Patents

Literature

32 results about "Pugmill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

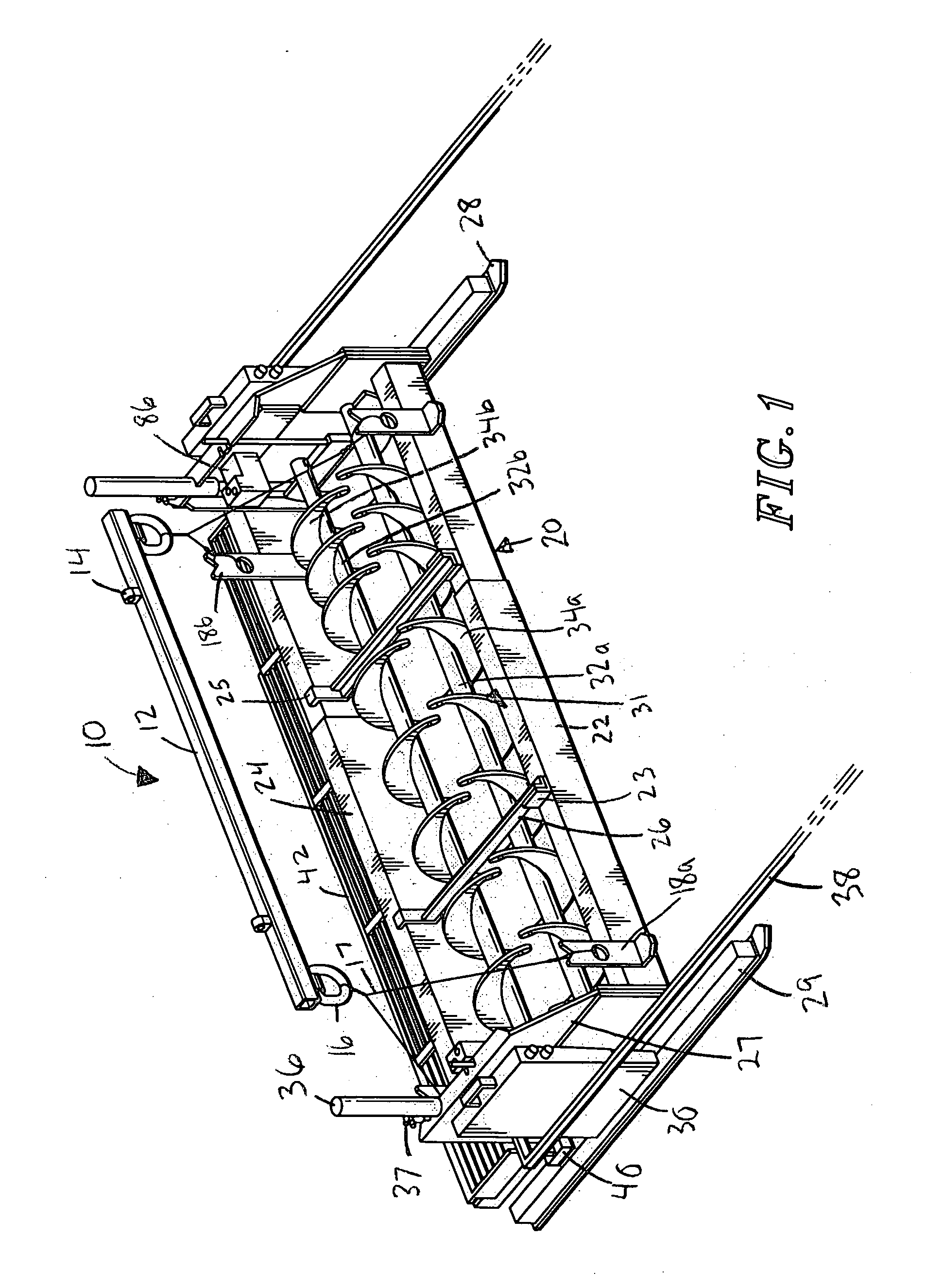

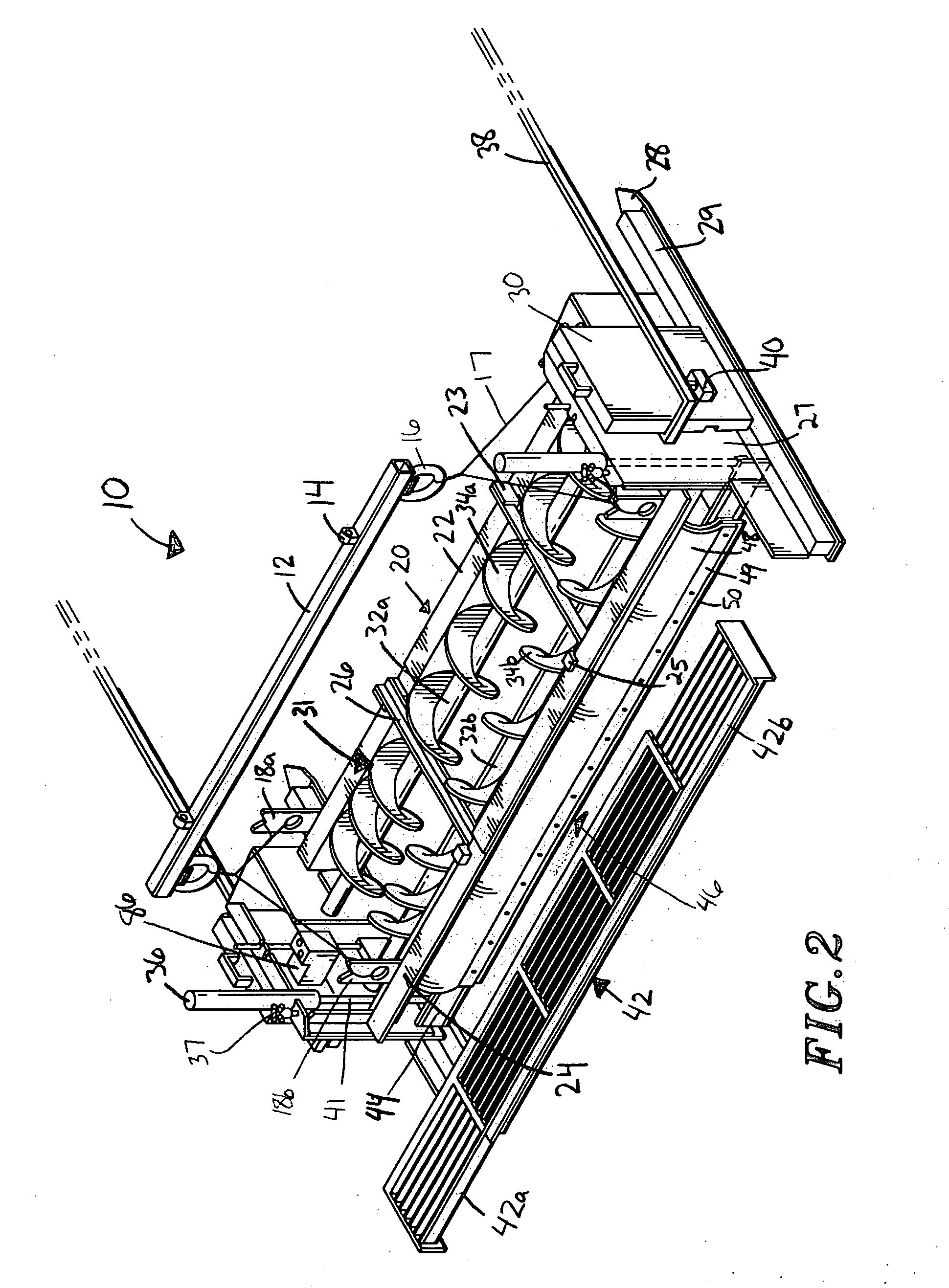

A pugmill or pug mill is a machine in which clay or other materials are mixed into a plastic state or a similar machine for the trituration of ore. Industrial applications are found in pottery, bricks, cement and some parts of the concrete and asphalt mixing processes. A pugmill may be a fast continuous mixer. A continuous pugmill can achieve a thoroughly mixed, homogeneous mixture in a few seconds, and the right machines can be matched to the right application by taking into account the factors of agitation, drive assembly, inlet, discharge, cost and maintenance. Mixing materials at optimum moisture content requires the forced mixing action of the pugmill paddles, while soupy materials might be mixed in a drum mixer. A typical pugmill consists of a horizontal boxlike chamber with a top inlet and a bottom discharge at the other end, 2 shafts with opposing paddles, and a drive assembly. Some of the factors affecting mixing and residence time are the number and the size of the paddles, paddle swing arc, overlap of left and right swing arc, size of mixing chamber, length of pugmill floor, and material being mixed.

Sewage sludge treatment

InactiveUS6966941B1Improve the mixing effectSludge treatment by de-watering/drying/thickeningAluminium compoundsSewageSewage sludge treatment

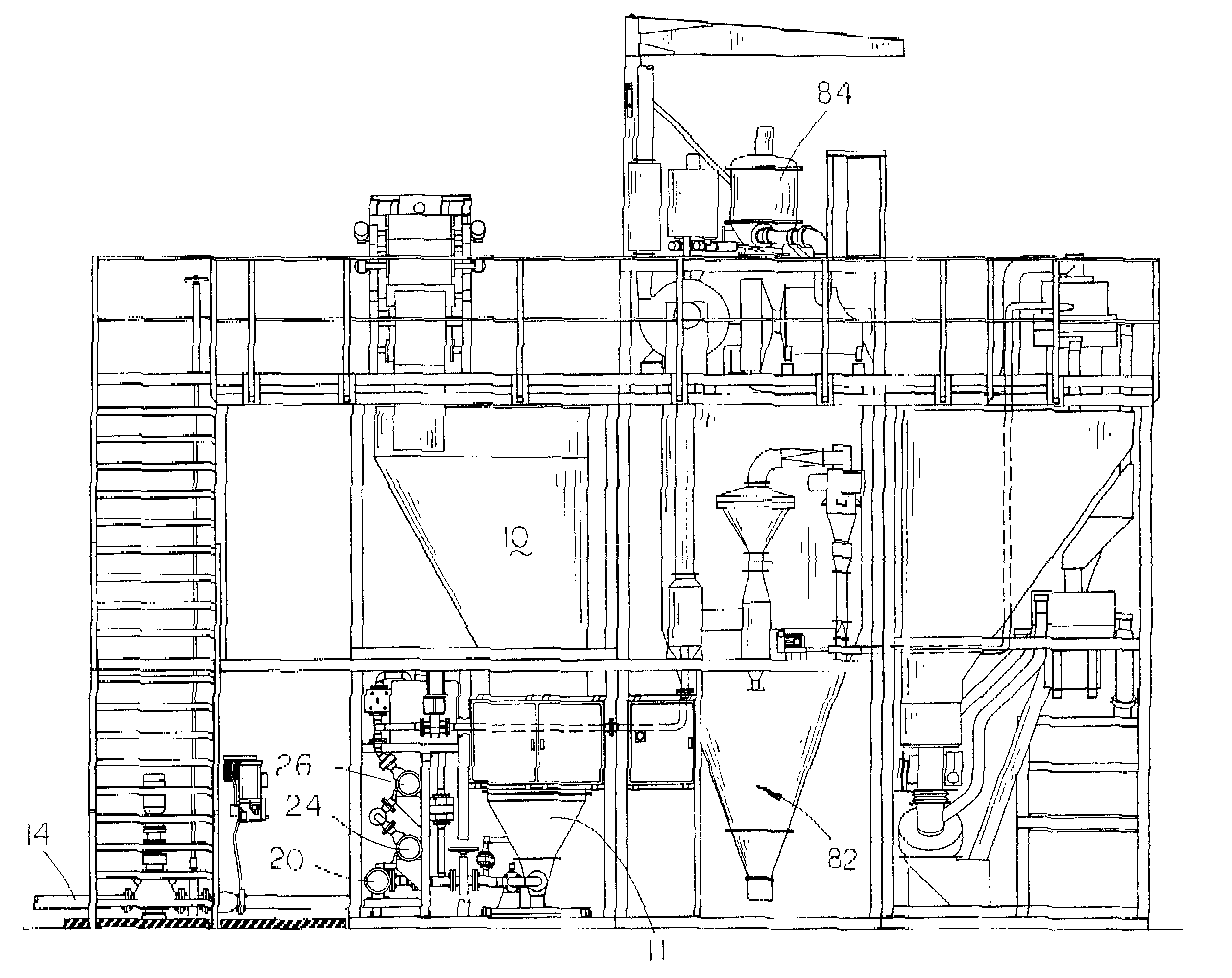

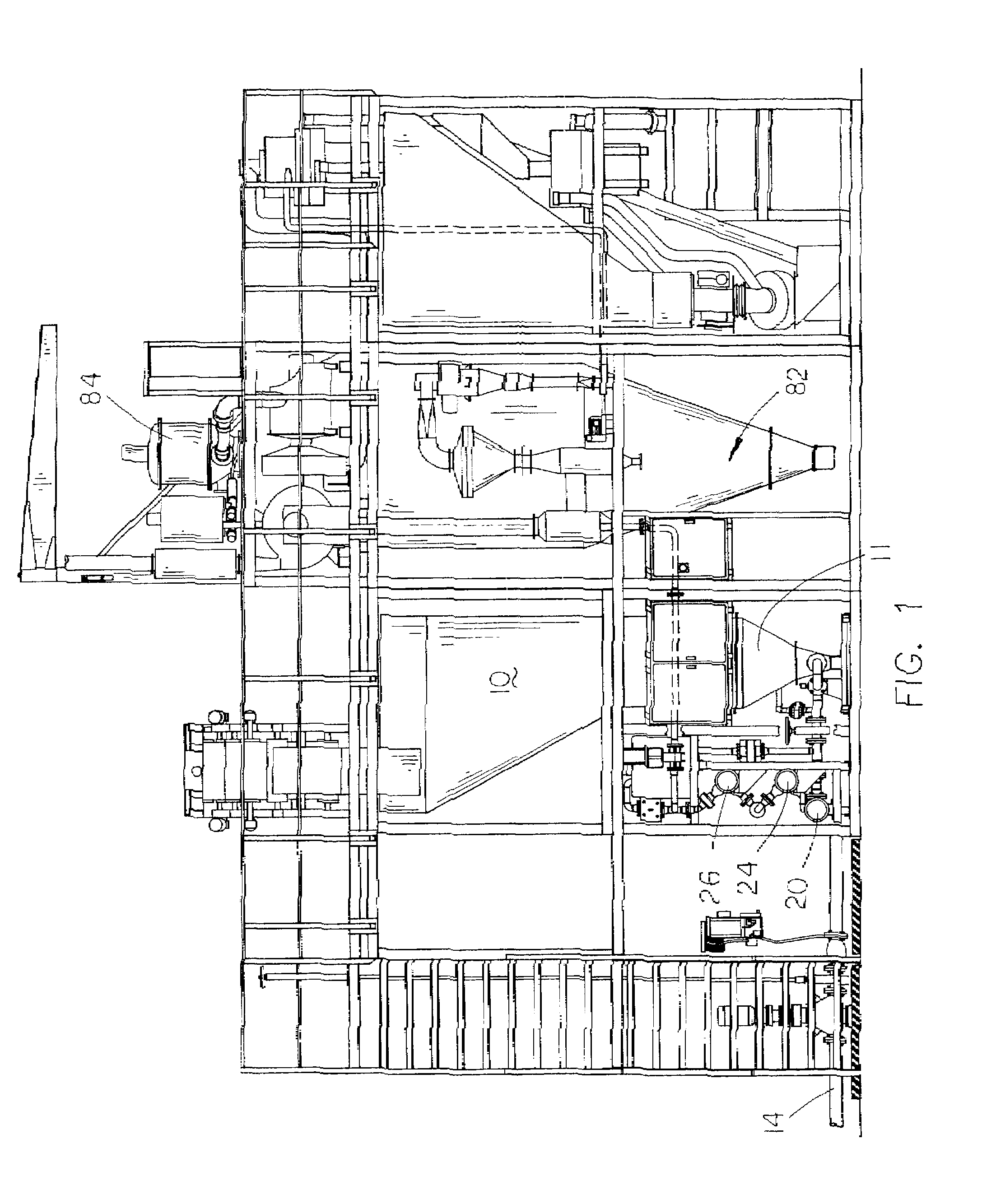

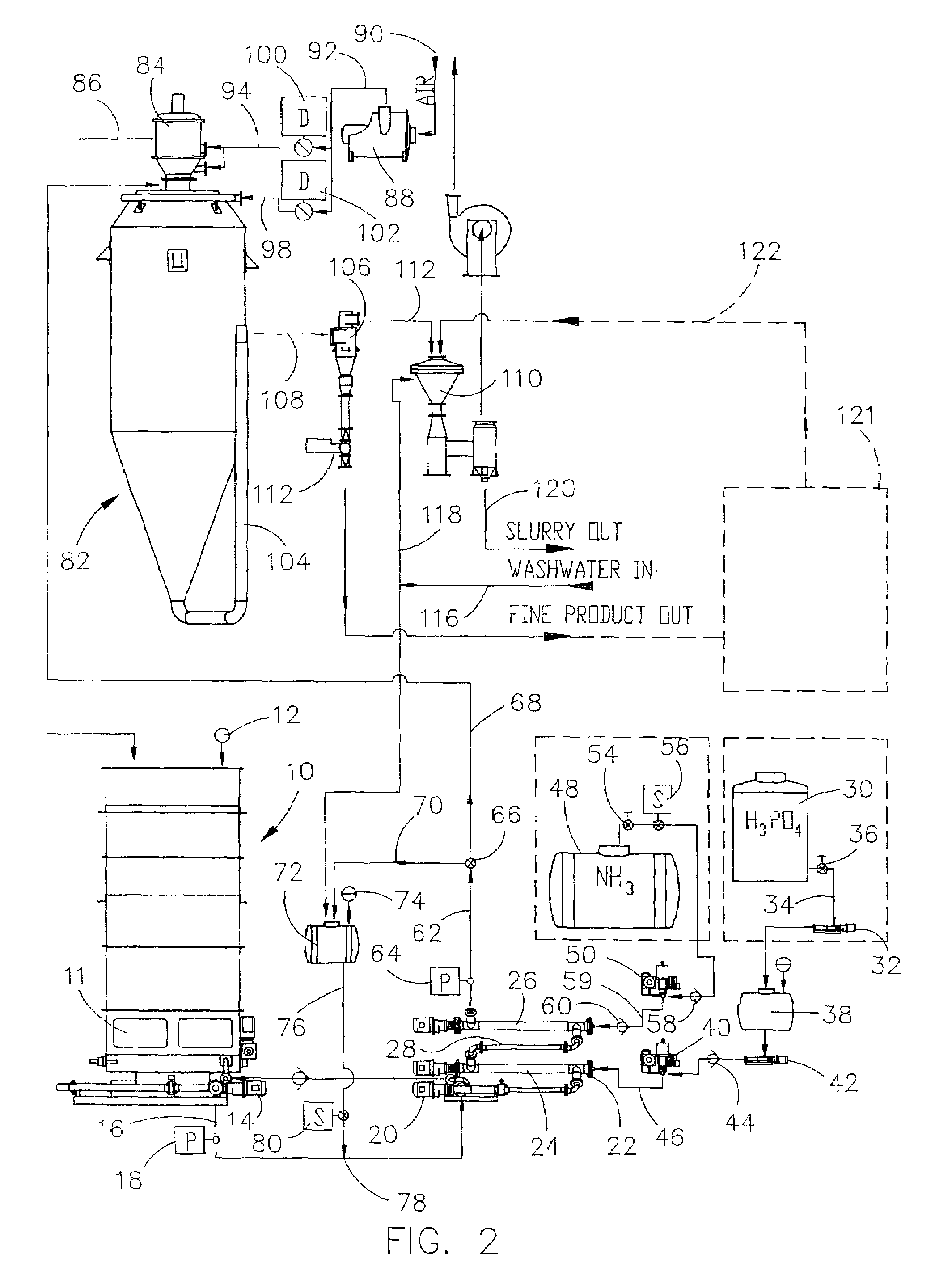

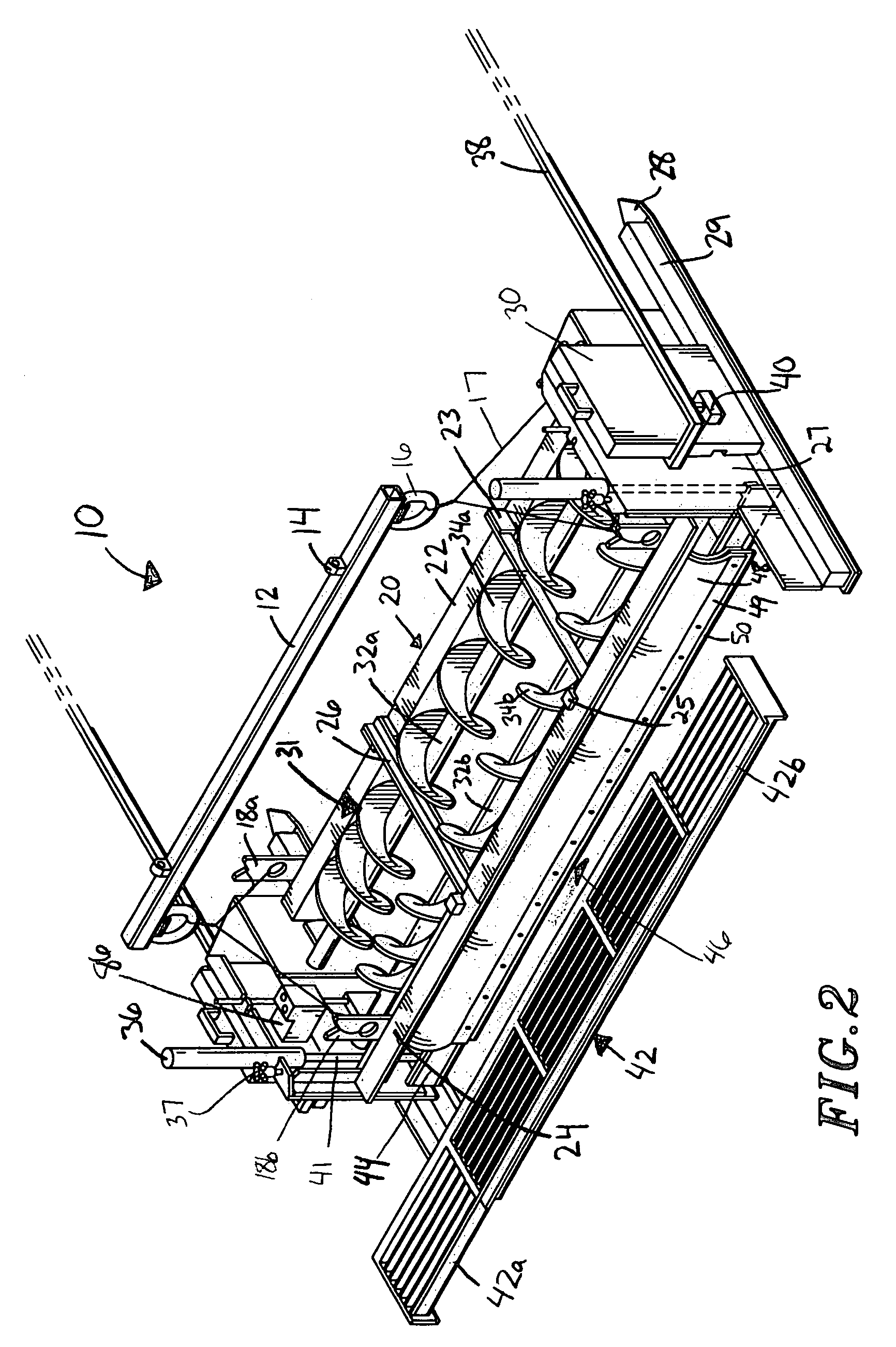

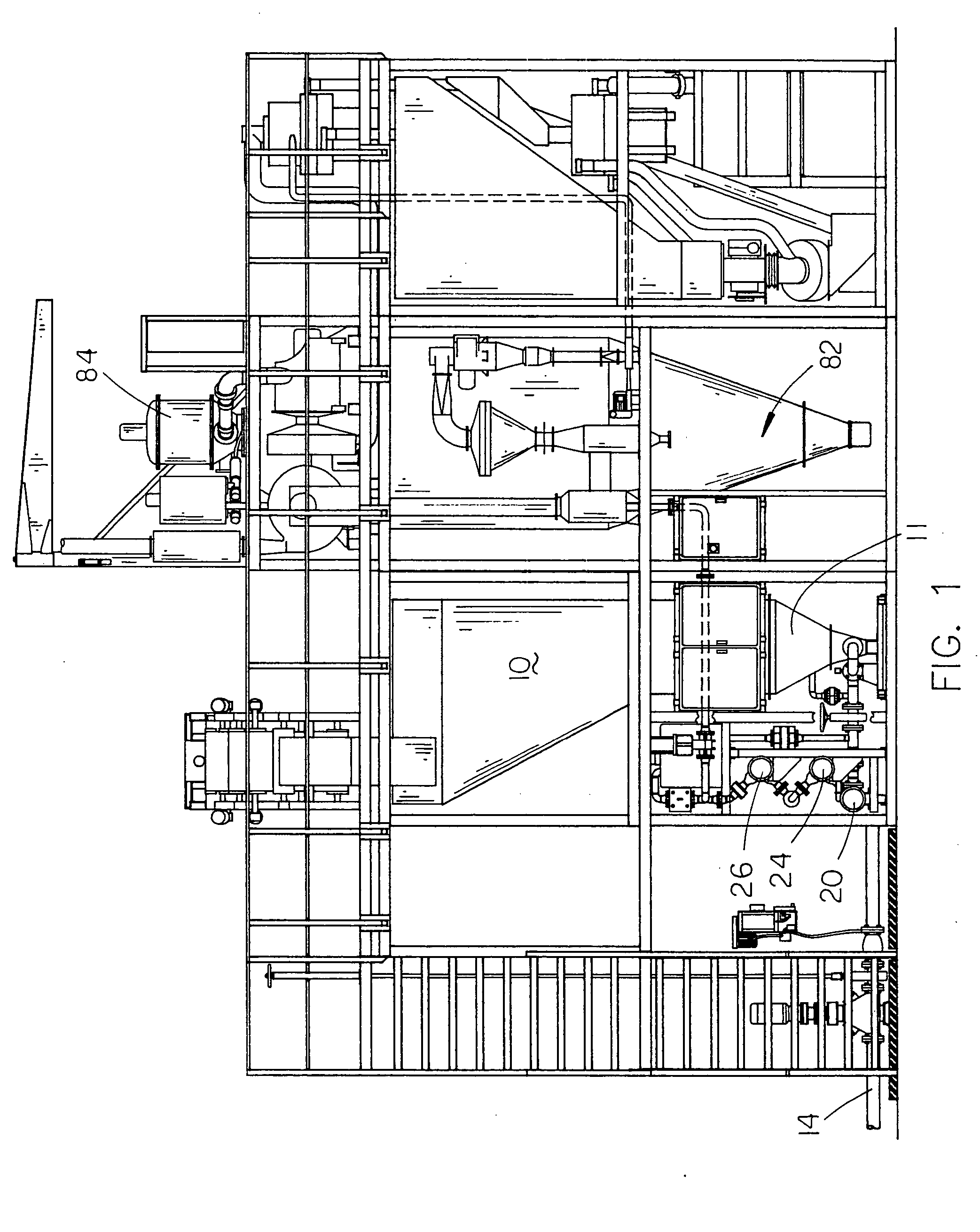

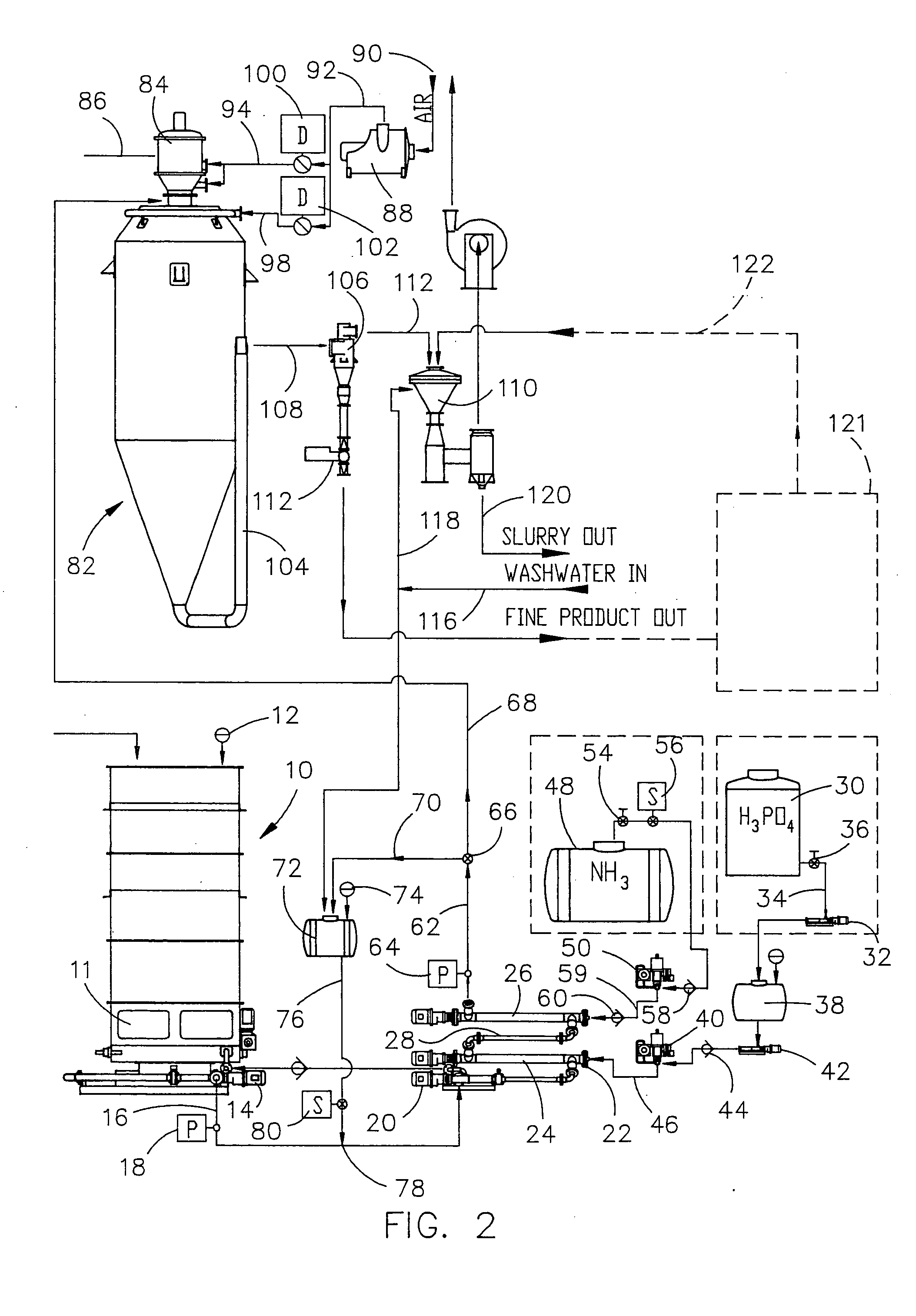

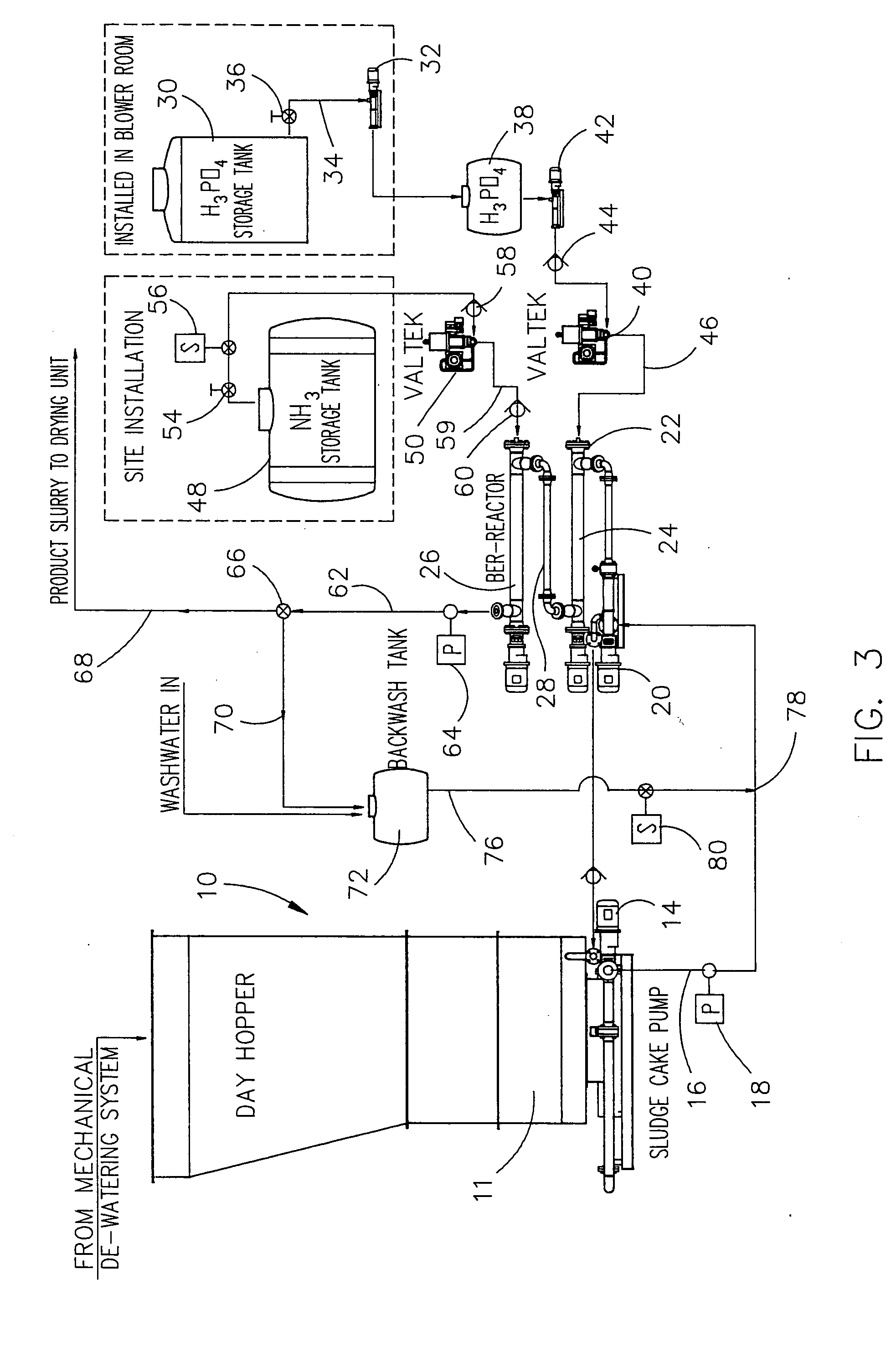

An apparatus and method for treating organic waste sludge such as sewage sludge is disclosed wherein the sludge is first dewatered, moved to a day hopper for storage, and then successively passed through first and second reactors. As the sludge is passed through the first reactor, in a continuous fashion, the sludge and acid are thoroughly mixed and has the pH thereof substantially lowered due to the addition of acid in the first reactor. The sludge is then moved through the second reactor where the sludge is subjected to a base material to substantially raise the pH thereof. The treated sludge is then pumped from the second reactor to a pugmill and then to a dryer which dries the material. The dried material is then suitable for use as a fertilizer.

Owner:BER SYST

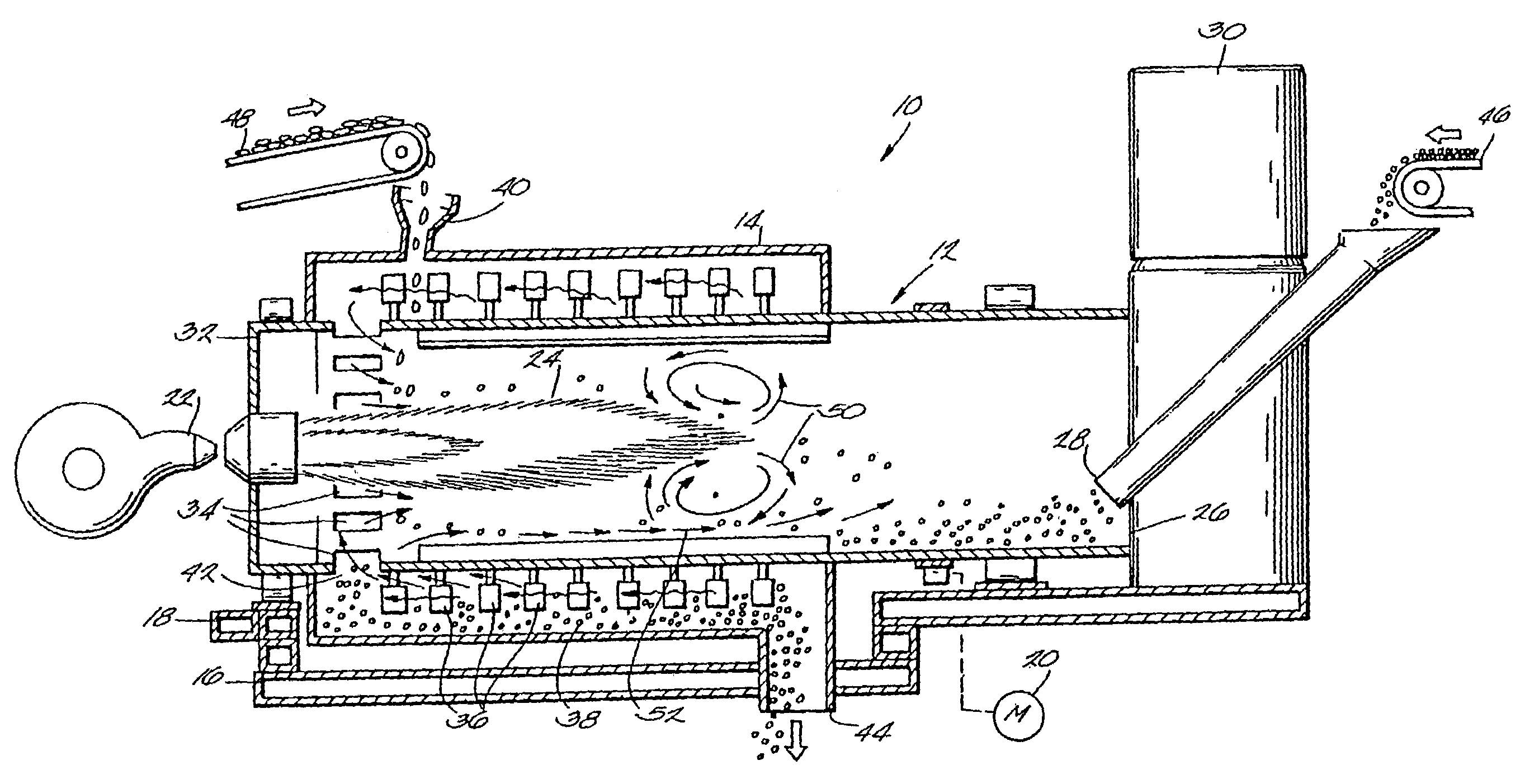

Apparatus and method for a hot mix asphalt plant using a high percentage of recycled asphalt products

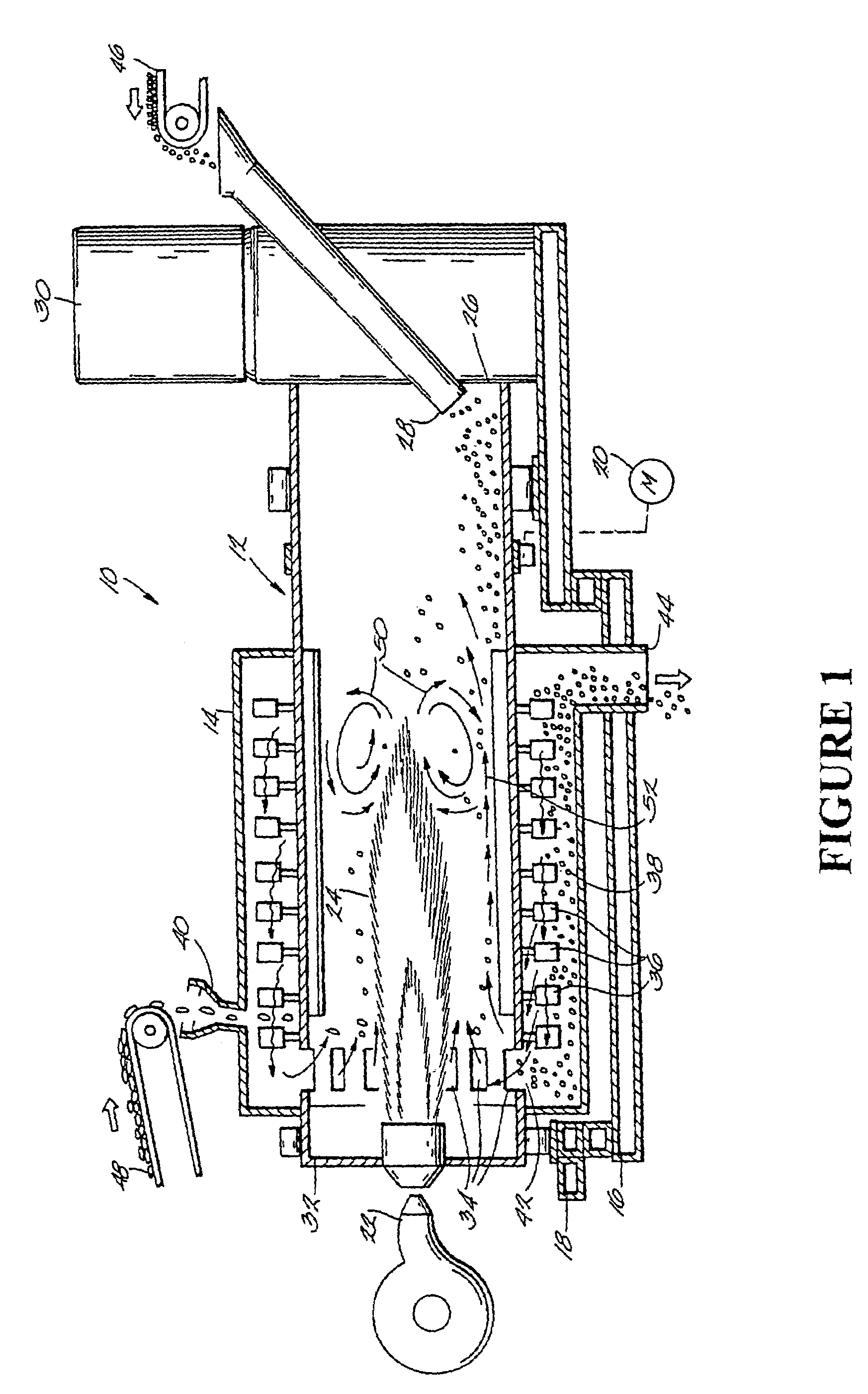

A hot mix asphalt plant for producing hot mix asphalt using a high percentage of RAP comprising a first dryer adapted to receive and mix virgin aggregates and RAP fines and a first burner assembly adapted to produce a burner flame and heat and dry the virgin aggregates in the first dryer. The plant also includes a second dryer adapted to receive coarse RAP and a second burner assembly adapted to produce a burner flame and heat and dry the coarse RAP in the second dryer. The plant further comprises a pugmill adapted to receive the virgin aggregates and the RAP fines from the first dryer and the coarse RAP from the second dryer and mix the virgin aggregates, the RAP fines and the coarse RAP to produce hot mix asphalt. The method of the invention includes the steps of providing first dryer, a first burner, a second dryer, and a second burner, conveying the virgin aggregates to the first dryer, heating and drying the virgin aggregates in the first dryer, conveying the RAP fines to the first dryer, mixing the virgin aggregates and the RAP fines in the first dryer, conveying the coarse RAP to the second dryer, heating and drying the coarse RAP in the second dryer, and mixing the coarse RAP, the RAP fines and the virgin aggregates to produce hot mix asphalt.

Owner:ASTEC

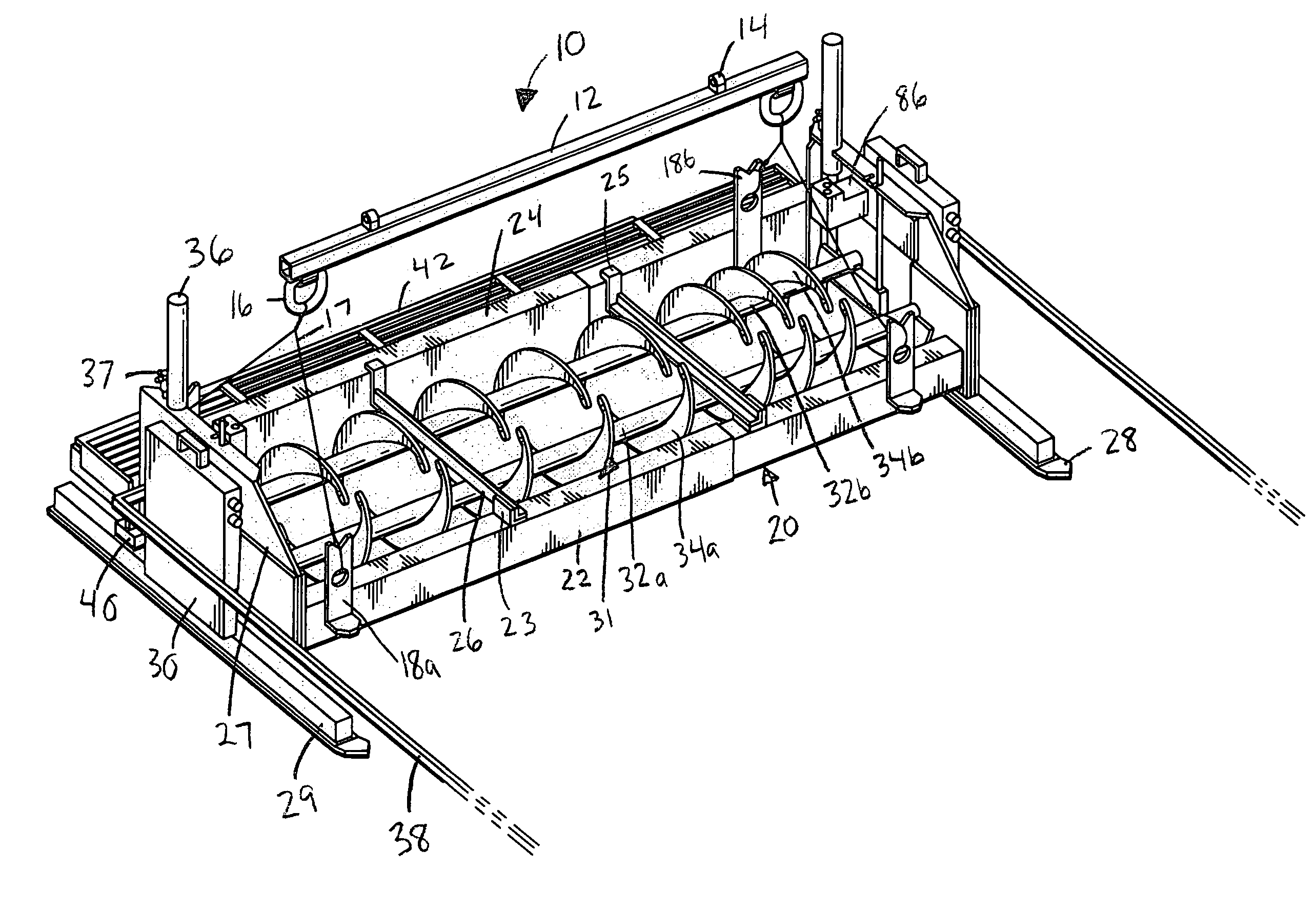

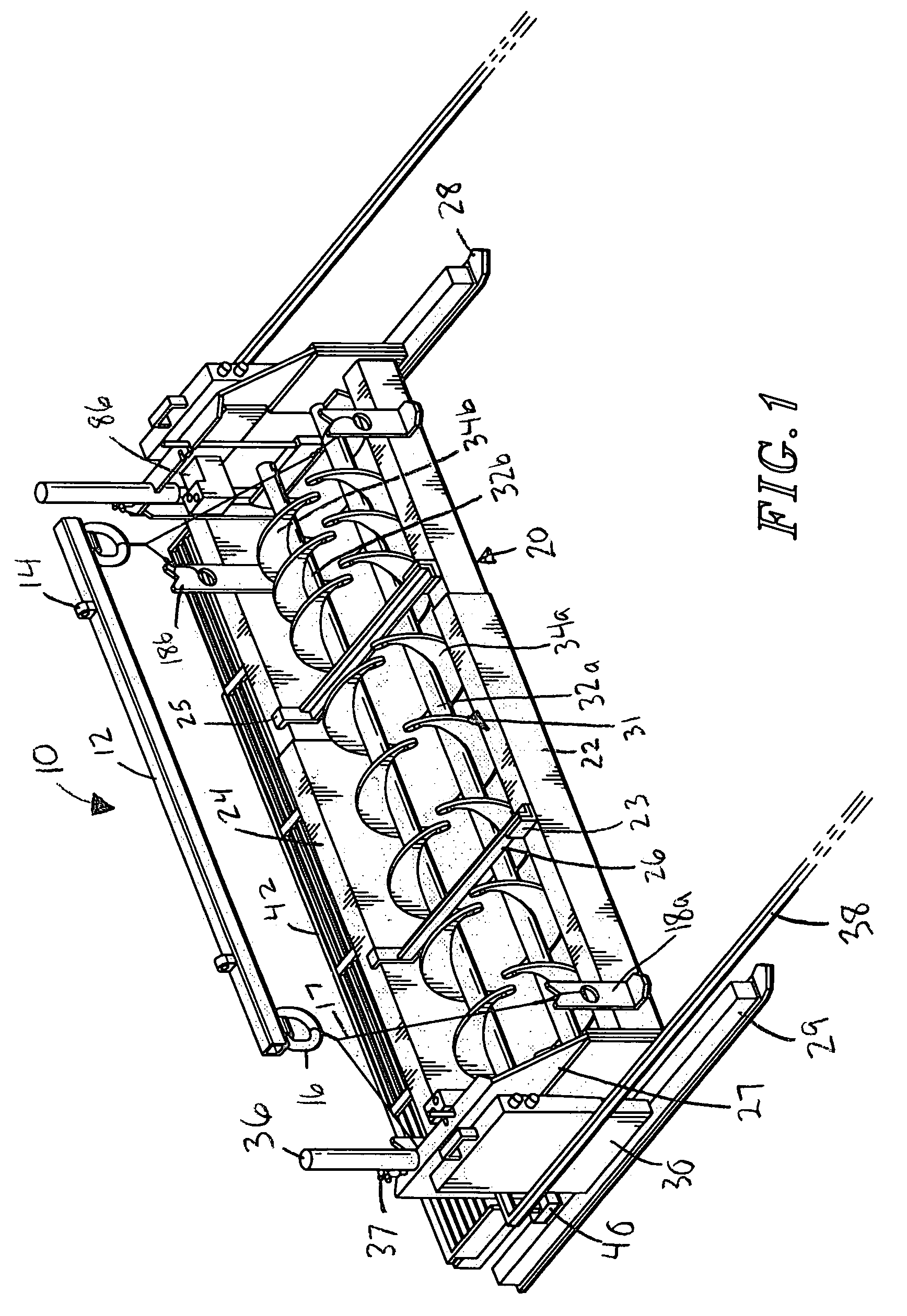

Portable drag box with automated shearing device

A drag box for use in applying cold mix asphalt paving material to a surface includes a pugmill for distributing the cold mix over the surface, a strike blade for shearing the asphalt mixture to a desired thickness, cylinders for raising and lowering the strike blade in response to elevational changes in the surface, at least one signal generator associated with each cylinder and adapted to produce a signal indicative of the elevation of the surface, and at least one signal receiver associated with each signal generator. The drag box is pulled behind a prime mover but preferably is not rigidly coupled with the prime mover. The blade is raised and lowered in response to signals emanating from the generator as the elevation of the surface changes, allowing surface level variations to be evened out while paving.

Owner:ARR MAZ PRODS

Method for preparing environment friendly ceramic gaged brick by Yellow River sediment

The invention belongs to the technical field of building materials, and provides a method for preparing an environment-friendly ceramic plain brick by sediment of the Yellow River. The method is characterized by comprising the following: 1) a step of blank preparation, in which, the sediment of the Yellow River is dug up from riverbed, and is deposited for more than 10 years to be deposited sediment of the Yellow River; the blank comprises the following compositions in weight percentage: 60 to 80 percent of the deposited sediment of the Yellow River, 5 to 10 percent of pulverized fuel ash, 5 to 10 percent of coal refuse, 5 to 10 percent of fluxing agent, and 5 to 10 percent of grog refractory; the compositions are selected for standby; water is added to the mixture for mixing and stirring, wherein the amount of the water is 20 to 22 percent of gross weight of the deposited sediment of the Yellow River, the pulverized fuel ash, the coal refuse, the fluxing agent and the grog refractory; mud is milled by a vacuum pugmill, and is cut into mud cakes; after the mud cakes are aged for 3 days, the blank is produced for standby; 2) a step of glaze preparation; 3) a step of shaping; 4) a step of glazing; 5) a step of drying; and 6) a step of maturing, thereby producing the environment-friendly ceramic plain brick with water content ratio of between 6 and 8 weight percent. The plain brick prepared by the method has the characteristics of high regularity, high strength and strong decoration, and can be directly used for walls bricklaying without external decorating.

Owner:WUHAN UNIV OF TECH

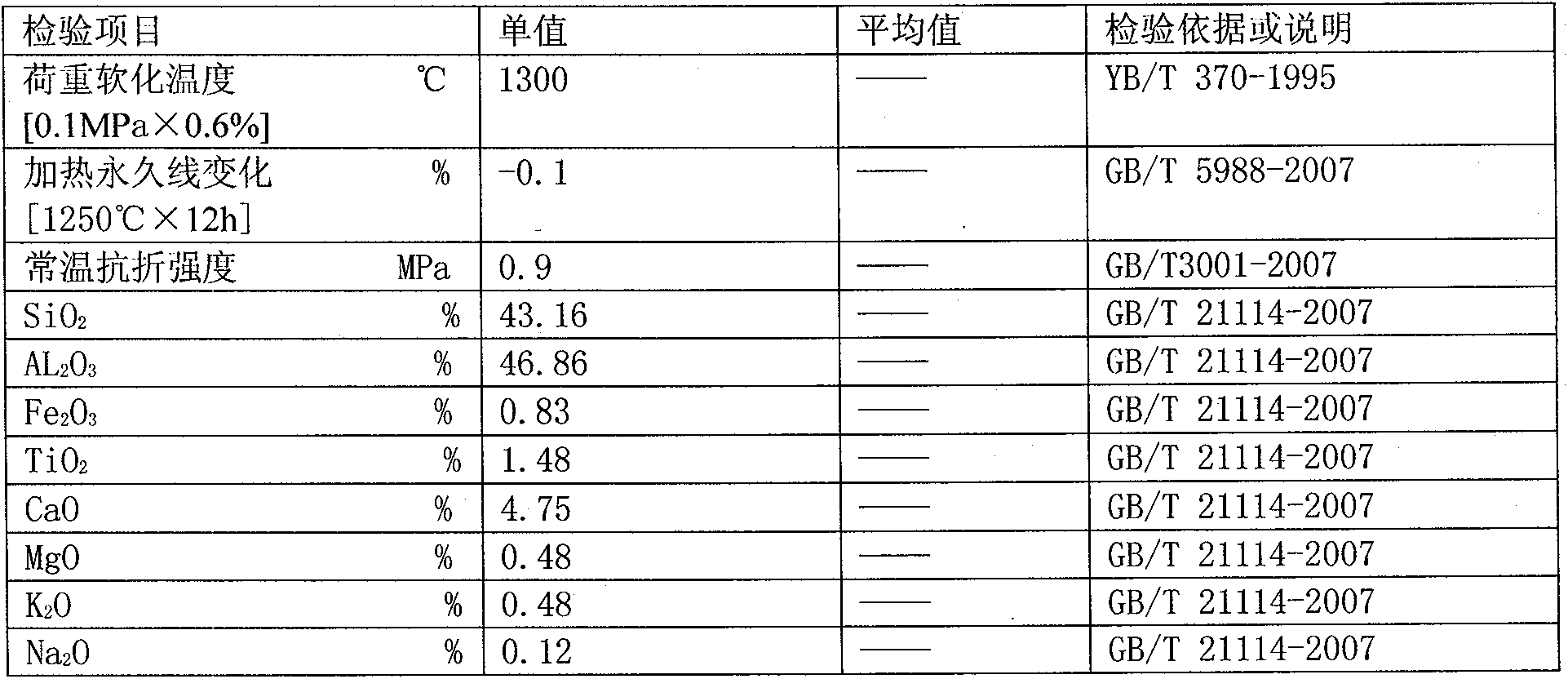

Honeycomb heat accumulator made of silicon carbide-corundum composite materials

ActiveCN101798212ASimple compositionHigh refractorinessChemical industrySmall footprintPetrochemical

The invention relates to a honeycomb heat accumulator made of silicon carbide-corundum composite materials, which comprises the following main raw materials: 20-30wt% of silicon carbide powder, 4-8wt% of zirconia corundum powder, 20-30wt% of corundum powder, 15-20wt% of porzite powder, 15-30wt% of composition of kyanite, andalusite and sillimanite, 4-8wt% of kaolin and 2-5wt% of cellulose powder. The preparation method of the honeycomb heat accumulator comprises the following steps: adding the main raw materials into a ball mill for ball milling; adding stearic acid of which the weight is not greater than 1% of the total weight of the main raw materials for ball milling, and then, sieving to obtain a mixture; respectively adding tung oil of which the weight is not greater than 1% of the weight of the mixture and glycerol of which the weight is not greater than 1% of the weight of the mixture for mixing, aging and vacuum pugmill to form pug segments; carrying out extrusion forming in a mold, and drying; and insulating at the temperature of 1400-1450 DEG C for 4-8 hours, and then, calcining. The honeycomb heat accumulator of the invention has the characteristics of high fire resistance, good thermal shock resistance, strong corrosion resistance, large heat exchange area, small gas flow resistance, high heat accumulating efficiency, small floor space and long service life which can be more than two years, and is widely used for heat accumulating type heating furnaces of black and non-ferrous smelting, thermal power generation, petrochemical industry, ceramics, glass, machining, civil cookers and the like.

Owner:JIANGXI SHINCO ENVIRONMENTAL PROTECTION CO LTD

Zirconia honeycomb ceramic body

InactiveCN101323537AImprove thermal stabilityImprove crack resistanceCeramicwareCelluloseSocial benefits

The invention discloses a zirconia honeycomb ceramic body which comprises the raw materials as follows: ceramic raw material, alpha-Al2O3 powder, clay, Mgo, organic cellulose, a binder and ZrO2 powder. The raw materials are mixed evenly by weight percentage and then the binder and moderate amount of water are added, and ball milling, mixed milling and staleness are carried out to prepare pug; the pug is put into a vacuum pugmill for pug milling, and then extrusion molding wet honeycomb ceramic body is put into a far-infrared kiln for drying and shaping into a dry blank; the honeycomb ceramic body is calcined at 1500 DEG C to 1700 DEG C and then cooled and taken out from the kiln. The zirconia honeycomb ceramic body is not only applicable to be used under high temperature environment being over 1500 DEG C in a heating kiln; besides, the heat exchange of the heating kiln is fast and even, thus saving the fuel of the regenerative heating kiln by about 40 percent to 70 percent, promoting yield by more than 15 percent, reducing the emission of NOX gas to be lower than 100ppm and resulting in lower than 150 DEG C gas emission temperature; therefore, the zirconia honeycomb ceramic body greatly improves the burning effect of the regenerative heating kiln, saves fuel and energy, reduces the emission of harmful gases, prolongs the service life of the regenerative heating kiln, improves environment and promotes both economic and social benefits.

Owner:朱根源

Sewage sludge treatment

InactiveUS20050175516A1Improve the mixing effectSludge treatment by de-watering/drying/thickeningAluminium compoundsEngineeringSewage

An apparatus and method for treating organic waste sludge such as sewage sludge is disclosed wherein the sludge is first dewatered, moved to a day hopper for storage, and then successively passed through first and second reactors. As the sludge is passed through the first reactor, in a continuous fashion, the sludge and acid are thoroughly mixed and has the pH thereof substantially lowered due to the addition of acid in the first reactor. The sludge is then moved through the second reactor where the sludge is subjected to a base material to substantially raise the pH thereof. The treated sludge is then pumped from the second reactor to a pugmill and then to a dryer which dries the material. The dried material is then suitable for use as a fertilizer.

Owner:BER SYST

Remediation system

InactiveUS6926465B1Easy and efficient to manufactureDurable and reliable constructionSolid waste disposalContaminated soil reclamationFlocculationEngineering

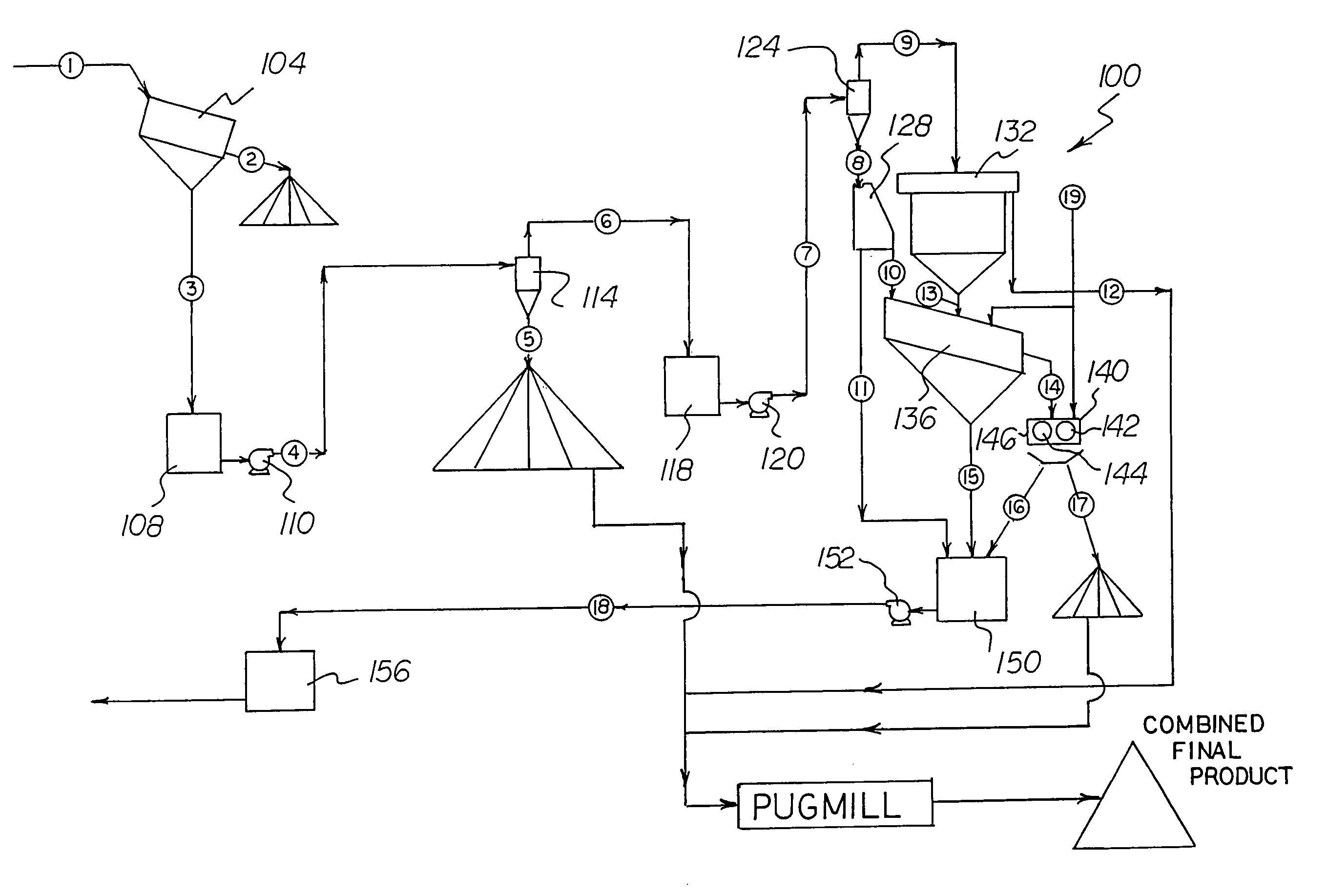

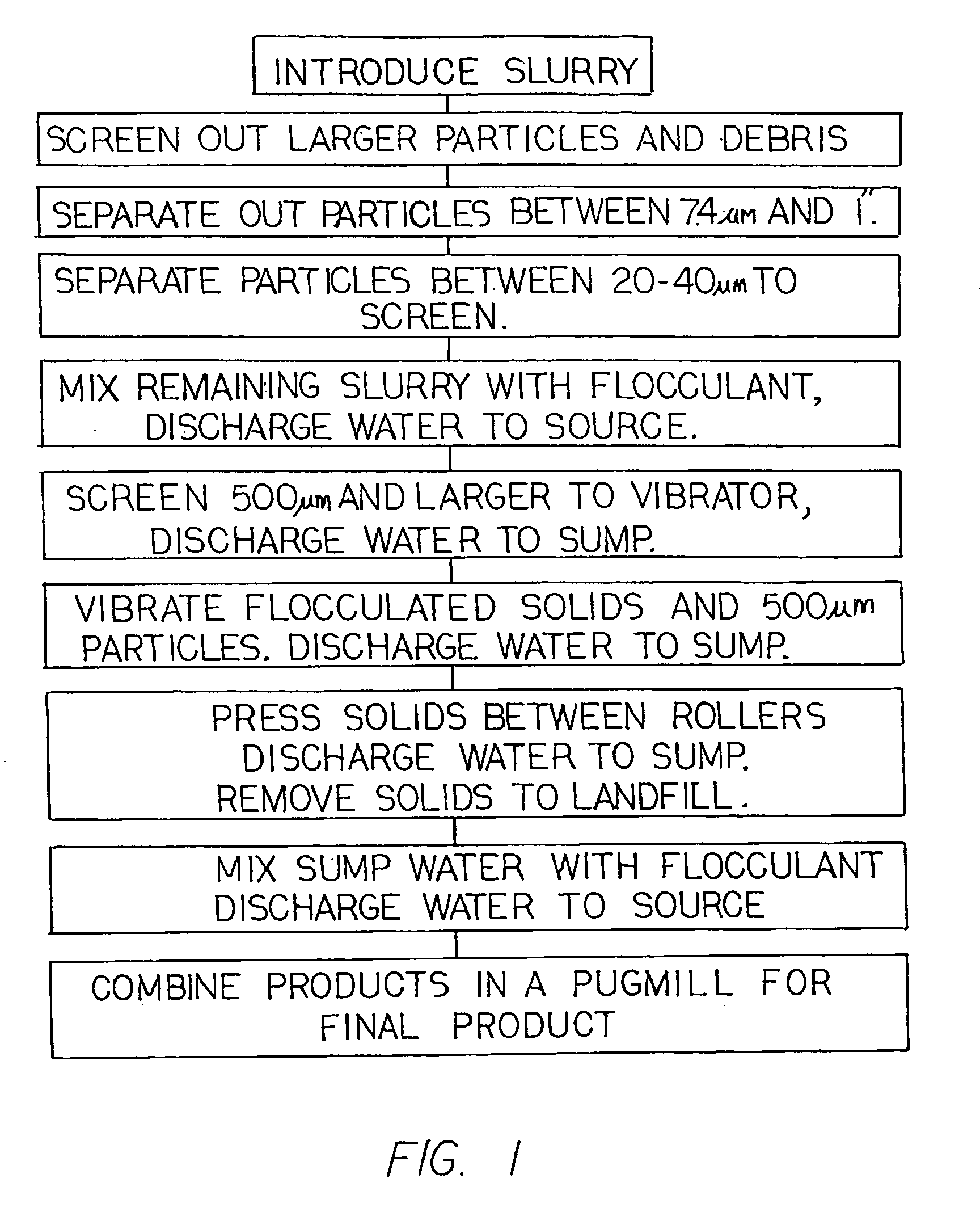

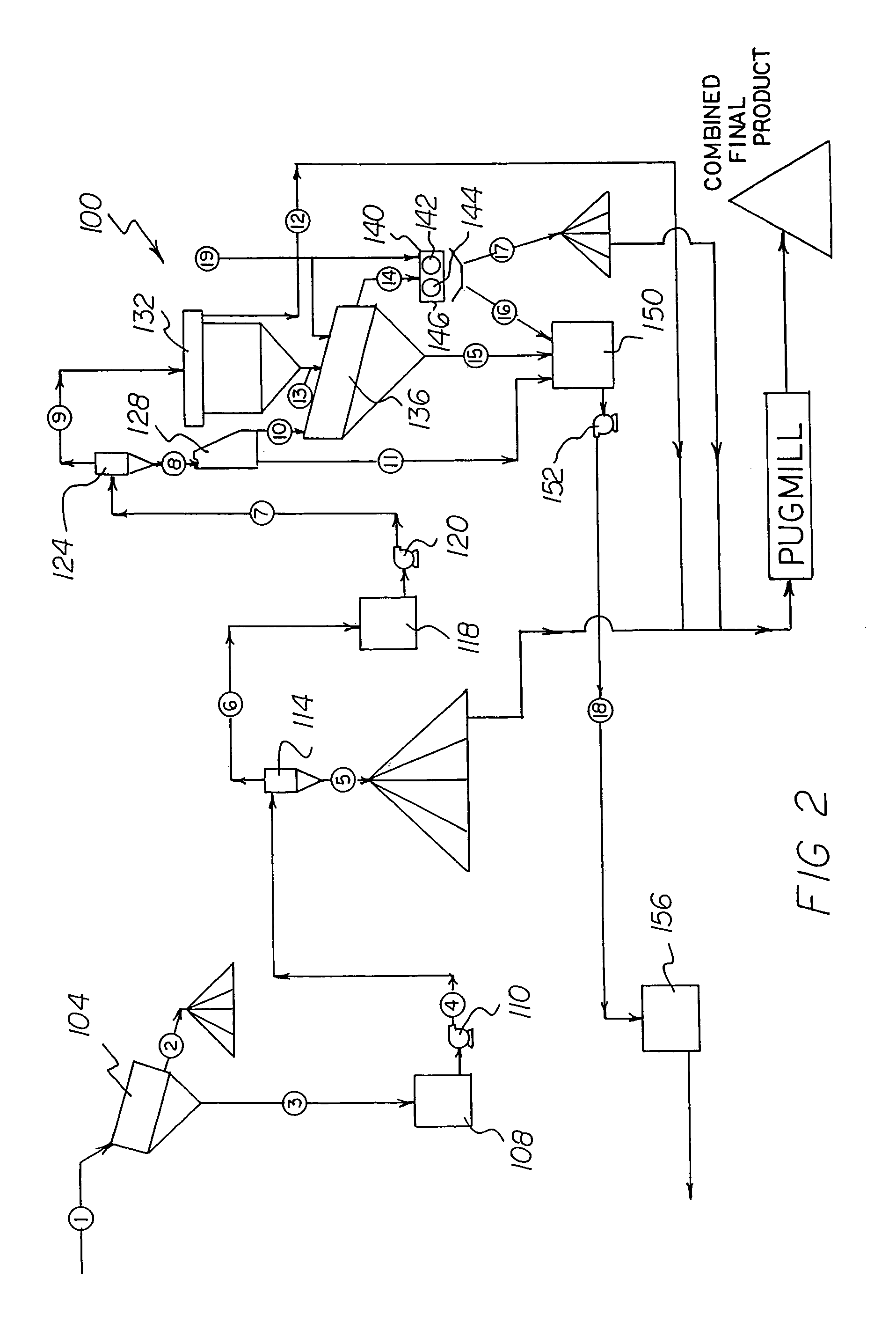

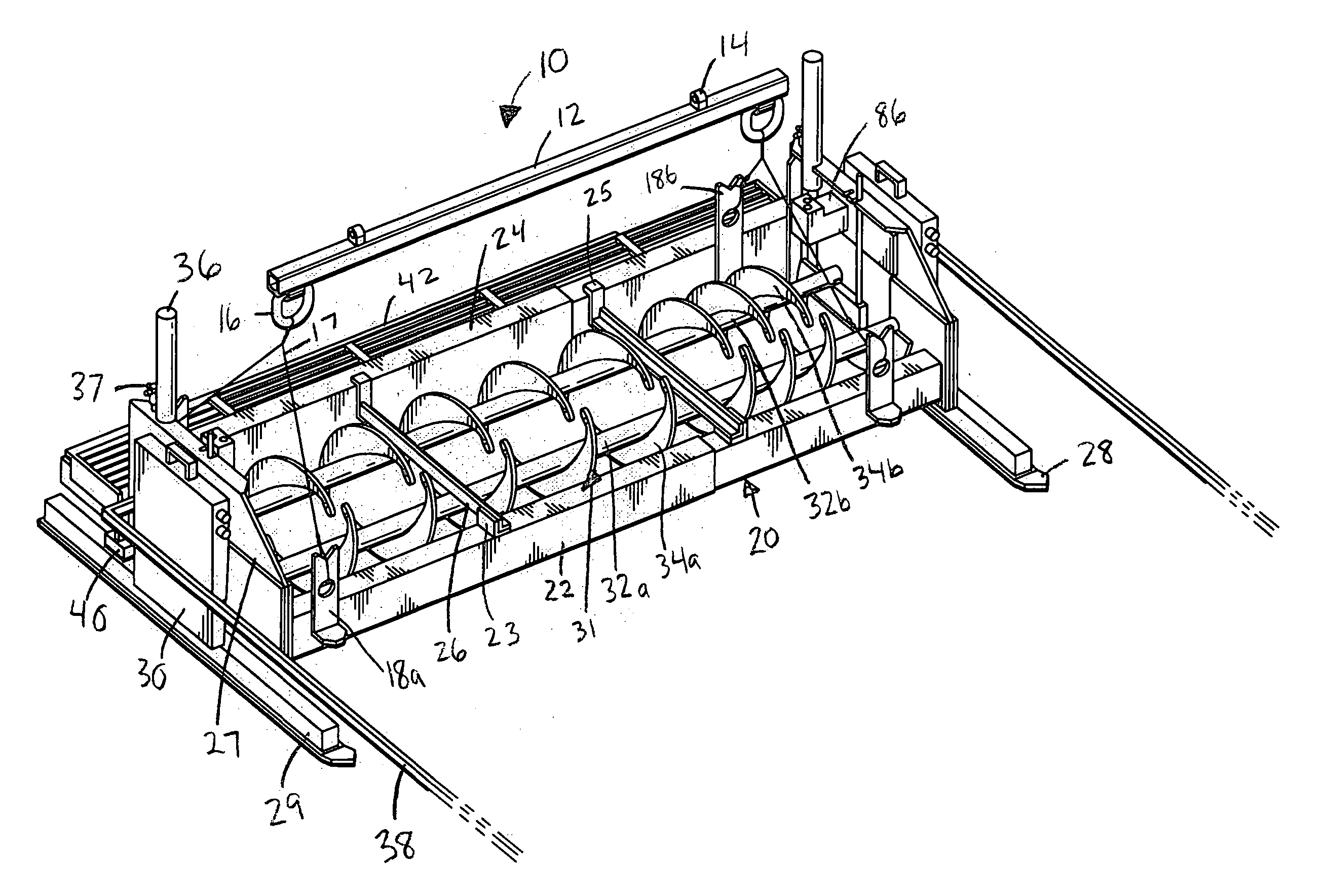

A remediation system comprises a primary scalping screen, a primary pump and sump, a large diameter maximum density separator with flocculant injection ring, a secondary pump and sump, a small diameter maximum density separator with flocculant injection ring, a static sieve screen, a flocculation sump, a vibrating screen, a dewatering device, a tertiary sump and pump, a secondary flocculation tank, and a pugmill. Screens move water and particulates through the components. In this manner larger particles are separated from smaller particles and the particles are further dewatered.

Owner:MANN MICHAEL J +1

Portable drag box with automated shearing device

A drag box for use in applying cold mix asphalt paving material to a surface is provided. The drag box includes a pugmill for distributing the cold mix over the surface, a strike blade for shearing the asphalt mixture to a desired thickness, cylinders for raising and lowering the strike blade in response to elevational changes in the surface, at least one signal generator associated with each cylinder and adapted to produce a signal indicative of the elevation of the surface, and at least one signal receiver associated with each signal generator. The drag box is pulled behind a prime mover but preferably is not rigidly coupled with the prime mover. The blade is raised and lowered in response to signals emanating from the generator as the elevation of the surface changes, allowing surface level variations to be evened out while paving.

Owner:ARR MAZ PRODS

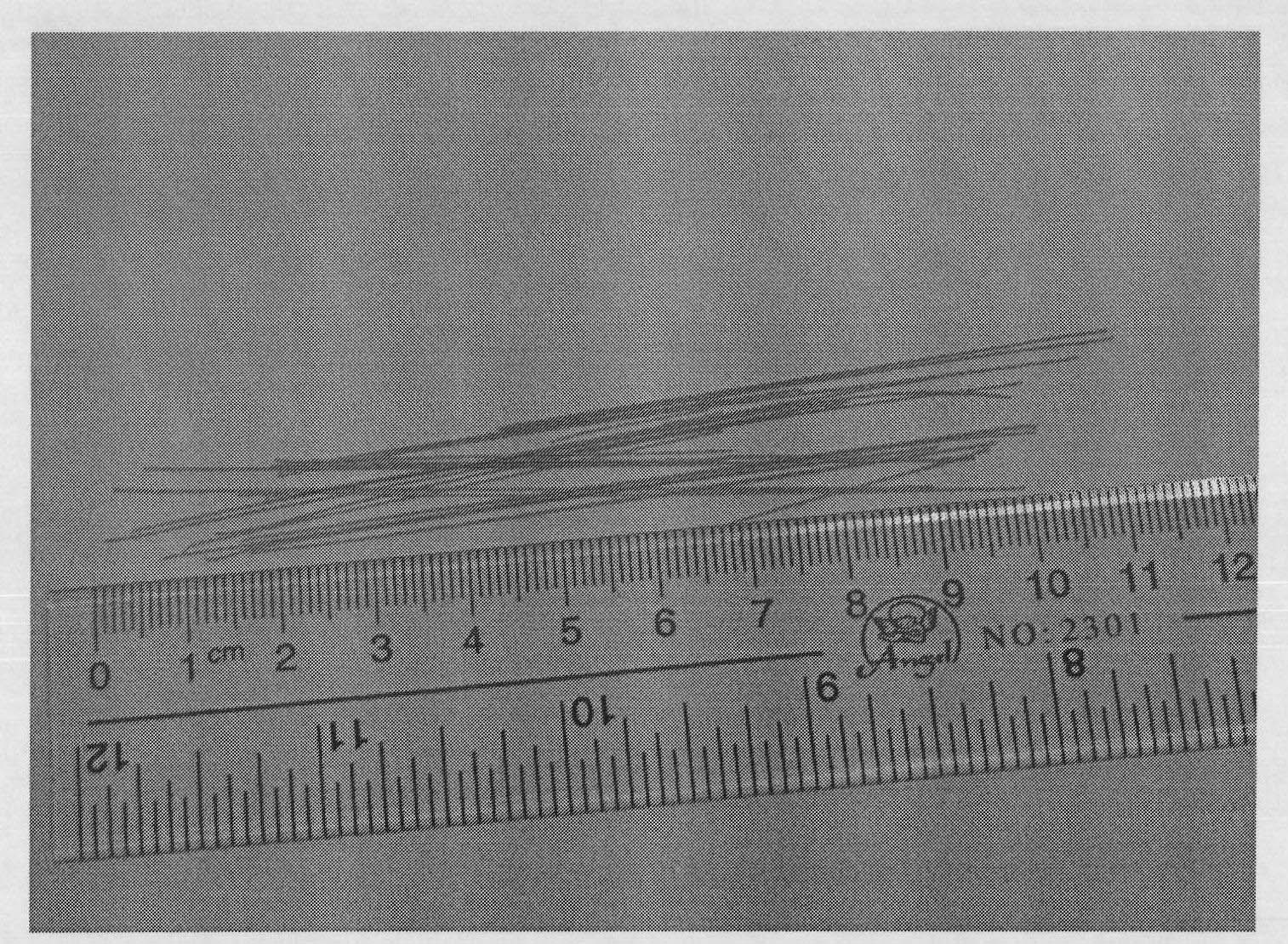

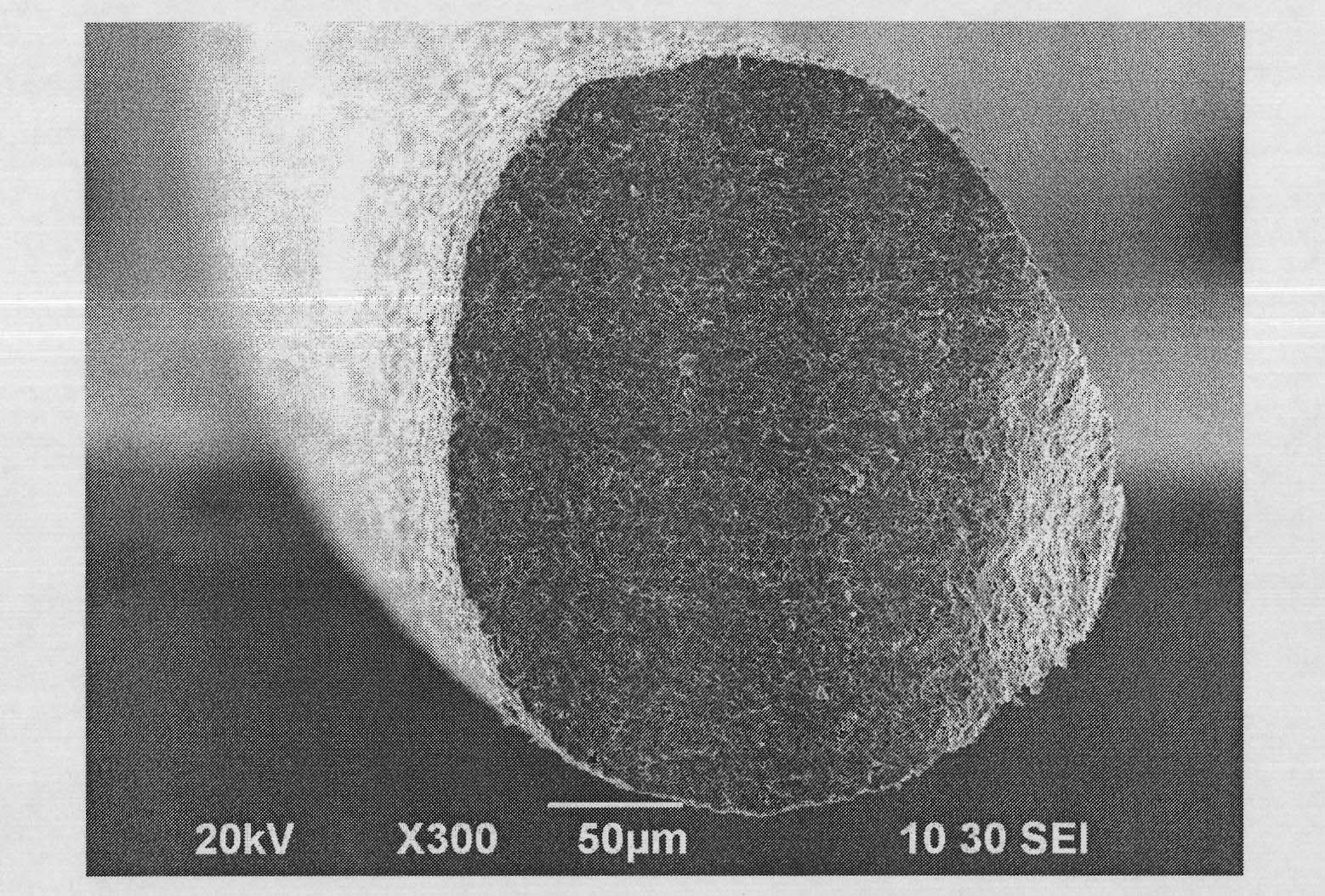

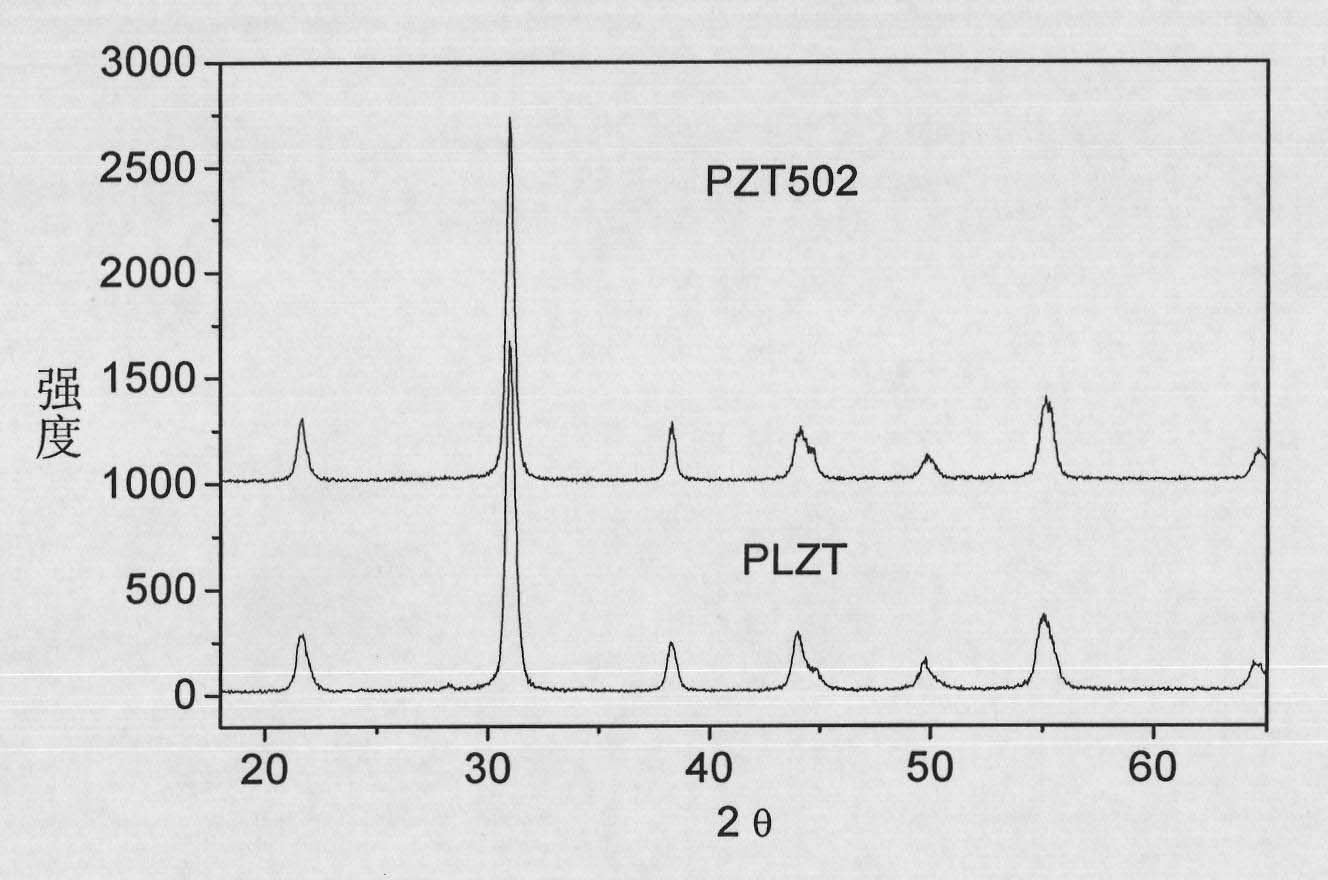

Method for preparing bending-free piezoelectric ceramic fiber with low cost

The invention discloses a method for preparing a bending-free piezoelectric ceramic fiber with a low cost. The method comprises the following steps of: fully and uniformly stirring one or two of polyvinyl alcohol, polyvinyl pyrrolidone and cellulose acetate serving as adhesives, water serving as a solvent and lead zirconate titanate series powder with a grain diameter of smaller than 1 micron serving as a raw material, degassing the mixture under the negative pressure of between 10<-2> and 10<-3> Pa or degassing the mixture in a vacuum pugmill to form a briquette; putting the briquette into a melt spinning machine for spinning, straightening the spun briquette and drying the straightened briquette in the air to form a continuous fiber, and cutting the continuous fiber into short fiber briquettes with lengths of between 100 and 350 millimeters; pyrolyzing the fiber briquettes in a muffle furnace at the temperature of 550 DEG C for 1 hour, raising the temperature to 85 to 900 DEG C at a speed of 5 DEG C per minute, preserving the heat for 2 hours and cooling the fiber briquettes; and hanging pre-burnt fiber briquettes in an aperture formed between two square corundum strips in a corundum crucible, raising the temperature to a needed temperature at the speed of 5 DEG C per minute and preserving the heat for about 90 minutes to obtain the ceramic fiber. The method has low cost; the prepared ceramic fiber is bending-free; and the sintered ceramic fiber has low porosity, good uniformity and good piezoelectric property.

Owner:江苏为一新材料科技有限公司

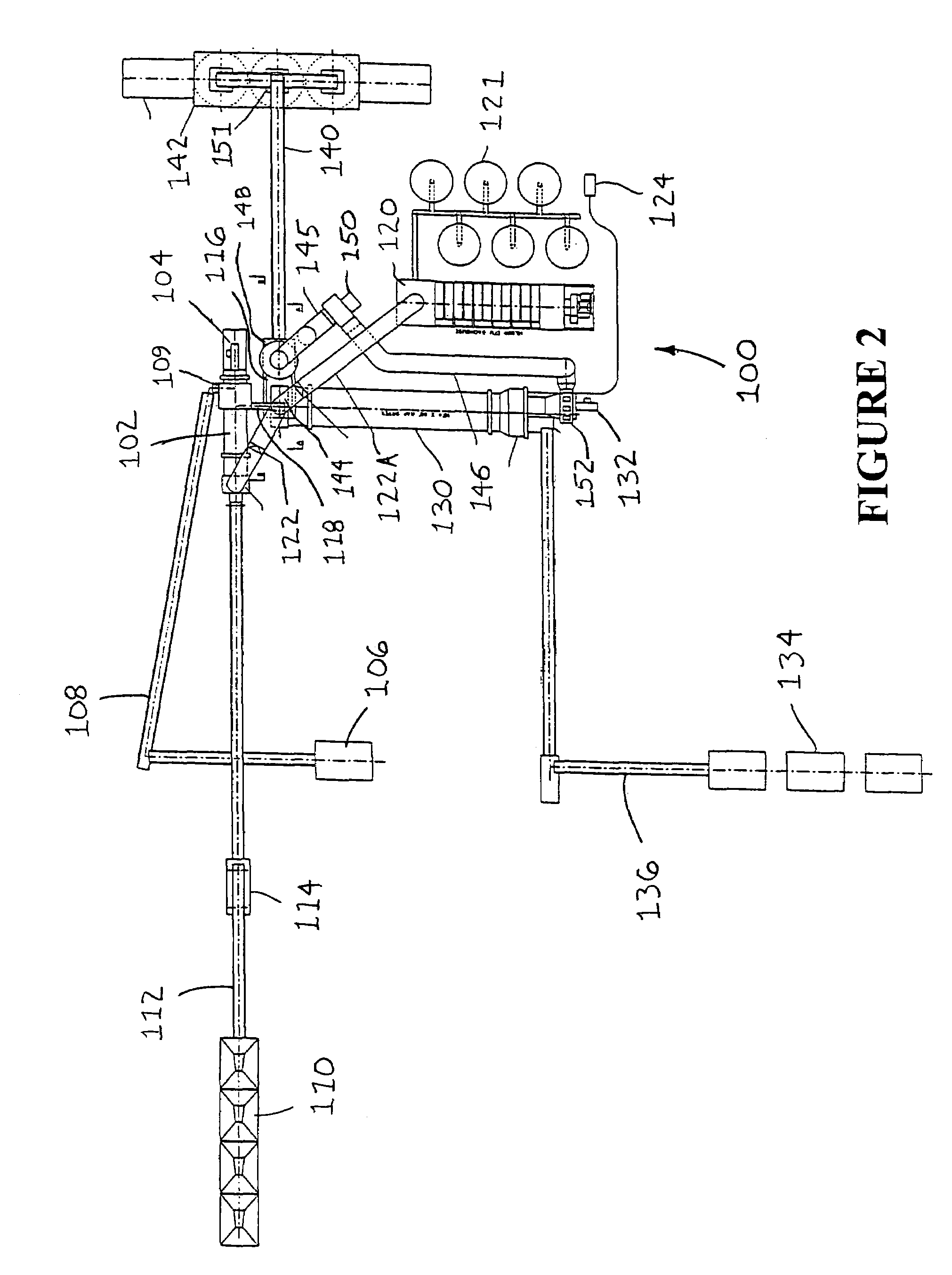

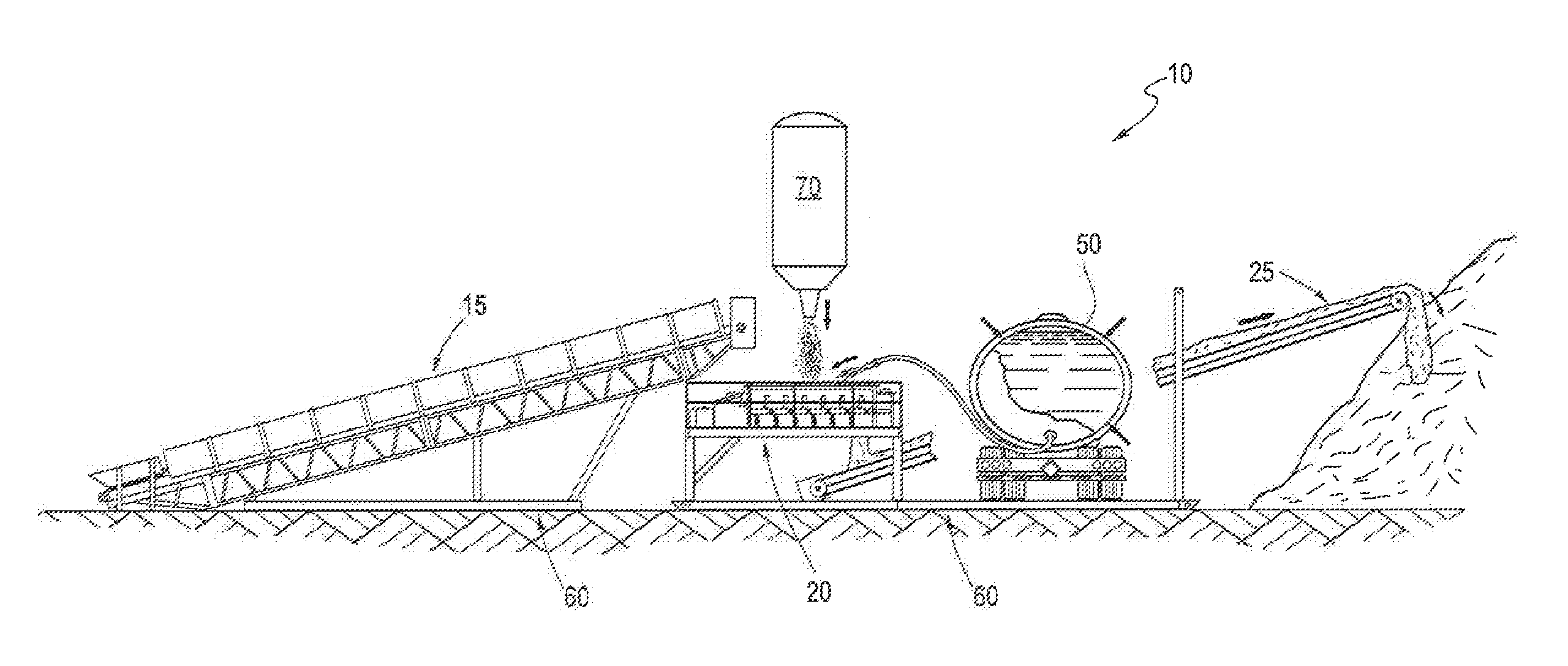

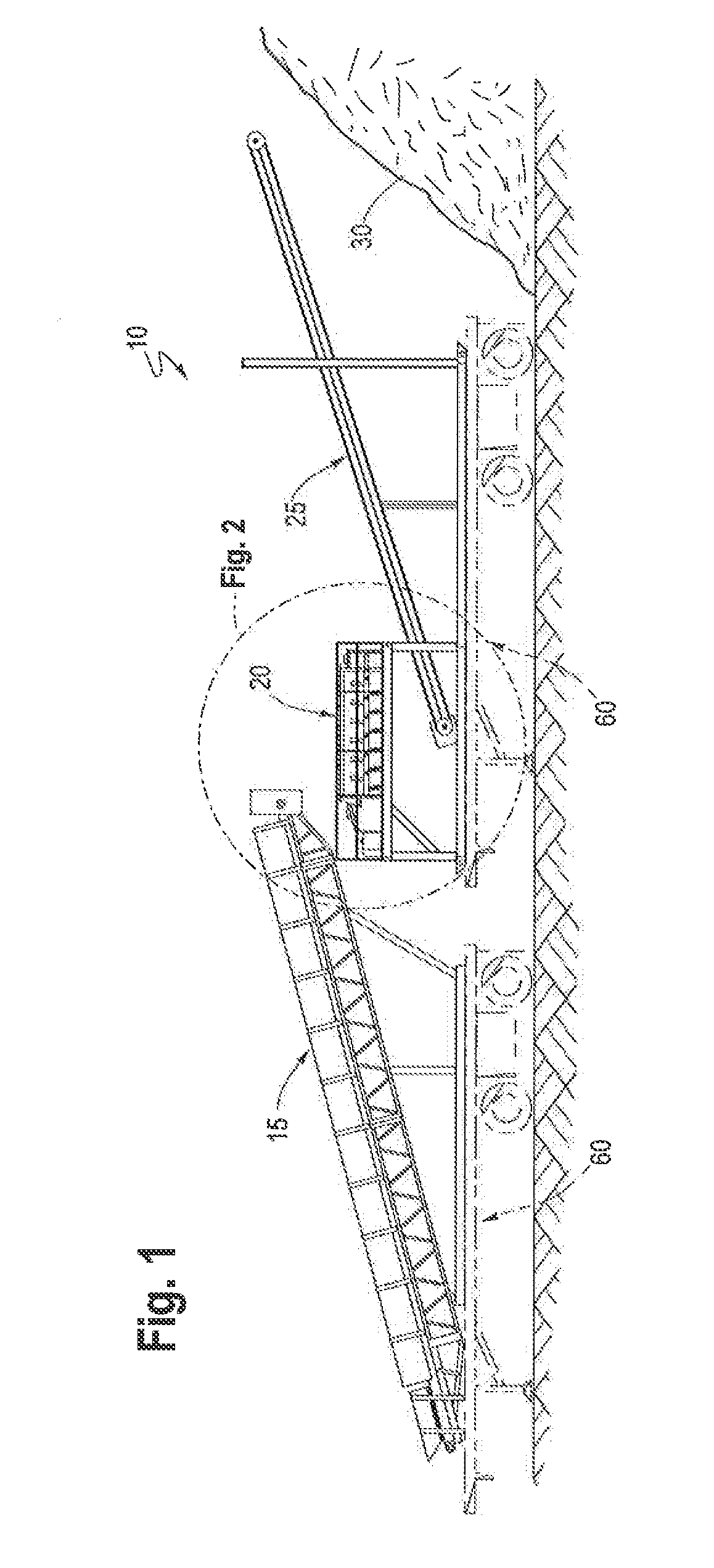

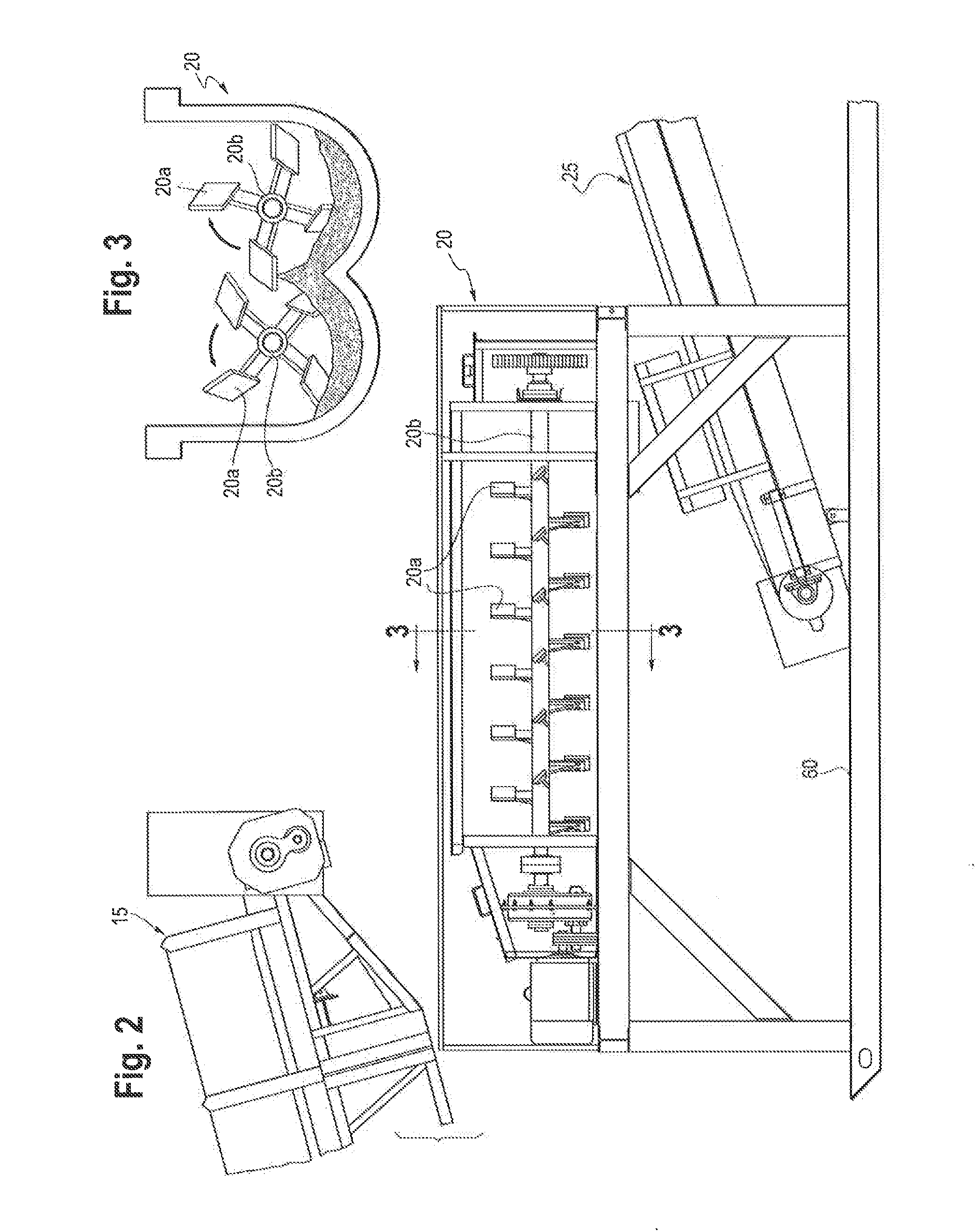

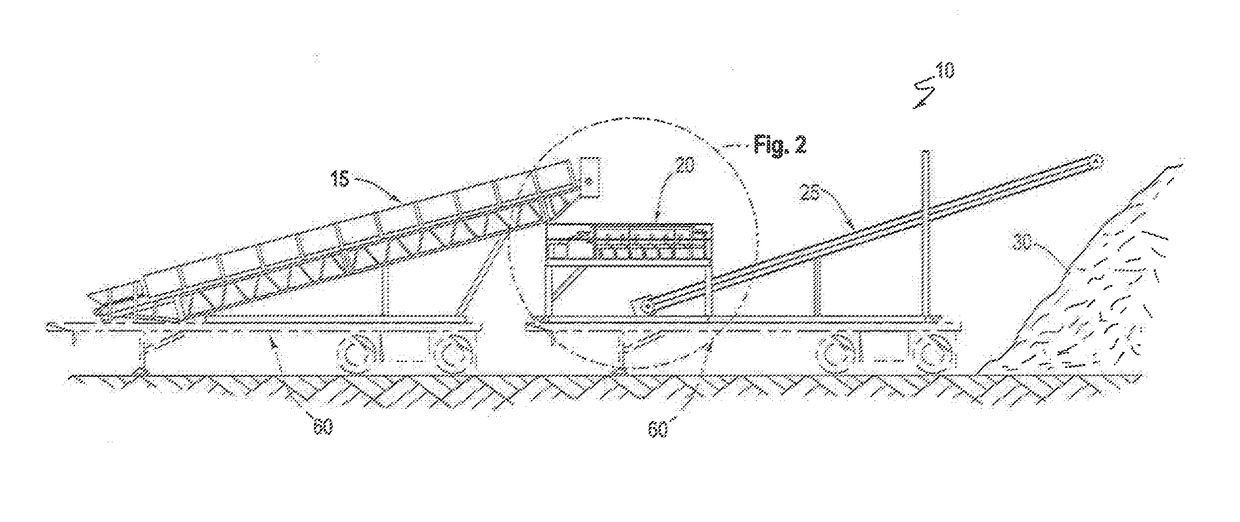

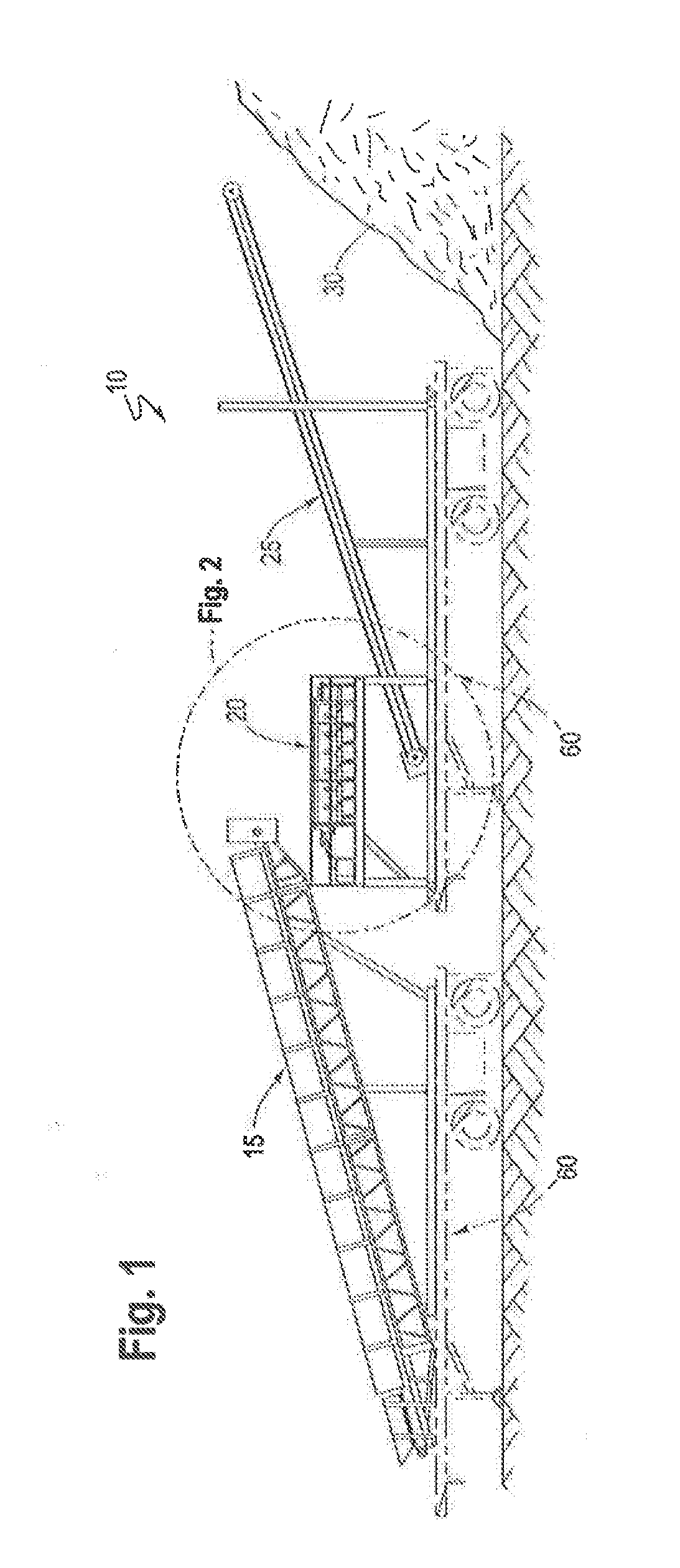

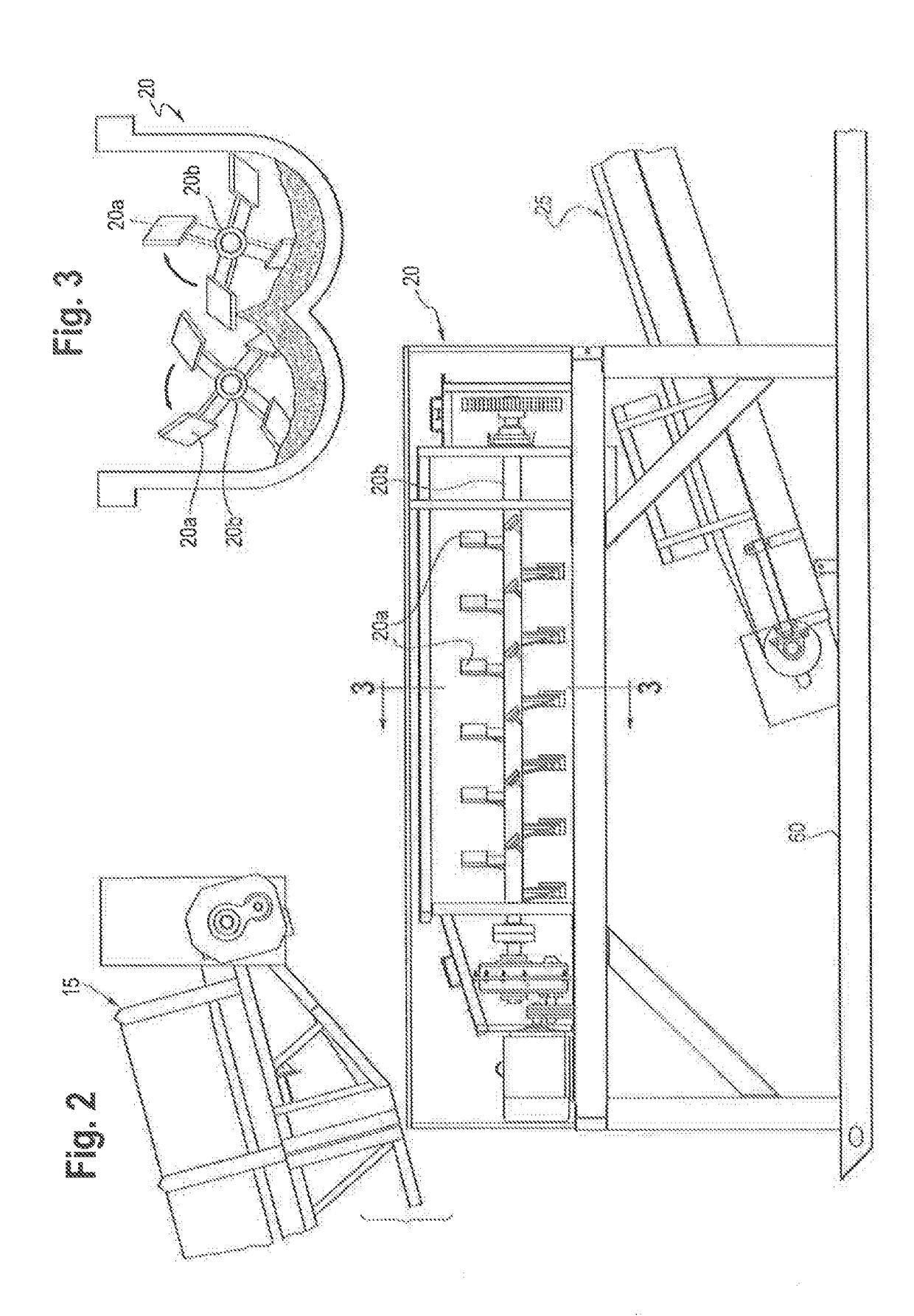

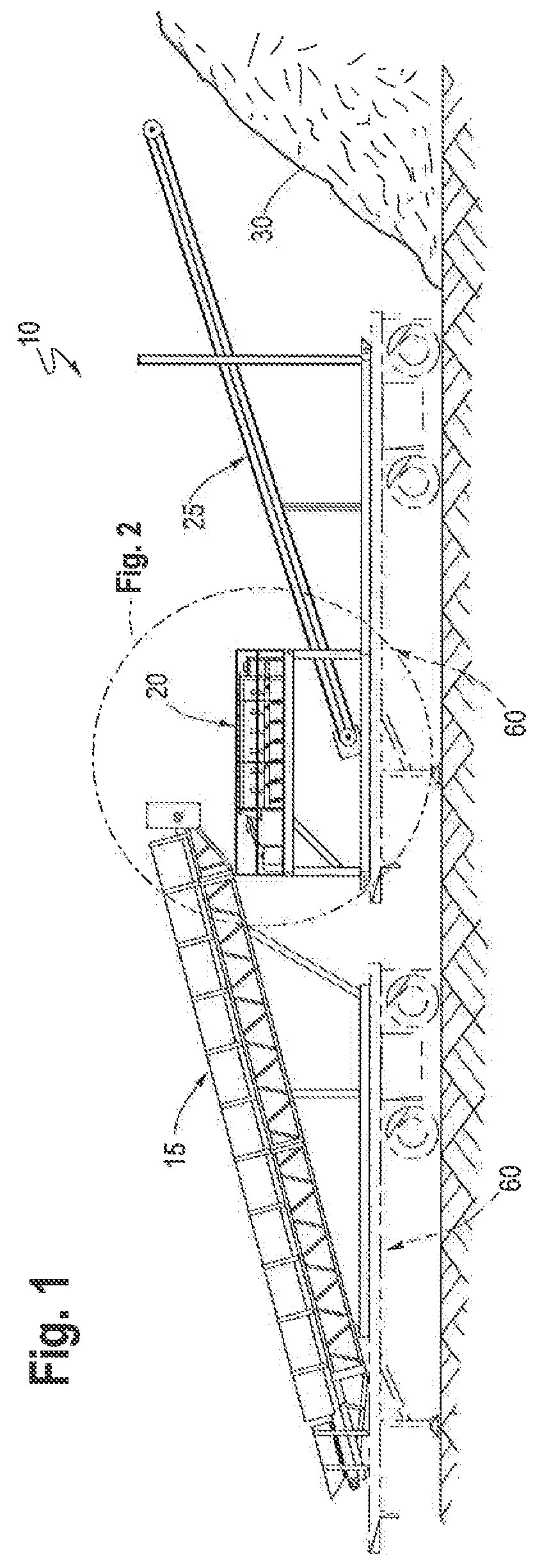

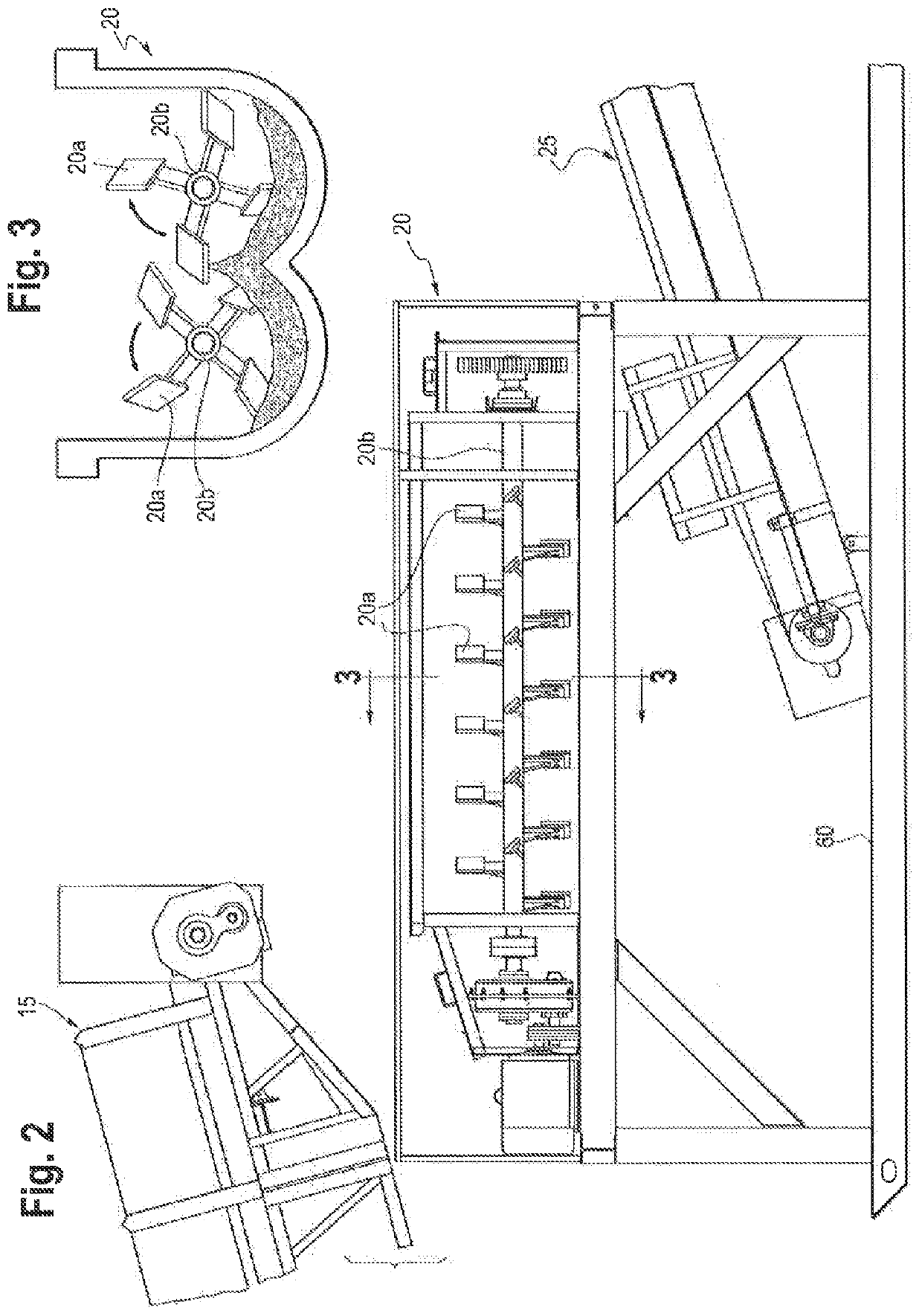

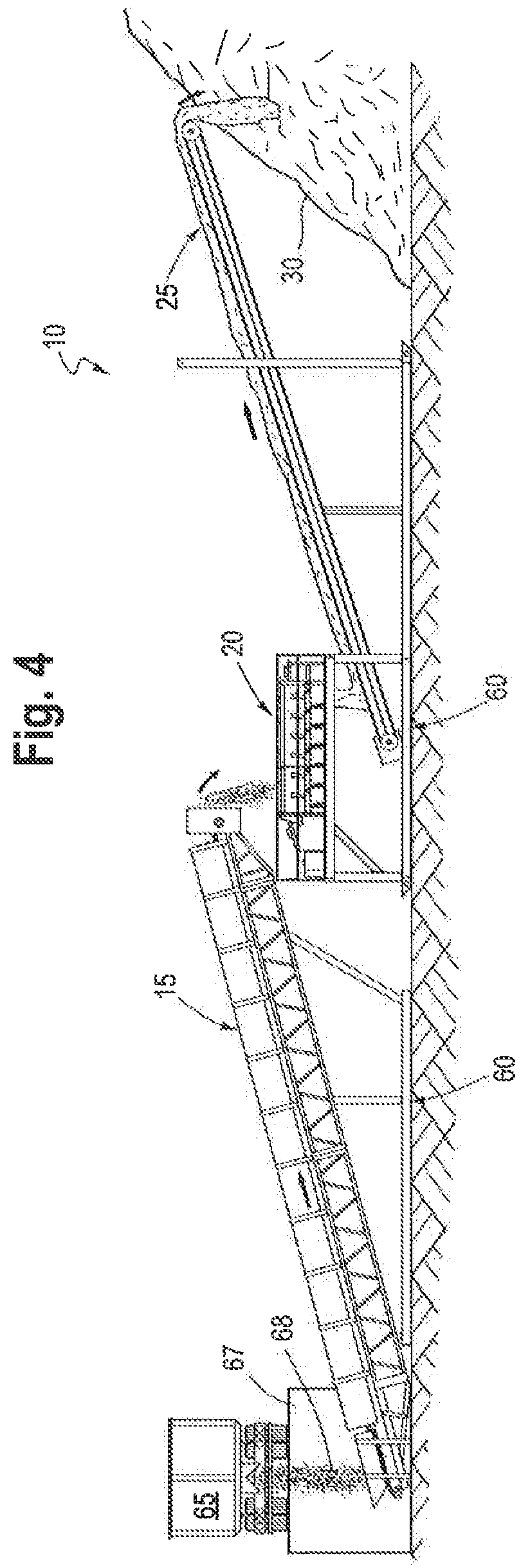

Portable system and method for processing waste to be placed in landfill

ActiveUS20160114364A1Reduce dustEfficient and effectiveSolid waste disposalTransportation and packagingEnvironmental engineeringActive cell

A portable system and method for processing waste to be solidified and placed in an active cell of a landfill. A portable pugmill is moveable adjacent an active cell of a landfill; and portable devices, which may be mounted on sleds or trailers, may be used for feeding the pugmill with waste to be solidified into a landfill-ready state. The waste may be fed to the pugmill without the need for long-term waste storage devices, and avoiding substantial delays between discharge of the waste from trucks to the pugmill-feeding steps.

Owner:PERRY RIDGE LANDFILL INC

Portable system and method for processing waste to be placed in landfill

A portable system and method for processing waste to be solidified and placed in an active cell of a landfill. A portable pugmill is moveable adjacent an active cell of a landfill; and portable devices, which may be mounted on sleds or trailers, may be used for feeding the pugmill with waste to be solidified into a landfill-ready state. The waste may be fed to the pugmill without the need for long-term waste storage devices, and avoiding substantial delays between discharge of the waste from trucks to the pugmill-feeding steps.

Owner:PERRY RIDGE LANDFILL INC

Making process of efficient flat ceramic membrane

ActiveCN106810212AHas the effect of disinfection and sterilizationImprove filtering effectSemi-permeable membranesMembranesCeramic membraneFilter effect

The invention discloses a making process of an efficient flat ceramic membrane. The making process includes: making a flat ceramic membrane supporting body; preparing the efficient flat ceramic membrane, wherein nano-silver is added during preparation of the efficient flat ceramic membrane. The making process has the advantages that by adding the nano-silver, the efficient flat ceramic membrane has disinfecting and sterilizing effects, thereby having better filtering effect; through pug milling in a vacuum pugmill, influence of gravity on materials can be eliminated to sufficiently mix the materials, so that uniformizing of the materials at all positions of pug is facilitated, and the made flat ceramic membrane supporting body is high in quality; by using alumina as a main raw material for sintering to prepare the flat ceramic membrane supporting body, performance stability of the ceramic membrane supporting body can be improved, and enough strength of the supporting body can be ensured while light weight is realized.

Owner:HAITIAN WATER GRP CO LTD

Zircon honeycomb ceramic body

InactiveCN103204690AImprove high temperature resistanceHigh temperature resistance hasCeramicwareCelluloseCombustion

The invention discloses a zircon honeycomb ceramic body comprising the following raw material ingredients: a ceramic raw material, alpha-Al2O3 powder, clay, MgO, organic cellulose, an adhesive and ZrO2 powder. The zircon honeycomb ceramic body is prepared by uniformly mixing the raw materials at a weight ratio, adding the adhesive and a proper dosage of water, and performing ball grinding, mixed milling and staling on the mixture to obtain pug; smelting the pug in a vacuum pugmill, and putting, drying and sizing an extrusion formed wet honeycomb ceramic body in an infrared furnace to obtain a dry blank; and roasting the honeycomb ceramic body at a temperature of 1500-1700 DEG C, cooling and discharging the honeycomb ceramic body from the furnace. The zircon honeycomb ceramic body can be used in a heating furnace with temperature higher than 1500 DEG C, and furthermore, the heat exchange of the heating furnace is quick and uniform, so that 40-70% of fuel of the heat accumulation type heating furnace is saved, the yield is improved by more than 15%, the emission of NOX gases is reduced to be lower than 100 ppm, the flue gas exhaust temperature is lower than 150 DEG C, the combustion effect of the heat accumulation type heating furnace is improved, the fuel energy source is saved, the emission of harmful gases is reduced, and the service life of the heat accumulation type heating furnace is prolonged.

Owner:朱根源

Hollow flat plate whole ceramic filtering membrane element

InactiveCN108392990AQuality improvementWell mixedSemi-permeable membranesMembranesCeramic membraneFilter effect

The invention relates to a hollow flat plate whole ceramic filtering membrane element. The prepared filtering membrane element has the sterilization and disinfection effects through the addition of nanometer silver, so that the filtering effect of the filtering membrane element is higher. Through the mud milling in a vacuum pugmill, the influence of gravity on the materials can be eliminated, so that the materials can be sufficiently and uniformly mixed; therefore the materials in each position of the mud materials can favorably become uniform; a prepared flat plate ceramic membrane support body has high quality; by using aluminum oxide as a major raw materials for preparing the flat plate ceramic membrane support body through sintering, the performance stability of the ceramic membrane support body can be improved; the support body is enabled to have sufficient intensity on the premise of light weight.

Owner:江苏新时高温材料股份有限公司

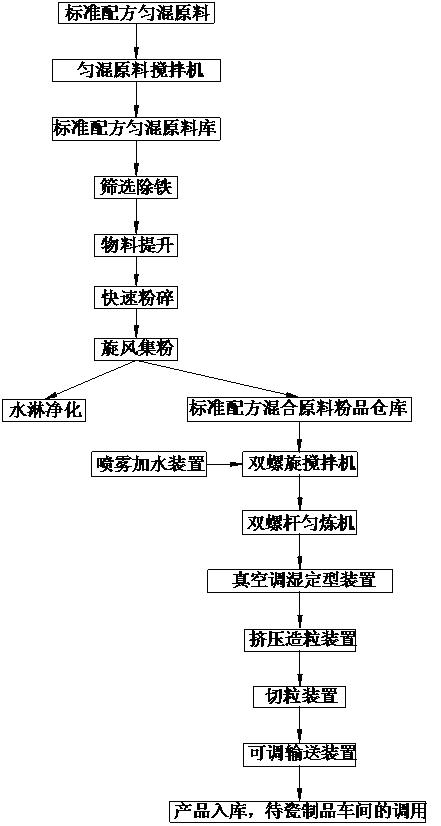

Dry granulating method of ceramic raw material powder and complete equipment thereof

InactiveCN102614810AReduce energy consumptionIncrease productivityRotary stirring mixersMixer accessoriesRapid processingMixed materials

The invention relates to a dry granulating method of ceramic raw material powder and complete equipment thereof. The method is carried out by the following steps of: (1) selecting a standard formulation raw material dry powder made by using a ceramic powder raw material rapid processing method; and feeding the dry powder to a double-screw powder stirrer through an adjustable conveying and feeding device; (2) spraying a proper amount of water mist into a mixed material in the double-screw stirrer according to the humidity of the mixed material in the double-screw powder stirrer; and continuously stirring the mixed material so that mineral powder particles are sufficiently dispersed with uniform humidity; (3) conveying the uniformly mixed wet material into a vacuum pugmill and granulating device, milled in the vacuum pugmill and granulating device and automatically extruded and granulated in the vacuum pugmill and granulating device; and (4) placing the product into storage for a ceramic workshop to invoke. By using the production method and the complete equipment provided by the invention, the traditional liquid powder dehydrating and granulating method is changed, the energy consumption is saved, the cost is reduced, the production efficiency is enhanced and the mixed material is more uniform; meanwhile, the mixed material is also milled in a vacuum state to ensure excellent granulating density quality so as improve the ceramic quality.

Owner:张文墩

Graphene ceramic product and preparation method thereof

The invention discloses a graphene ceramic product and a preparation method of the graphene ceramic product. Raw materials of the ceramic product comprises, by weight, 0.2-0.5 part of graphene, 75.5-80.8 parts of argil and 15 parts of zirconium oxide. The preparation method comprises the steps that the raw materials are mixed in proportion and injected into a ball mill, water is added to the raw materials, and then powder grinding is conducted; ground slurry is subjected to sedimentation; after sedimentation, supernatant liquid is pumped out, sediment is taken out, placed on the clean ground and dried in the sun; the dried clay is placed into a pugmill for clay smelting, and air in the clay is removed; the smelted clay is made into a green body, and the green body is dried in a drying room at the temperature ranging from 30 DEG C to 40 DEG C; the dried green body is burned into a ceramic green body, the ceramic green body naturally cools, and then the graphene ceramic product is obtained. According to the graphene ceramic product and the preparation method of the graphene ceramic product, on the condition that other properties of ceramic remain unaffected, the strength and wear resisting performance of the green body are improved, so the prepared ceramic product has excellent hardness and strength, is large in tensile strength and has great practical value.

Owner:SHANGHAI GAOCHENG CREATIVE TECH GRP

Coal ash poly-light brick

InactiveCN103360033AHigh dimensional accuracyWhite appearanceCeramic materials productionCeramicwareTunnel kilnBrick

The invention discloses a coal ash poly-light brick. The coal ash poly-light brick is manufactured from the following raw materials in percentage: 50%-60% of coal ash, 30%-40% of clay, 7%-8% of gangue powder, 1%-2% of polystyrene and 0.5%-1.5% of saw dust. A manufacturing process of the coal ash poly-light brick comprises the following steps of: (1) weighing coal ash, clay, gangue powder, polystyrene and saw dust by the proportion of the raw materials; (2) fully mixing and stirring the weighed materials to form clods; (3) putting the clods into a pugmill to mould the clods by extrusion; (4) delivering the rolled blank body to a chain type drying kiln and drying at 100-150 DEG C so that the water content of the blank body is lower than 2%-6%; (5) delivering the dried blank body to a tunnel kiln, calcining the blank body at a high temperature of 1200-1300 DEG C for 38-42 minutes, and drying the blank body by the afterheat generated after calcining; and (6) cutting and grinding the calcined blank body to form a finished product. The coal ash poly-light brick disclosed by the invention is energy-saving and environment-friendly and has a low heat conduction coefficient and good thermal shock stability.

Owner:SHUOZHOU SHUOXIANG CERAMICS

Making method for pure natural green ceramic product

The invention discloses a making method for a pure natural green ceramic product. The method includes: adopting dry red rock mud and pottery clay as raw materials, putting the raw materials into a ball mill and adding water to conduct ball-milling together to obtain pottery mud, putting the pottery mud into a pugmill to perform pugging so as to obtain wet pottery mud, then putting the wet pottery mud into a fermentation chamber to carry out fermentation in a natural temperature environment so as to obtain a ceramic product raw material, making the prepared ceramic product raw material into a semi-finished product of a ceramic craft or ceramic product by a manual or machine-made way, then putting the semi-finished product into a drying room to perform baking, and then putting the product into a kiln to conduct firing and cooling, thus obtaining the finished product of the pure natural green ceramic craft or ceramic product. The method provided by the invention no only has the advantage of low making cost, but also has the advantages that the product has natural tone and can keep the pure natural characteristics of ceramic products.

Owner:ZUNYI NINIUHUANG ARTS & CRAFTS CO LTD

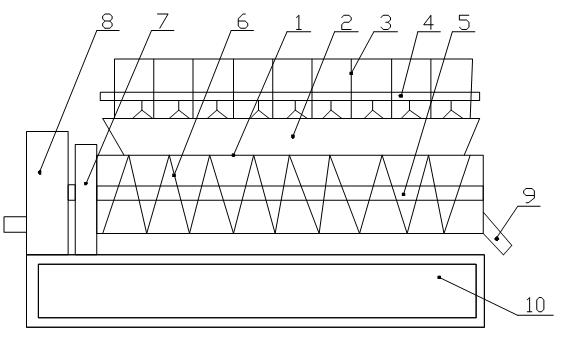

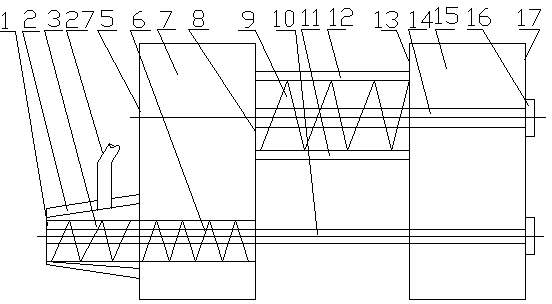

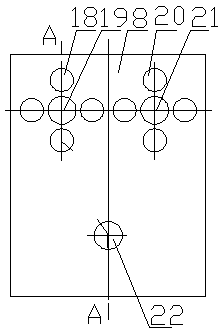

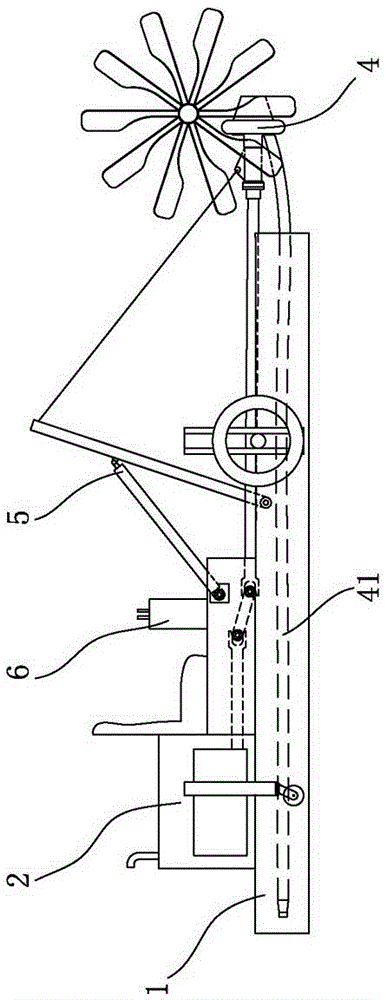

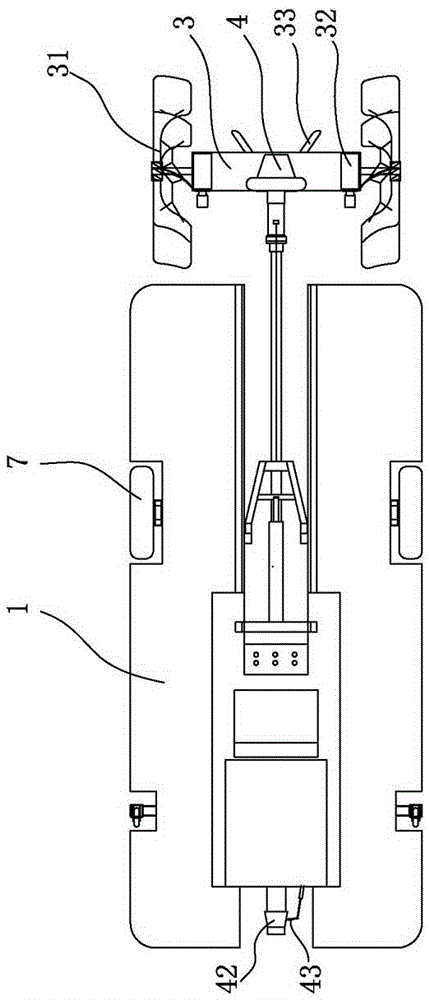

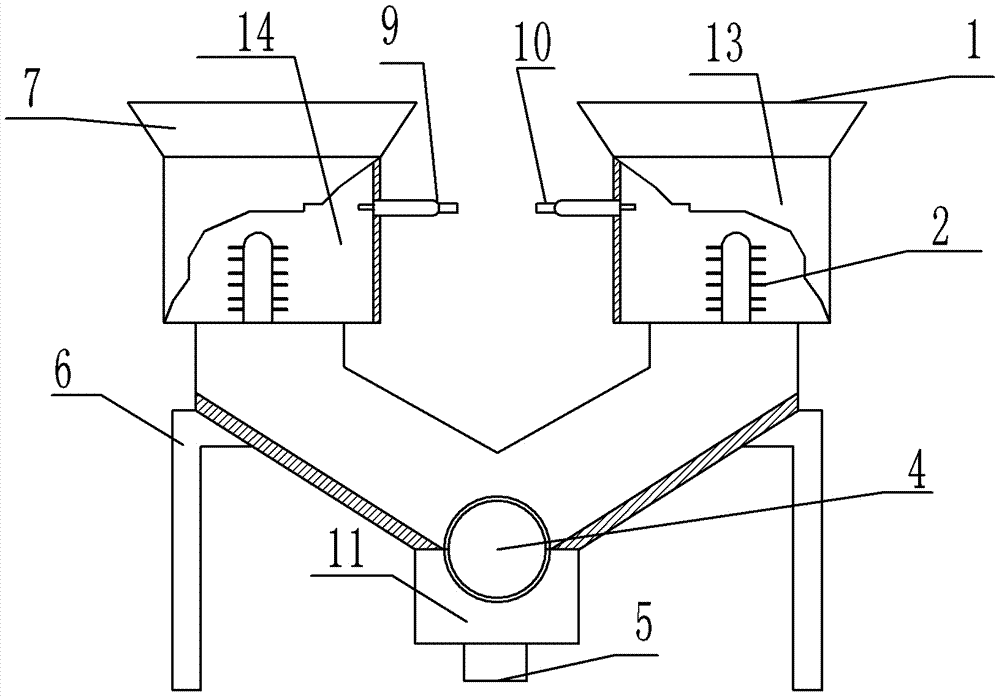

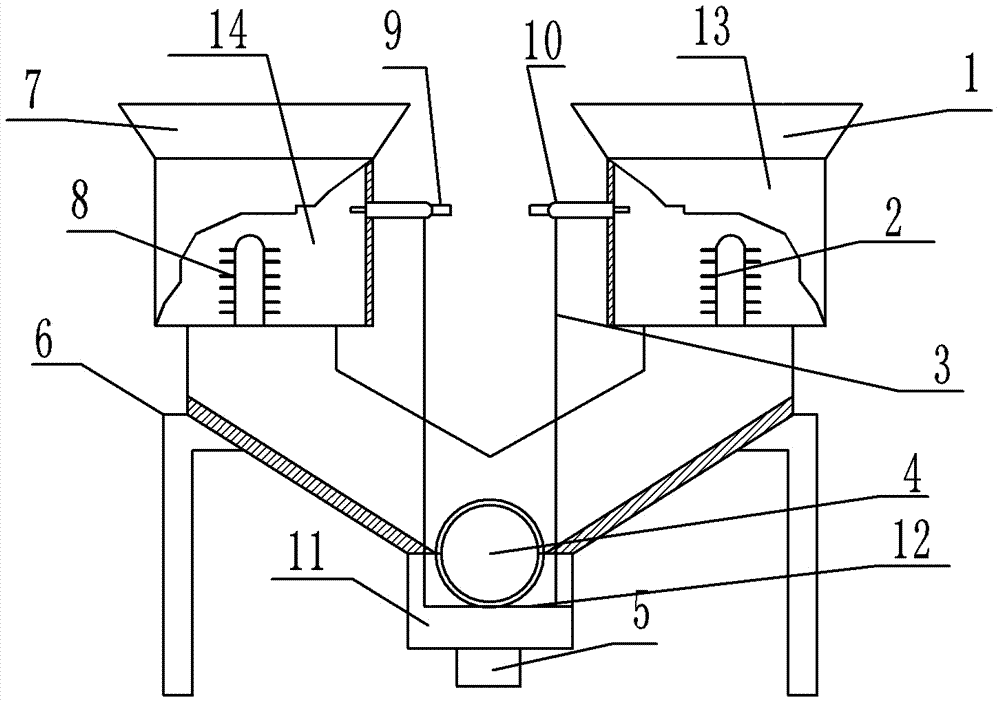

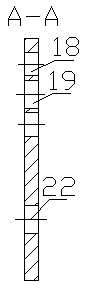

Ceramic pugmill

InactiveCN104149196AImprove uniformityImprove mud qualityCeramic shaping apparatusClay processing apparatusCeramicMaterials science

The invention discloses a ceramic pugmill. The ceramic pugmill comprises a motor, stirring shafts, a stirring drum, a screen and a baffle, wherein an inner cavity of the stirring drum is divided into two left and right parallel stirring cavities by a clapboard; a feeding hole is formed in the upper part of the front end of one stirring cavity and a discharge hole is formed in the lower part of the front end of the other stirring cavity; a discharge valve is arranged at the discharge hole; the front end of the clapboard is connected with the baffle and the rear end of the clapboard is connected with the screen; the stirring shafts are arranged in the two stirring cavities respectively; the fronts of the two stirring shafts extend out of the stirring drum and are connected by two gears meshed with each other; the front end of one stirring shaft is also connected with the motor. The ceramic pugmill has the advantages and characteristics that the ceramic pugmill is simple and is convenient to use; the stirring drum is divided into two parallel stirring cavities, so that the pugmill has a shorter body and double strokes, can mill pugs circularly and has high pug milling efficiency.

Owner:ZHONGLI CERAMICS

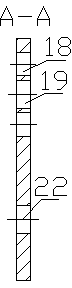

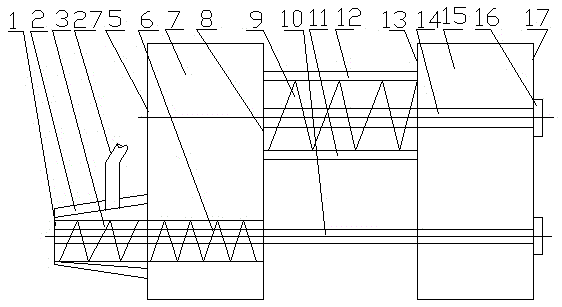

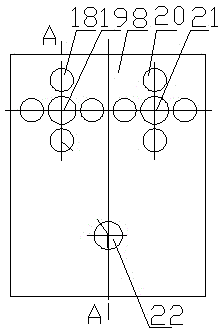

Cloud porcelain production equipment and technical method thereof

ActiveCN103934894AVarious patternsTight mudCeramic shaping plantsClay processing apparatusProcess engineeringMechanical engineering

The invention discloses cloud porcelain production equipment and a technical method of the cloud porcelain production equipment. The cloud porcelain production equipment is characterized in that a cloud porcelain clay feeding device is installed between a cloud porcelain pug kneading box and an original color pug conical roller and provided with a cloud porcelain pug auger, pug with more than one color is stirred through the cloud porcelain pug kneading box and then stirred and mixed with original color pug after the original color pug is mixed and stirred, then the mixed pug is stirred through a multi-color pug auger to obtain the cloud-type porcelain clay serving as the pug used for manufacturing porcelain such as tableware and tea ware. The production technical method includes the steps of pug preparing, ball milling, extrusion mixing, coarse pugging, extruding, forming, fettling, glazing, firing and packaging. According to pugging machines, a pugmill is machined and modified and provided with the cloud porcelain clay feeding device and the cloud porcelain clay auger, and an original color pug conical end cover is further provided with a vacuumizing pipe. The porcelain clay product obtained through stirring and extruding of the multi-color pug auger is fine in quality, diverse in color, high in aesthetic feeling, has natural beauty and is a colorful porcelain product with the natural beauty.

Owner:GUANGXI NANSHAN PORCELAIN

Method for preparing ceramics capable of repeatedly storing heat

The invention discloses a method for preparing ceramics capable of repeatedly storing heat. The method is characterized in that titanium oxide black blue powder and pottery clay are weighed according to a weight percentage, raw materials are injected into a ball mill after being mixed, and are ground after water is added; well ground slurry subsides; supernatant liquid is pumped out after subsiding, precipitates are taken out to be placed on the clean ground to be dried in the sun; the dried soil is placed into a pugmill to be pugged, and the air in the soil is discharged. Well pugged mud is made into corresponding green bodies and is dried, and the dried green bodies are put into a fire ceramic body to be calcined, and a ceramic product which can repeatedly store heat can be obtained after natural cooling. The ceramic product capable of repeatedly storing heat is placed in an illumination position, titanium oxide can be converted into lambda-titanium oxide, can store heat, and is converted into beta-titanium oxide to release heat under definite conditions, then the beta-titanium oxide is converted into lambada-titanium oxide after the ceramic product is heated, and the ceramic product can continuous to absorb and store heat.

Owner:SHANGHAI GAOCHENG CREATIVE TECH GRP +1

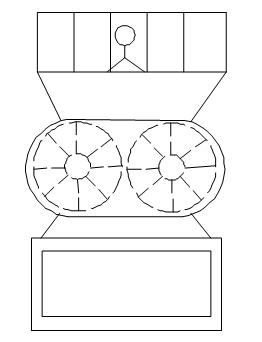

Ceramic pugmill

InactiveCN104149194AEasy to cleanEasy to replaceCeramic shaping apparatusClay processing apparatusCeramicMaterials science

The invention relates to the technical field of ceramic product production and processing and in particular relates to a ceramic pugmill. The ceramic pugmill comprises a feed box, wherein a first rolling shaft is arranged in the feed box; a filter device is arranged in the feed box body behind the first rolling shaft and comprises a plurality of screen plates, slots and extension holes; the slots are formed in one side of the side wall of the feed box; the extension holes are formed in the other side of the feed box; screen holes are formed in the screen plates; a cross rod is arranged on one side of each screen plate; the thickness of each cross rod is equal to the width of a slot body of each slot, so that the cross rods can be matched and clamped with the slots into a whole; a handle is arranged on the other side of each screen plate. The ceramic pugmill has the beneficial effects that the two ends of the screen plates are erected on the feed box body via the slots and the extension holes, so that the screen plates can be conveniently taken out from the feed box to be washed or changed; meanwhile, the screen plates with different screen hole sizes can be used aiming at different milled pug quality requirements, thus meeting the production requirement of multiple purposes of one machine.

Owner:ZHONGLI CERAMICS

Method for preparing environment friendly ceramic gaged brick by Yellow River sediment

The invention belongs to the technical field of building materials, and provides a method for preparing an environment-friendly ceramic plain brick by sediment of the Yellow River. The method is characterized by comprising the following: 1) a step of blank preparation, in which, the sediment of the Yellow River is dug up from riverbed, and is deposited for more than 10 years to be deposited sediment of the Yellow River; the blank comprises the following compositions in weight percentage: 60 to 80 percent of the deposited sediment of the Yellow River, 5 to 10 percent of pulverized fuel ash, 5 to 10 percent of coal refuse, 5 to 10 percent of fluxing agent, and 5 to 10 percent of grog refractory; the compositions are selected for standby; water is added to the mixture for mixing and stirring, wherein the amount of the water is 20 to 22 percent of gross weight of the deposited sediment of the Yellow River, the pulverized fuel ash, the coal refuse, the fluxing agent and the grog refractory; mud is milled by a vacuum pugmill, and is cut into mud cakes; after the mud cakes are aged for 3 days, the blank is produced for standby; 2) a step of glaze preparation; 3) a step of shaping; 4) a step of glazing; 5) a step of drying; and 6) a step of maturing, thereby producing the environment-friendly ceramic plain brick with water content ratio of between 6 and 8 weight percent. The plain brick prepared by the method has the characteristics of high regularity, high strength and strong decoration, and can be directly used for walls bricklaying without external decorating.

Owner:WUHAN UNIV OF TECH

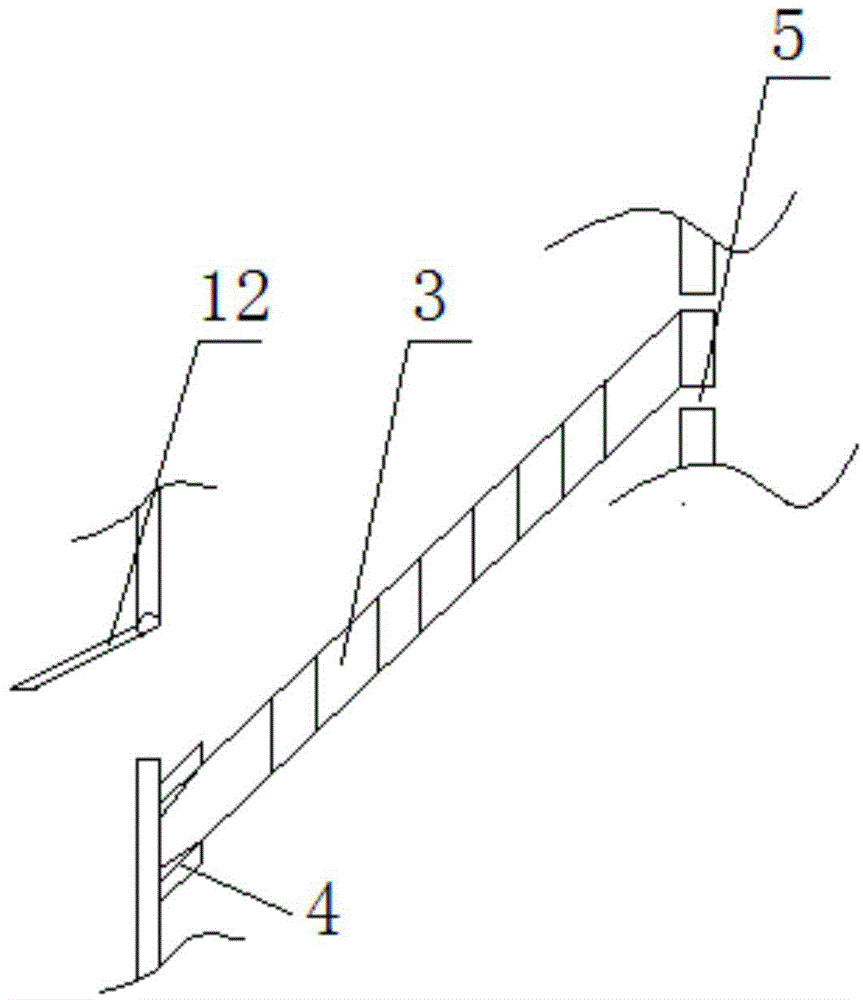

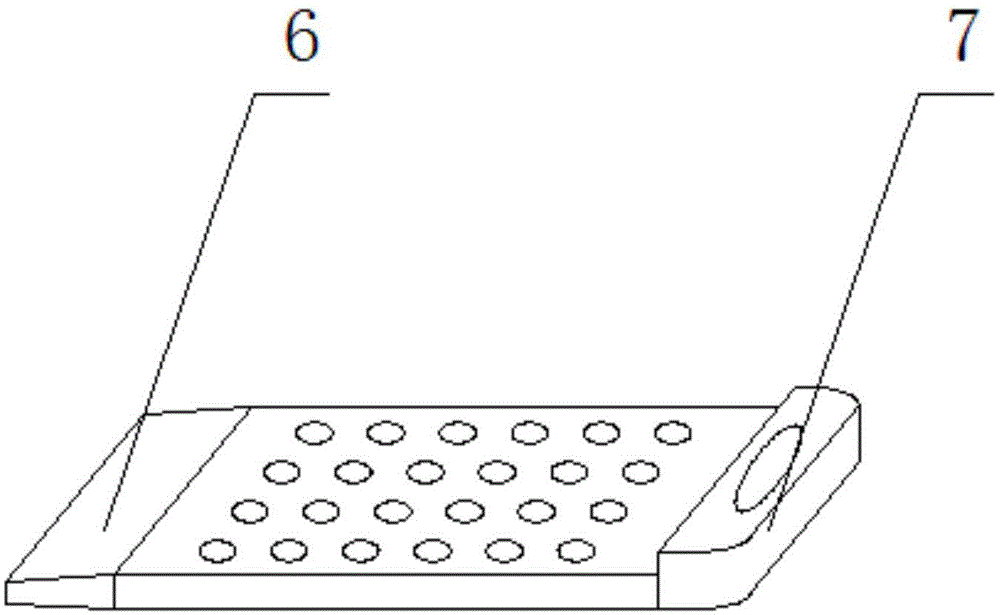

a dredging machine

Owner:梁培森

Portable system and method for processing waste to be placed in landfill

ActiveUS9375767B2Efficient and effectiveReduce dustTransportation and packagingSolid waste disposalLitterActive cell

A portable system and method for processing waste to be solidified and placed in an active cell of a landfill. A portable pugmill is moveable adjacent an active cell of a landfill; and portable devices, which may be mounted on sleds or trailers, may be used for feeding the pugmill with waste to be solidified into a landfill-ready state. The waste may be fed to the pugmill without the need for long-term waste storage devices, and avoiding substantial delays between discharge of the waste from trucks to the pugmill-feeding steps.

Owner:PERRY RIDGE LANDFILL INC

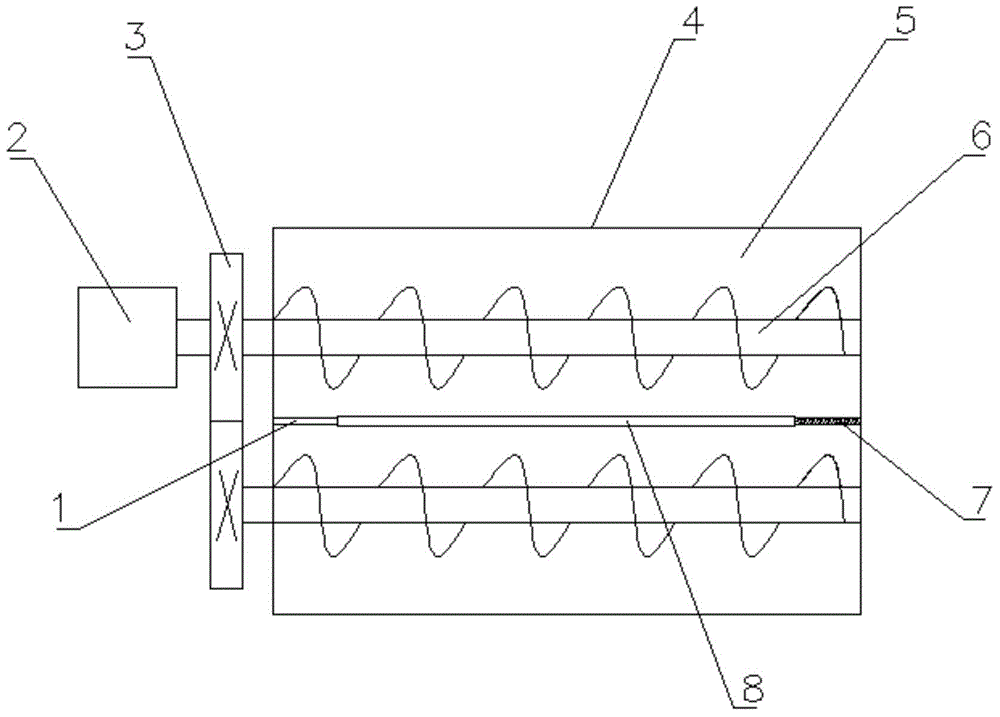

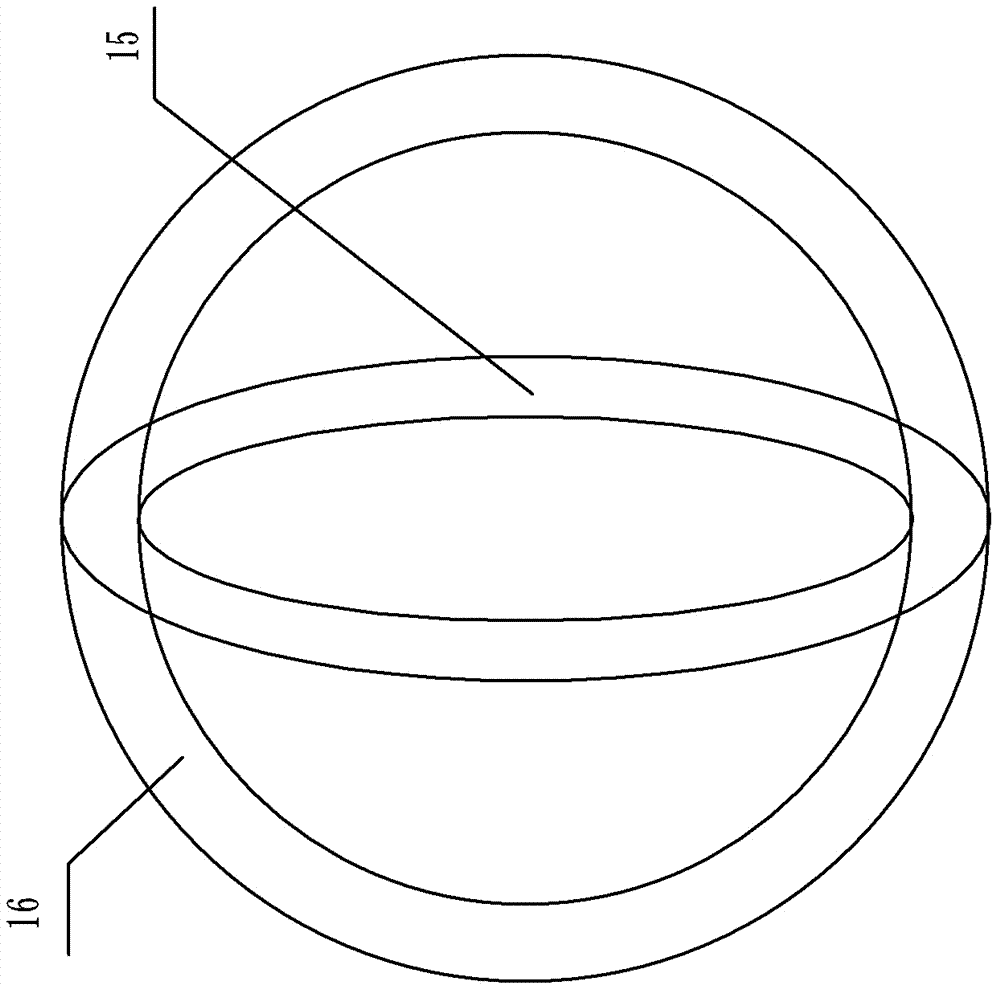

Vacuum pugmill

ActiveCN107030878AReduce stressQuality improvementClay processing apparatusCeramic materials productionMechanical engineeringCeramic

The invention discloses a vacuum pugmill, and relates to the field of ceramic manufacturing. After two pug milling cavities are set to be at different vacuum degrees for pug milling, pug is stirred through a third stirrer arranged in a third pug milling cavity. Particles of the pug obtained by means of mechanical pug milling are in directional alignment, stresses are concealed in the pug, and the stresses can be released in high-temperature firing to influence manufacturing of ceramics. The vacuum pugmill is provided with the third pug milling cavity, the third stirrer in the third pug milling cavity is used for stirring the pug which leaks into the third pug milling cavity after being stirred in the first pug milling cavity and the second pug milling cavity in the way that the turning directions of an inner circle and an outer circle are different, the vacuum degrees inside the two pug milling cavities are different, then random stirring by the third stirrer in different directions is conducted, and the obtained pug particles are irregularly arranged. The vacuum pugmill is simple in structure and suitable for industrial processing of pottery, and the obtained pug gets closer to pug obtained by means of manual pug milling.

Owner:ZUNYI NINIUHUANG ARTS & CRAFTS CO LTD

Honeycomb heat accumulator made of silicon carbide-corundum composite materials

ActiveCN101798212BHigh refractorinessImprove thermal shock resistanceChemical industryGlycerolSmall footprint

The invention relates to a honeycomb heat accumulator made of silicon carbide-corundum composite materials, which comprises the following main raw materials: 20-30wt% of silicon carbide powder, 4-8wt% of zirconia corundum powder, 20-30wt% of corundum powder, 15-20wt% of porzite powder, 15-30wt% of composition of kyanite, andalusite and sillimanite, 4-8wt% of kaolin and 2-5wt% of cellulose powder.The preparation method of the honeycomb heat accumulator comprises the following steps: adding the main raw materials into a ball mill for ball milling; adding stearic acid of which the weight is notgreater than 1% of the total weight of the main raw materials for ball milling, and then, sieving to obtain a mixture; respectively adding tung oil of which the weight is not greater than 1% of the weight of the mixture and glycerol of which the weight is not greater than 1% of the weight of the mixture for mixing, aging and vacuum pugmill to form pug segments; carrying out extrusion forming in amold, and drying; and insulating at the temperature of 1400-1450 DEG C for 4-8 hours, and then, calcining. The honeycomb heat accumulator of the invention has the characteristics of high fire resistance, good thermal shock resistance, strong corrosion resistance, large heat exchange area, small gas flow resistance, high heat accumulating efficiency, small floor space and long service life which can be more than two years, and is widely used for heat accumulating type heating furnaces of black and non-ferrous smelting, thermal power generation, petrochemical industry, ceramics, glass, machining, civil cookers and the like.

Owner:JIANGXI SHINCO ENVIRONMENTAL PROTECTION CO LTD

A method and material for preparing porous building materials using waste residue produced in the process of recycling valuable metals in waste lithium-ion batteries

ActiveCN107200598BSolve the pollution of the environmentHigh strengthCeramic materials productionCeramicwareSlagLithium-ion battery

The invention belongs to the field of comprehensive utilization of industrial waste residues, and discloses a method for preparing a porous building material from waste residues produced in a process of recovering valuable metals in a waste lithium ion battery and the porous building material obtained by the method. The method comprises the following steps: (1) uniformly mixing the waste residues produced in the process of recovering the valuable metals in the waste lithium ion battery, clay and / or fly ash, adding water, and performing mixing to obtain a primary mixture; (2) aging and putting the primary mixture in a pugmill, and performing blank making and drying to obtain a dry blank; (3) calcining the dry blank, and performing cooling to obtain the porous building material, wherein the porous building material is prepared from the following materials in percentage by mass: 50 to 70 percent of the waste residues and 30 to 50 percent of the clay and / or the fly ash. According to the method, the porous building material is prepared by adopting the waste residues produced in the process of recovering the valuable metal in the waste lithium ion battery as a main material and utilizing a carbon powder residue and a calcium carbonate residue in the waste residues as a pore-forming agent, so that not only is the problem of environmental pollution solved, but also waste is turned into wealth.

Owner:HUNAN BRUNP RECYCLING TECH CO LTD +1

A kind of cloud porcelain production equipment and its process method

ActiveCN103934894BImprove the finishCeramic shaping plantsClay processing apparatusComputer scienceVacuum tube

The invention discloses cloud porcelain production equipment and a technical method of the cloud porcelain production equipment. The cloud porcelain production equipment is characterized in that a cloud porcelain clay feeding device is installed between a cloud porcelain pug kneading box and an original color pug conical roller and provided with a cloud porcelain pug auger, pug with more than one color is stirred through the cloud porcelain pug kneading box and then stirred and mixed with original color pug after the original color pug is mixed and stirred, then the mixed pug is stirred through a multi-color pug auger to obtain the cloud-type porcelain clay serving as the pug used for manufacturing porcelain such as tableware and tea ware. The production technical method includes the steps of pug preparing, ball milling, extrusion mixing, coarse pugging, extruding, forming, fettling, glazing, firing and packaging. According to pugging machines, a pugmill is machined and modified and provided with the cloud porcelain clay feeding device and the cloud porcelain clay auger, and an original color pug conical end cover is further provided with a vacuumizing pipe. The porcelain clay product obtained through stirring and extruding of the multi-color pug auger is fine in quality, diverse in color, high in aesthetic feeling, has natural beauty and is a colorful porcelain product with the natural beauty.

Owner:GUANGXI NANSHAN PORCELAIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com