Vacuum pugmill

A vacuum mud refiner and mud refining technology, applied to clay preparation devices, chemical instruments and methods, clay processing equipment, etc., can solve the problems of increased deformation rate, low quality of porcelain, and inability to rotate in random directions at the same time , to achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

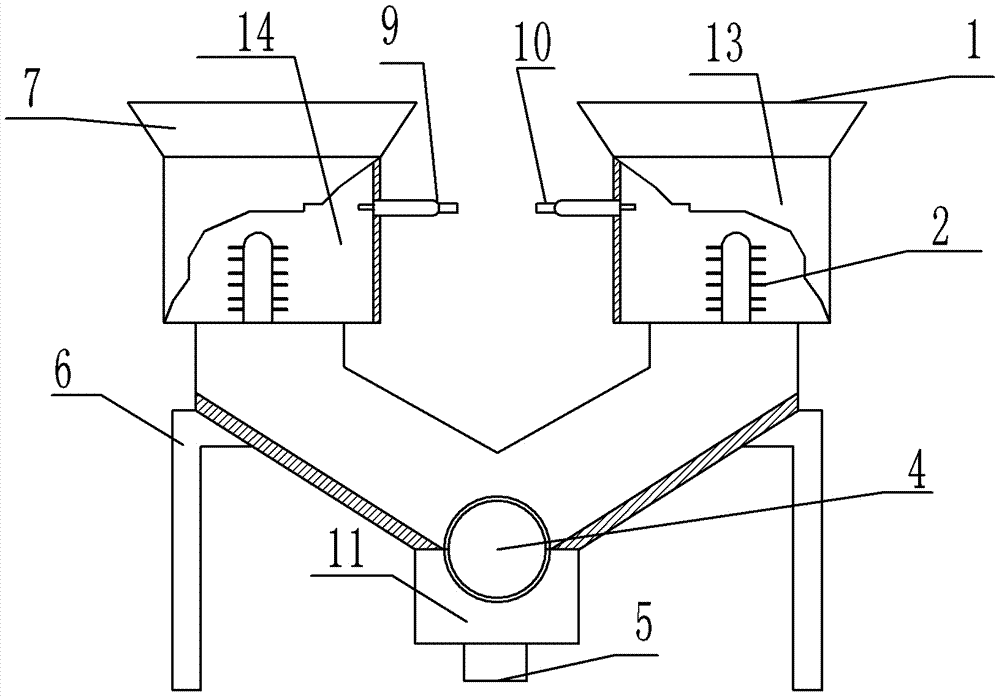

[0031] Embodiment 1 is basically as attached figure 1 Shown: When mud refining is required, start the mud refining machine, put slurry into the first feeding tank 1 and the second feeding tank 7 respectively, start the first vacuum pump 9 and the second vacuum pump 10 to pair the first mud refining chamber 14, the second The mud refining chamber 13 carries out vacuum treatment, and the vacuum pump adopts a gas capture pump to vacuumize the mud refining chamber; the pressure value of the vacuum pump is set to different values so that the vacuum degree in the first mud refining chamber 14 and the second mud refining chamber 13 is different values. The first agitator 2 and the second agitator 8 use stirring rods to stir, and after stirring, the mud material is stirred into mud, and then the mud enters the third mud-making chamber 11, and passes through the third agitator 4 in the third mud-making chamber. The stirring of the mud material in the third mud refining chamber 11 is...

Embodiment 2

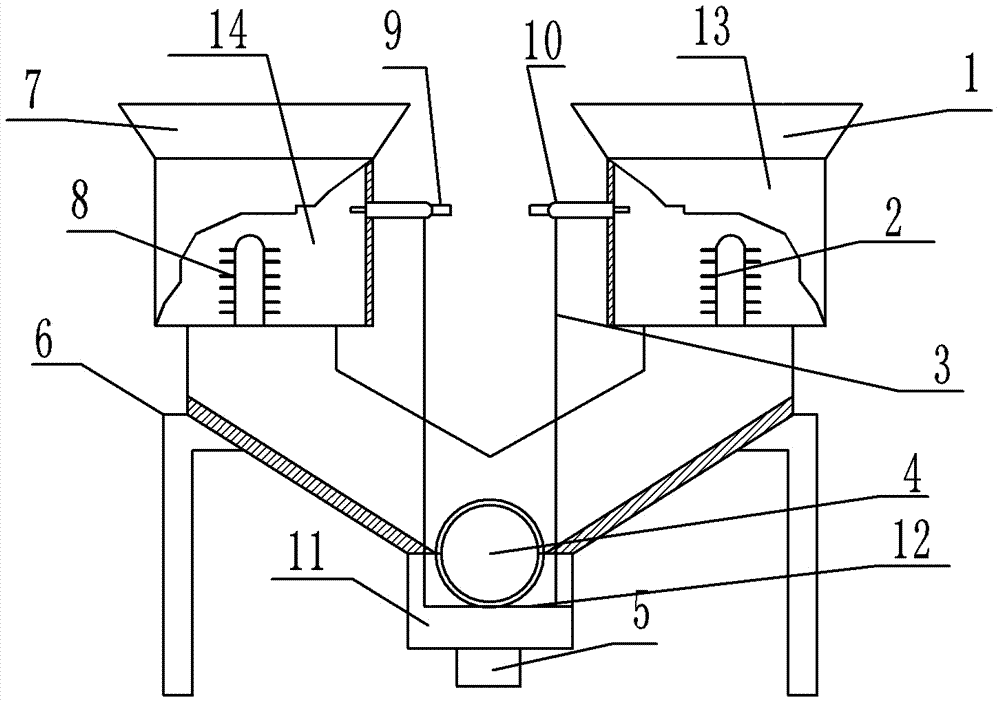

[0032] Embodiment 2: Different from Embodiment 1, a vibrating plate 12 is also provided in the third mud-making chamber 11 and connected to a vacuum pump through a connecting rod 3 . The vibration generated by the vacuum pump during operation is transmitted to the vibrating plate through the connecting rod to make the vibrating plate vibrate; this scheme is more capable of stirring the mud material so that the mud particles are arranged irregularly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com