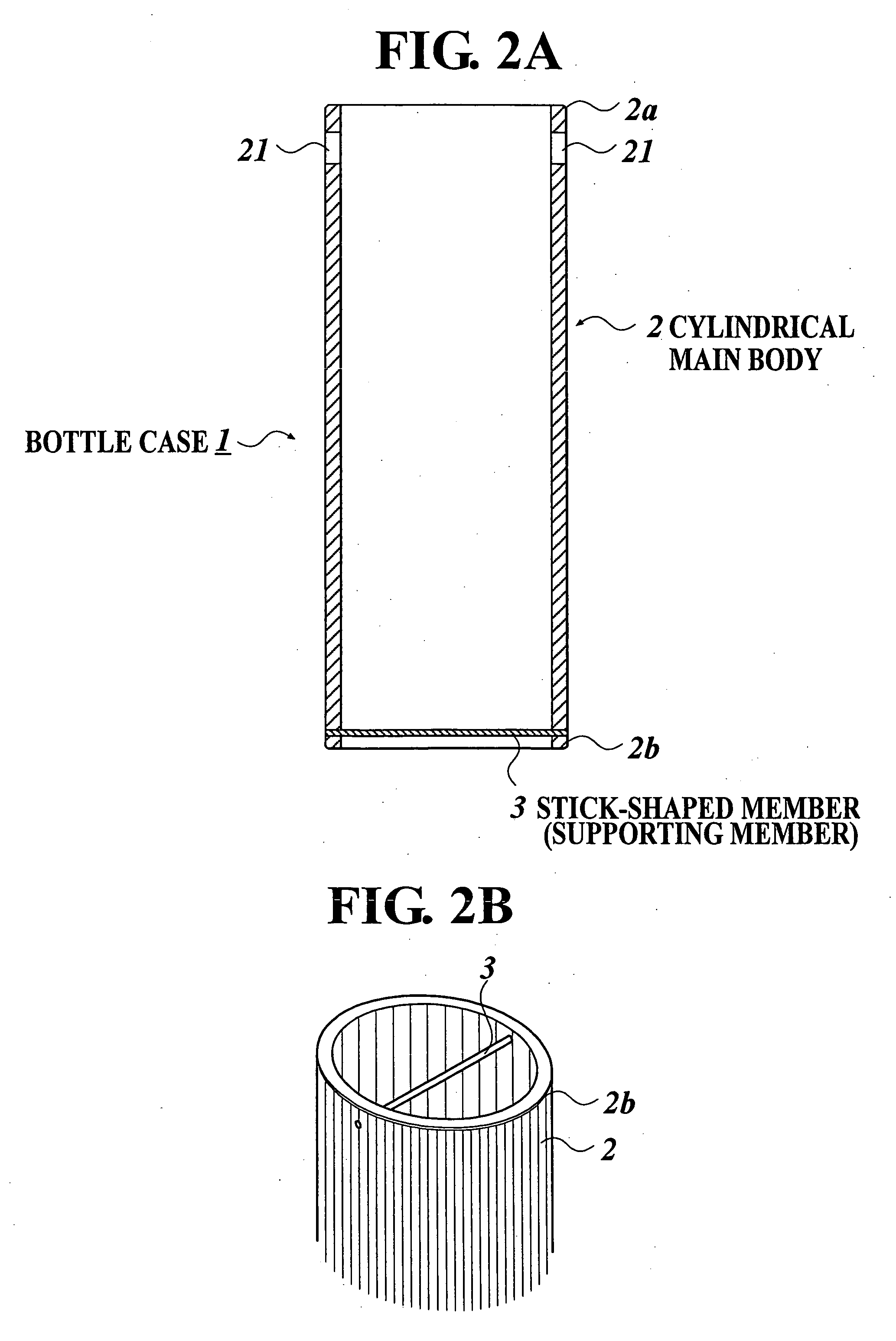

Woody molding, it's production system and production method

InactiveUS20060060592A1Favorable wood-like featureIncrease waste materialCandle holdersBottlesWine bottleEngineering

A wood-like molded product which is permitted to have wood-like features without using a natural wood material, and is usable as a bottle case to keep a wine bottle or the like inserted therein, and the like. The wood-like molded product includes: a cylindrical main body (2) which is made of a mixed material containing: fine cellulose powder particles (N) obtained from a wood material; and resin (P), and permits a bottle to be inserted thereinto; and a supporting member (3) provided in the cylindrical main body, to support a bottom face of the bottle inserted in the cylindrical main body.

Owner:MISAWA HOMES CO LTD

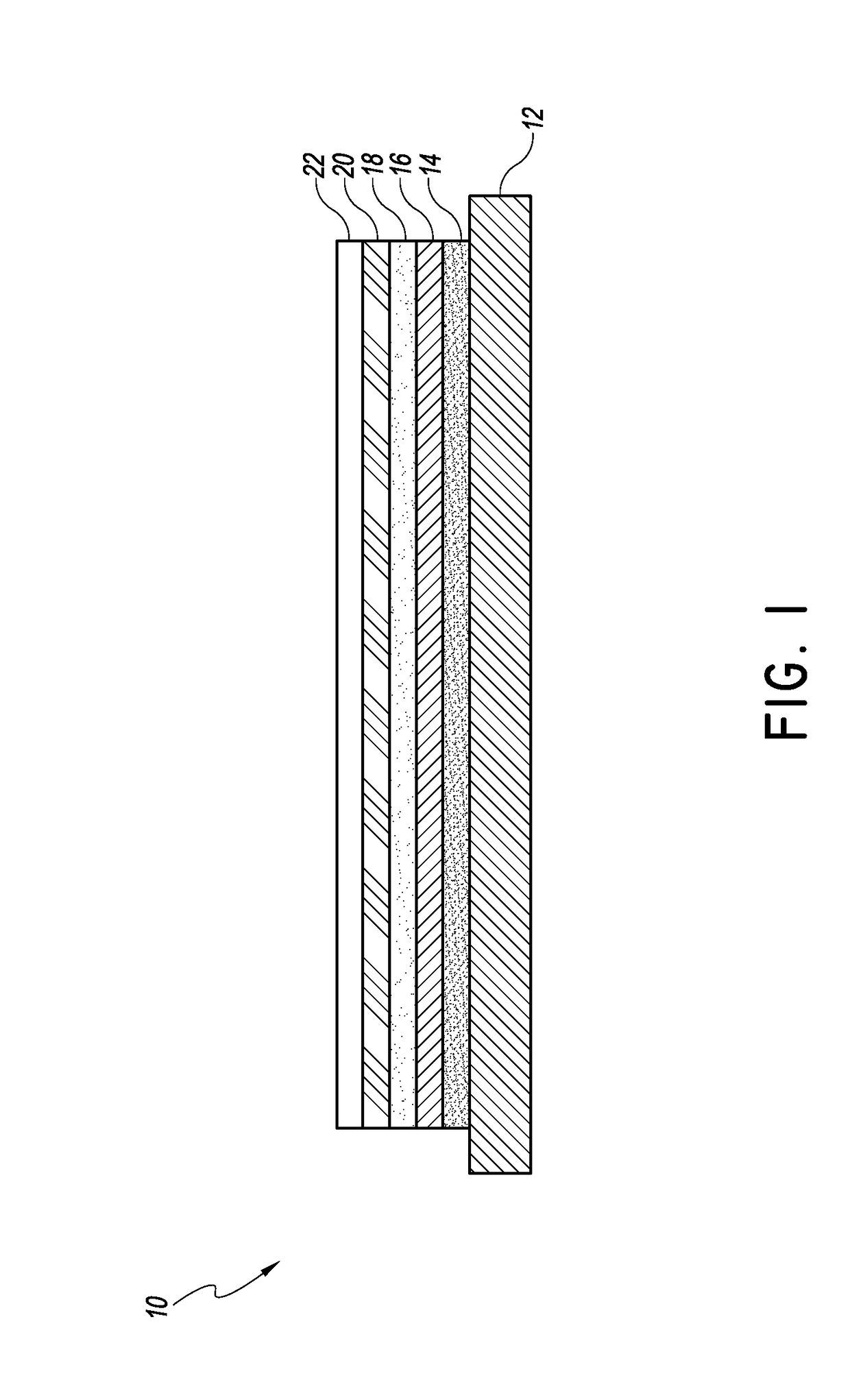

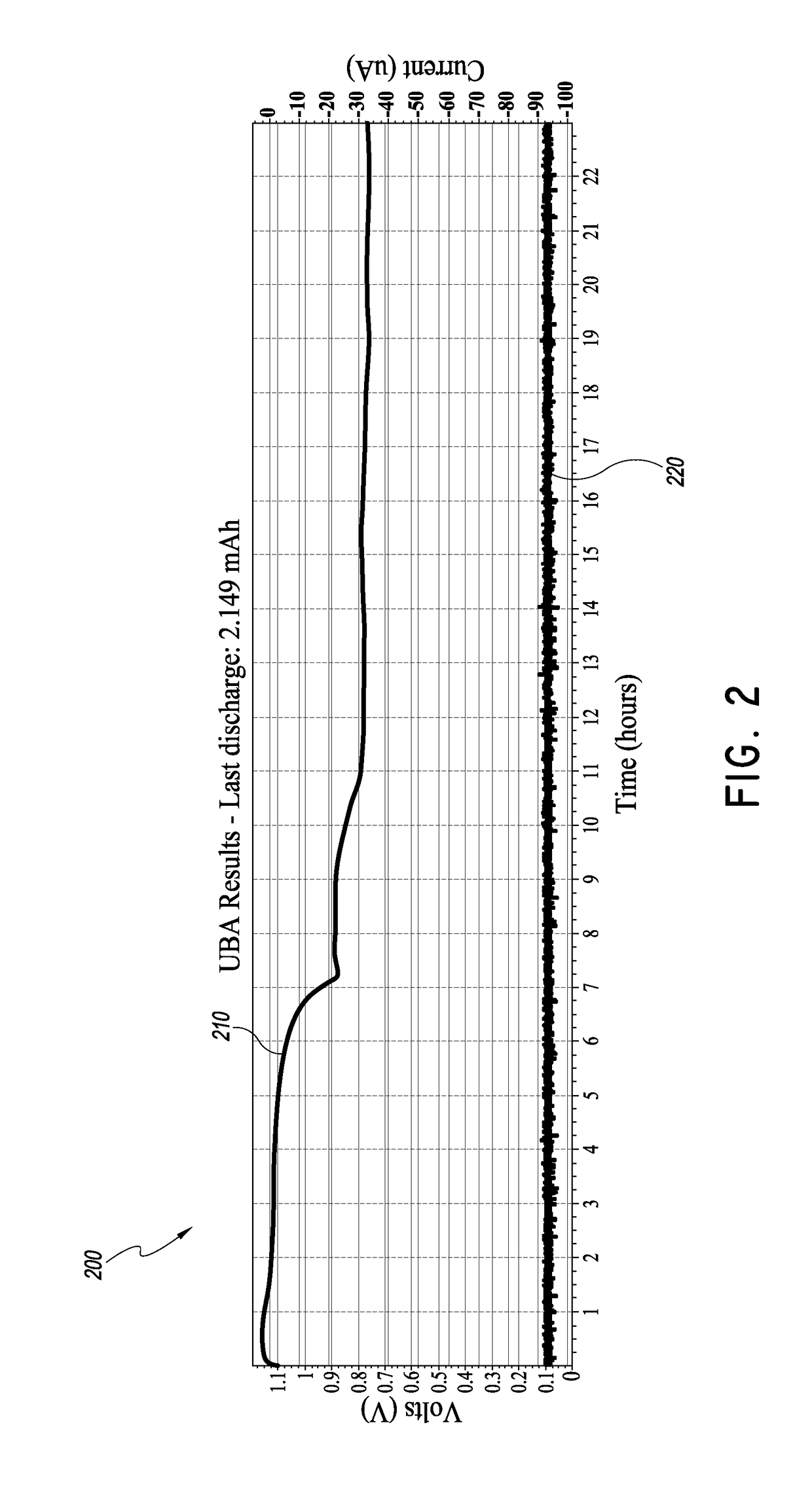

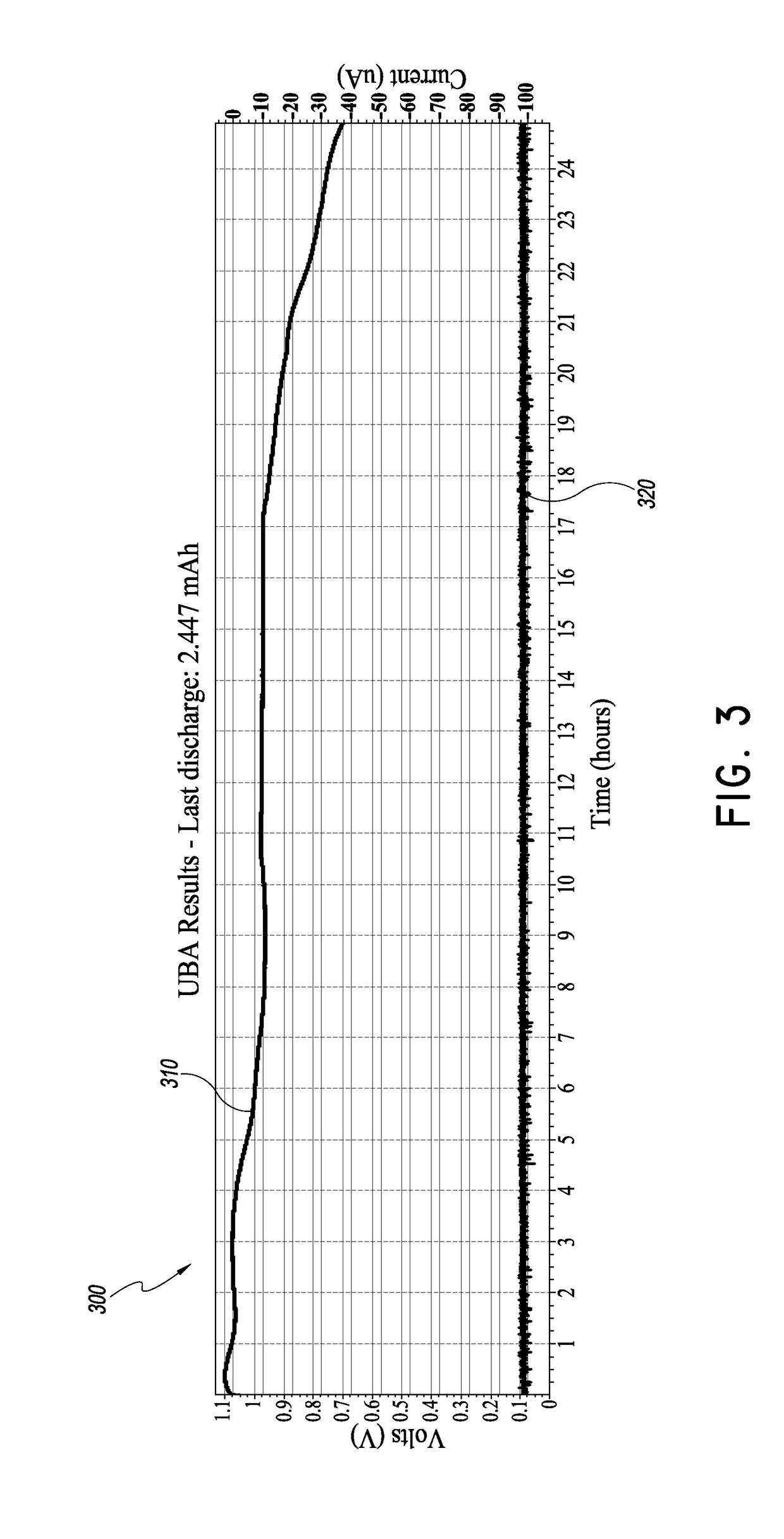

Printed silver oxide batteries

ActiveUS9786926B2Improve adhesionImprove wettabilitySilver accumulatorsElectrochemical processing of electrodesManufacturing technologyPyridinium

An energy storage device, such as a silver oxide battery, can include a silver-containing cathode and an electrolyte having an ionic liquid. An anion of the ionic liquid is selected from the group consisting of: methanesulfonate, methylsulfate, acetate, and fluoroacetate. A cation of the ionic liquid can be selected from the group consisting of: imidazolium, pyridinium, ammonium, piperidinium, pyrrolidinium, sulfonium, and phosphonium. The energy storage device may include a printed or non-printed separator. The printed separator can include a gel including dissolved cellulose powder and the electrolyte. The non-printed separator can include a gel including at least partially dissolved regenerate cellulose and the electrolyte. An energy storage device fabrication process can include applying a plasma treatment to a surface of each of a cathode, anode, separator, and current collectors. The plasma treatment process can improve wettability, adhesion, electron and / or ionic transport across the treated surface.

Owner:PRINTED ENERGY PTY LTD

Transparent paper supplementary with regenerated cellulose and manufacturing method thereof

ActiveCN106192550ASimple processShorten the production cycleSynthetic cellulose fibresProcess equipmentUltimate tensile strength

The invention discloses transparent paper supplementary with regenerated cellulose and a manufacturing method thereof. The method comprises the following steps: firstly, adding fine cellulose powder into EMIMMeOPO2H ionic liquid; heating cellulose till fully dissolving; slowly adding the cellulose solution into a regenerating solution under quick stirring state; cutting a large amount of accumulated cellulose molecules into countless small cellulose molecule groups under the high-speed shearing effect of an emulsifying machine, wherein the small groups are regenerated cellulose; mixing the regenerated cellulose with fully pulped plant fibers and forming into an end product of paper. The thickness of the transparent paper is 30-100mu m, the light transmissivity is 60-90%, the tensile strength is 20-60 Mpa and the stretch rate is (10-30)%. According to the invention, paper pulp is taken as the raw material, the process is environmentally friendly, the cost is low, the production period is short, only 30-120min is required by the whole process, the present paper machine, technique and equipment are locally modified and the industrial production can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

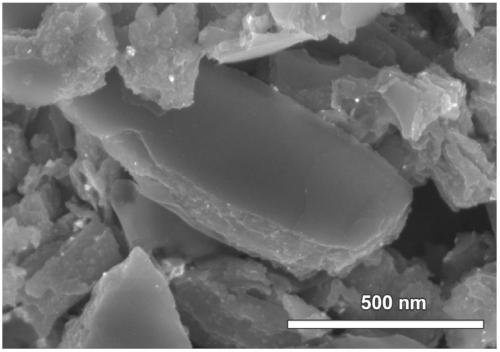

High-efficiency preparation method of cellulose nanocrystal (CNC)

The invention discloses a macroscopic preparation method of a cellulose nanocrystal (CNC), which is green and environment-friendly. Firstly, cellulose is crushed and then is pretreated; afterwards, an oxometallate solution and an organic acid are added, the oxydrolysis is carried out, and the CNC with a carboxyl group on a surface is obtained after centrifugal dialysis treatment. The yield of the preparation method can exceed 70 percent; the length of the made CNC can be adjusted in the range of 195nm to 260nm; the content of the carboxyl group on the surface can reach 50mmol / g; compared with a CNC made by a sulfuric-acid acid hydrolysis method, the CNC made by the macroscopic preparation method provided by the invention is increased by 50 to 100 DEG C in heat resistance; used oxometallate and organic acid are both green reagents and are further a few in use levels; problems that the preparation cost of the CNC is high and further the environmental pollution is easily caused, and the like, at present are solved.

Owner:QINGDAO UNIV OF SCI & TECH

Dyed cellulose comminution sheet, dyed nonwoven material, and processes for their production

InactiveUS20100311296A1Natural cellulose pulp/paperSpecial paperCellulose fiberVolumetric Mass Density

The present invention relates to a process for the dyeing of cellulosic fibers in the form of a comminution sheet to produce a dyed cellulose pulp comminution sheet with high moisture content. The dyed cellulose comminution sheet contains (a) a cellulose pulp comminution sheet having a cellulose content of from about 60 weight percent to about 99.9 weight percent cellulose based on the total weight of solids in the cellulose pulp comminution sheet, and a density of from about 0.3 g / cm3 to about 0.95 g / cm3; (b) a moisture content of from about 25 weight percent to about 55 weight percent, based on the total weight of the dyed cellulose comminution sheet, wherein the moisture content does not exceed bleed point of the comminution sheet; and (c) a dye.

Owner:GEORGIA PACIFIC NONWOVENS LLC

Cellulose powder

ActiveUS20070028801A1Not limitedHigh hardnessSugar productsPharmaceutical non-active ingredientsPolymer sciencePolyethylene glycol

A cellulose powder which has an average degree of polymerization of 150 to 450, an average particle diameter of 30 to 250 μm, an apparent specific volume exceeding 7 cm3 / g, and a retention of polyethylene glycol having a molecular weight of 400 to 190% or higher.

Owner:ASAHI KASEI CHEM CORP

Magnetic amphoteric cellulose powder material, preparation method and applications

ActiveCN104448659AAchieve superparamagnetic functionHigh reactivityOther chemical processesMagnetite NanoparticlesBiocompatibility

The invention discloses a magnetic amphoteric cellulose powder material, a preparation method and applications. The preparation method comprises the following steps: by taking amphoteric microcrystalline cellulose as a carrier, generating ferroferric oxide magnetic nanoparticles through in-situ co-precipitation, and adhering on the surface of the amphoteric microcrystalline cellulose and in pore ducts in situ, to realize the superpara magnetism function of the amphoteric microcrystalline cellulose, wherein the prepared amphoteric microcrystalline cellulose has intelligent response characteristic to an additional magnetic field. Through the amphoteric characteristic, high hydrophility and high specific area, the magnetic amphoteric cellulose powder material can be used for adsorbing waste water as a high-efficiency adsorption material, especially has the capability of obviously removing heavy metal ions and organic pollutants, can be easily separated and recovered under the additional magnetic field, and is economic and practical. In addition, due to the biocompatibility, biodegradability, favorable affinity and superpara magnetism characteristics, the magnetic amphoteric cellulose powder material can be used as a target drug carrier material, a target functional timbering material, a target vascular blocking material, a target medical adsorption material and the like, and the intelligent guide control can be easily realized through the additional magnetic field.

Owner:HAIMEN ZHUOWEI TEXTILE CO LTD

Cellulose powder

ActiveUS7514552B2High hardnessImproves friabilitySugar productsPharmaceutical non-active ingredientsPolymer sciencePolyethylene glycol

A cellulose powder which has an average degree of polymerization of 150 to 450, an average particle diameter of 30 to 250 μm, an apparent specific volume exceeding 7 cm3 / g, and a retention of polyethylene glycol having a molecular weight of 400 to 190% or higher.

Owner:ASAHI KASEI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com