Method for preparing bending-free piezoelectric ceramic fiber with low cost

A piezoelectric ceramic, non-bending technology, applied in the field of ultrasonic imaging and non-destructive flaw detection, can solve the problems of high cost, inability to prepare, consume large carbon fibers, etc., and achieve good piezoelectric performance, good uniformity, and low porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

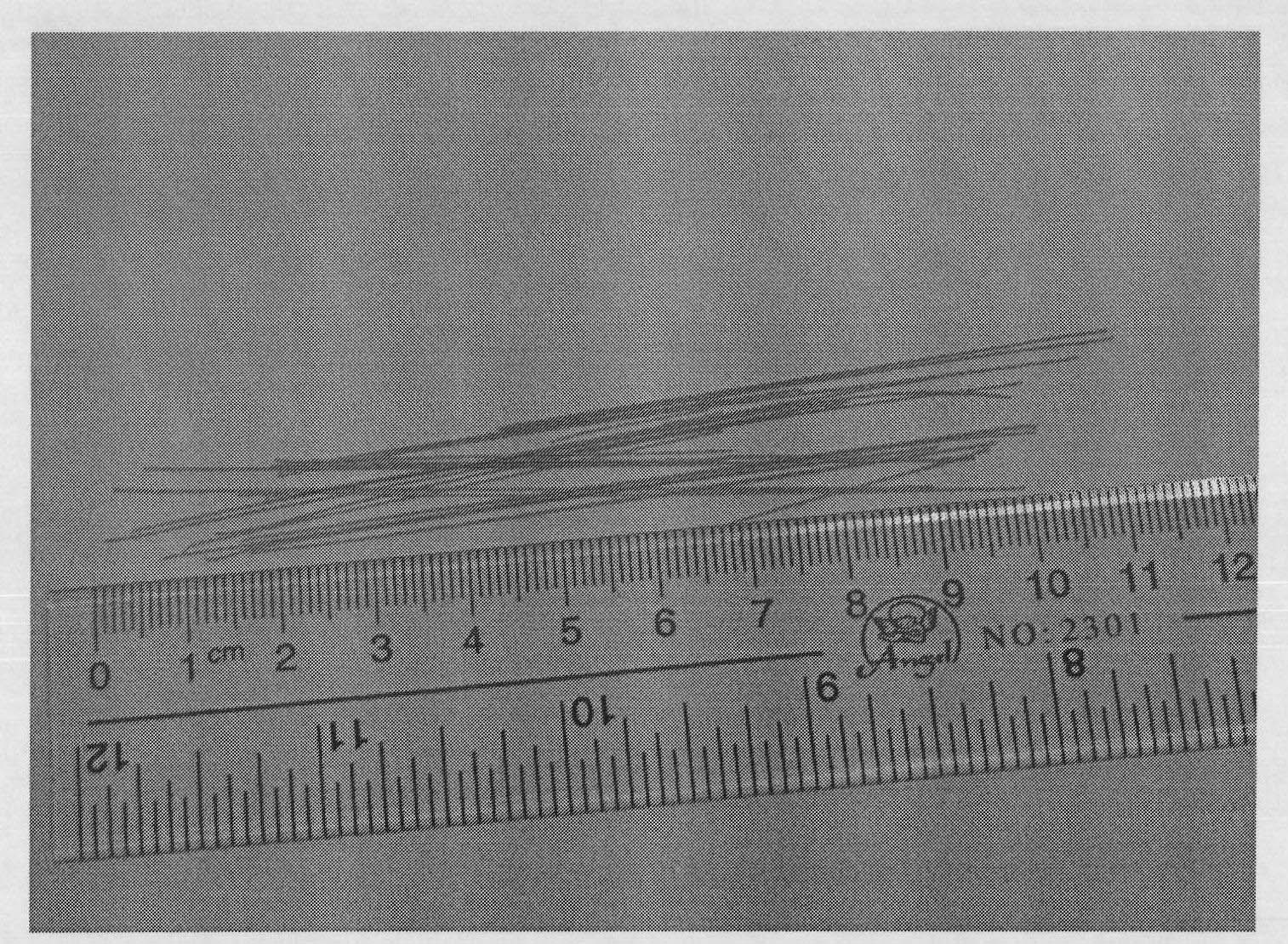

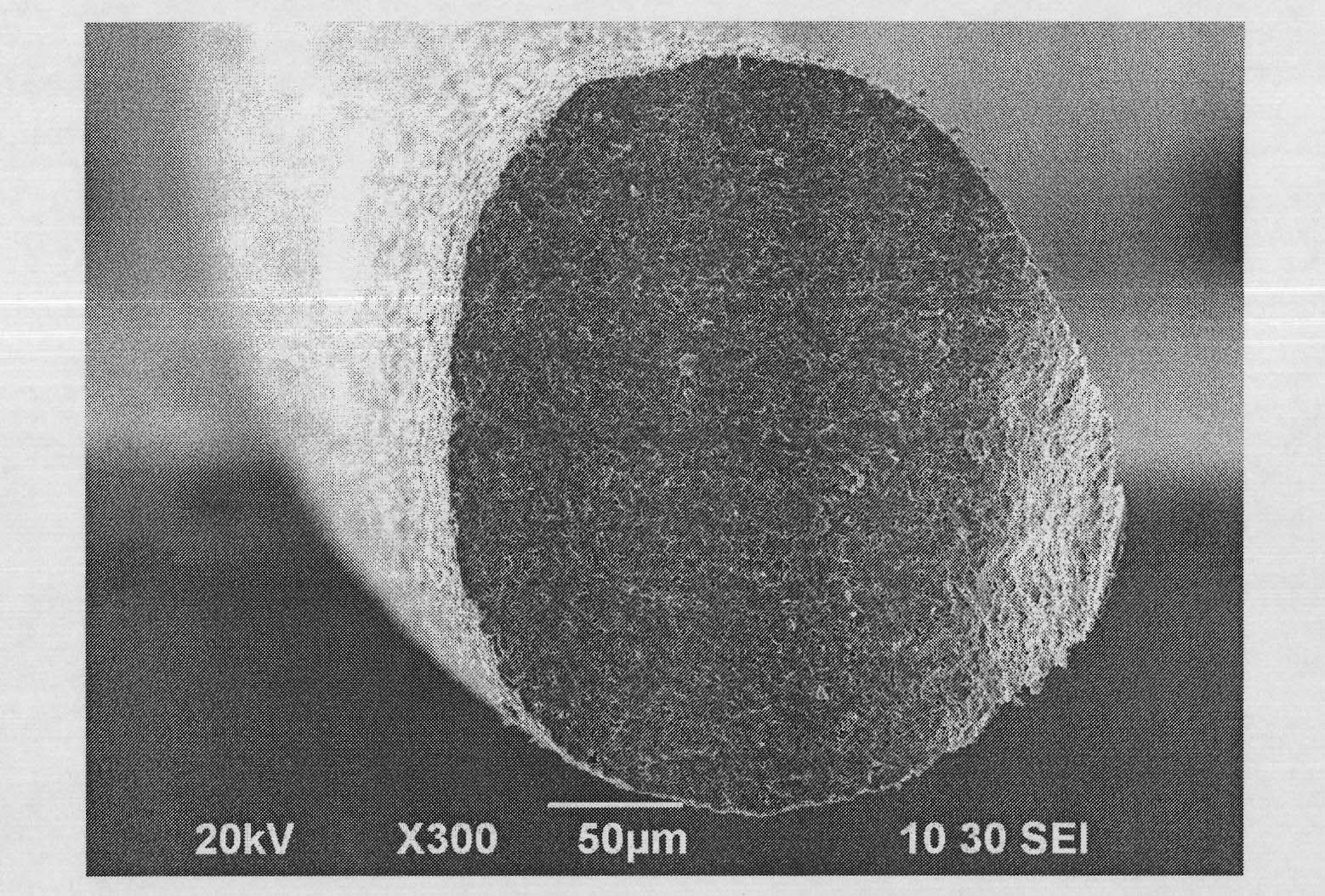

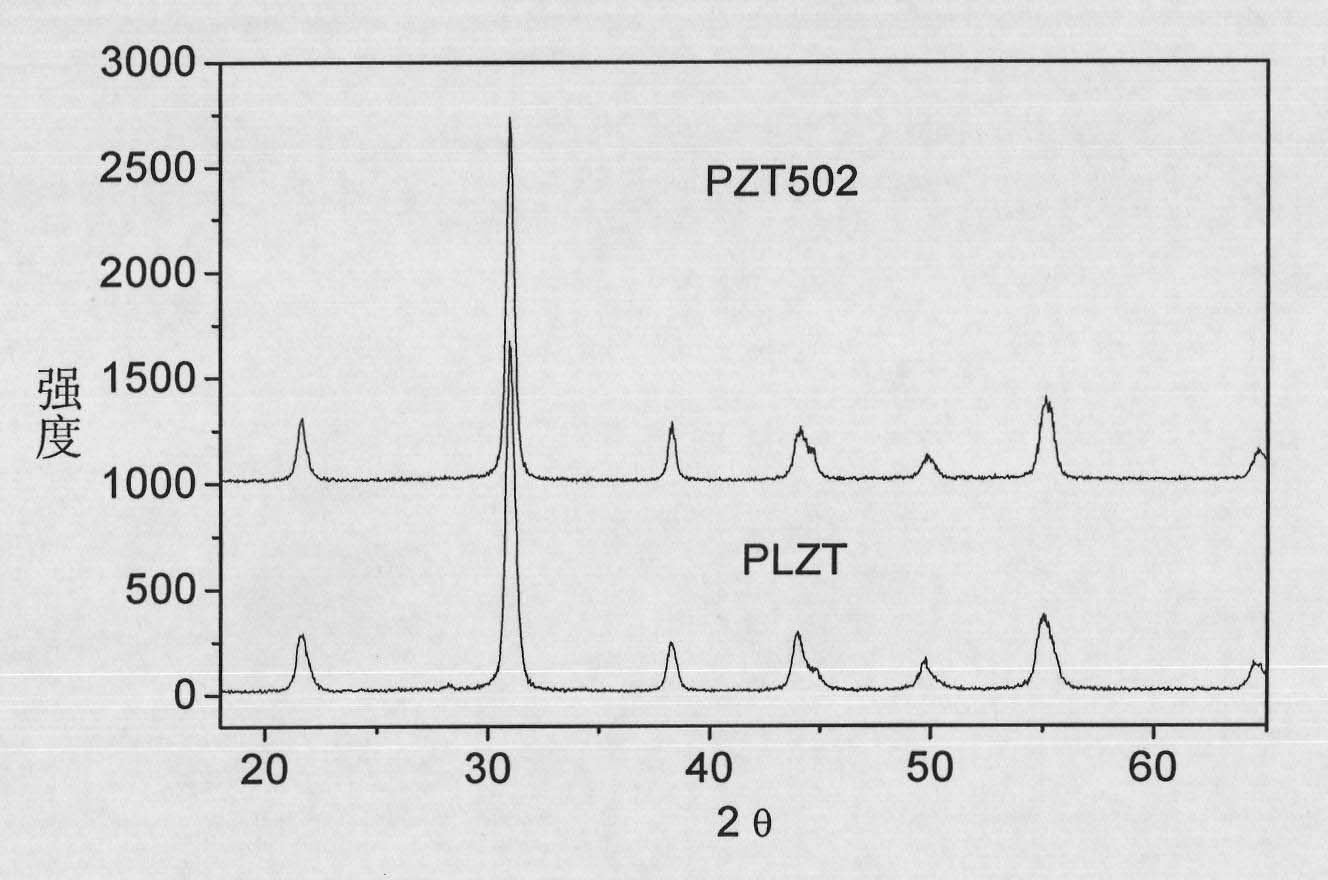

[0039] Using analytically pure lead oxide, titanium dioxide, zirconium dioxide, lanthanum trioxide, niobium pentoxide and bismuth trioxide as raw materials, the traditional mixed oxide sintering process was adopted, and the materials were mixed and pre-sintered at 850 °C for 3 hours. After crushing, the powder and zirconia balls (diameter of 2mm, mass ratio of 3mm and 8mm are 8:5:3) were put into a nylon ball mill in a mass ratio of 1:4, and milled with water as the medium for 6 hours. Preparation of lead lanthanum zirconate titanate [Pb 1-1.5x La x (Zr 0.58 Ti 0.42 ) 1-1.25y Nb y O 3 +0.01weight%Bi 2 O 3 (x=0.06, y=0.02); PLZT] powder particle size analysis by laser particle size analyzer (LS908A, Zhuhai Omega) and scanning electron microscope (JEOL, JSM-6490) showed that the most particle size The diameter is about 0.72 μm. The polyvinyl alcohol and water were put into a beaker at a ratio of 8:92, and were dissolved at 80° C. for more than 8 hours under stirring to ...

example 2

[0045] The commercial product PZT502 standard raw material powder and zirconia beads (diameter 2mm, 3mm and 8mm mass ratio of 8:5:3) were put into a nylon ball mill in a mass ratio of 1:4, and milled for 6 hours with water as the medium. The particle size analysis of the powder by laser particle size analyzer (LS908A, Zhuhai Omega) and scanning electron microscope (JEOL, JSM-6490) shows that the most probable particle size is about 0.52 μm. Put polyvinyl alcohol, polyvinylpyrrolidone and water in a beaker at a ratio of 10:8:82, and dissolve at 80° C. for more than 8 hours under stirring to obtain a viscous binder aqueous solution.

[0046] Mix PZT502 and binder aqueous solution at a ratio of 70:30, stir well and -3 Degassed for 30 minutes under Pa pressure to become a mud billet. The plastic sludge is loaded into the barrel of the spinning machine, heated to 55-60°C, and extruded through a spinneret hole with a diameter of 350 microns to form a fiber blank. The fiber blank w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com