Ceramic pugmill

A technology of mud refining machine and ceramics, which is applied to ceramic molding machines, clay processing equipment, clay preparation devices, etc., can solve the problems of low mud refining efficiency, troublesome process, large labor amount, etc., and achieve high mud refining efficiency and improve uniformity. The effect of improving the quality of mud training

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following will be further described with reference to the accompanying drawings and in conjunction with specific embodiments, so that those skilled in the art can implement it by referring to the text of the description, and the scope of protection is not limited by the embodiments of the technical solution.

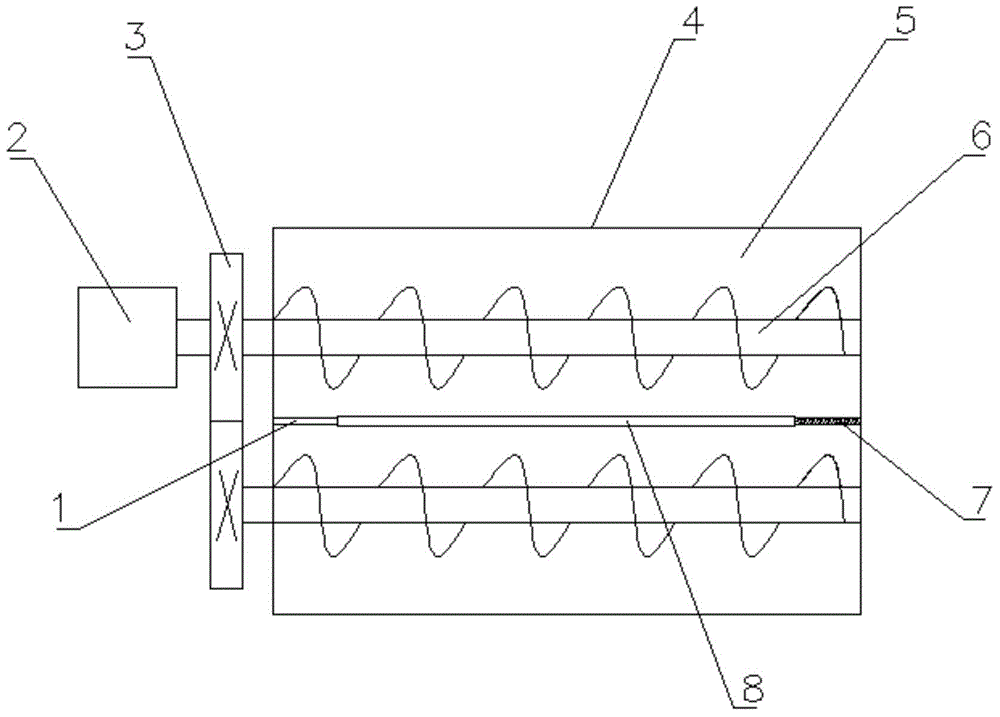

[0012] Such as figure 1 As shown, the present invention is realized through the following technical solutions: a kind of ceramic mud refining machine, comprising: motor 2, stirring shaft 6, mixing drum 4, screen cloth 7 and baffle plate 1, the inner cavity of mixing drum 4 passes through dividing plate 8 It is divided into two mixing chambers 5 side by side. One of the stirring chambers 5 is provided with a feed inlet above the front end, and the other stirring chamber 5 is provided with a discharge port below the front end. A discharge valve is provided on the discharge port to control Whether to discharge or not; the front end of the partition 8 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com