High-efficiency preparation method of cellulose nanocrystal (CNC)

A cellulose and nanocrystal technology, applied in the macro-scale preparation of environmental protection and green fields, can solve the problems of large acid consumption, environmental pollution, high price, etc., to reduce environmental pollution, expand the scope of application, and reduce the preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Break 5g of pulp cellulose into cotton wool with a mixer, add 250mL of 4% sodium hydroxide solution, soak for 24h, filter it with suction and wash until neutral, then disperse the alkali-pretreated cellulose in 300mL Add 2.5g of potassium ferrate and 1mL of malic acid into deionized water, stir at 90°C for 6h, centrifuge the cellulose hydrolyzate at a speed of 8000rpm / min for 10min with a high-speed centrifuge, then wash the precipitate and separate again until the supernatant The liquid becomes cloudy. The obtained cellulose nanocrystal suspension is ultrasonicated to obtain a stable cellulose nanocrystal suspension. The measured average length of the cellulose nanocrystal is about 260 nm, the yield is 60%, and the particle size dispersion index (PDI) is 0.3. The content is 0.5mmol / g.

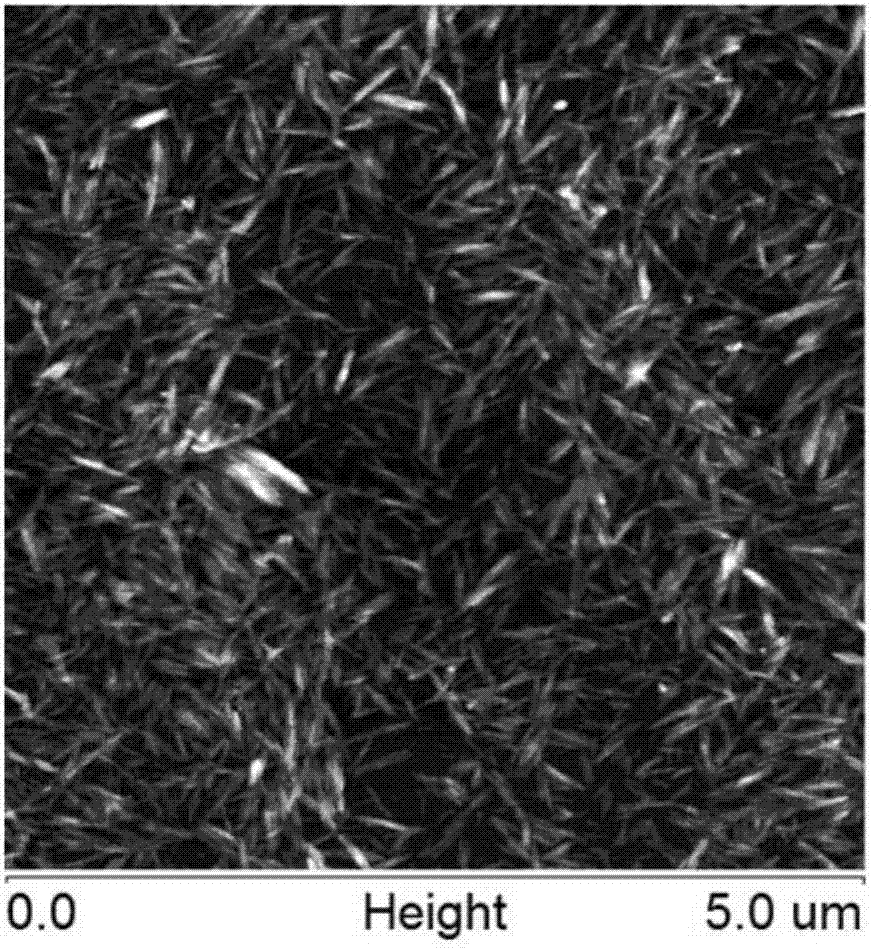

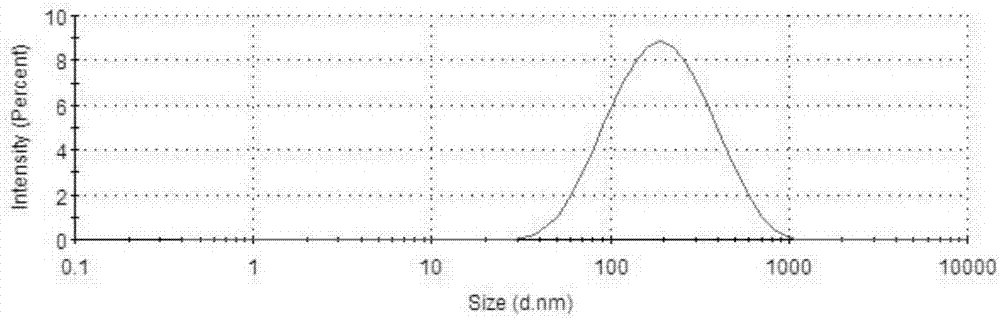

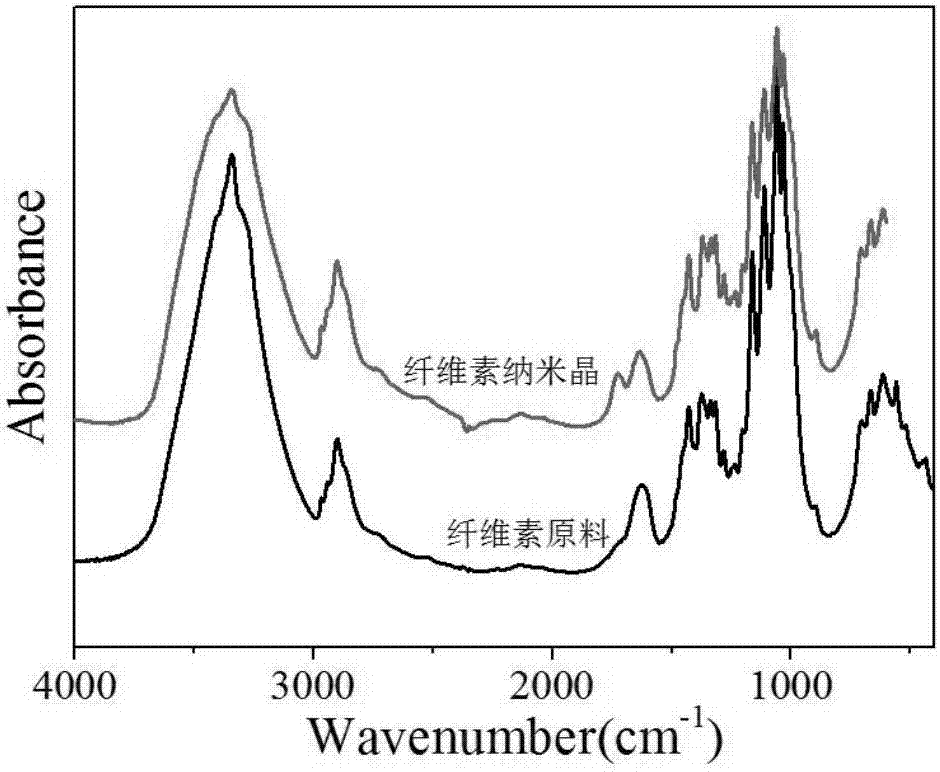

[0043] The morphology and particle size distribution of the prepared cellulose nanocrystals are as follows: figure 1 and figure 2 , the infrared spectrum of the prepared cellulose n...

Embodiment 2

[0045] The type of raw materials used, the amount and the process flow are the same as in Example 1, except that the amount of potassium ferrate used is 5 g to obtain a stable suspension of cellulose nanocrystals. The average length of the measured cellulose nanocrystals is about 220 nm. The yield was 69%, the PDI was 0.2, and the carboxyl content was 6.5 mmol / g.

Embodiment 3

[0047] The types of raw materials used, the amount and the process flow are the same as in Example 1, except that the amount of potassium ferrate used is 7.5 g to obtain a stable suspension of cellulose nanocrystals, and the average length of the obtained cellulose nanocrystals is about 210 nm. , the yield was 75%, the PDI was 0.2, and the carboxyl content was 9.2mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com