Method for making blowing balloon type multicolor blending EVA shooting foaming product

A production method and product technology, applied in the direction of coating, etc., to achieve the effect of special color and various patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Proceed as follows:

[0018] 1. Prepare the required mixture of various colors, whose weight accounts for 30% of the total weight of the required material;

[0019] 2. Bake the mixture in an oven at a temperature of 70 degrees Celsius and a baking time of 40 minutes;

[0020] 3. The obtained multi-color mixture is extruded by manual extrusion;

[0021] 4. Put the baked multi-color mixture into the cavity of the mold and cover the mouth of the feeder, and close the mold;

[0022] 4. The rest of the total required materials are injected into the mold by the injection machine, and the products are formed by heating and curing.

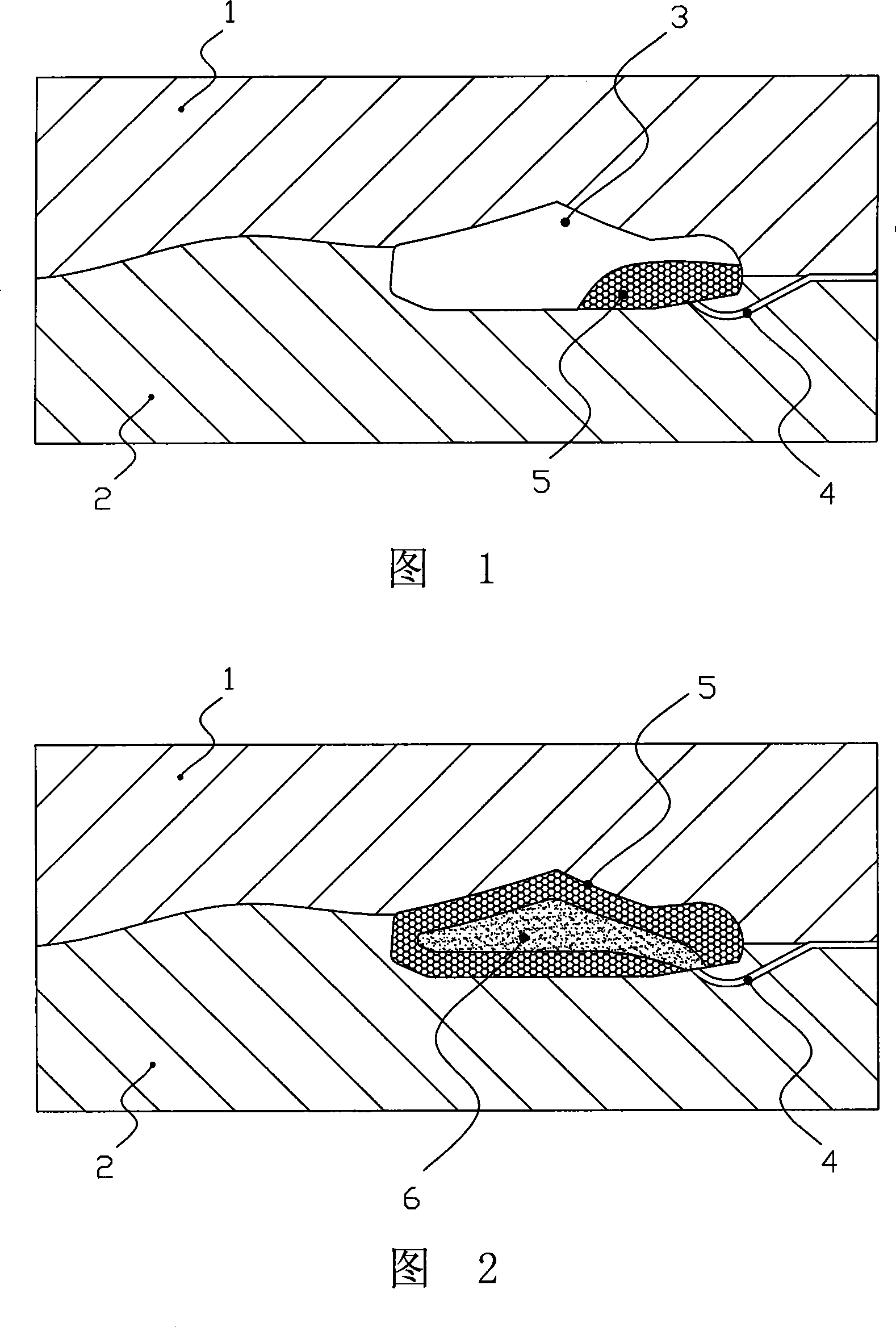

[0023] As shown in Figure 1 and Figure 2, the injection material of the injection machine is concentrated inside the product, and the mixed camouflage material is extended and distributed on the surface of the product to form a multi-color camouflage effect.

[0024] The multi-color mixture is put into the mold after being baked, which can great...

Embodiment 2

[0026] Proceed as follows:

[0027] 1. Prepare the required mixed materials of various colors, the amount of which accounts for 50% of the total required materials;

[0028] 2. Bake the mixture in an oven at a temperature of 95 degrees Celsius and a baking time of 30 minutes; press 6kg of the mixture to exhaust it by mechanical extrusion;

[0029] 3. Put the baked multi-color mixture into the cavity of the mold and cover the mouth of the feeder, and close the mold;

[0030] 4. The rest of the total required materials are injected into the mold by the injection machine, and the products are formed by heating and curing.

Embodiment 3

[0032] Proceed as follows:

[0033] 1. Prepare the required mixed materials of various colors, the amount of which accounts for 70% of the total required materials;

[0034] 2. Bake the mixture in an oven, the baking temperature range is 120 degrees Celsius, and the baking time is 20 minutes; the obtained mixture is extruded by mechanical extrusion according to 10kg;

[0035] 3. Put the baked multi-color mixture into the cavity of the mold and cover the mouth of the feeder, and close the mold;

[0036] 4. The rest of the total required materials are injected into the mold by the injection machine, and the products are formed by heating and curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com