Method for preparing Pickering emulsion by utilizing modified nano-crystalline cellulose

A nano-cellulose modification technology, applied in the field of Pickering emulsion prepared by using modified nano-cellulose, can solve the problem of ineffective stable emulsion and achieve the effects of less CNC consumption, large surface area, and low application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

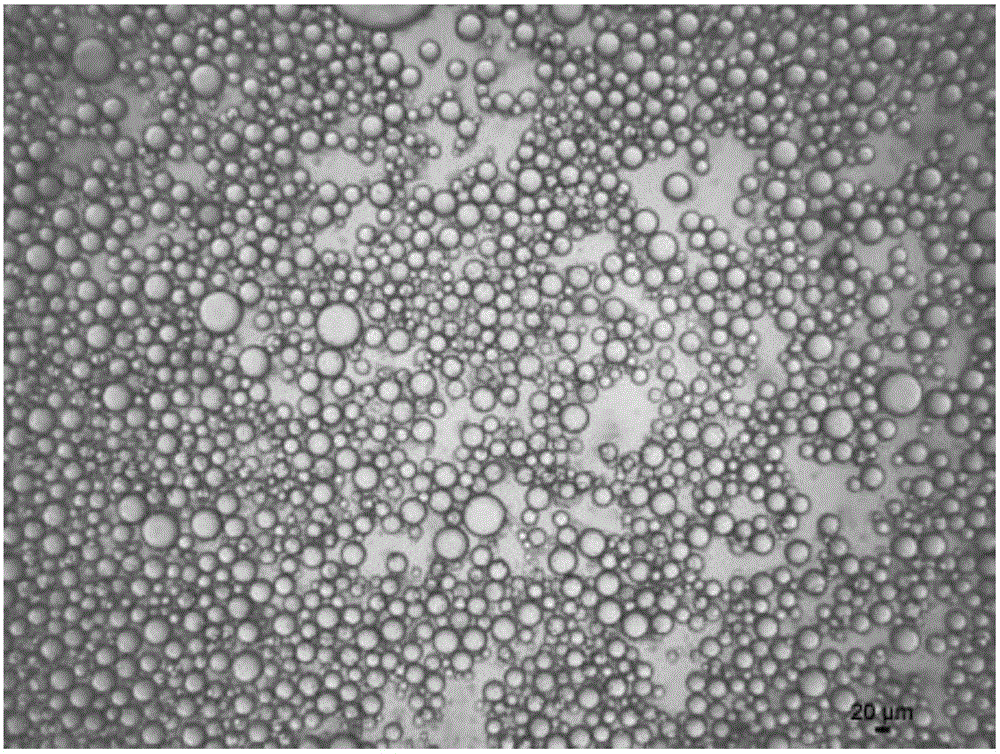

Image

Examples

Embodiment 1

[0042] Get amphiphilic block copolymer modified nanocellulose (MCNC) and grind it into powder to obtain amphiphilic block copolymer modified nanocellulose powder;

[0043] Weigh the amphiphilic block copolymer modified nanocellulose powder and deionized water at a mass ratio of 1:1000; weigh the amphiphilic block copolymer modified nanocellulose powder and deionized water Mix with water to form a mixed solution; place the mixed solution in an ultrasonic cell pulverizer with a power of 20% and disperse for 5 minutes to obtain a light yellow modified nanocellulose dispersion;

[0044] Weigh liquid paraffin and add it to the modified nanocellulose dispersion, wherein the volume ratio of liquid paraffin to the modified nanocellulose dispersion is 1:9 to form a mixture; wherein, the pH range of the modified nanocellulose dispersion is is 1; the obtained mixture is mixed and emulsified in an ultrasonic cell pulverizer with a power of 20%, to obtain a stable Pickering emulsion.

Embodiment 2

[0046] Get amphiphilic block copolymer modified nanocellulose (MCNC) and grind it into powder to obtain amphiphilic block copolymer modified nanocellulose powder;

[0047] Weigh the amphiphilic block copolymer modified nano-cellulose powder and deionized water at a mass ratio of 1:100; weigh the amphiphilic block copolymer-modified nano-cellulose powder and deionized water mixed with water to form a mixed solution; the mixed solution was dispersed in an ultrasonic cell pulverizer with a power of 30% for 10 minutes to obtain a light yellow modified nanocellulose dispersion;

[0048]Weigh n-heptane and add it to the modified nanocellulose dispersion, wherein the volume ratio of n-heptane to the modified nanocellulose dispersion is 1:7 to form a mixture; wherein, the pH of the modified nanocellulose dispersion The value range is 7; the obtained mixture is mixed and emulsified in an ultrasonic cell pulverizer with a power of 30%, to obtain a stable Pickering emulsion.

Embodiment 3

[0050] Get amphiphilic block copolymer modified nanocellulose (MCNC) and grind it into powder to obtain amphiphilic block copolymer modified nanocellulose powder;

[0051] Weigh the amphiphilic block copolymer modified nanocellulose powder and deionized water respectively according to the mass ratio of 1:25; the weighed amphiphilic block copolymer modified nanocellulose powder and deionized water Mix with water to form a mixed solution; place the mixed solution in an ultrasonic cell pulverizer with a power of 30% and disperse for 20 minutes to obtain a light yellow modified nanocellulose dispersion;

[0052] Weigh methyl methacrylate and add it to the modified nanocellulose dispersion, wherein the volume ratio of methyl methacrylate to the modified nanocellulose dispersion is 1:1 to form a mixture; wherein, the modified nanocellulose The pH range of the dispersion liquid was 9; the obtained mixture was mixed and emulsified in an ultrasonic cell pulverizer with a power of 40%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com