Patents

Literature

44results about How to "Overcome the problem of easy reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

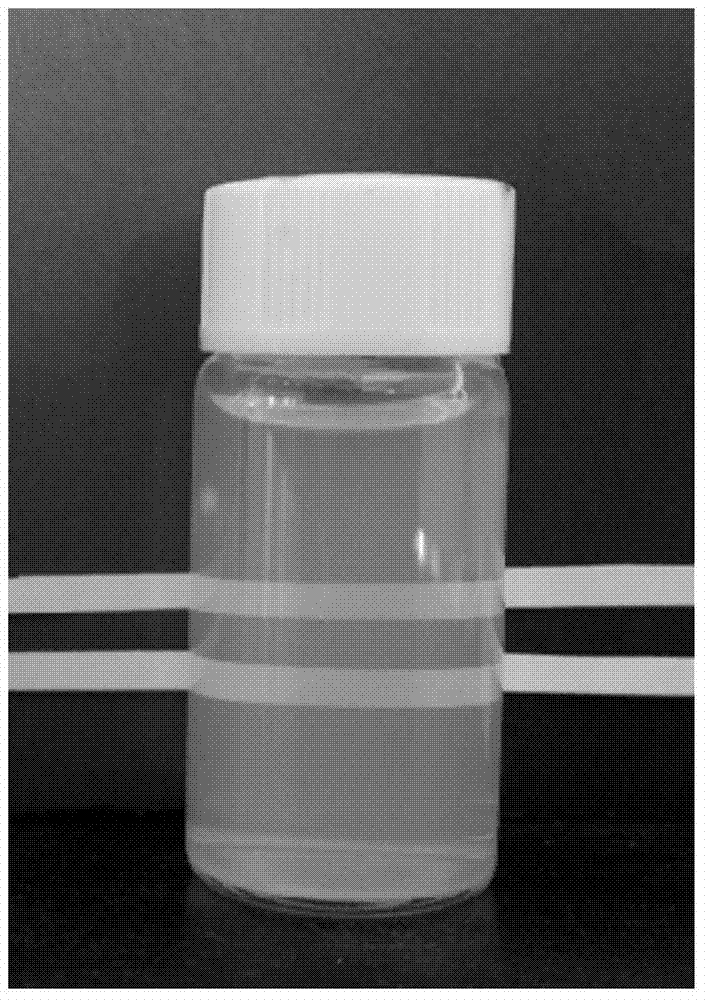

Transparent nanometer zirconium dioxide liquid phase dispersoid, and preparation method and application thereof

ActiveCN106277049ALong-term stable and uniform dispersionOvercome the problem of easy reunionNanotechnologyZirconium oxidesOrganic solventWater soluble

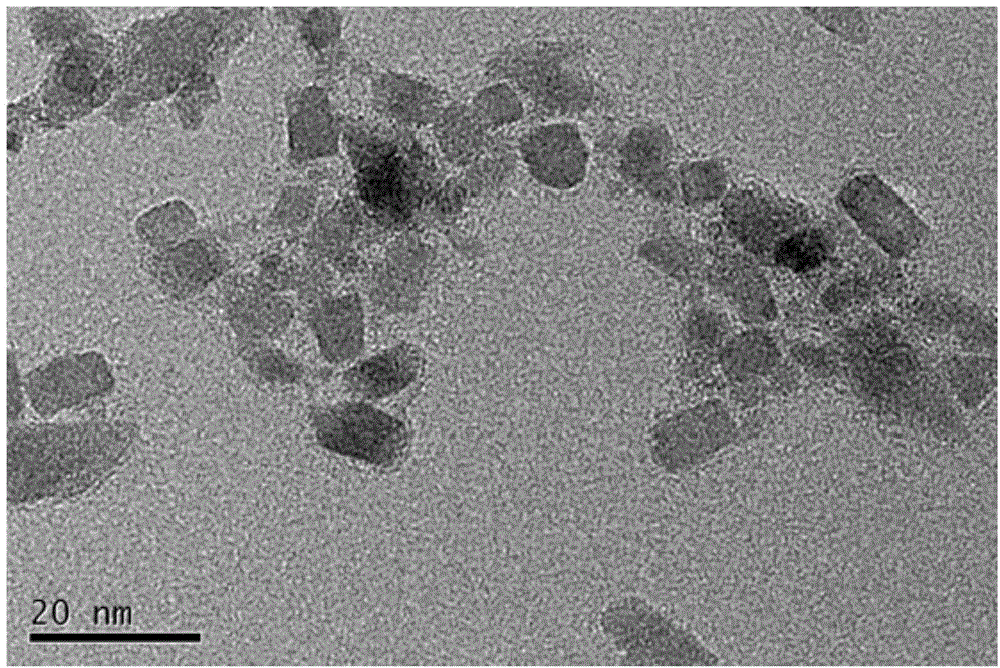

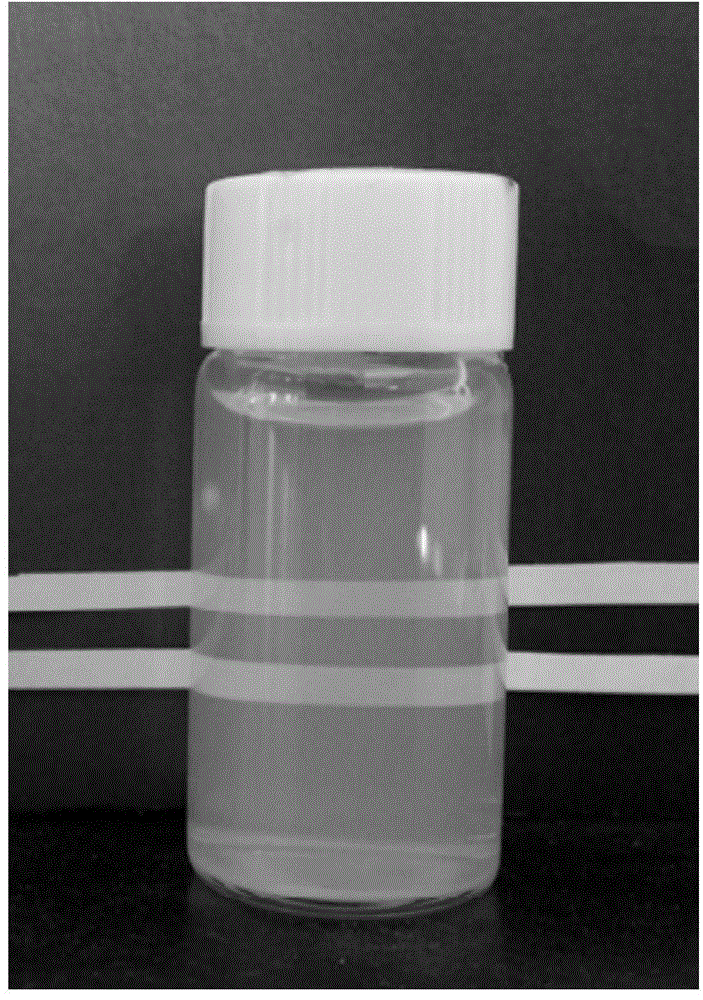

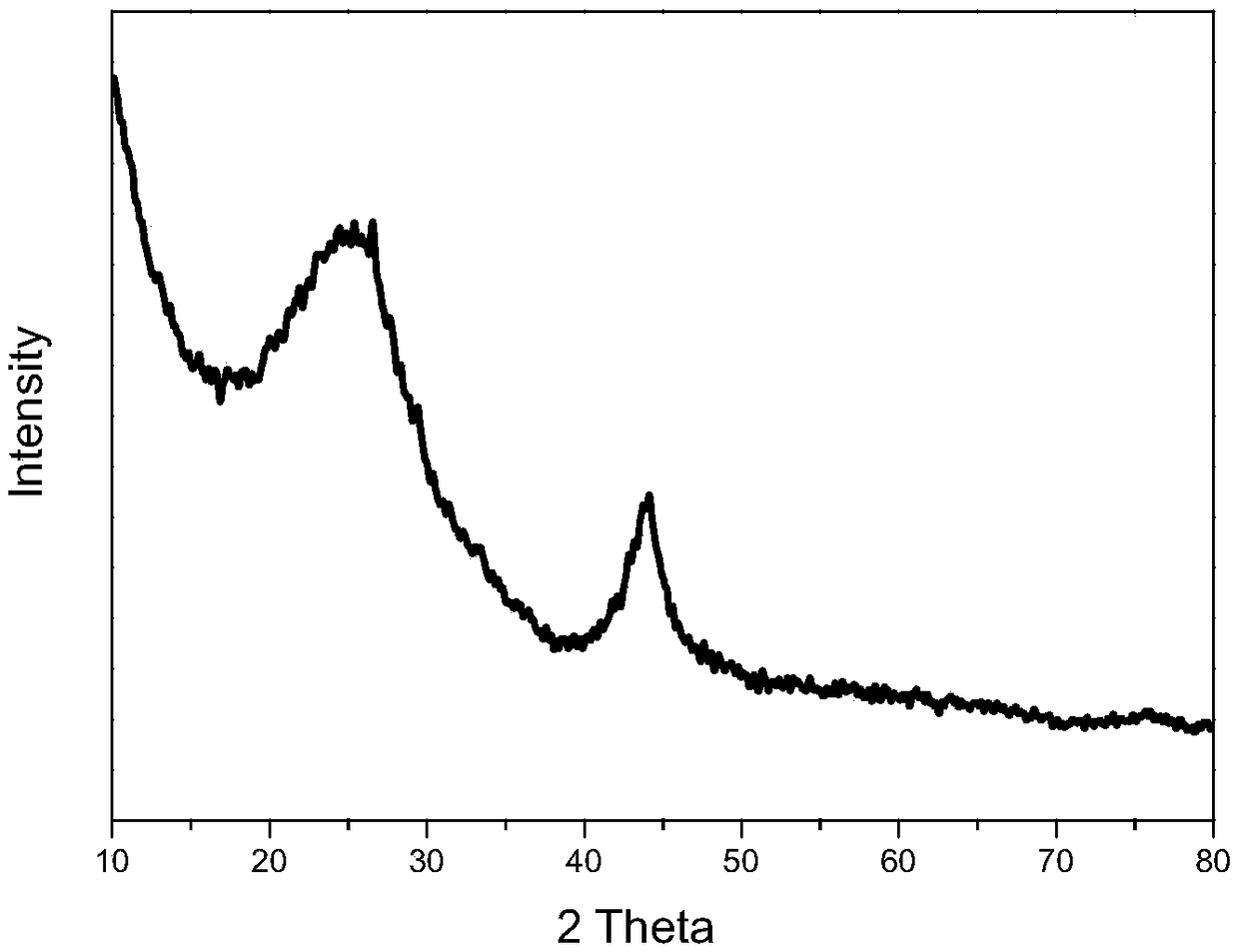

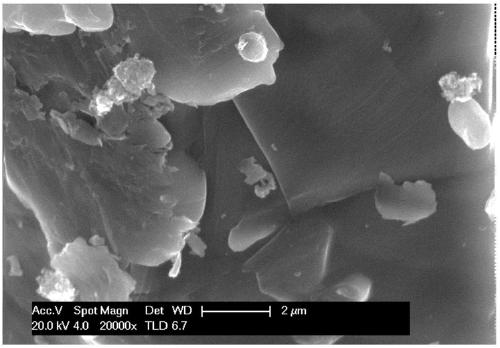

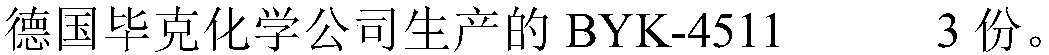

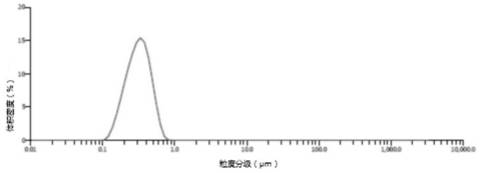

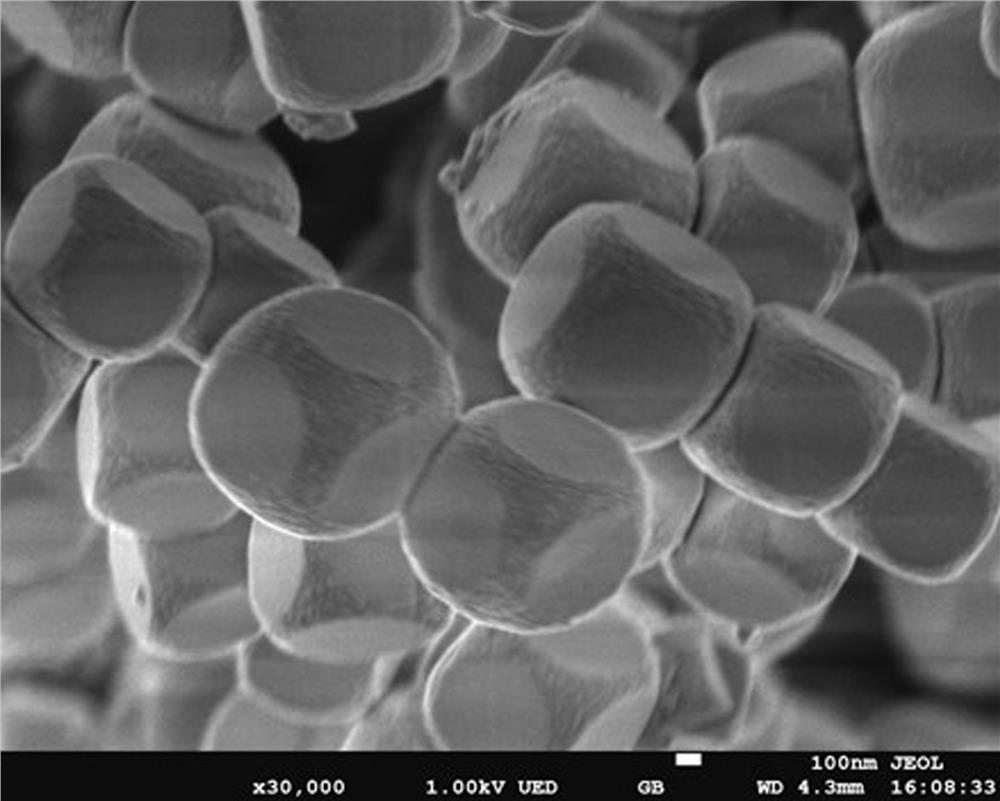

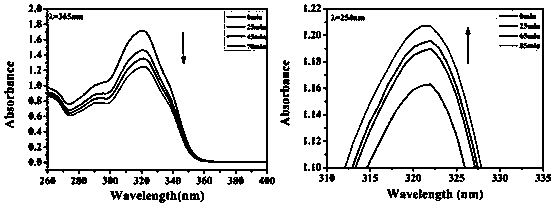

The invention discloses transparent nanometer zirconium dioxide liquid phase dispersoid, and a preparation method and application thereof. The dispersoid comprises liquid phase media and nanometer zirconium dioxide particles, wherein the nanometer zirconium dioxide particles are uniformly dispersed into liquid phase media; the solid content of the dispersoid is 1 weight percent to 50 weight percent; the one-dimensional dimension of the nanometer zirconium dioxide particles is 1 to 12nm; the liquid phase media are water, organic solvents, a mixture of water-soluble organic solvents and water, or a mixture of different organic solvents. The nanometer zirconium dioxide in the product has high crystallinity degree; the particle diameter is small; the distribution is uniform; any surfactant is not contained; the purity is high; the dispersion effect is good; no sedimentation occurs after the still standing for 6 months or longer. The product prepared by the method does not need any treatment, and is directly the transparent nanometer zirconium dioxide liquid phase dispersoid; any substance does not need to be added for dispersion assistance; the problems of easy agglomeration, poor dispersibility and poor optical performance of the composite material are solved; higher application performance and wider application ranges are given to the product.

Owner:BEIJING UNIV OF CHEM TECH

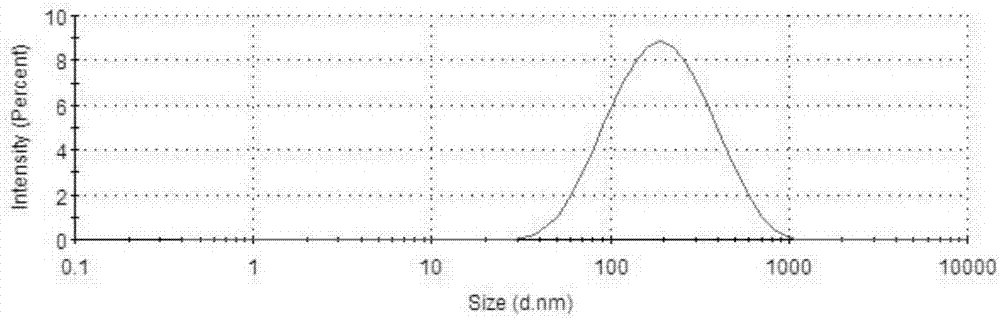

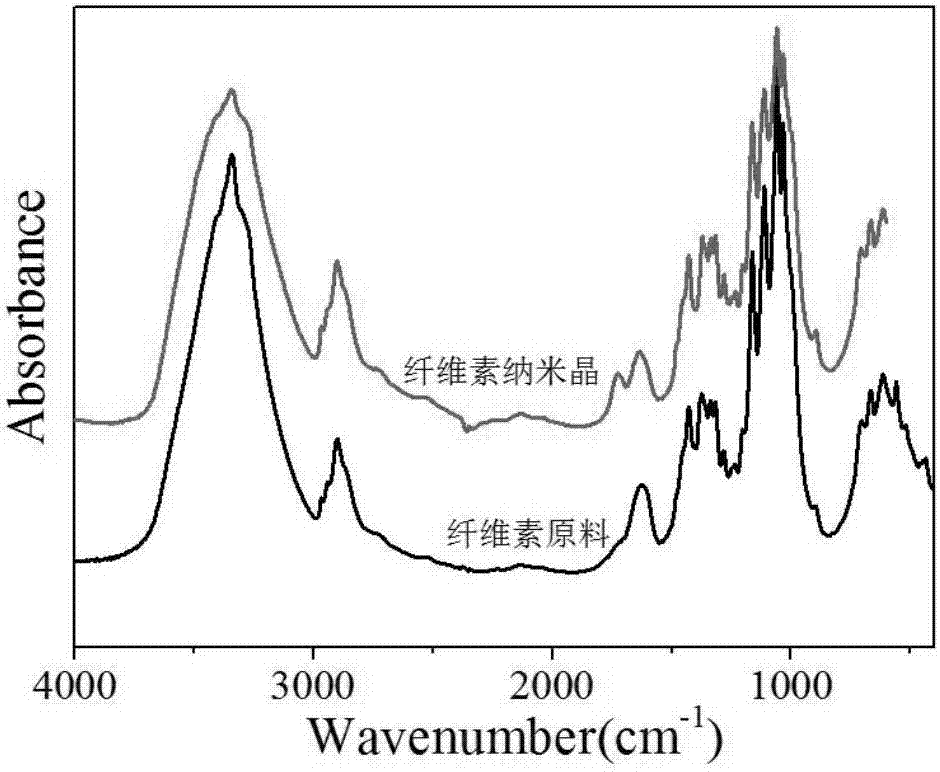

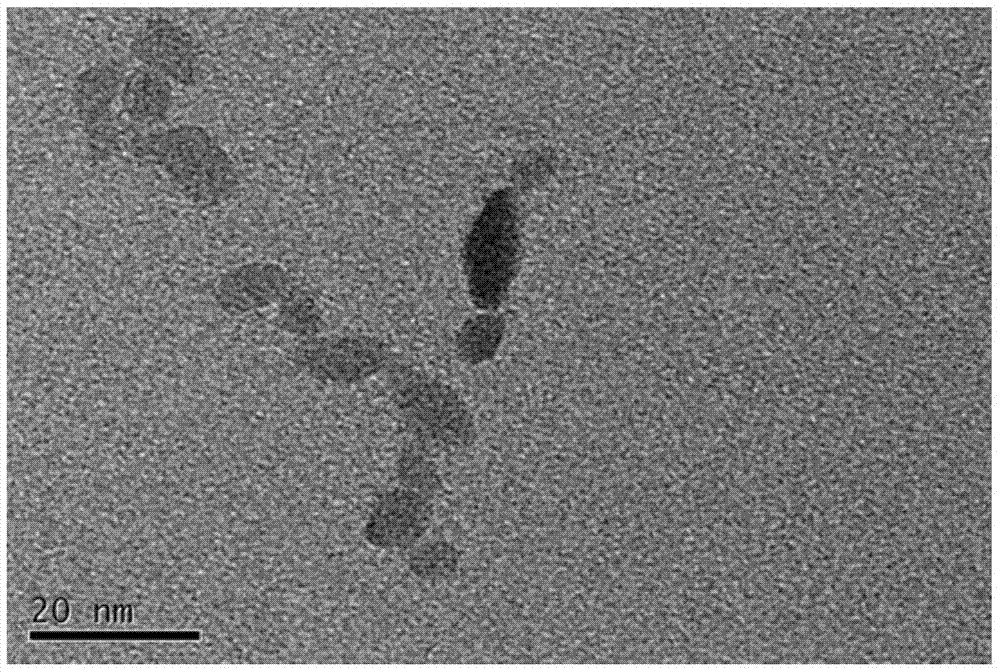

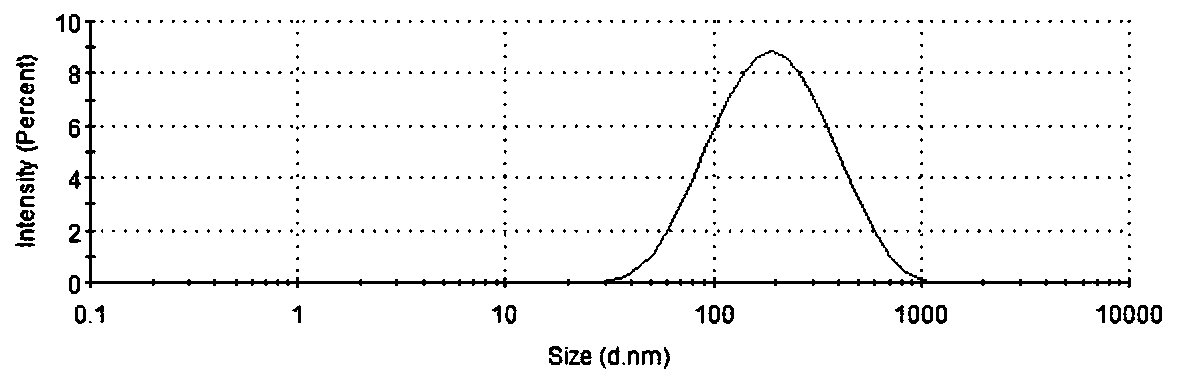

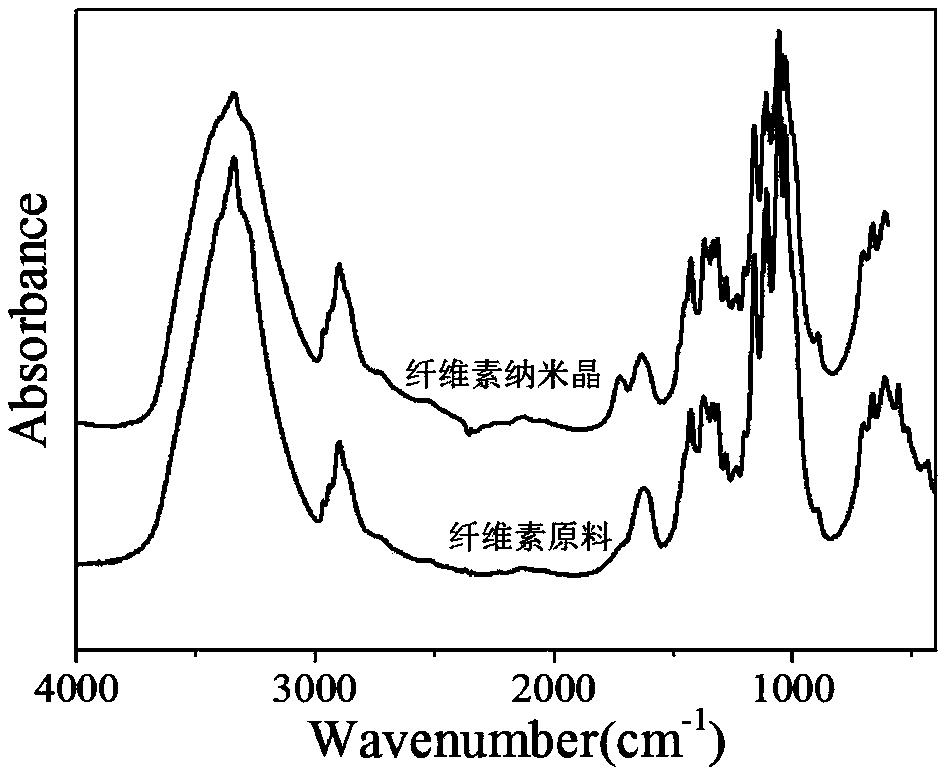

High-efficiency preparation method of cellulose nanocrystal (CNC)

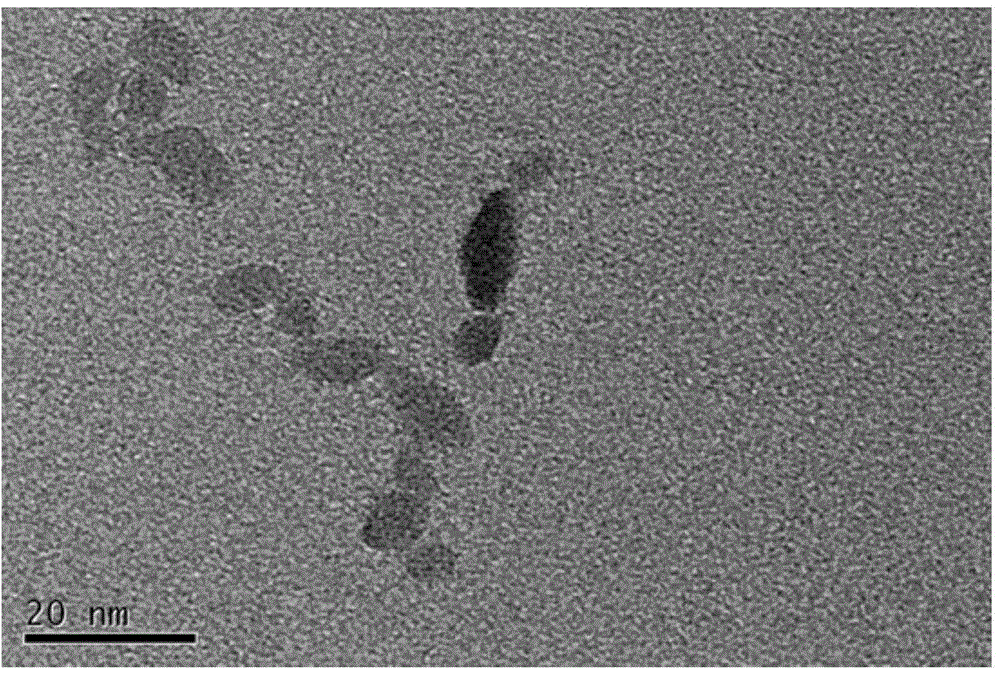

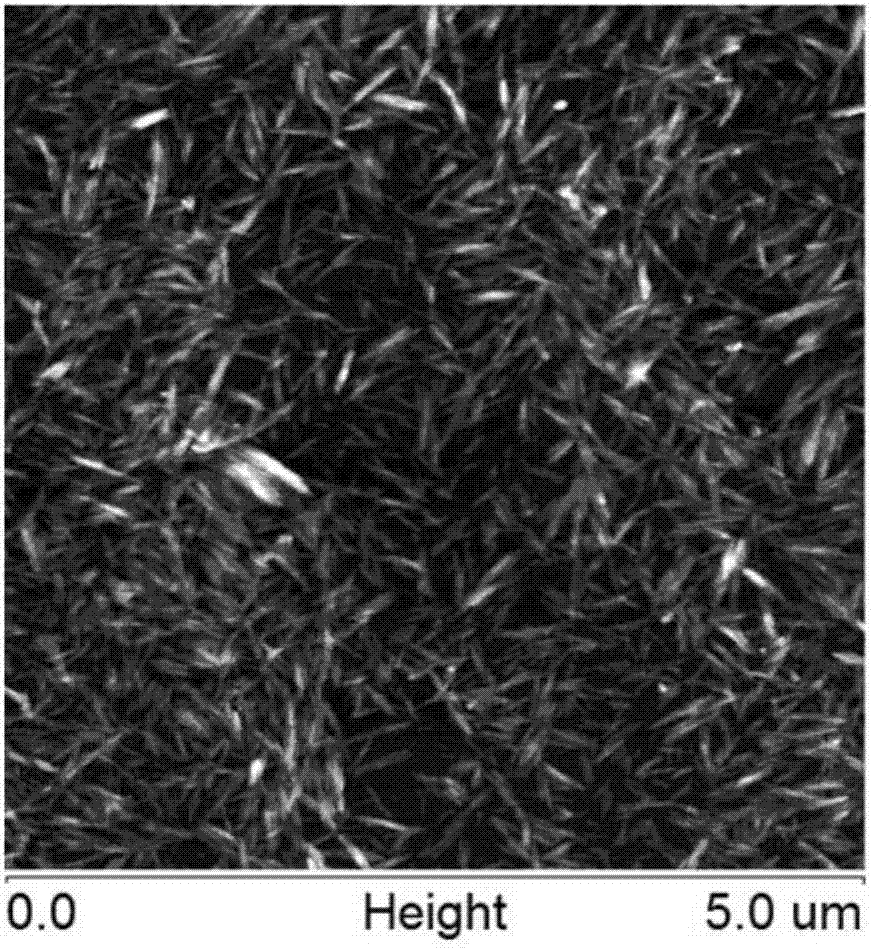

The invention discloses a macroscopic preparation method of a cellulose nanocrystal (CNC), which is green and environment-friendly. Firstly, cellulose is crushed and then is pretreated; afterwards, an oxometallate solution and an organic acid are added, the oxydrolysis is carried out, and the CNC with a carboxyl group on a surface is obtained after centrifugal dialysis treatment. The yield of the preparation method can exceed 70 percent; the length of the made CNC can be adjusted in the range of 195nm to 260nm; the content of the carboxyl group on the surface can reach 50mmol / g; compared with a CNC made by a sulfuric-acid acid hydrolysis method, the CNC made by the macroscopic preparation method provided by the invention is increased by 50 to 100 DEG C in heat resistance; used oxometallate and organic acid are both green reagents and are further a few in use levels; problems that the preparation cost of the CNC is high and further the environmental pollution is easily caused, and the like, at present are solved.

Owner:QINGDAO UNIV OF SCI & TECH

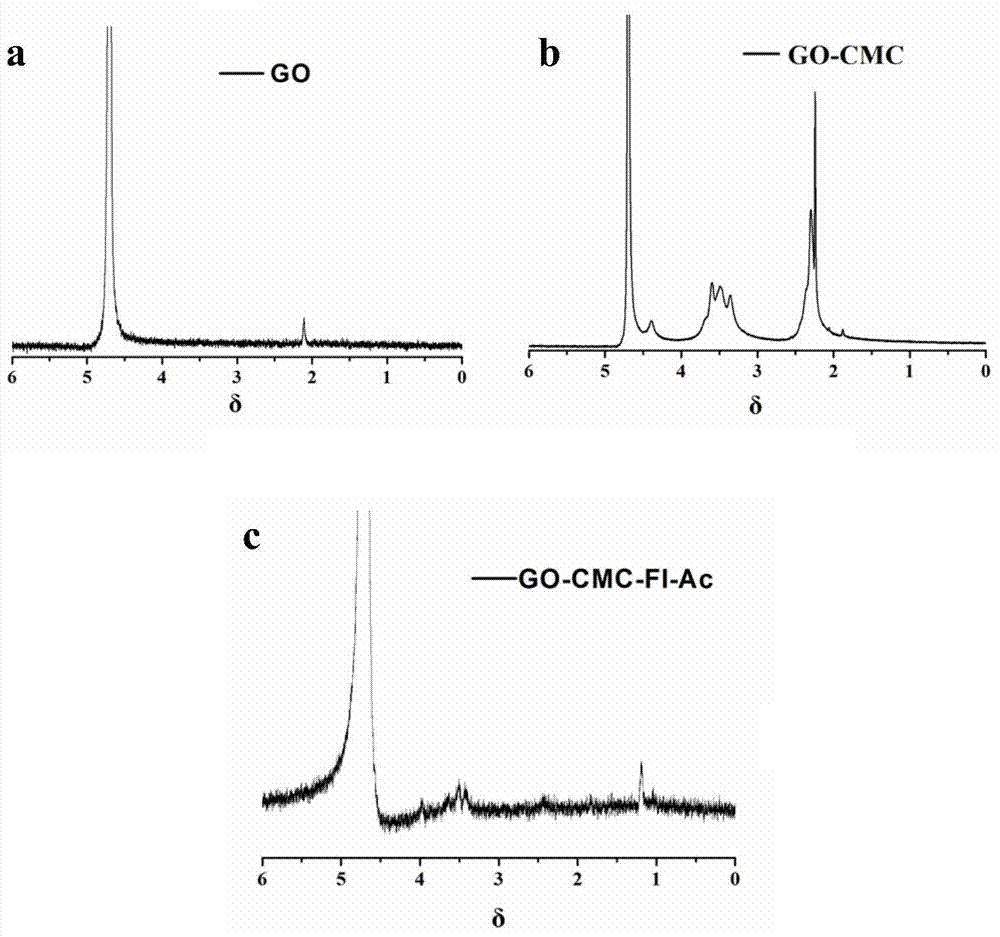

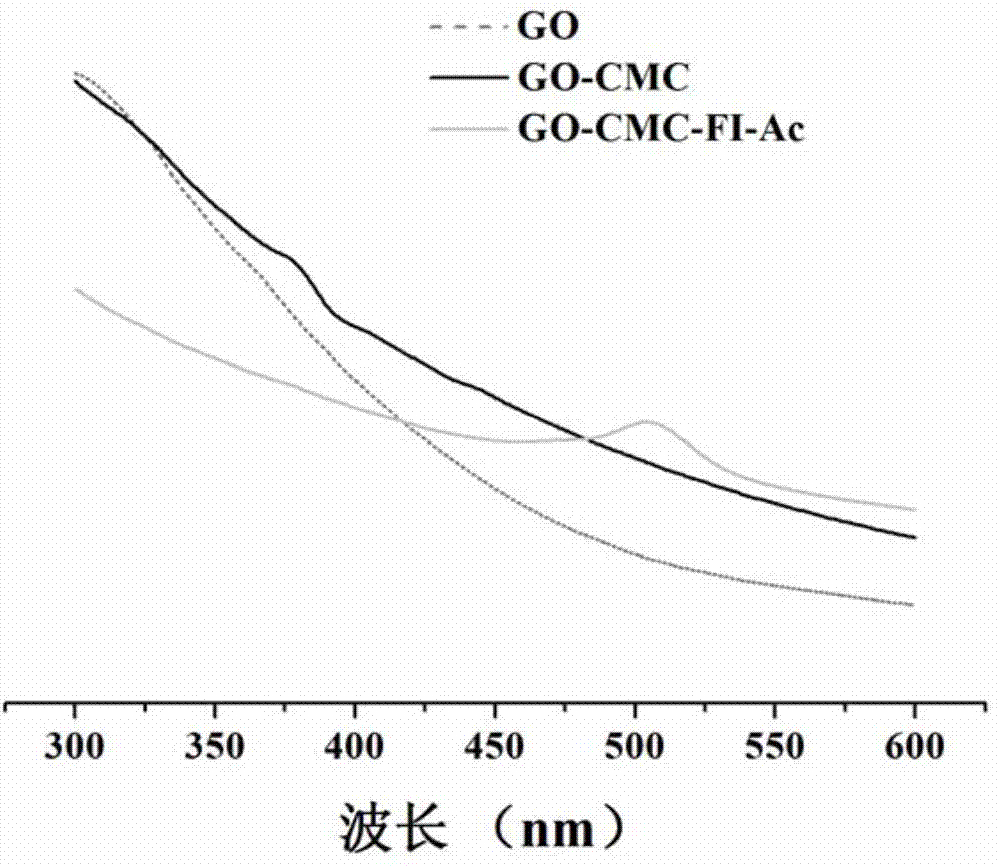

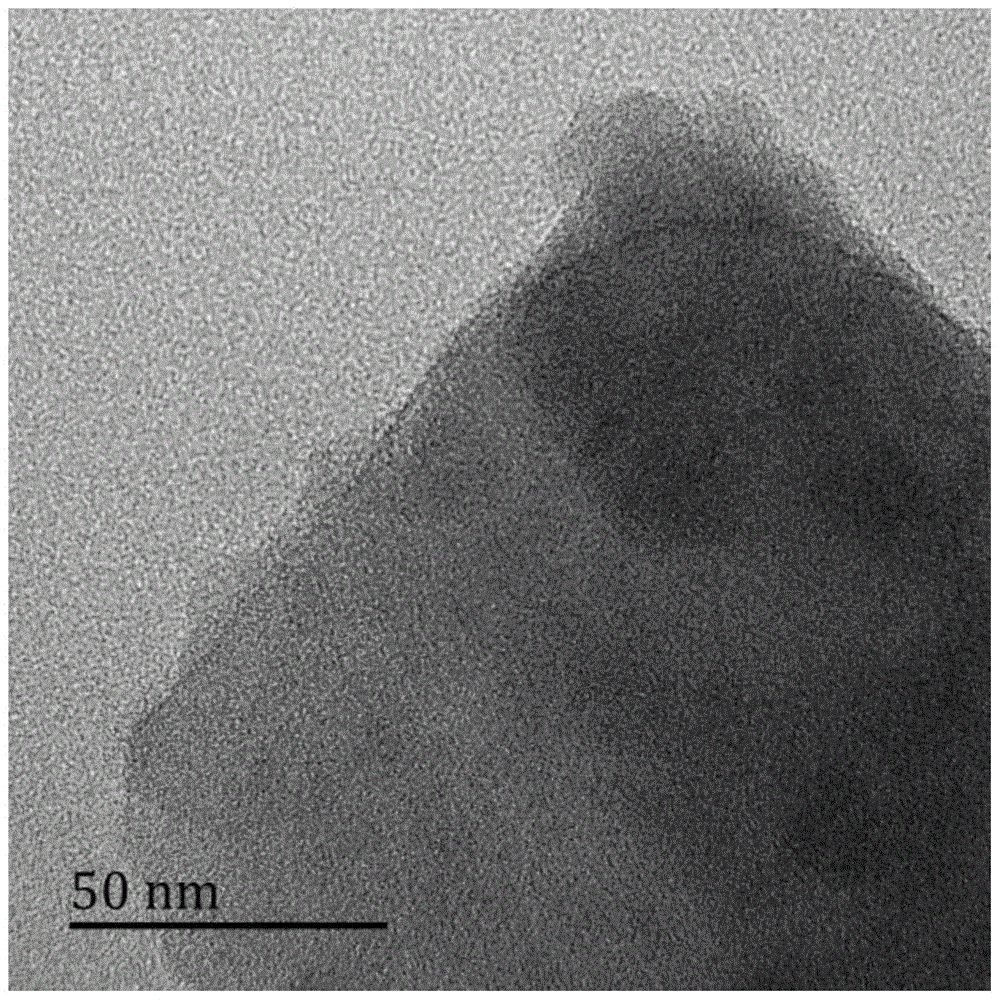

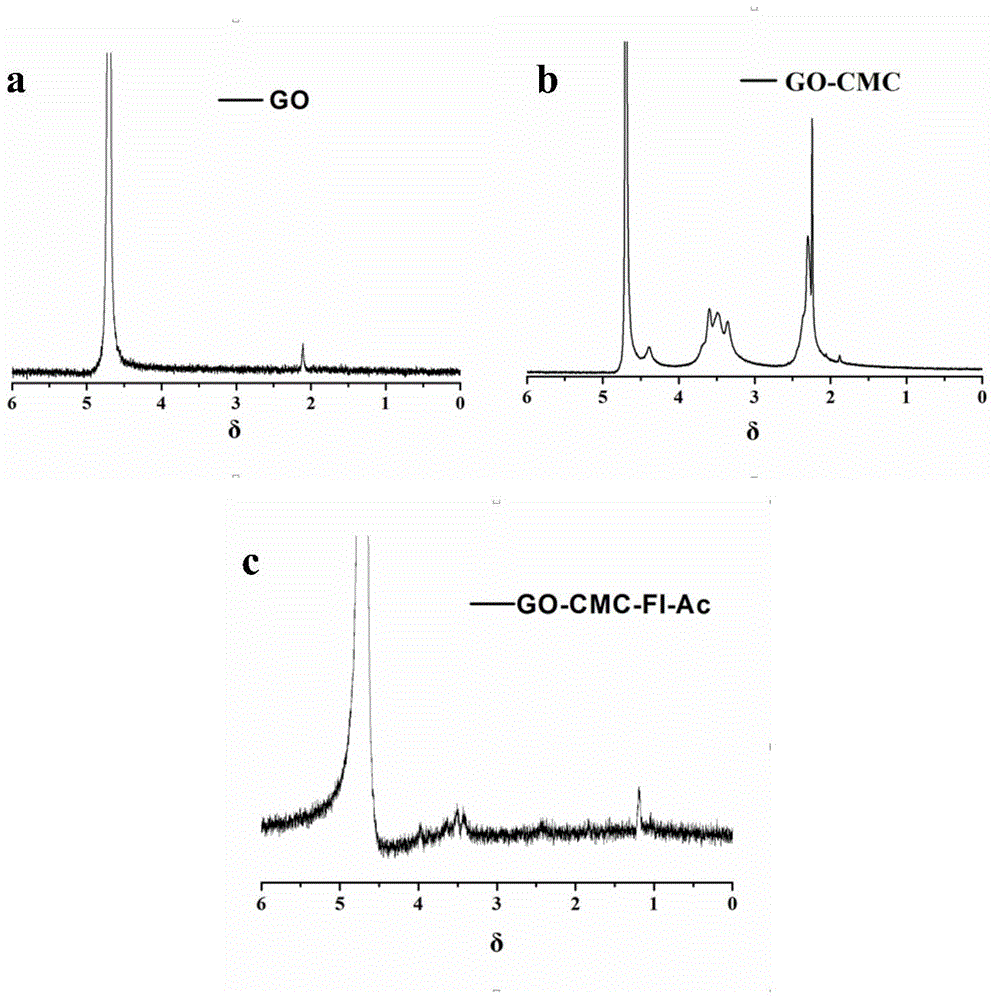

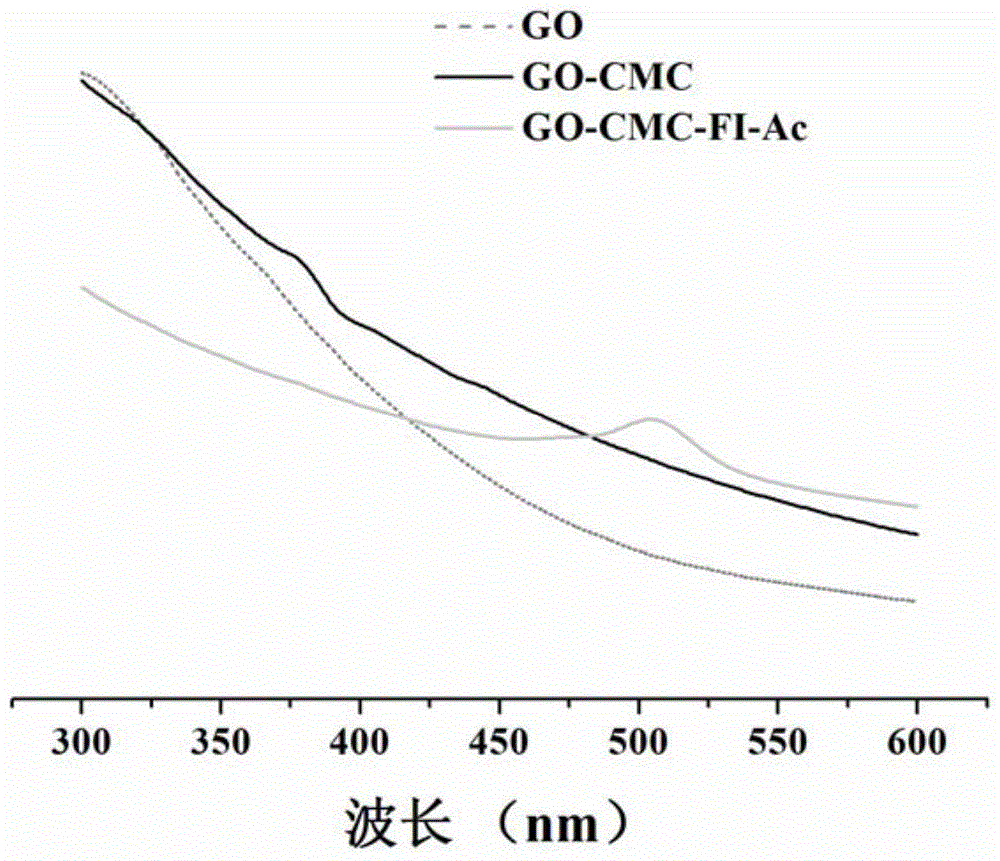

Preparation method of carboxymethyl chitosan modified graphene oxide composite material

The invention relates to a preparation method of a carboxymethyl chitosan modified graphene oxide composite material; the preparation method includes the steps: (1) under the action of activating agents EDC and NHS, allowing graphene oxide dispersed in water to generate chemical bond connection with CMC, carrying out a reaction for 24 h at room temperature, to obtain a suspension with relatively good micro-particle dispersity, dialyzing, freeze-drying, and thus synthesizing GO-CMC; and (2) dissolving the obtained product in distilled water, adding an appropriate amount of fluorescein FITC; and acetylating the product, carrying out a stirring reaction for 24 h at room temperature, dialyzing, freeze-drying, and thus synthesizing the graphene oxide GO-CMC-FI-Ac composite material. The preparation method is simple to operate, and the product is easy to handle; and the composite material can be applicable to drug sustained release and cell imaging, and the cost is low.

Owner:DONGHUA UNIV

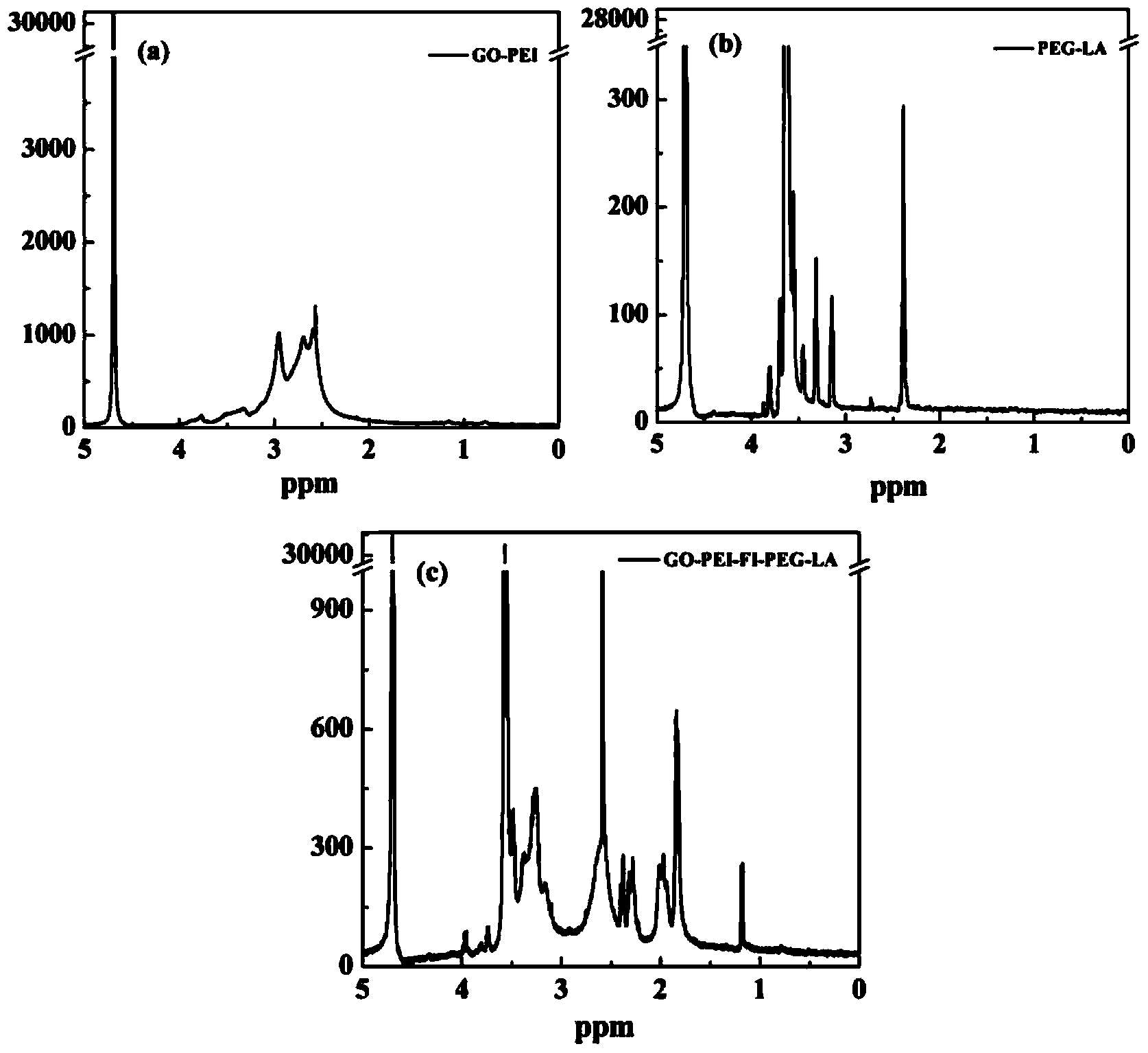

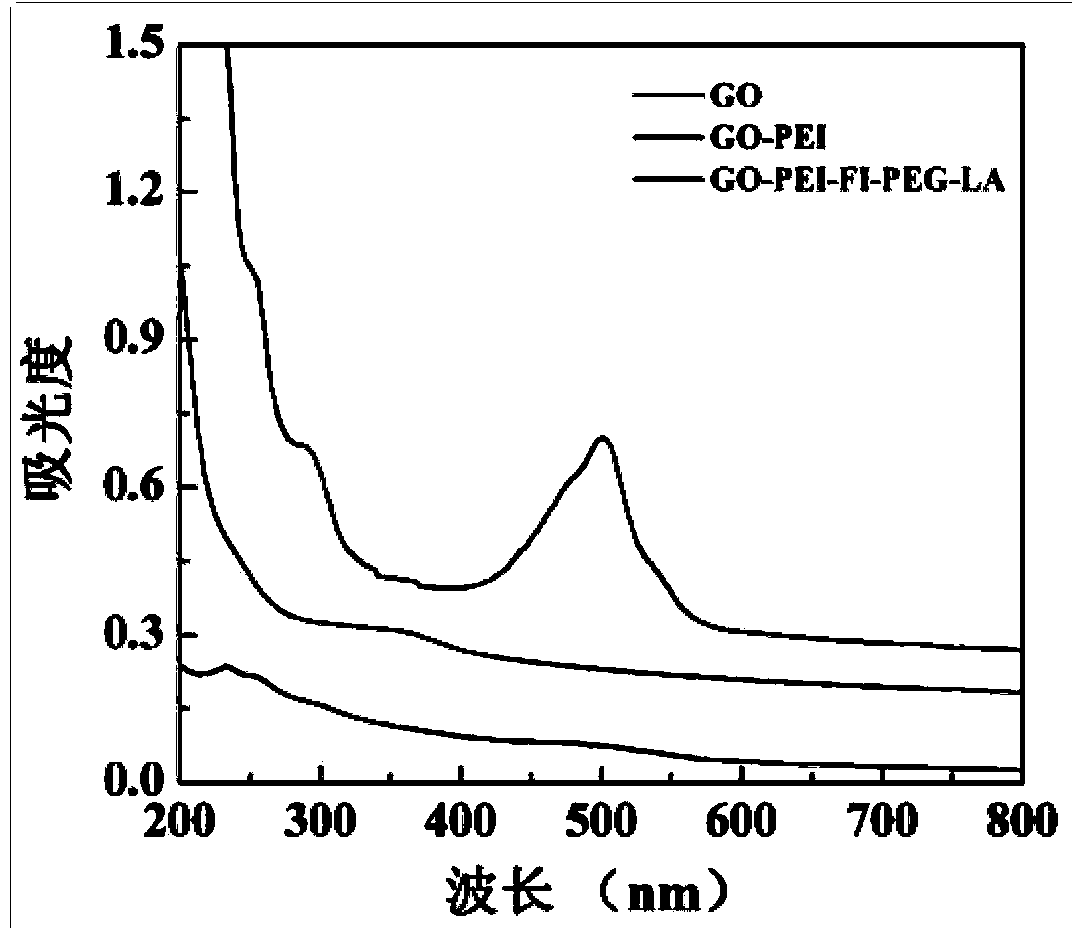

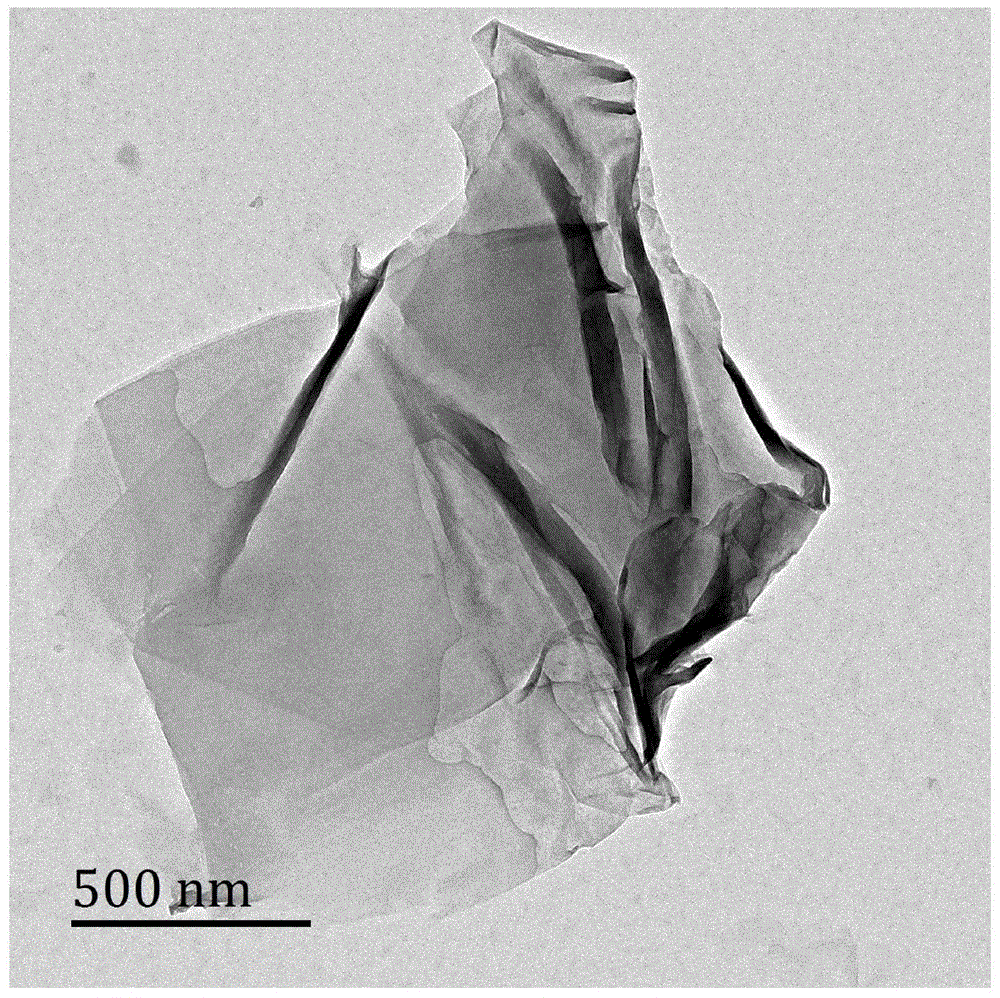

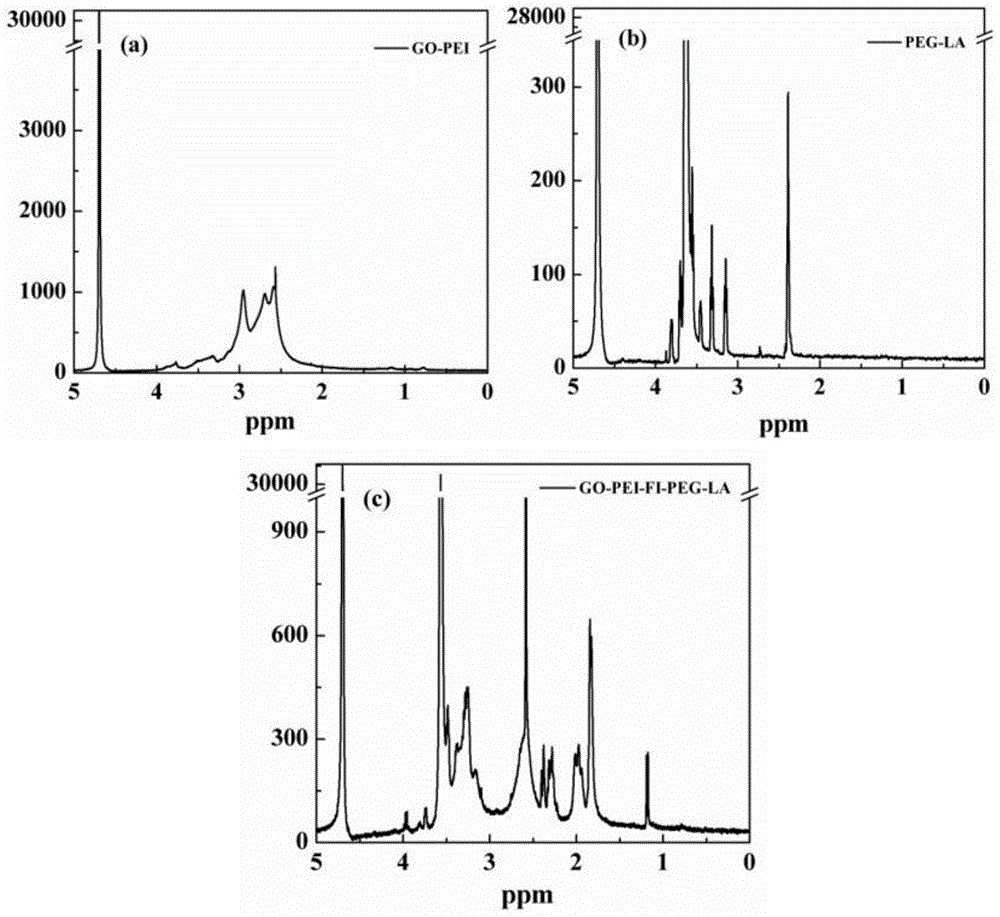

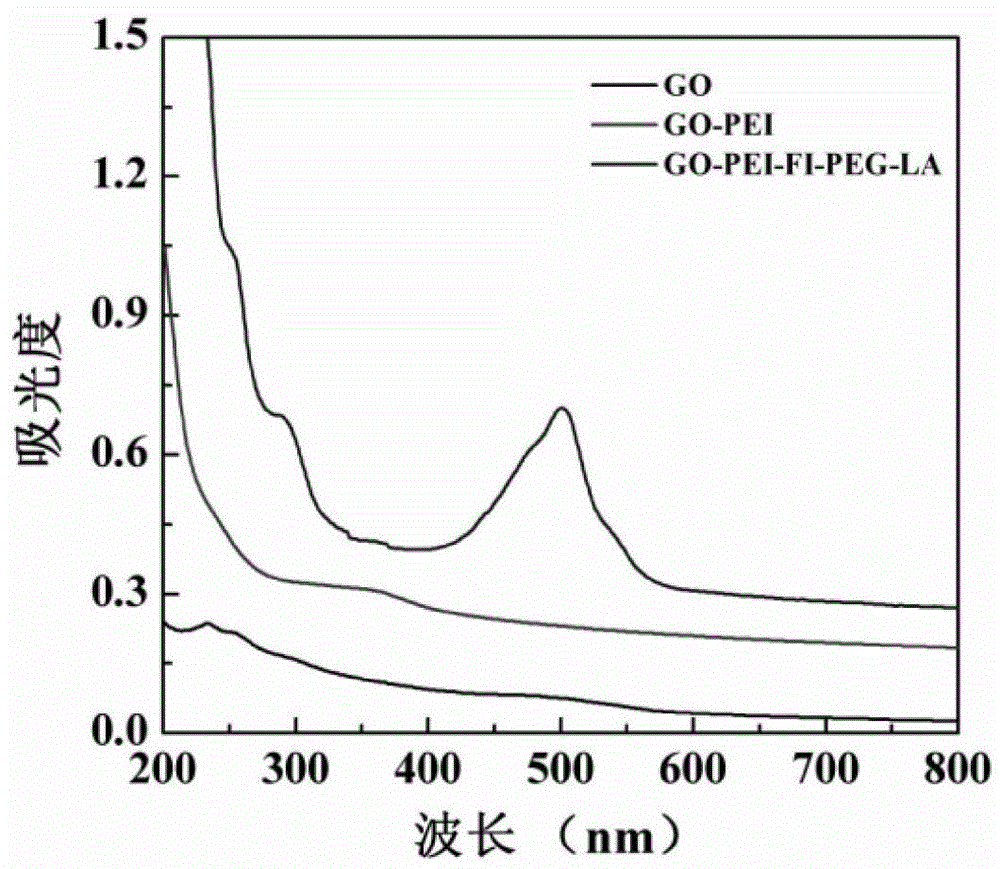

Preparation method of composite material containing lactobionic acid-modified graphene oxide

The invention relates to a preparation method of a composite material containing lactobionic acid-modified graphene oxide, and the method is as follows: chemically bonding graphene oxide (GO) and PEI (polyethyleneimine) in dimethyl sulfoxide by the effect of activator EDC (1-(3-Dimethylaminopropyl)-3-ethylcarbodiimide), dialyzing, and freeze-drying for synthesis of GO-PEI; dissolving the LA in a phosphate buffer solution, adding EDC and NHS (N-Hydroxysuccinimide) for activation, adding NH2-mPEG-COOH, reacting for 12-24h at room temperature, dialyzing, and freeze-drying to obtain PEG-LA; dissolving the GO-PEI in water, adding a FITC (fluorescein isothiocyanate) solution; adding the EDC and the NHS into the PEG-LA for activation, adding the GO-PEI solution for reaction to obtain GO-PEI-FI-PEG-LA, adding triethylamine for mixing, adding acetic anhydride, reacting at room temperature, dialyzing, and freeze-drying to obtain the graphene oxide composite material. The preparation process of the preparation method is simple, the experimental conditions are normal temperature and pressure, and the preparation method is easy to operate.

Owner:DONGHUA UNIV

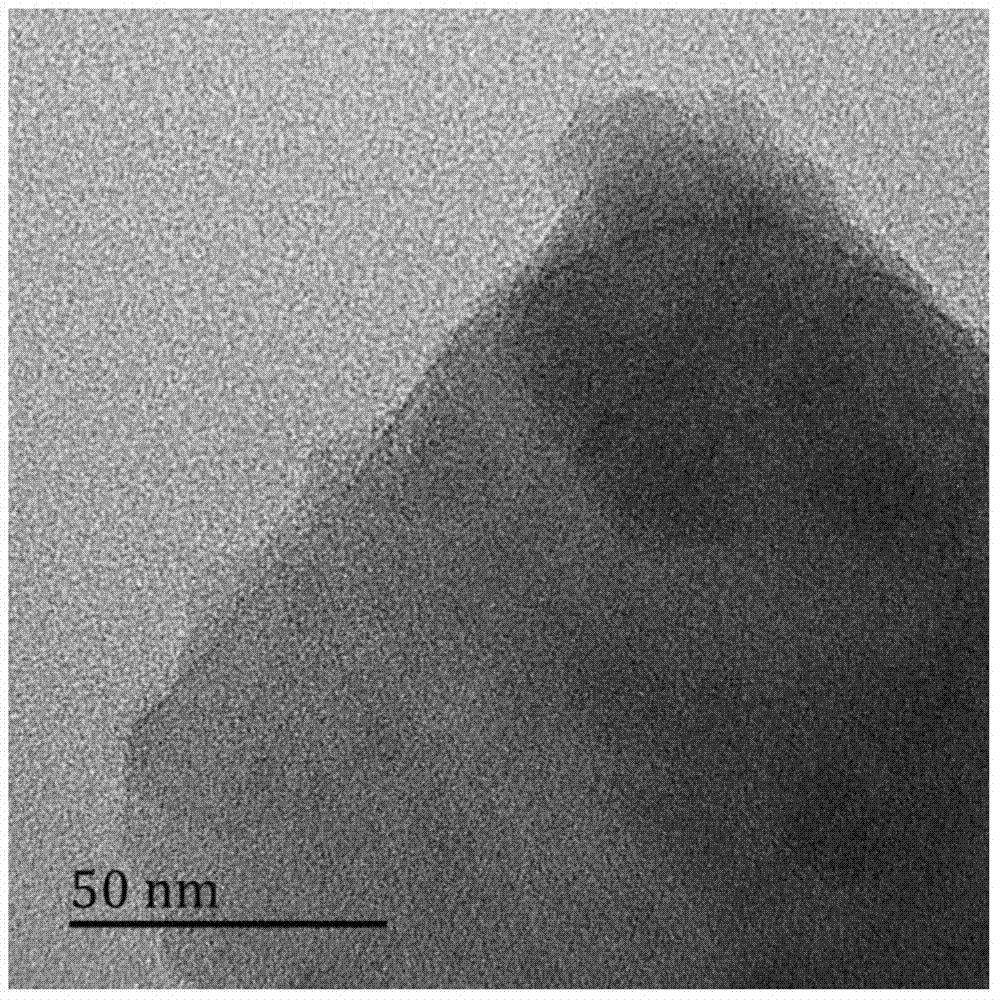

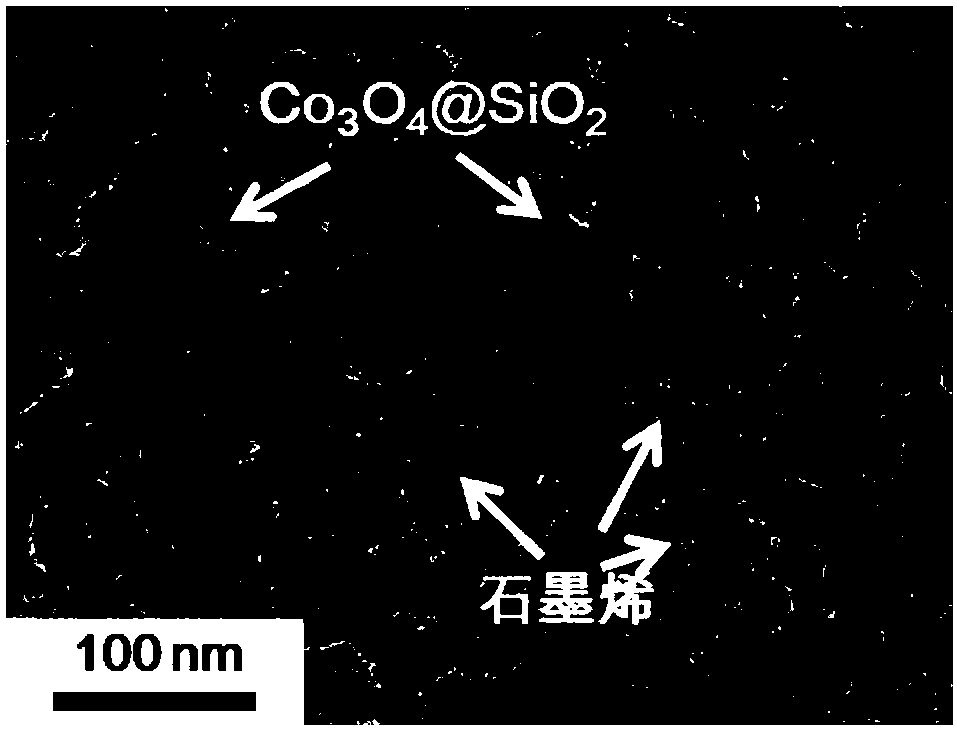

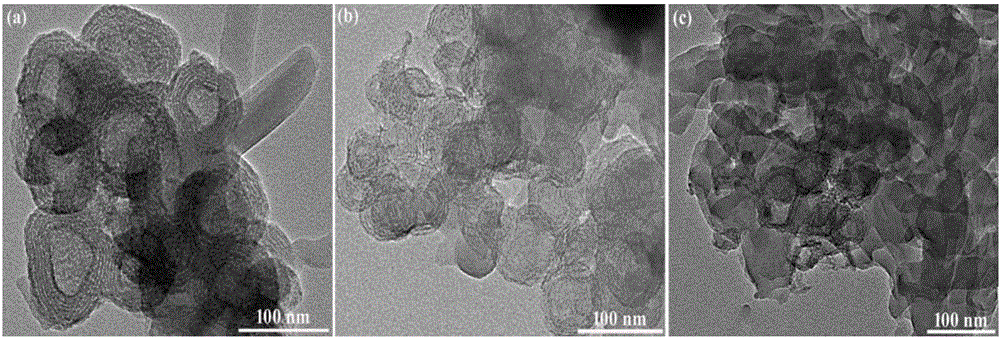

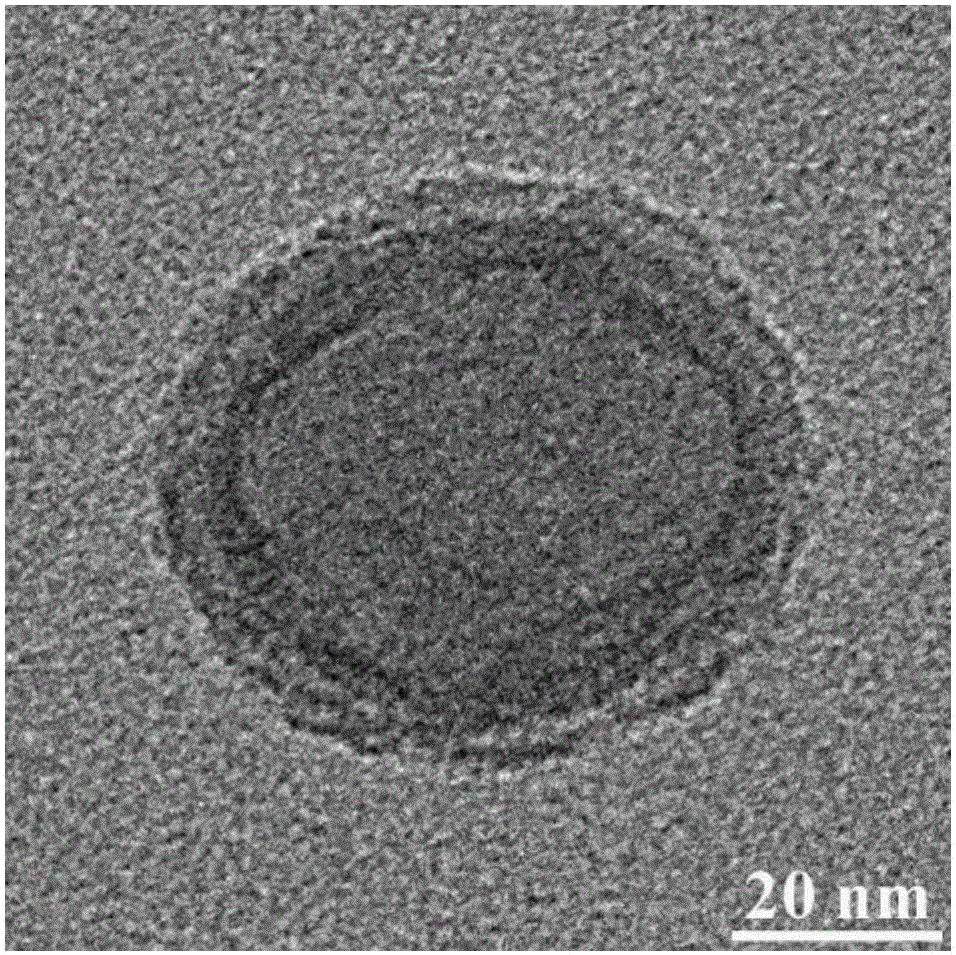

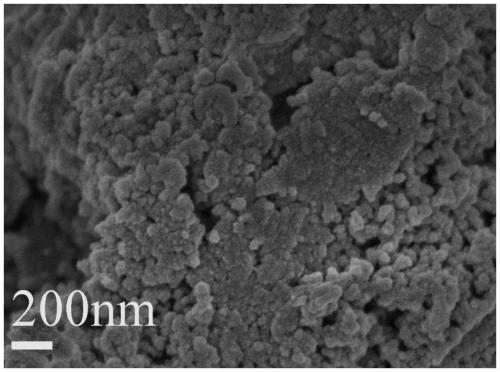

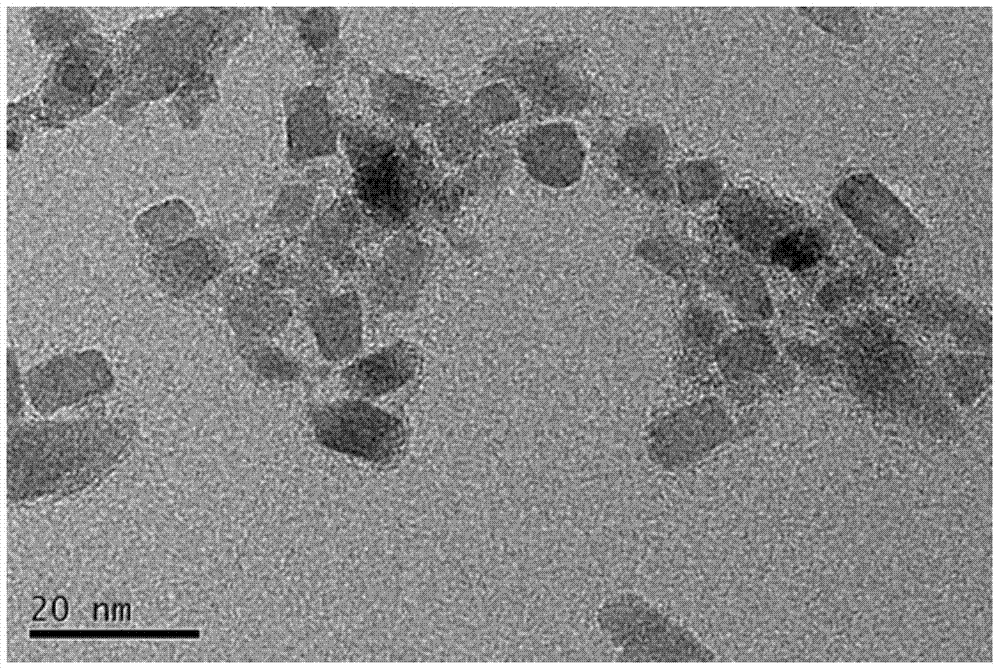

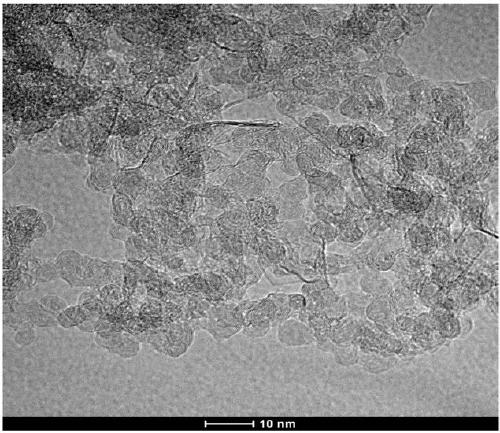

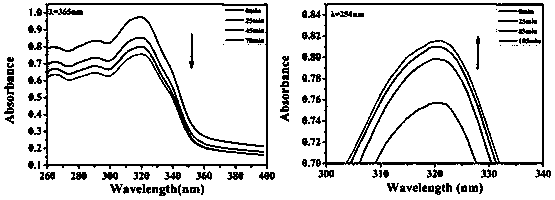

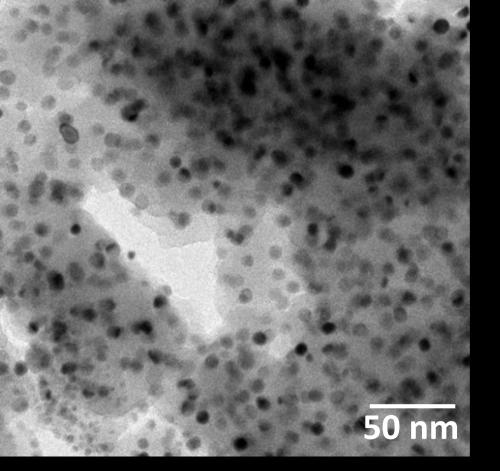

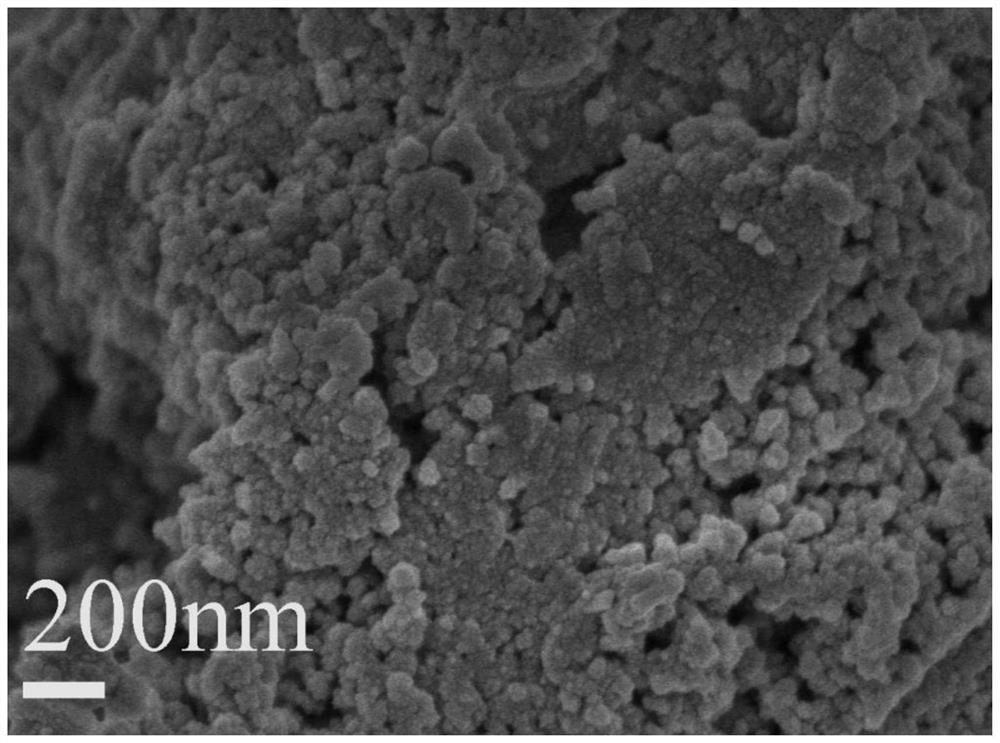

Small-particle-size metal phosphide nanoparticle/reduced graphene composite material and preparation method thereof

ActiveCN108452816ASmall particle sizeGood dispersionMaterial nanotechnologyPhysical/chemical process catalystsNanoparticleReactive site

The invention discloses a small-particle-size metal phosphide nanoparticle / reduced graphene composite material and a preparation method thereof. The preparation method comprises the following steps: 1) preparing silica-coated metal oxide composite particles; 2) loading the composite particles onto graphene oxide to obtain a graphene oxide-based compound; 3) removing silica of the composite particles in the graphene oxide-based compound; and 4) carrying out phosphating treatment so as to obtain the small-particle-size metal phosphide nanoparticle / reduced graphene composite material. Metal phosphide in the composite material of the invention has a small particle size, in a range of 3 nm to 5 nm; and the phosphide nanoparticles are highly dispersed in reduced graphene, which is favorable forincreasing the exposure degree of active sites. The preparation method is simple in process, low in cost, and favorable for large-scale production.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

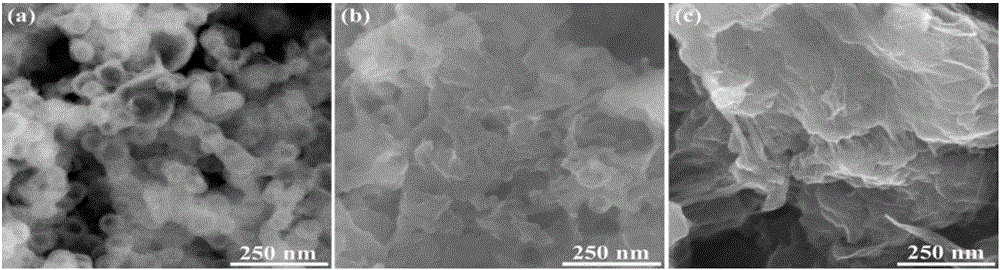

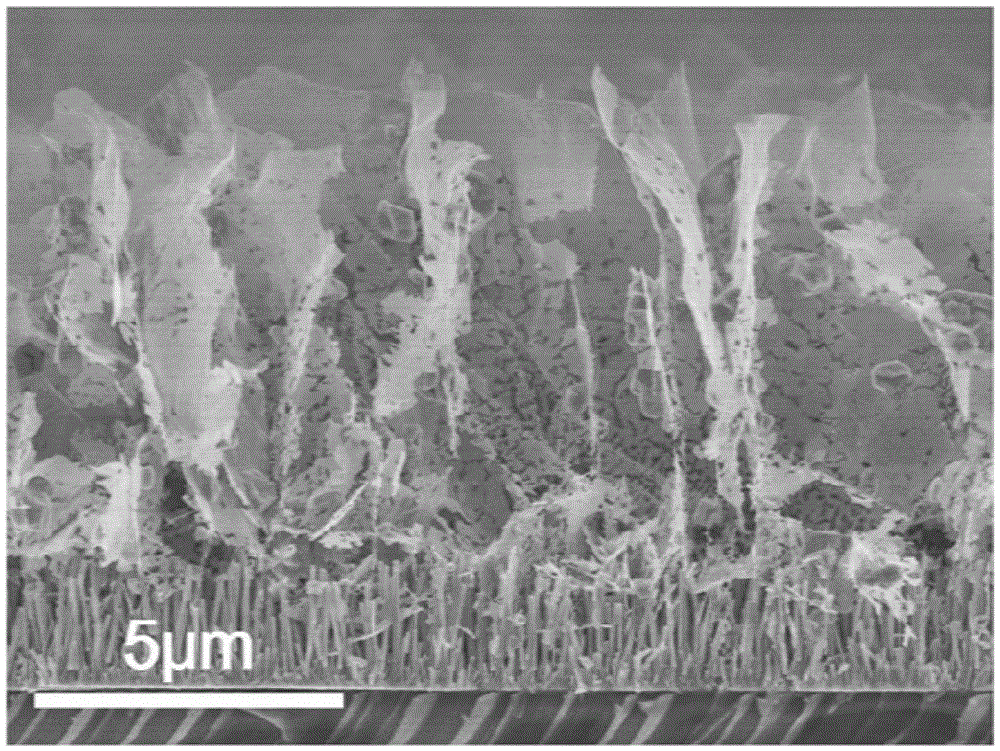

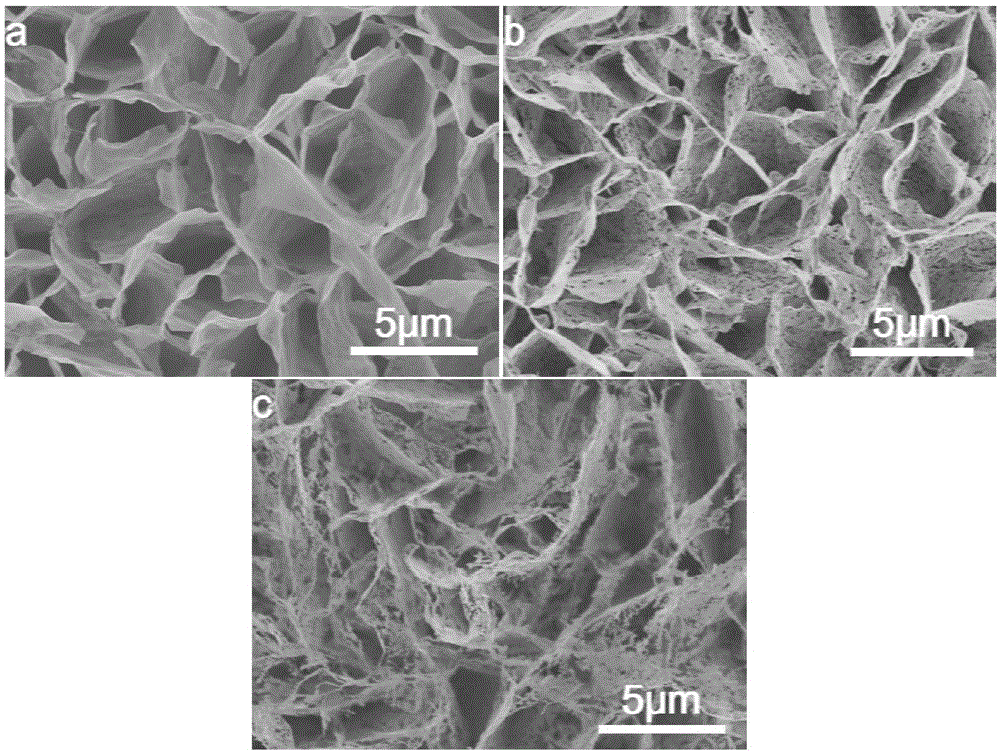

A three-layer vesicular polyaniline/graphene composite material and a preparing method thereof

A three-layer vesicular polyaniline / graphene composite material and a preparing method thereof are disclosed. The composite material is prepared by firstly preparing layer-number-adjustable SiO2, preparing a layer-number-adjustable SiO2 / polyaniline composite material by adopting the layer-number-adjustable SiO2 as a hard template and adopting aniline as a raw material through an in-situ polymerization process, etching SiO2 to obtain three-layer vesicular polyaniline, preparing a three-layer vesicular polyaniline / graphene oxide composite material through a graphene oxide self-assembling process, and preparing the three-layer vesicular polyaniline / graphene composite material through a high-temperature hydrothermal reduction process. The vesicular polyaniline / graphene composite material having same layer numbers can be obtained by regulating the layer-number-adjustable SiO2. No oxidant or reductant is needed. The method is green. During preparation of the three-layer vesicular polyaniline / graphene composite material, the method is simple, safe in process, low in energy consumption and high in operability.

Owner:山东济清科技服务有限公司

Preparation method and application of graphene-polypyrrole-gold nanoparticle composite material

ActiveCN108760855AGood dispersionOvercome the problem of easy reunionMaterial electrochemical variablesEscherichia coliPolypyrrole

The invention discloses a graphene-polypyrrole-gold nanoparticle composite material which is characterized in that a method combining in-situ chemical polymerization with electrostatic adsorption is adopted to load gold nanoparticles onto a graphene-polypyrrole composite material. The preparation method comprises the following steps: 1) configuration of a solution; 2) preparation of a polypyrrole-graphene nano-composite material by a mixed reaction of the solution; 3) preparation of a gold nanoparticle solution; 4) adsorption of the gold nanoparticles. The invention further discloses the application of the graphene-polypyrrole-gold nanoparticle composite material, and the composite material is applied to the modification of electrodes of an impedance type escherichia coli biosensor, wherea linear range of detection of the escherichia coli is 1*102-1*107 CFU / mL, and the minimum detection limit is 100 CFU / mL. The impedance type escherichia coli biosensor prepared by the invention has the advantages of simple operation, low cost, convenient use, high selectivity and the like, and thus has great potential application values in the fields of food safety, clinical analysis and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

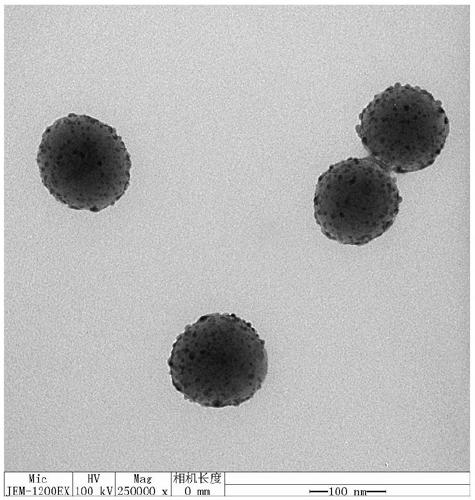

Preparation method of silicon-coated nano magnetic spheres

ActiveCN107768061AOvercome the problem of easy reunionIncrease concentrationMaterial nanotechnologyInductances/transformers/magnets manufactureDispersityAlcohol

The invention discloses a preparation method of silicon-coated nano magnetic spheres. Magnetic spheres adsorbing silicon spheres are obtained through preparing a silicon sphere solution containing silicon dioxide nanoparticles, preparing the magnetic spheres and stirring and mixing the silicon sphere solution and the magnetic spheres; the magnetic spheres adsorbing the silicon spheres are transferred into an alcohol-water system and the silicon spheres form silicon layers on the surfaces of the magnetic spheres by using a TEOS sol-gel method; and the product silicon-coated nano magnetic spheres are obtained through washing after magnetic separation. The preparation method of the silicon-coated nano magnetic spheres is simple, safe, low in raw material cost and suitable for industrial large-scale production; the prepared nano magnetic spheres are good in dispersity and high in magnetic responsiveness; and the monodisperse silicon-coated nano magnetic spheres have a wide application prospect in the fields of bioseparation, environment, catalysis, solid-phase extraction and the like.

Owner:HUAQIAO UNIVERSITY

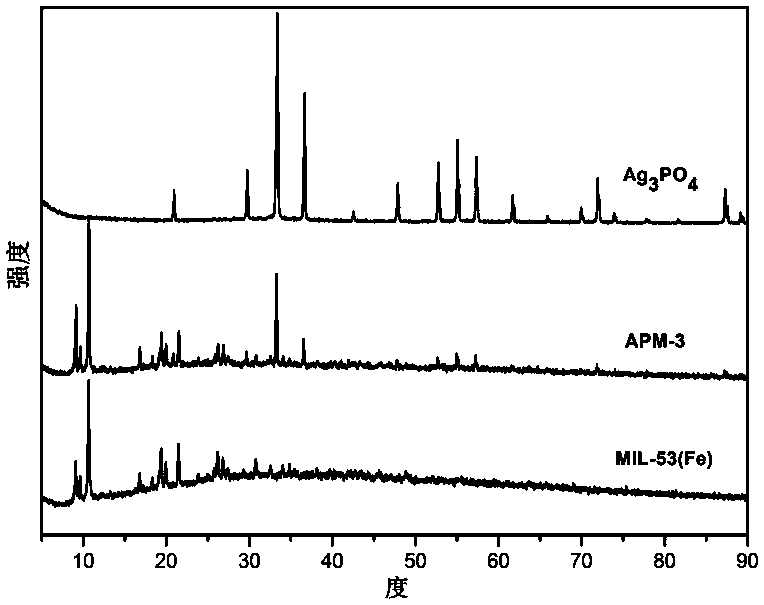

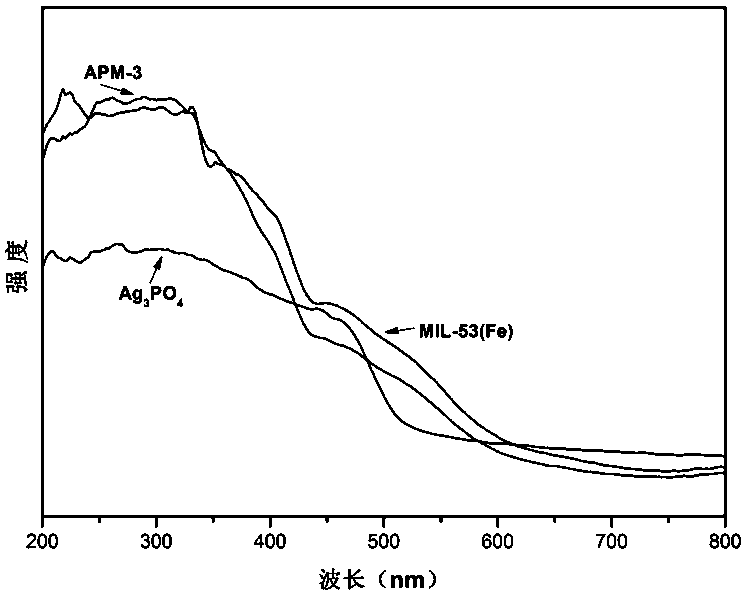

Silver phosphate/metal organic framework composite material, as well as preparation method and application thereof

InactiveCN108219157AImprove structural stabilityImprove stabilityWater/sewage treatment by irradiationWater treatment compoundsDispersityWastewater

The invention discloses a silver phosphate / metal organic framework composite material, as well as a preparation method and application thereof. The silver phosphate / metal organic framework composite material is prepared from silver phosphate and MIL-53 (Fe), wherein the silver phosphate is doped in the MIL-53(Fe). The preparation method comprises the following steps: dispersing the MIL-53(Fe) in aqueous solution, and carrying out ultrasonic treatment, thus obtaining dispersed liquid containing the MIL-53(Fe); adding Ag<+> and PO4<3-> into the dispersed liquid containing the MIL-53(Fe) in sequence, and stirring to obtain the silver phosphate / metal organic framework composite material. The silver phosphate / metal organic framework composite material disclosed by the invention has the advantages of large specific surface area, good dispersity, good stability, good photocatalytic property and the like; the preparation method disclosed by the invention has the advantages of simple operation,fewer raw-material varieties, low cost and the like, and is suitable for large-scale preparation. The silver phosphate / metal organic framework composite material can be used for treating antibiotic waste water, and can realize high-efficiency removal of antibiotics, so as to have better application prospect.

Owner:HUNAN UNIV

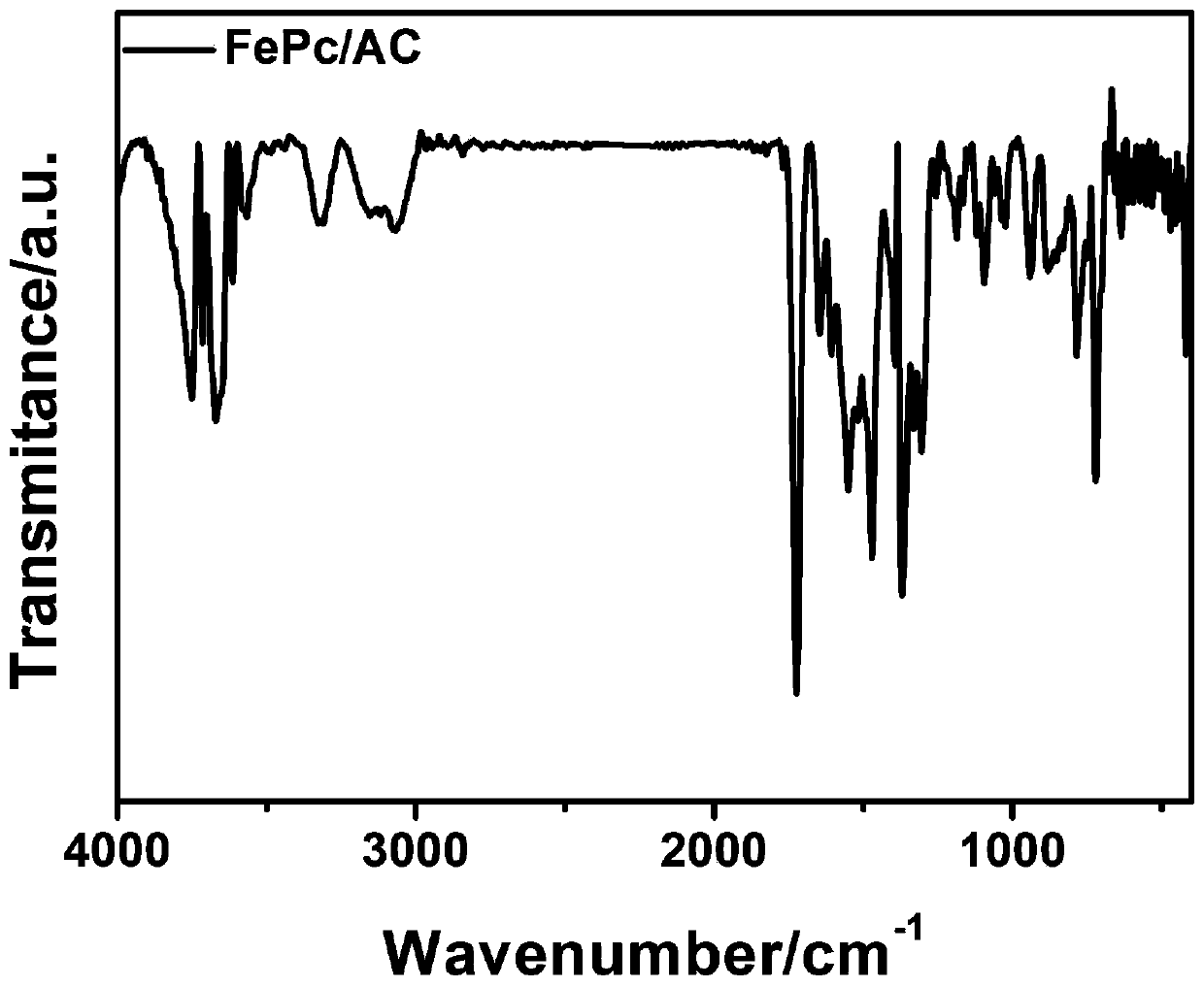

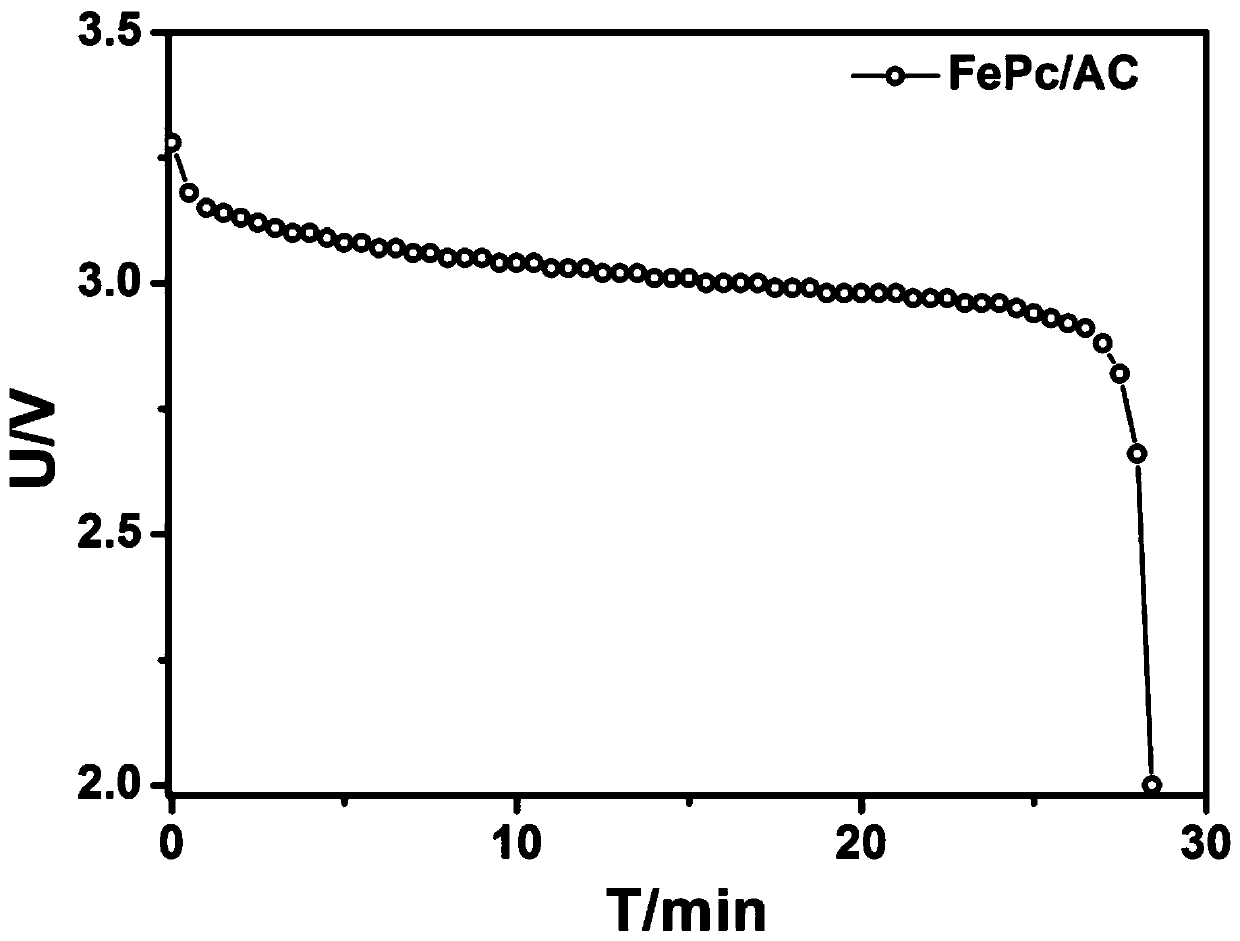

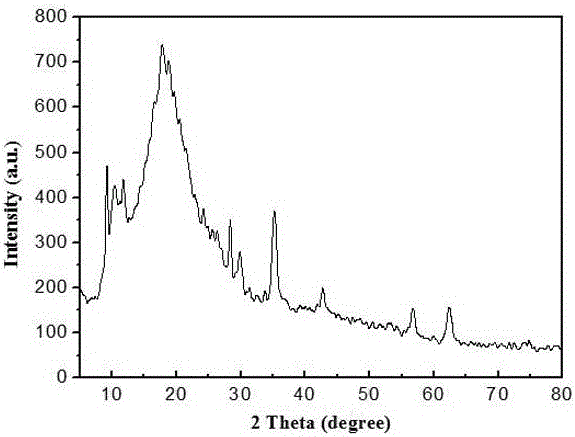

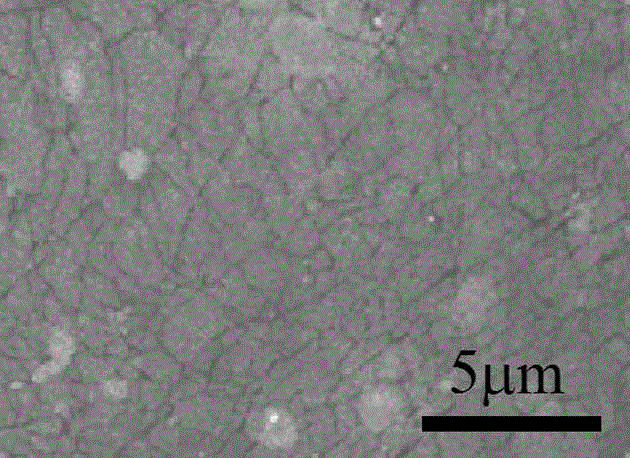

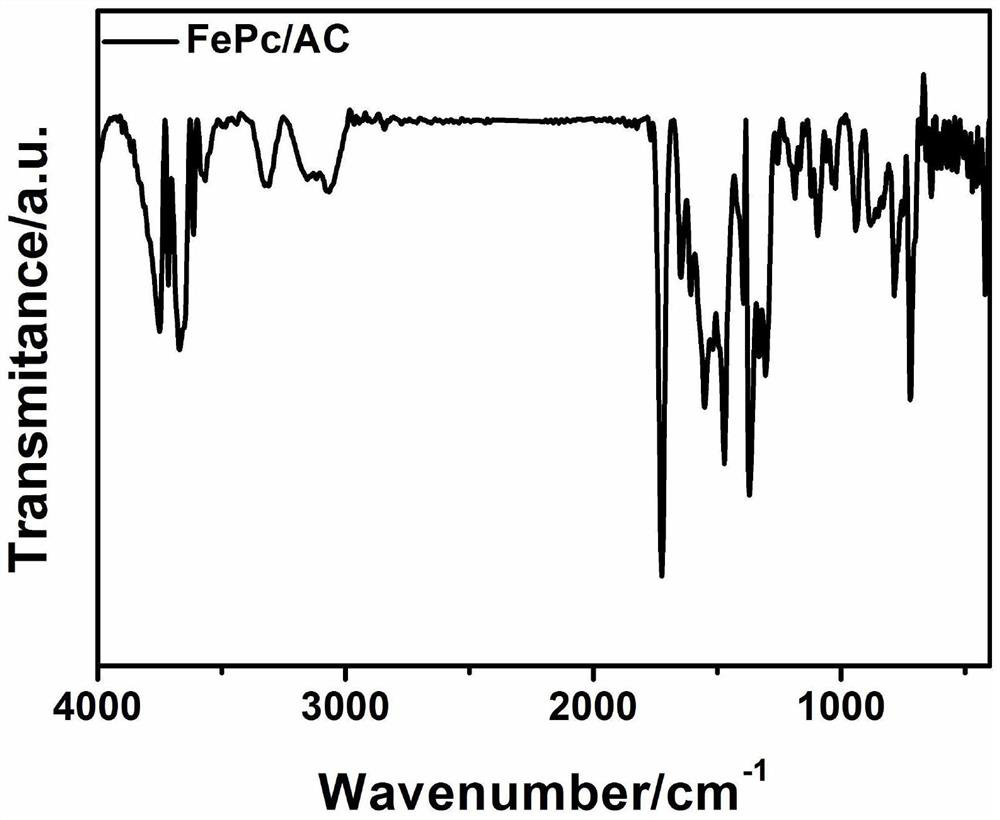

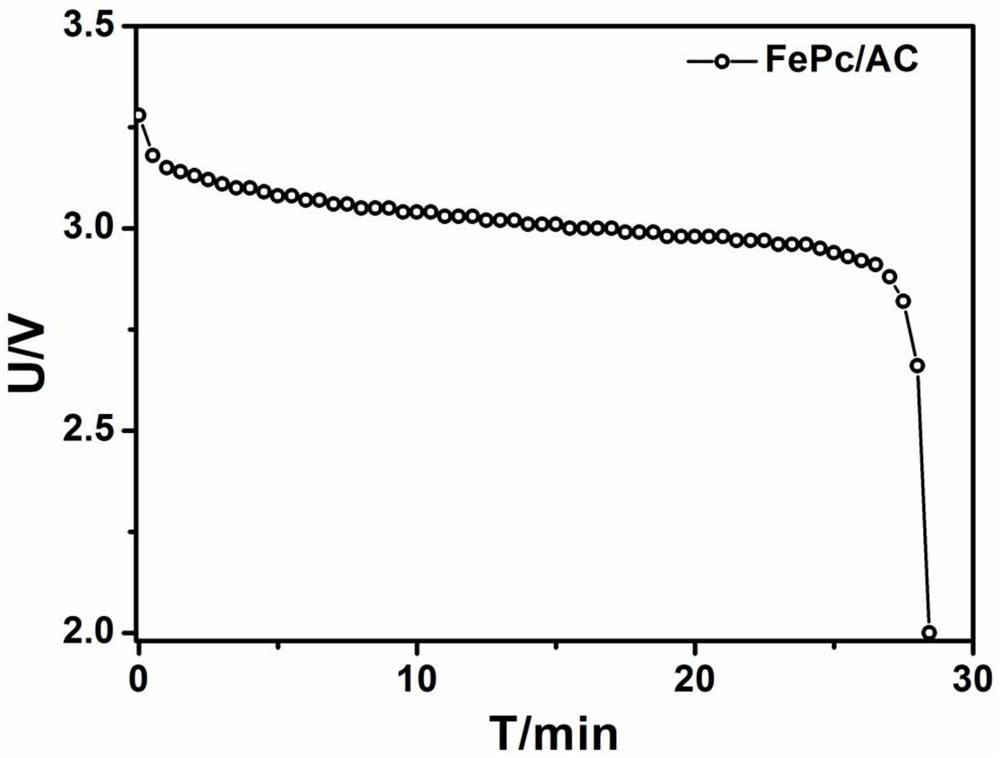

Preparation method of iron phthalocyanine/activated carbon Li/SOCl2 battery positive electrode catalytic material

ActiveCN111063889AIncrease capacityWork lessCell electrodesNon-aqueous electrolyte cellsActivated carbonAmmonium ferrous sulfate

The invention discloses a preparation method of an iron phthalocyanine / activated carbon Li / SOCl2 battery positive electrode catalytic material, which comprises the following steps: taking and mixing phthalic anhydride and activated carbon to obtain a mixture; taking and mixing urea, ammonium molybdate and ammonium ferrous sulfate hexahydrate with the mixture, grinding the obtained mixture, puttingthe ground mixture into a ceramic crucible, putting the ceramic crucible in a muffle furnace and carrying out sintering to obtain a sinter; and cooling the sinter to room temperature, cleaning and filtering the sinter after immersion cleaning, and drying the sinter to obtain the iron phthalocyanine / activated carbon Li / SOCl2 battery positive electrode catalytic material. The method has the advantages of good product dispersion degree, high purity, short synthesis period, low cost and the like.

Owner:SHAANXI UNIV OF SCI & TECH

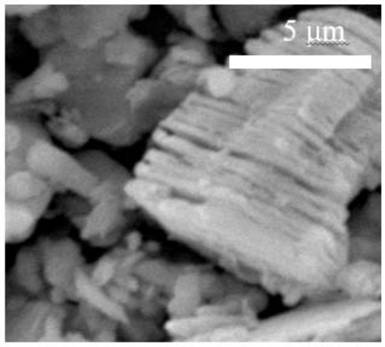

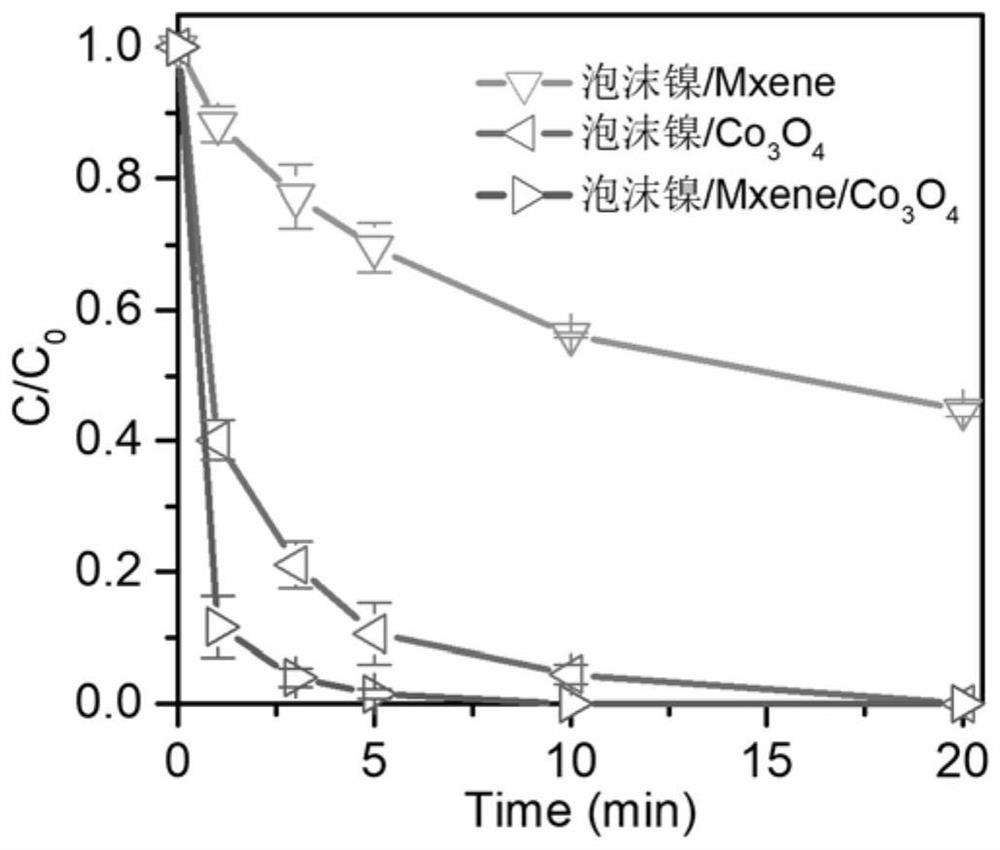

Foamed nickel/MXene-Co3O4 composite electrode and preparation method thereof

ActiveCN113277601ALarge specific surface areaReduce usageMaterial nanotechnologyTransportation and packagingComposite electrodePtru catalyst

The invention discloses a foamed nickel / MXene-Co3O4 composite electrode and a preparation method thereof. The preparation method comprises the following steps of: (1) pretreatment of foamed nickel, namely, taking the foamed nickel, carrying out ultrasonic cleaning with sulfuric acid, ethanol and deionized water in sequence, and performing drying at a constant temperature; and (2) preparation of a composite electrode, namely, mixing MXene and Co3O4 to prepare mixed powder, coating the surface of the foamed nickel with the mixed powder, and performing vacuum plasma sintering to prepare the composite electrode. The foam material composite electrode is prepared through the foamed nickel, the MXene and the Co3O4, the MXene-Co3O4 mixed powder is stably combined through the foamed nickel under the high-temperature and high-pressure effects of a vacuum plasma sintering furnace, use of an adhesive is avoided, the preparation cost is reduced, and the preparation time is only 40-60 min; the organ-shaped structure of MXene can effectively accommodate and disperse a catalyst, the problem that the catalyst is easy to agglomerate is overcome, the activity and stability of the catalyst are improved, and the prepared electrode is large in specific surface area, and good in conductivity, and an electrode material with excellent performance can be formed.

Owner:DONGGUAN UNIV OF TECH

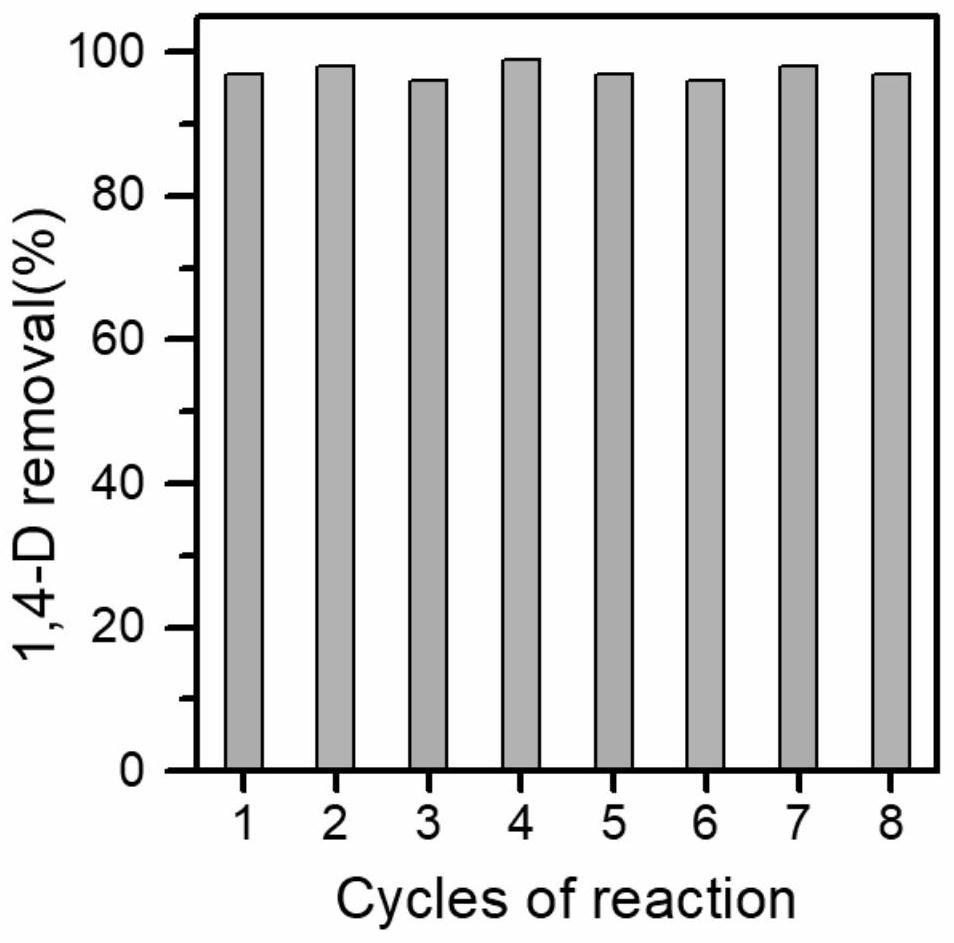

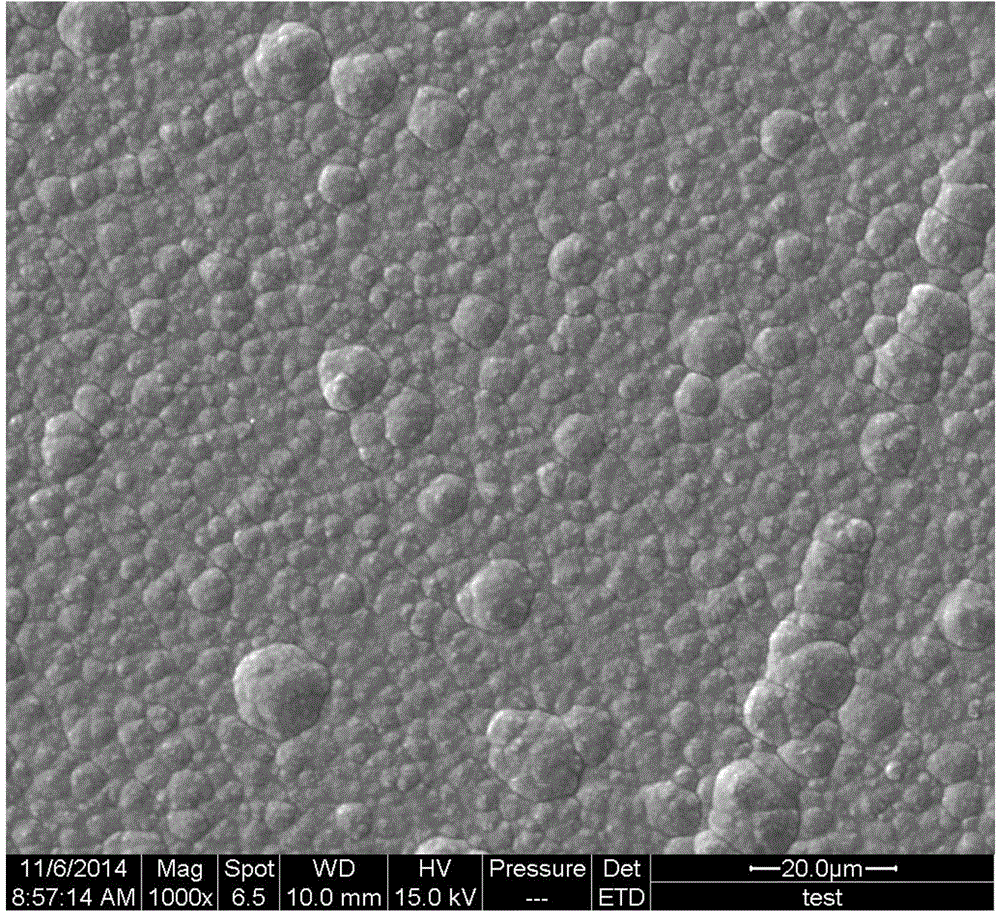

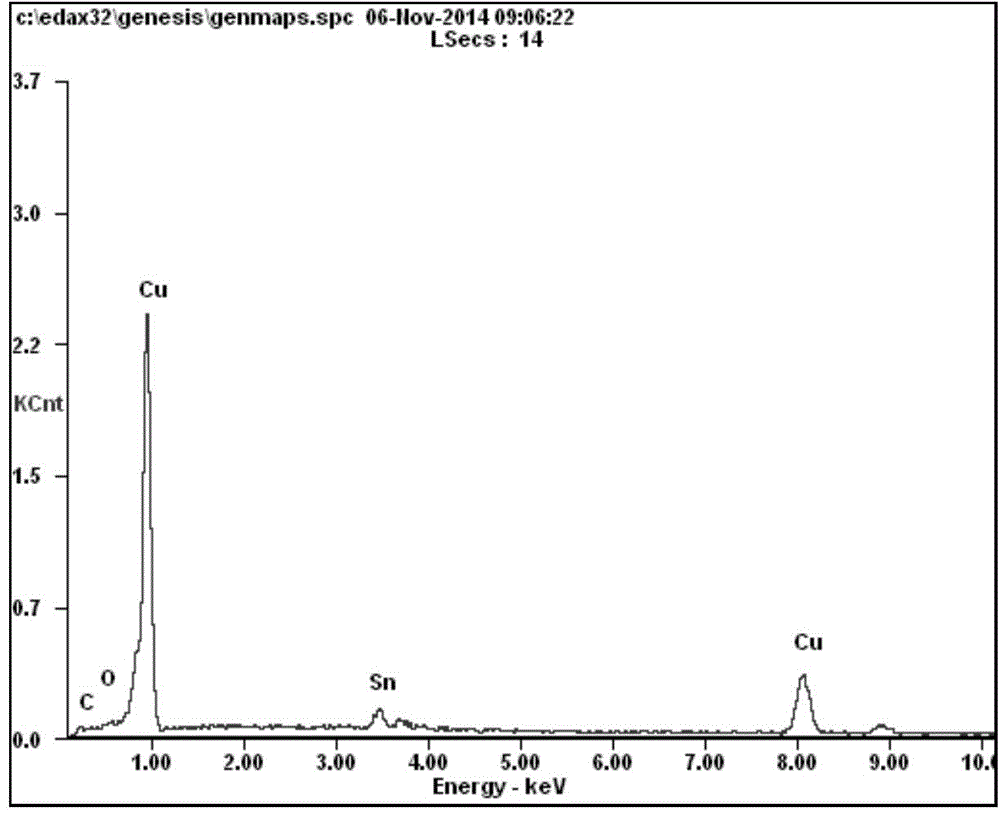

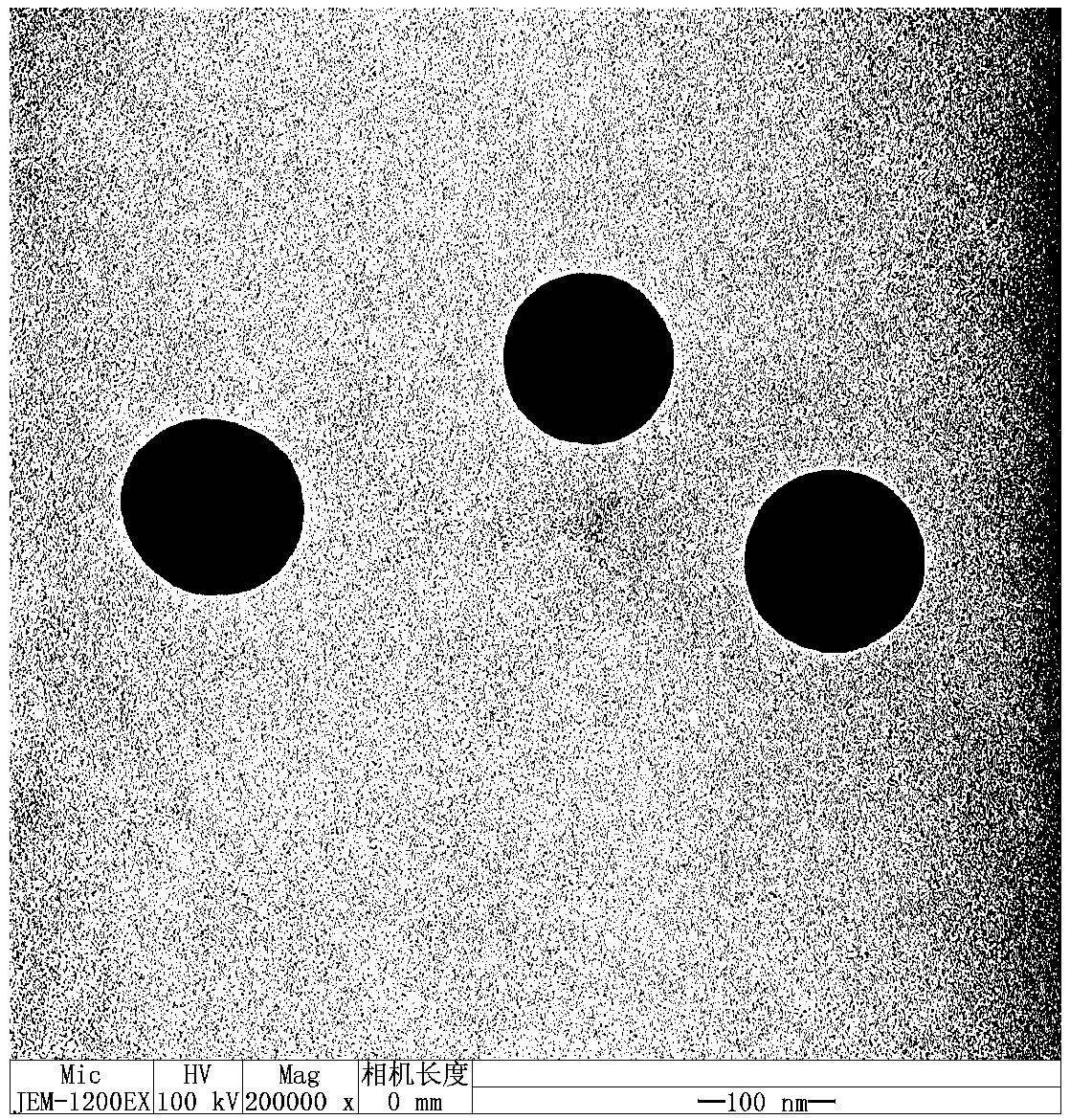

Method for obtaining nano Cu-Sn-graphite composite coating and Cu-Sn-graphite electroplating solution

InactiveCN104694997AOvercome the problem of easy reunionImprove compactnessElectrolytic coatingsSteam drumPollution

The invention provides a method for obtaining a nano Cu-Sn-graphite composite coating and a Cu-Sn-graphite electroplating solution. The method comprises the following steps: adding a nano graphite sol prepared by an electrolytic process into a Cu-Sn plating solution to prepare a Cu-Sn-graphite electroplating solution, putting a metal component into the Cu-Sn-graphite electroplating solution, and carrying out electroplating under the following conditions to obtain the composite coating containing copper, tin, graphite and copper-tin crystallized product: the temperature is 35-45 DEG C, the stirring speed is 100-200 r / min, the pH value is 9-10, the current form is pulse current, the current density is 2-4 A / dm<2>, the duty ratio is 30-80%, and the frequency is 50-5000Hz. The method can perform plating on a complex curved surface, has the advantages of no pollution of the plating solution and the like, and can easily implement large-scale production. The coating obtained by the method has the advantages of excellent wearability, low friction factor, favorable corrosion resistance, favorable compactness, uniform and controllable thickness, no pinhole steam drum and the like.

Owner:HARBIN ENG UNIV

Silicon dioxide-rare earth-titanium dioxide hybrid material and preparation method thereof

The invention puts forward a silicon dioxide-rare earth-titanium dioxide hybrid material and a preparation method thereof. The material comprises silicon dioxide, a rare earth complex and titanium dioxide. The silicon dioxide is the core and is externally coated with the rare earth complex to form a first shell, and the rare earth complex is external coated with titanium dioxide to form a second shell; and the mass ratio of silicon dioxide to the rare earth complex to titanium dioxide in the hybrid material is 1:0.3:0.6-2:0.1:1.7. The hybrid material has a core-shell structure, uniform size distribution, good morphology and uniform dispersion; the rare earth complex is coated with silica spheres to overcome the problem that the rare earth complex is easy to agglomerate, has good fluorescence performance, and is greatly applied in the fields of energy storage, solar cells, photonic devices, catalysis and the like; titanium dioxide is at the outermost layer of the hybrid material, whicheffectively reduces the nonradiative transition of rare earth complexes, optimizes the luminous efficiency of the rare earth complex and improves stability.

Owner:QINGDAO UNIV

A kind of transparent nano-zirconia liquid phase dispersion and its preparation method and application

ActiveCN106277049BLong-term stable and uniform dispersionOvercome the problem of easy reunionNanotechnologyZirconium oxidesActive agentSurface-active agents

The invention discloses transparent nanometer zirconium dioxide liquid phase dispersoid, and a preparation method and application thereof. The dispersoid comprises liquid phase media and nanometer zirconium dioxide particles, wherein the nanometer zirconium dioxide particles are uniformly dispersed into liquid phase media; the solid content of the dispersoid is 1 weight percent to 50 weight percent; the one-dimensional dimension of the nanometer zirconium dioxide particles is 1 to 12nm; the liquid phase media are water, organic solvents, a mixture of water-soluble organic solvents and water, or a mixture of different organic solvents. The nanometer zirconium dioxide in the product has high crystallinity degree; the particle diameter is small; the distribution is uniform; any surfactant is not contained; the purity is high; the dispersion effect is good; no sedimentation occurs after the still standing for 6 months or longer. The product prepared by the method does not need any treatment, and is directly the transparent nanometer zirconium dioxide liquid phase dispersoid; any substance does not need to be added for dispersion assistance; the problems of easy agglomeration, poor dispersibility and poor optical performance of the composite material are solved; higher application performance and wider application ranges are given to the product.

Owner:BEIJING UNIV OF CHEM TECH

In-situ synthesis of cadmium oxide nanometer gas-sensitive element with secondary pore structure

InactiveCN105548274AOvercome the problem of easy reunionHigh selectivityDecorative surface effectsMaterial resistanceDiethyl etherNitrogen gas

The invention discloses a cadmium oxide nanometer gas-sensitive element with a secondary pore structure. The cadmium oxide nanometer gas sensitive element is synthesized through the following steps: with ethylene glycol monomethyl ether as a solvent, preparing a mixed solution of 0.1 M of zinc acetate and 0.2 M of ethanolamine, soaking a glass slide into the mixed solution, and carrying out annealing treatment; preparing a mixed solution of 0.025 M of zinc nitrate and 0.025 M of hexamethylene tetramine, soaking the above-mentioned glass slide into the mixed solution, and carrying out heat-preserving so as to obtain a nanorod array of zinc oxide, wherein the nanorod array is used as a seed layer for growing cadmium oxide; placing cadmium sulfide (CdS) powder into an evacuated tubular furnace, placing an above-mentioned zinc oxide-grown substrate at a position 30 cm below the cadmium sulfide (CdS) powder, then introducing nitrogen and air, carrying out heating to 650 DEG C so as to obtain a nanosheet array of cadmium (Cd), and carrying out heat-preserving at 360 to 440 DEG C for 30 min so as to obtain a nanometer structure of cadmium oxide; and cutting the glass slide into a rectangular shape with a size of 0.5 cm * 1.0 cm, and carrying out coating with electrodes so as to prepare the gas-sensitive element. The gas-sensitive element provided by the invention has the following advantages: at a temperature of 215 DEG C, sensitivity to diethyl ether with a concentration 100 ppm is 138%, and response time and recovery time are 15 seconds and 27 seconds, respectively; meanwhile, the synthetic process is simple, safe and controllable, has low cost and is applicable to large-scale production.

Owner:TIANJIN UNIV

Nanometer onion carbon enhanced titanium-based composite material and preparation method thereof

ActiveCN109112330AImprove mechanical propertiesComplete structureCarbon compoundsTitanium matrix compositesTitanium

The invention discloses a nanometer onion carbon enhanced titanium-based composite material and a preparation method thereof. The composite material is mainly prepared from nanometer onion carbon andbase body titanium, wherein the nanometer onion carbon is used as an enhancing phase and is uniformly distributed in the metal titanium base body to achieve a diffusion enhancing effect. The inventionalso discloses a preparation method of the nanometer onion carbon enhanced titanium-based composite material. By aiming at the defects in the prior art, nanometer diamond is used as raw materials tosynthesize the nanometer onion carbon; the nanometer onion carbon is added into the titanium base body to realize the uniform distribution; sintering shaping is performed to obtain the compact titanium-based composite material. The distribution of the nanometer onion carbon in the titanium-based composite material prepared by the method is uniform; the impurity content is low; the complete form can be maintained in the base body, so that the composite material has excellent comprehensive mechanical property.

Owner:SOUTHEAST UNIV

Graphene based epoxy waterproof and anti-corrosive potting slurry and preparation method thereof

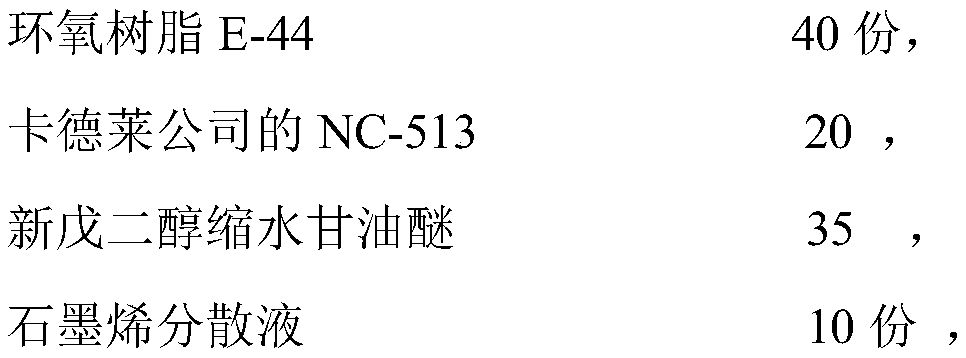

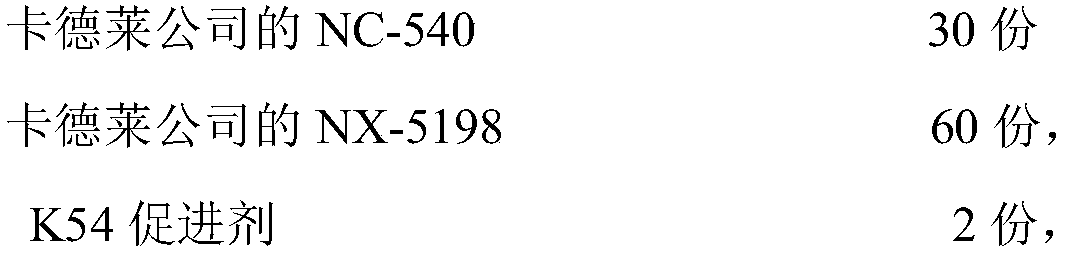

ActiveCN109679553AImprove waterproof performanceImprove anti-corrosion performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyPliability

The invention provides graphene based flexible epoxy waterproof and anti-corrosive potting slurry. The slurry contains a component A and a component B. By means of addition of a graphene anti-corrosive material, graphene is dispersed in epoxy resin uniformly through a dispersion liquid or in a manner of being mixed with glass beads, the concrete potting slurry with excellent waterproof and anti-corrosive effects and flexibility is obtained, cracking in a using process is reduced, and functional service life of concrete is prolonged.

Owner:SICHUAN SHUYANG WATERPROOF MATERIAL

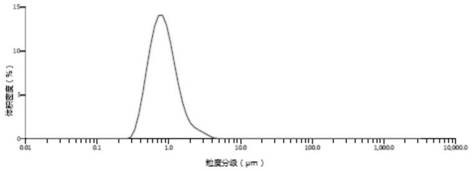

High-dispersity indium oxide and preparation method thereof

InactiveCN112645379AGood dispersionHigh crystallinityElectrolysis componentsGallium/indium/thallium compoundsElectrolytic agentCrystallinity

The invention provides high-dispersity indium oxide and a preparation method thereof. The preparation method comprises the following steps: a) taking metal indium as an anode, an inert electrode as a cathode and an ammonium nitrate aqueous solution as an electrolyte, and obtaining indium hydroxide slurry through an electrolytic method; b) adding an indium nitrate solution into the indium hydroxide slurry obtained in the step a) to enable the mass ratio of the added indium ions to indium hydroxide to be 0.01%-1%, adjusting the pH value to be 4-8, then carrying out hydrothermal reaction, and washing and drying a product to obtain indium hydroxide powder with high crystallinity and high dispersity; and c) calcining the high-crystallinity and high-dispersity indium hydroxide powder obtained in the step b) to obtain the high-dispersity indium oxide. According to the preparation method, indium hydroxide and indium oxide which are uniform in size distribution, high in dispersity and complete in crystal structure are successfully prepared in an electrolytic hydrothermal method combined mode, and the problem that indium oxide prepared from fine indium hydroxide powder synthesized through a common electrolytic method is prone to agglomeration in the calcining process is solved.

Owner:FIRST RARE MATERIALS CO LTD

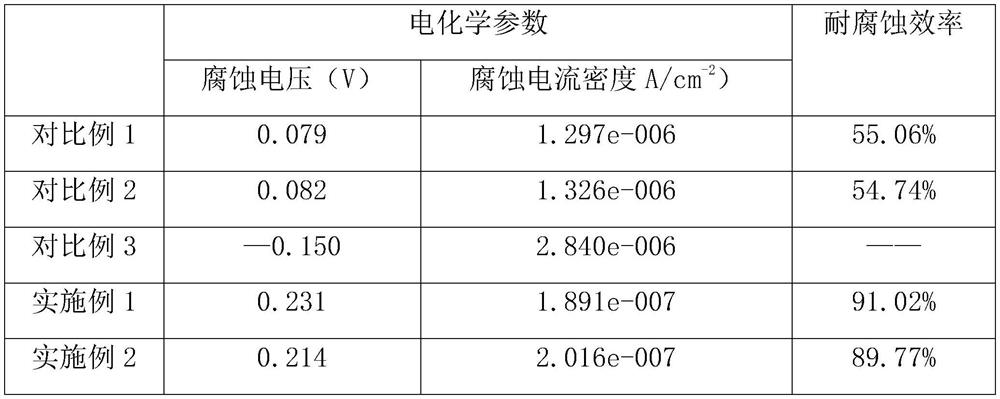

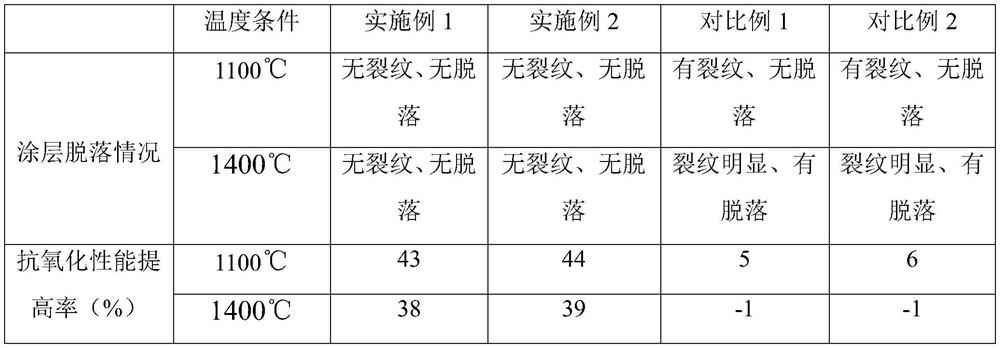

Graphene oxide coated ceramic particle corrosion-resistant gradient coating and preparation method thereof

PendingCN114477965AWrap implementationOvercome the problem of easy reunionHeat inorganic powder coatingCeramic coatingAdhesive

The invention discloses a preparation method of a graphene oxide coated ceramic particle corrosion-resistant gradient coating. The preparation method comprises the following steps: preparing graphene oxide coated Cr3C2 ceramic particles, carrying out dispersion reaction on the graphene oxide coated Cr3C2 ceramic particles and metal oxide powder to generate a hybrid reactant, finally mixing the hybrid reactant with ceramic aggregate and an adhesive, and curing and sintering to prepare the corrosion-resistant ceramic coating. The core-shell structure of the ceramic particles and the graphene oxide is favorable for improving the bonding strength of the graphene oxide and a ceramic matrix, avoiding gaps on an interface, improving the compactness of the coating, reducing the generation of cracks of the coating and improving the high-temperature corrosion resistance of the coating; and meanwhile, the core-shell structure is beneficial to improving the oxidation resistance of the coating and prolonging the service life of the coating.

Owner:ZHAOSHAN TECH BEIJING CO LTD

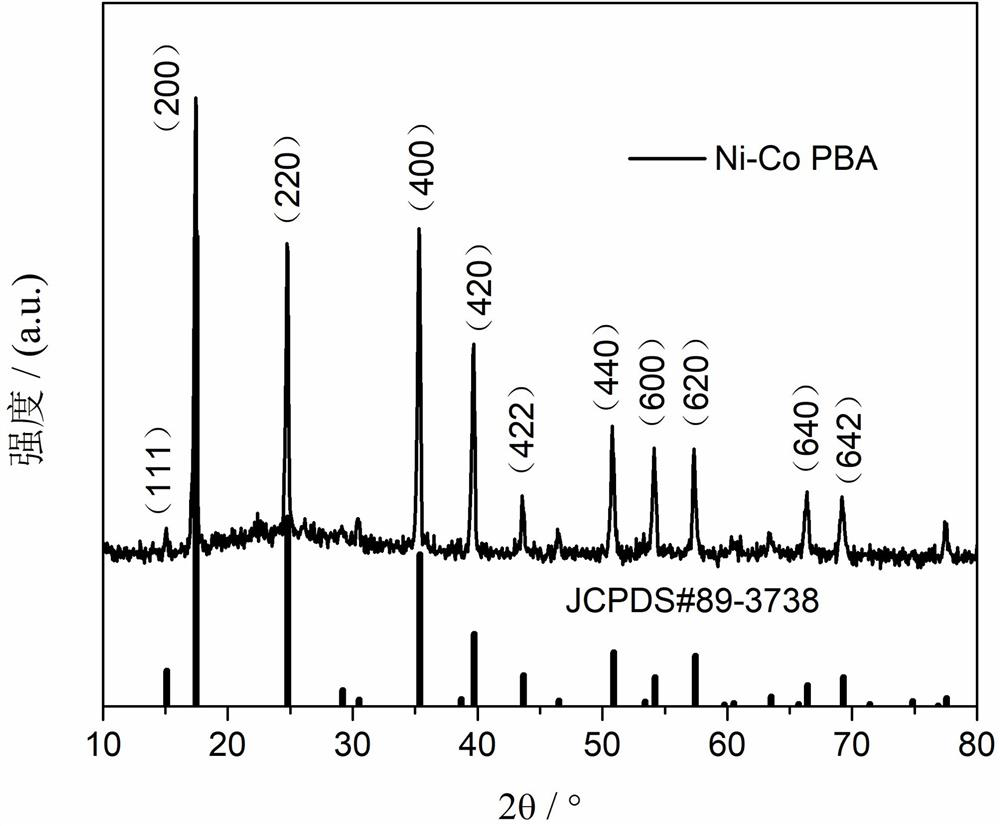

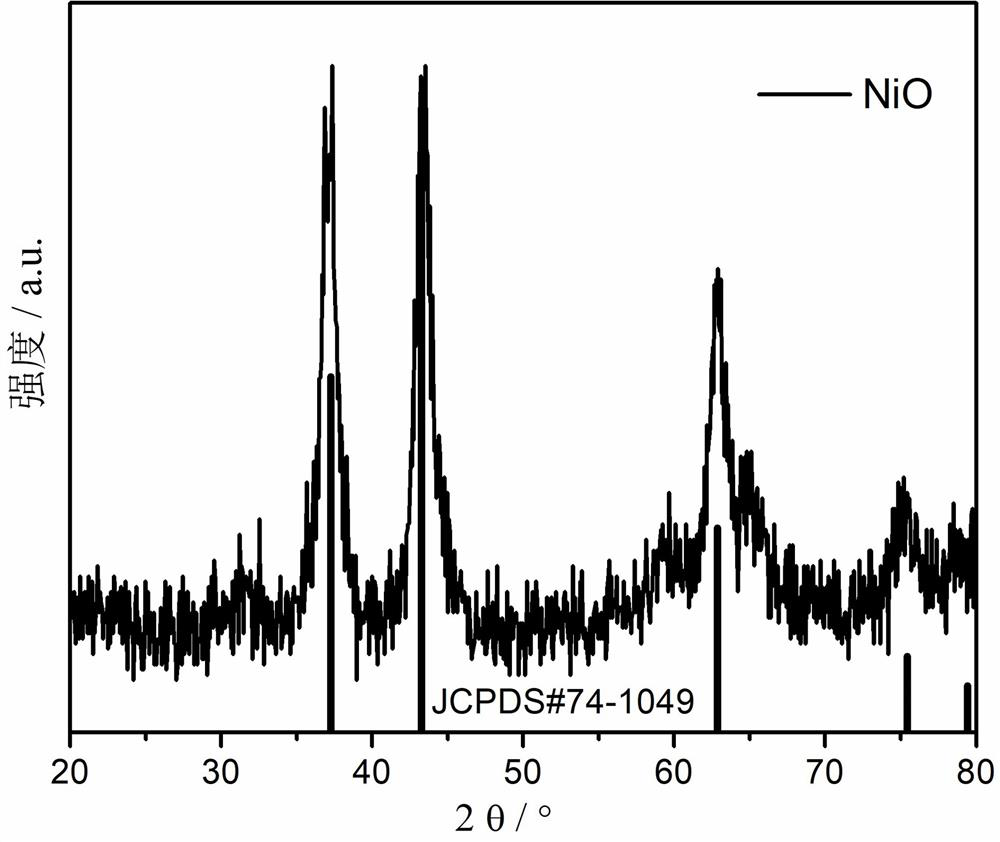

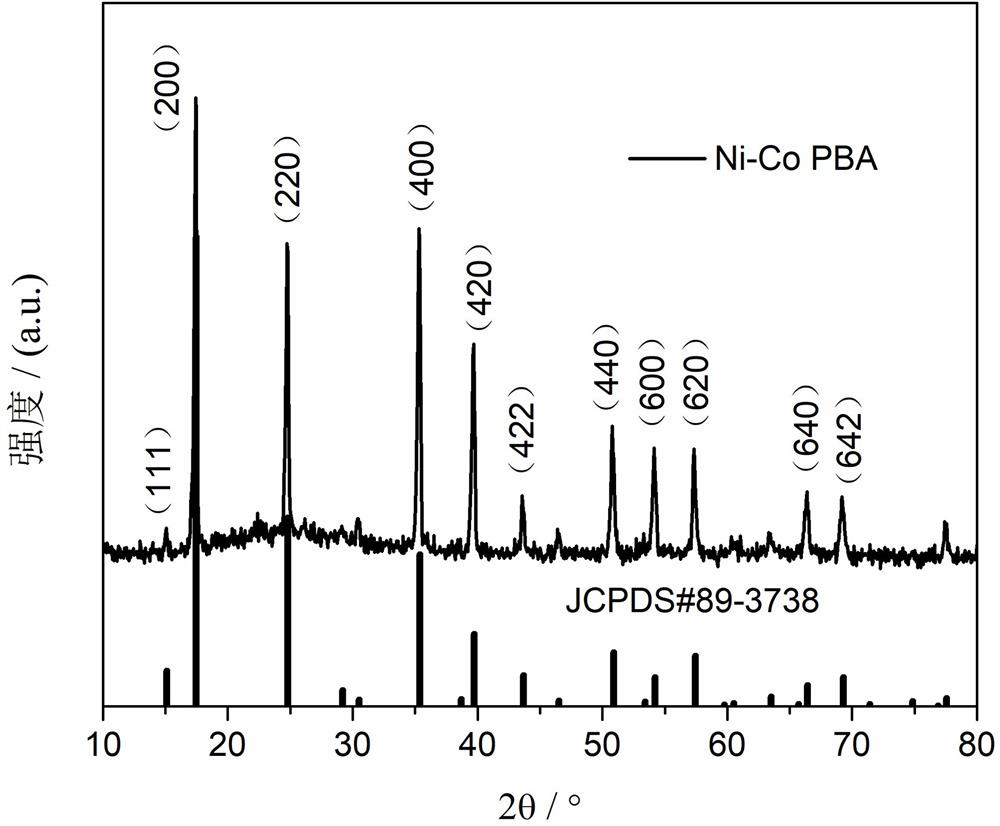

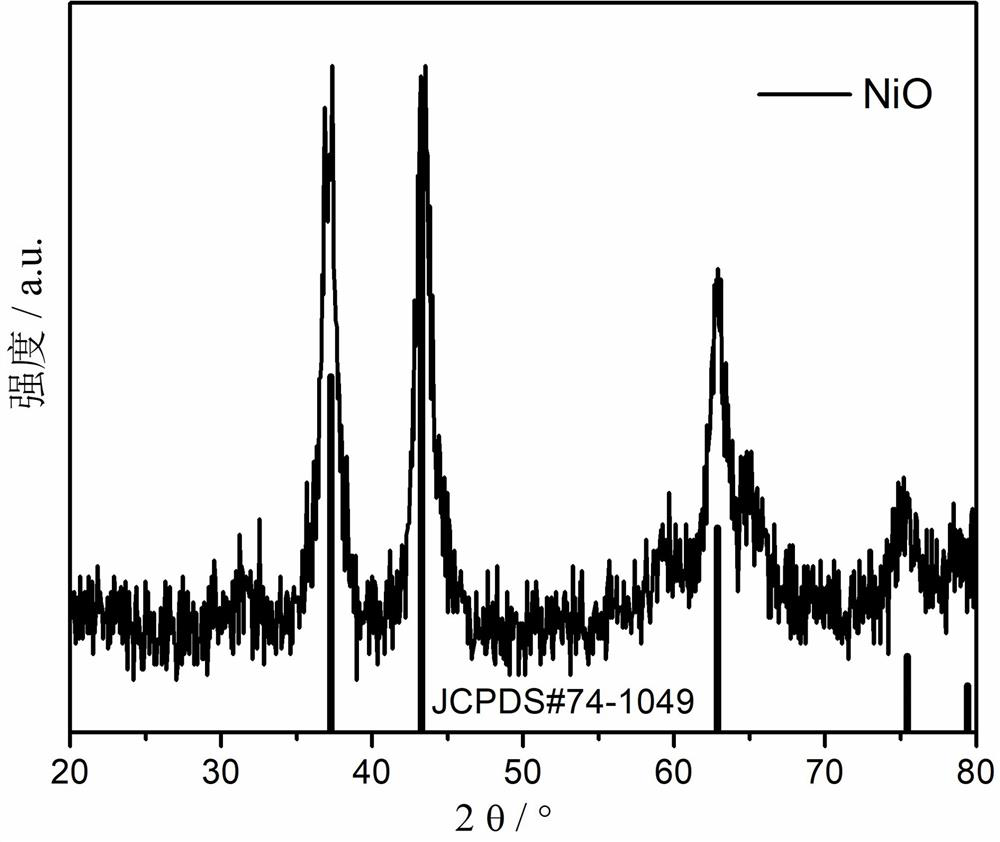

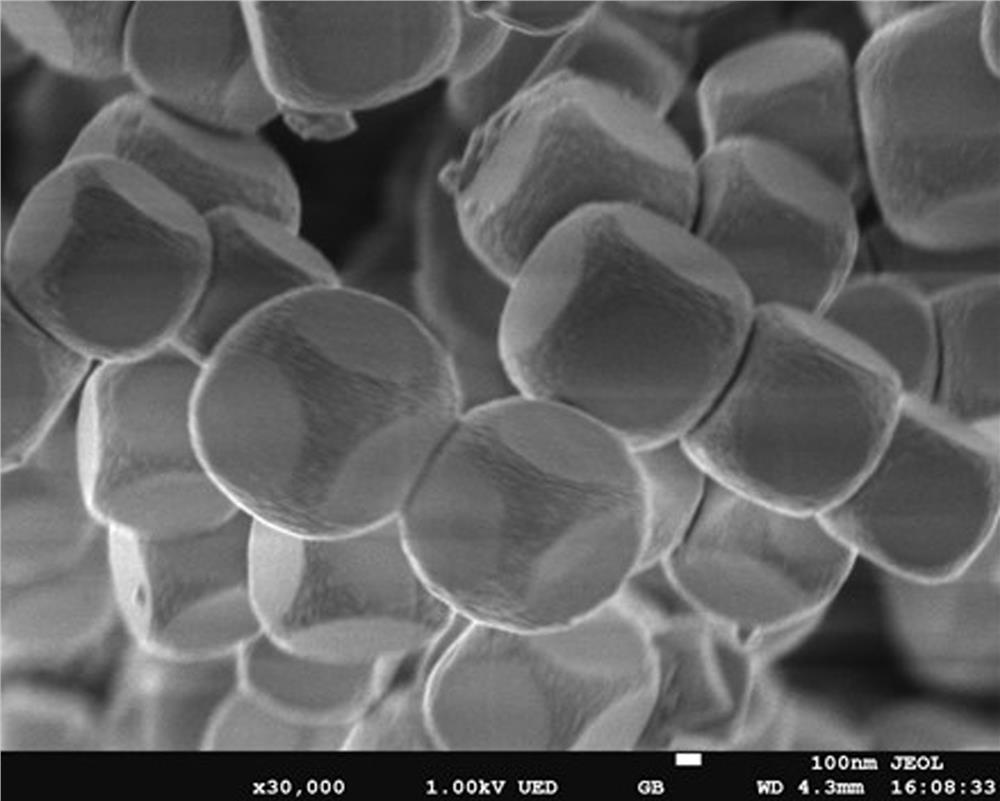

Preparation method of NiO electrode material derived from MOFs

ActiveCN113506689ALarge specific surface areaPore adjustableHybrid/EDL manufactureAlcoholPotassium cyanide

The invention particularly relates to a preparation method of a NiO electrode material derived from MOFs (Metal-Organic Frameworks), and solves the problems that an existing preparation method of a NiO electrode material is relatively small in quantity of prepared samples and easy to agglomerate. The invention relates to a preparation method of a NiO electrode material derived from MOFs. The method is realized by adopting the following steps: S1, dissolving nickel nitrate hexahydrate in deionized water; S2, adding sodium citrate dehydrate into the solution to obtain a solution A; S3, dissolving cobalt potassium cyanide in deionized water to obtain a solution B; S4, pouring the solution B into the solution A, stirring, and standing to obtain a precipitate C; S5, washing the precipitate with deionized water and absolute ethyl alcohol to obtain a washed precipitate C; S6, drying to obtain powder C; and S7, carrying out heat treatment on the powder C to prepare the NiO supercapacitor electrode material. The NiCo-PBA is used as the precursor, the NiO supercapacitor electrode material with good performance is obtained through direct calcination, the operation process is simple, the production cost is low, and large-scale preparation can be achieved.

Owner:ZHONGBEI UNIV

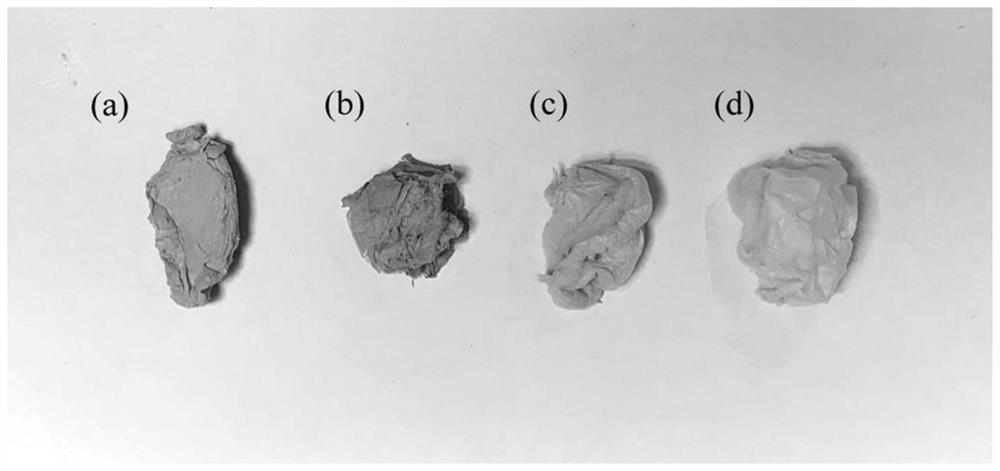

Method for modifying cellulose nanocrystals by using photoresponsive fluorine-containing amphiphilic block copolymer

ActiveCN110938211AOvercoming the strong hydrophilicityOvercome the problem of easy reunionACRYLATES COPOLYMERPolymer chemistry

The invention discloses a method for modifying cellulose nanocrystals by using a photoresponsive fluorine-containing amphiphilic block copolymer. The method is specifically implemented according to the following steps: step 1, preparing a hydrophilic acrylate polymer; 2, preparing a hydrophilic acrylate copolymer containing an epoxy group; step 3, preparing a fluorine-containing amphiphilic blockcopolymer; step 4, preparing the pure photoresponsive fluorine-containing amphiphilic block copolymer; and step 5, preparing the photoresponsive fluorine-containing amphiphilic block copolymer modified cellulose nanocrystals. According to the invention, the problems of strong hydrophilicity and easy agglomeration of cellulose nanocrystals are overcome, and the material is endowed with the characteristic of photoresponse.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of preparation method and application of graphene-polypyrrole-gold nanoparticle composite material

ActiveCN108760855BGood dispersionOvercome the problem of easy reunionMaterial electrochemical variablesEscherichia coliPolypyrrole

The invention discloses a graphene-polypyrrole-gold nanoparticle composite material which is characterized in that a method combining in-situ chemical polymerization with electrostatic adsorption is adopted to load gold nanoparticles onto a graphene-polypyrrole composite material. The preparation method comprises the following steps: 1) configuration of a solution; 2) preparation of a polypyrrole-graphene nano-composite material by a mixed reaction of the solution; 3) preparation of a gold nanoparticle solution; 4) adsorption of the gold nanoparticles. The invention further discloses the application of the graphene-polypyrrole-gold nanoparticle composite material, and the composite material is applied to the modification of electrodes of an impedance type escherichia coli biosensor, wherea linear range of detection of the escherichia coli is 1*102-1*107 CFU / mL, and the minimum detection limit is 100 CFU / mL. The impedance type escherichia coli biosensor prepared by the invention has the advantages of simple operation, low cost, convenient use, high selectivity and the like, and thus has great potential application values in the fields of food safety, clinical analysis and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

A kind of preparation method of graphene oxide composite material containing lactobionic acid modification

The invention relates to a preparation method of a graphene oxide composite material modified with lactobionic acid, comprising: producing chemical bonds between graphene oxide and PEI through the action of an activator EDC in dimethyl sulfoxide, dialysis and freeze-drying, and synthesizing GO ‑PEI; Dissolve LA in phosphate buffer, add EDC, activate with NHS, add NH 2 ‑mPEG‑COOH, at room temperature, react for 12‑24 hours, dialyze, freeze-dry to obtain PEG‑LA; dissolve the above GO‑PEI in water, add FITC solution; add the above PEG‑LA to EDC and NHS for activation, add GO‑LA PEI solution, react to get GO‑PEI‑FI‑PEG‑LA, add triethylamine to mix, add acetic anhydride, react at room temperature, dialyze, freeze-dry to obtain. The preparation process of the invention is simple, the experimental conditions are normal temperature and pressure, and the operation is easy.

Owner:DONGHUA UNIV

fe 3 o 4 @go/nrMagnetic elastomer composite material and its preparation method

The invention relates to magnetic elastomer composite materials, in particular to a Fe3O4@GO / NR magnetic elastomer composite material and a preparation method, and solves the problem that magnetic particles in existing materials are nonuniform in dispersion, prone to gathering, unstable in structural performance and low in mechanical performance. The preparation method includes: 1), adopting a chemical co-precipitation method to prepare Fe3O4 water-base magnetic liquid; 2), adopting an improved Hummers method to prepare graphite oxide, and preparing GO suspension liquid; 3), preparing stabilizer, vulcanizer and promoter dispersoid; 4), adopting an emulsion blending method to prepare the Fe3O4@GO / NR magnetic elastomer composite material. The Fe3O4@GO / NR magnetic elastomer composite material and the preparation method have the advantages that a, vulcanizing temperature is low, preparation process is simple, dispersity of the magnetic particles and GO is improved, the problem of proneness to gathering is solved, and the composite material is stable in structure; b, graphene oxide serves as reactive enhanceosome, so that mechanical performance is improved, the magnetic particles are stabilized, sedimentation and aggregation are prevented, and mechanical performance and magnetic performance are improved; c, the composite material can display excellent elastic mechanical performance, magnetic performance, heat resistance and solvent resistance under low concentration.

Owner:ZHONGBEI UNIV

A kind of iron phthalocyanine/activated carbon li/socl 2 Preparation method of battery cathode catalyst material

ActiveCN111063889BIncrease capacityWork lessCell electrodesNon-aqueous electrolyte cellsIron sulphateIron phthalocyanine

The invention discloses an iron phthalocyanine / activated carbon Li / SOCl 2 The preparation method of the positive electrode catalyst material of the battery comprises: taking phthalic anhydride and activated carbon and mixing them to obtain a mixture; taking urea, ammonium molybdate and ferrous ammonium sulfate hexahydrate and mixing them with the mixture, grinding them, then putting them into a ceramic crucible and Put it in a muffle furnace for sintering to obtain a sintered product; cool to room temperature, soak the sintered product, wash and filter, and dry to obtain iron phthalocyanine / activated carbon Li / SOCl 2 Catalyst material for battery positive electrode. The method has the advantages of good product dispersion, high purity, short synthesis cycle and low cost.

Owner:SHAANXI UNIV OF SCI & TECH

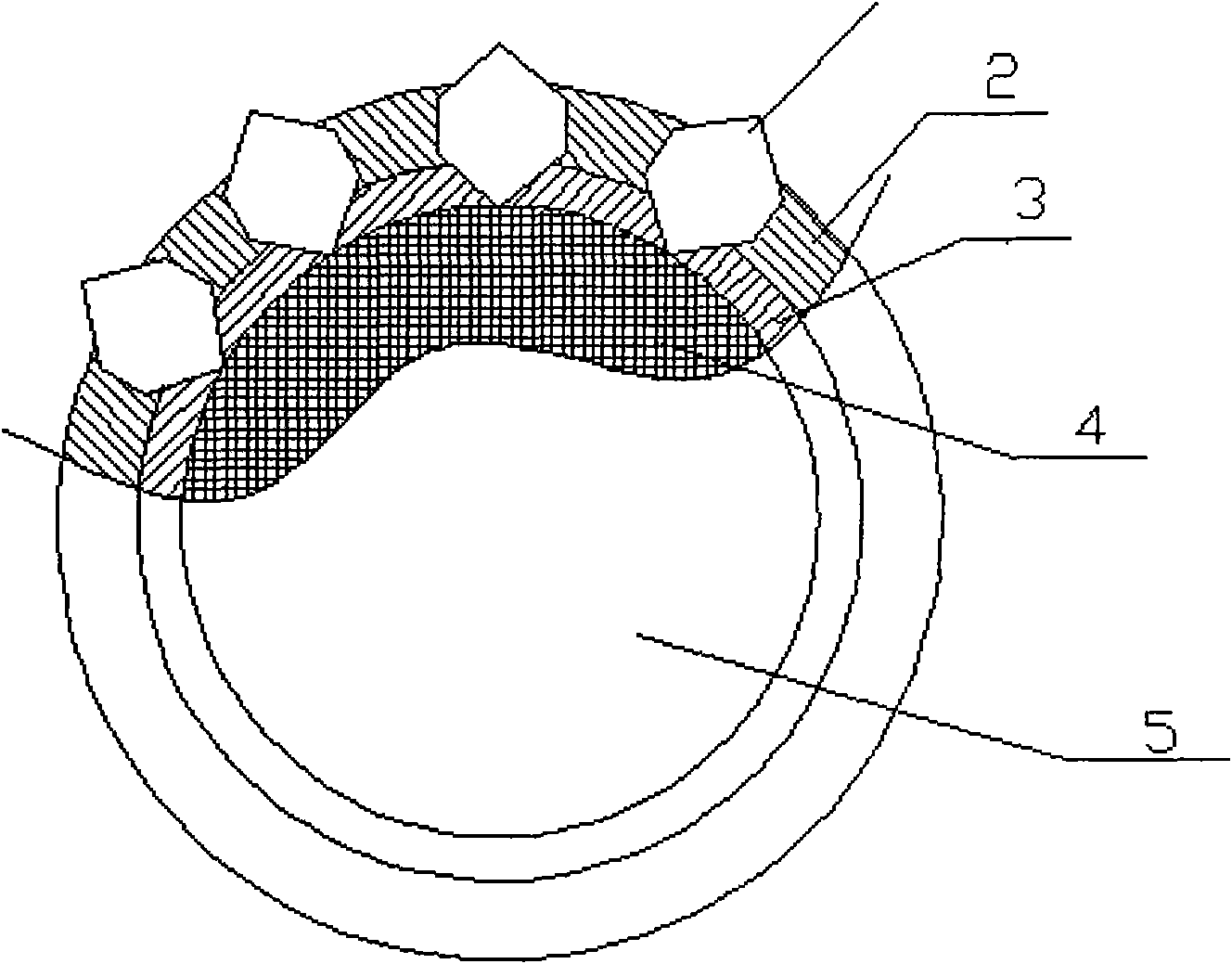

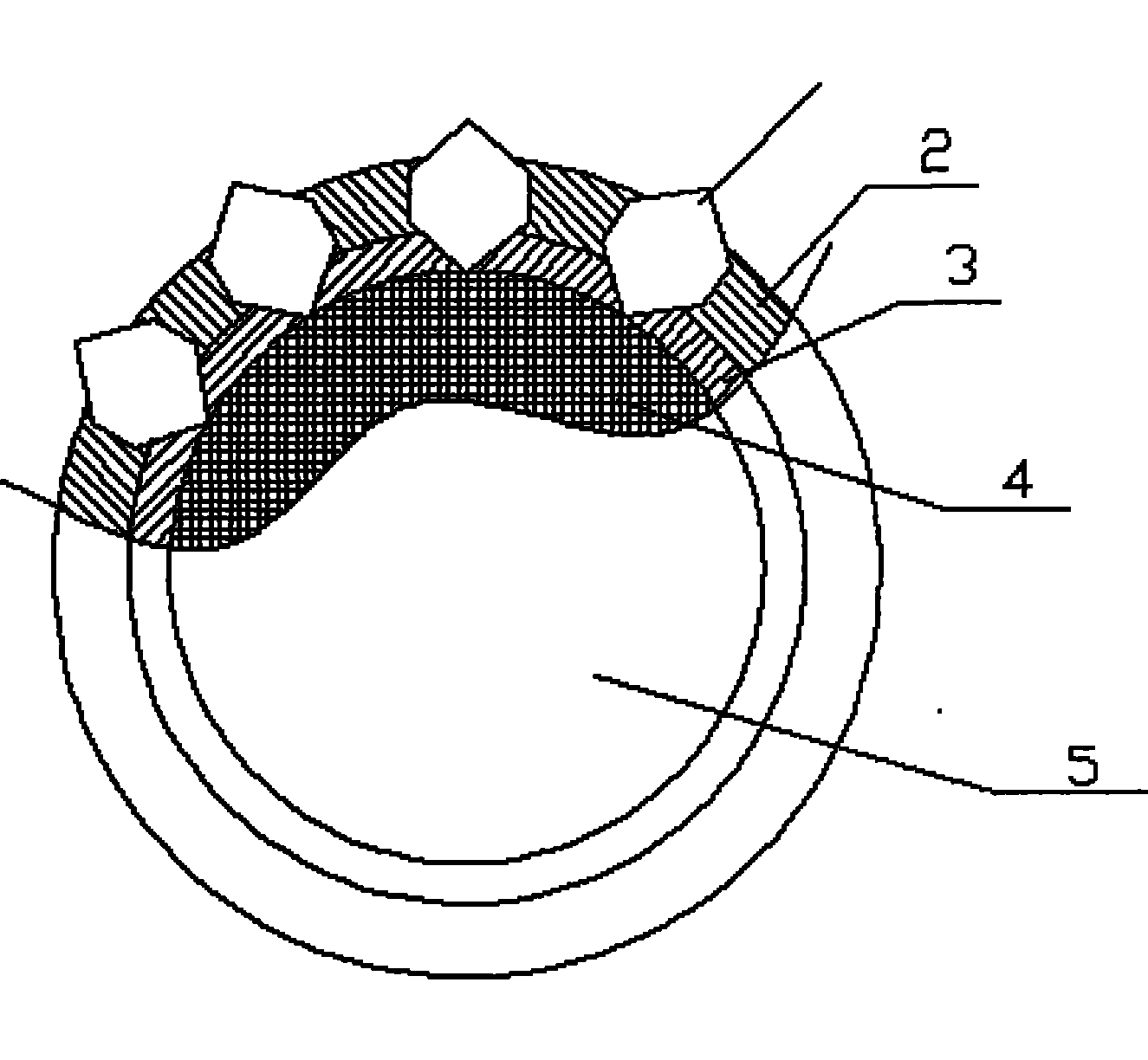

Wire saw for cutting hard and fragile materials and manufacturing method thereof

InactiveCN101564828BSolve problemsOvercome the problem of easy reunionAbrasion apparatusGrinding machinesCopper platingUV curing

Owner:NANJING NORMAL UNIVERSITY

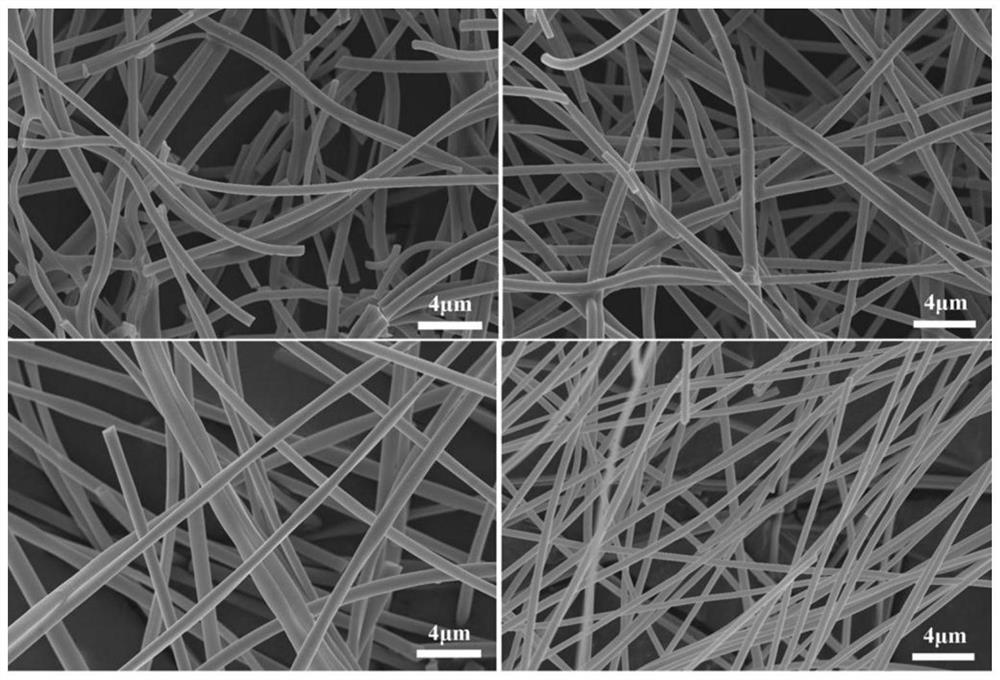

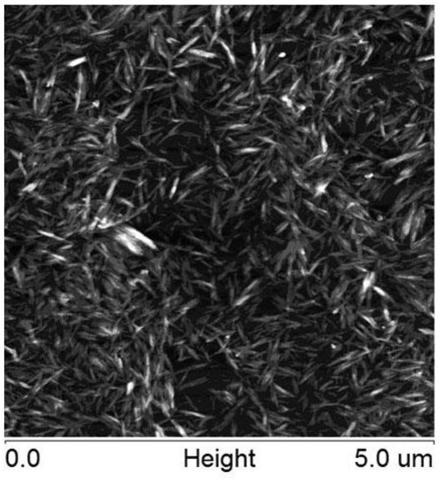

Flexible magnesium ferrite fiber and preparation method and application thereof

ActiveCN112239900AGood flexibilityStable supportOther chemical processesInorganic material artificial filamentsFiberSpinning

The invention relates to a flexible magnesium ferrite fiber and a preparation method and application thereof. The diameter of the magnesium ferrite fiber is about 0.5-1.5 microns, and the magnesium ferrite fiber is composed of magnesium ferrite nano-crystals. The preparation method comprises the following steps: dissolving an iron source, a magnesium source and citric acid in a solvent; adding a spinning aid, and adjusting the solvent to certain viscosity to obtain a precursor spinning solution; and carrying out electrostatic spinning to obtain precursor fibers, and obtaining the flexible magnesium ferrite fibers through heat treatment at a certain temperature. According to the flexible magnesium ferrite fiber prepared by the method, the problem that a magnesium ferrite nano material is easy to agglomerate in an adsorption process is solved, and the problem of poor flexibility of the fiber prepared from the spinning solution formed by directly dissolving the iron source and the magnesium source together with the spinning aid is solved. The fiber has excellent flexibility and self-supporting property, does not agglomerate in an aqueous solution, is easy to magnetically separate, andhas excellent adsorption performance on Pb<2+> ions.

Owner:SHANDONG UNIV

A kind of preparation method of cellulose nanocrystal

The invention discloses a macroscopic preparation method of a cellulose nanocrystal (CNC), which is green and environment-friendly. Firstly, cellulose is crushed and then is pretreated; afterwards, an oxometallate solution and an organic acid are added, the oxydrolysis is carried out, and the CNC with a carboxyl group on a surface is obtained after centrifugal dialysis treatment. The yield of the preparation method can exceed 70 percent; the length of the made CNC can be adjusted in the range of 195nm to 260nm; the content of the carboxyl group on the surface can reach 50mmol / g; compared with a CNC made by a sulfuric-acid acid hydrolysis method, the CNC made by the macroscopic preparation method provided by the invention is increased by 50 to 100 DEG C in heat resistance; used oxometallate and organic acid are both green reagents and are further a few in use levels; problems that the preparation cost of the CNC is high and further the environmental pollution is easily caused, and the like, at present are solved.

Owner:QINGDAO UNIV OF SCI & TECH

A kind of preparation method of mofs-derived nio electrode material

ActiveCN113506689BLarge specific surface areaPore adjustableHybrid/EDL manufacturePotassium cyanideSupercapacitor

The invention specifically relates to a preparation method of a NiO electrode material derived from MOFs, which solves the problems of less sample volume and easy agglomeration in the preparation method of the existing NiO electrode material. A preparation method of MOFs-derived NiO electrode material, the method is realized by the following steps: S1: dissolving nickel nitrate hexahydrate in deionized water; S2: adding sodium citrate dihydrate to the solution to obtain solution A; S3 : dissolve potassium cobalt cyanide in deionized water to obtain solution B; S4: pour solution B into solution A, stir and let stand to obtain precipitate C; S5: wash the precipitate with deionized water and absolute ethanol to obtain Washed precipitate C; S6: drying to obtain powder C; S7: heat treatment of powder C to prepare NiO supercapacitor electrode material. In the present invention, NiCo-PBA is used as a precursor, and NiO supercapacitor electrode material with good performance is obtained by direct calcination. The present invention has simple operation process, low production cost, and can realize mass preparation.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com