Cloud porcelain production equipment and technical method thereof

A production equipment, cloud porcelain technology, applied in clay processing equipment, chemical instruments and methods, manufacturing tools, etc., can solve the problems of inability to apply large-scale production, enterprise production, good aesthetics, etc., to achieve tight clay materials and various patterns. Versatile, high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

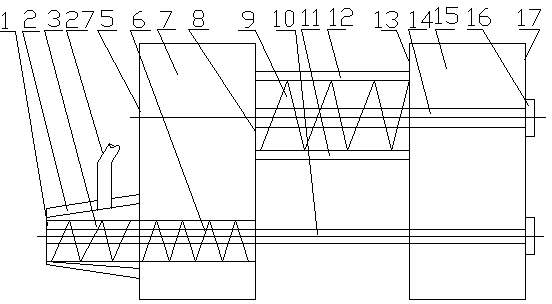

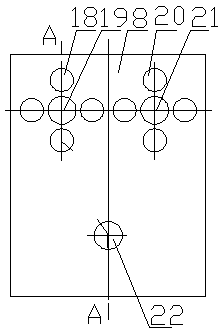

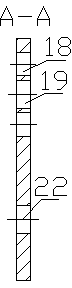

[0039] Embodiment 1, the installation box (15) is equipped with the rotating shaft of the motor and the transmission device, the transmission device is connected to the central shaft of the forming auger (10), and connected to the central shaft of the kneading auger (14) and the central shaft of the forming auger (10) Install and drive the primary color mud auger (6) and multi-color mud auger (3), the primary color mud auger (6) and the multi-color mud auger (3) are coaxially installed, the primary color mud auger (6) and The multi-color mud auger (3) is in the same body, and different motors and transmission devices are configured according to different speeds. Knead the mud auger central shaft (14) and install the transmission and knead the mud auger (9), and the base mud is first packed into the kneading mud auger (9). There are two first shaft holes (19) and second shaft holes (21) installed in parallel on the top of the mud-kneading orifice plate (8), and there are formin...

Embodiment 2

[0047] Example 2, the primary color mud auger (6) and the multi-color mud auger (3) are coaxial and in the same body, and they are regarded as one axis. The primary color mud is stirred by the primary color mud auger (6), and the primary color mud tapered end cover ( 2) The cloud porcelain mud feeding device (4) is installed on the outside, and the cloud porcelain mud feeding device (4) is equipped with a cloud porcelain mud auger (25) in the inner cavity, and the cloud porcelain mud is stirred by the cloud porcelain mud auger (25) Enter the inner cavity of the conical end cap (2) of the primary color mud material, mix and stir it with the multicolor mud auger (3), and then come out from the outlet (1) to obtain cloud porcelain mud material. The cloud porcelain mud feeding device (4) is conical, and the small cone mouth is installed on the conical end cover (2) of the primary color mud material, and the cloud porcelain mud feeding device (4) has a large cone mouth installed on ...

Embodiment 3

[0048] Example 3, the front section of the primary color mud kneading drum (30) is an oblique section, and its oblique section is the primary color mud conical end cap (2), the primary color mud conical end cap (2) and the primary color mud kneading drum (30) Install the multi-color mud auger (3) in the inner cavity, the multi-color mud auger (3) is a spiral screw, the multi-color mud auger (3) to the primary color mud kneading drum (30) and the primary color mud conical end cover ( 2) There is a gap between the inner cavities to accommodate the primary color mud for stirring movement. The cloud porcelain mud kneading box (26) is installed on the top and / or side of the primary color kneading mud cylinder (30), and the inner cavity of the cloud porcelain mud kneading box (26) is equipped with a mud auger, and the cloud porcelain mud kneading box ( 26) The outlet of the cloud porcelain mud feeding device (4) is installed, and the cloud porcelain mud auger (25) is installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com