Dry granulating method of ceramic raw material powder and complete equipment thereof

A technology for ceramic raw materials and production methods, which is applied in the direction of extrusion granulation of raw materials, chemical instruments and methods, extrusion granulation of molds, etc. High problems, to achieve the effect of good granulation density, good quality, energy saving and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

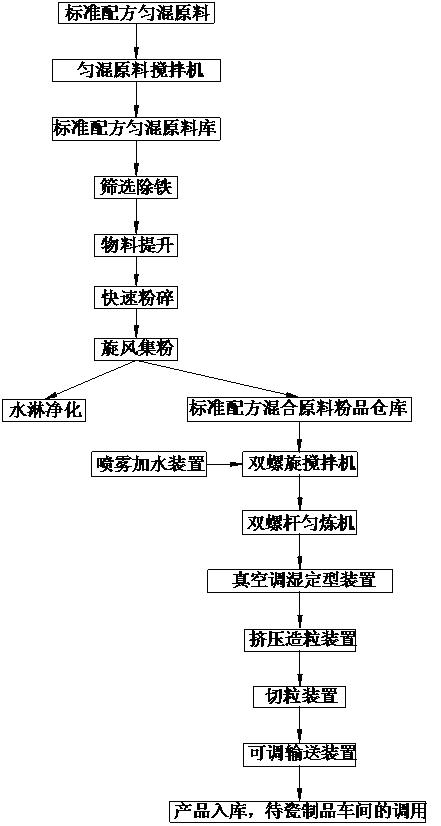

[0031] The technical solution of the present invention is to provide a dry granulation production method of ceramic raw material powder, which is carried out according to the following steps:

[0032] (1) Select the standard formula raw material dry powder produced by the "rapid processing method of ceramic powder raw material (patent number: 200610004085.6)", and feed it to the double-screw powder mixer through an adjustable conveying and feeding device;

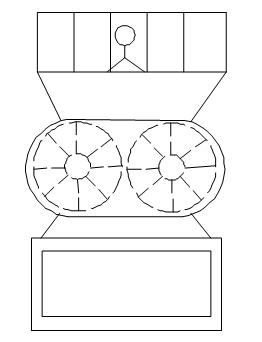

[0033] (2) According to the water content of the dry powder of the above raw materials, that is, the dry humidity, start the equipment, send the dry powder into the double-helix mixer, and feed, stir, and spray water at the same time until the moisture content of the mixed wet material is uniform. 12-16%, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com