A kind of transparent nano-zirconia liquid phase dispersion and its preparation method and application

A nano-zirconia, liquid-phase dispersion technology, applied in the field of nano-materials, can solve the problems of poor dispersion, poor optical properties of composite materials, easy agglomeration of nano-zirconia particles, etc. The effect of improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] A method for preparing transparent nano-zirconia liquid dispersion, including the following steps:

[0084] 1) Dissolve 1.74 g of zirconyl nitrate dihydrate in 70 ml of ethanol to prepare a solution of zirconyl nitrate;

[0085] 2) Dissolve 0.6g of sodium hydroxide in 60ml of ethanol to prepare a sodium hydroxide solution;

[0086] 3) The zirconyl nitrate solution was added dropwise to the sodium hydroxide solution, the reaction temperature was controlled to 15°C, the stirring rate was 800r / min, and the sodium hydroxide solution was used to adjust and control the final pH of the reaction system to 7;

[0087] 4) After reaching the final pH requirement of the reaction system, aging at 65°C for 2 hours;

[0088] 5) Filter the solution and then wash and purify with water to obtain a filter cake;

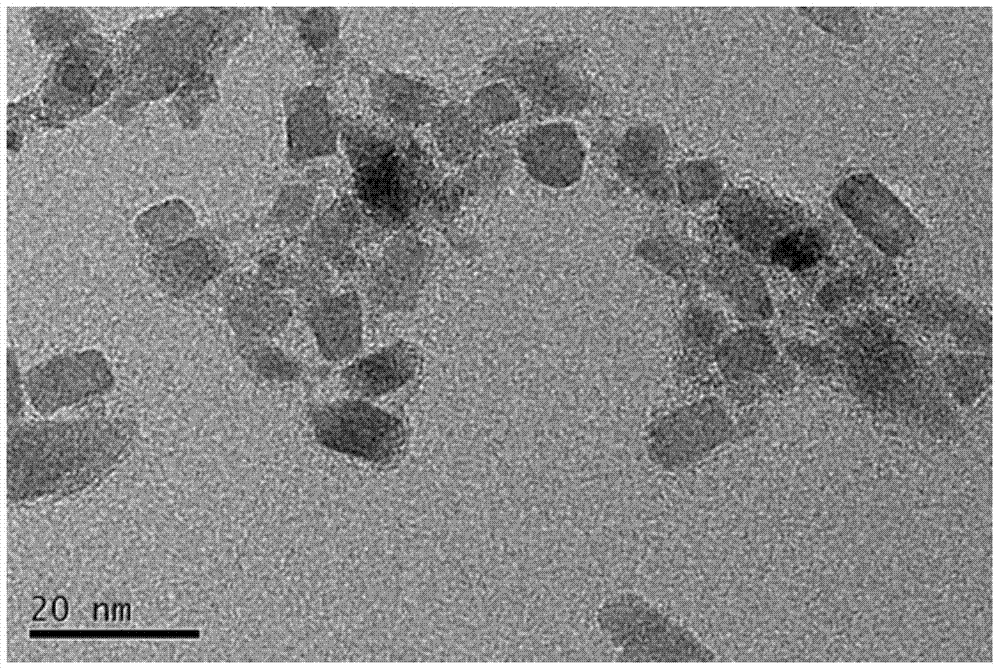

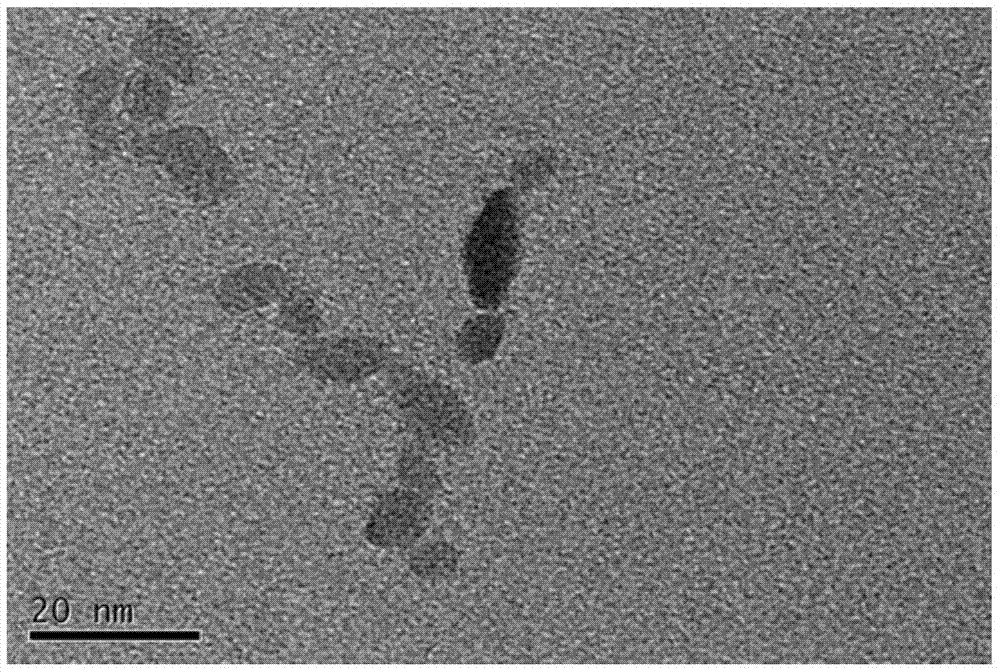

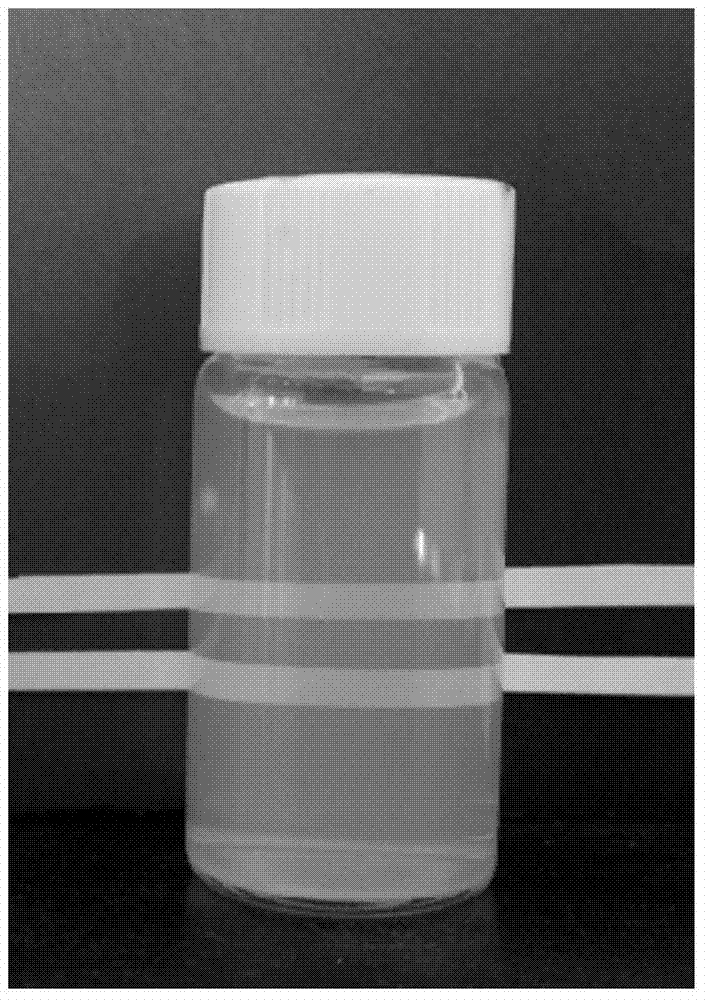

[0089] 6) The purified filter cake was ultrasonically dispersed in 7.2 g of water, transferred to an autoclave, and hydrothermally treated at 150° C. for 24 hours to obtain a transparent an...

Embodiment 2

[0092] A method for preparing transparent nano-zirconia liquid dispersion, including the following steps:

[0093] 1) Dissolve 2.8g zirconium nitrate pentahydrate in 100ml methanol to prepare zirconium nitrate solution;

[0094] 2) Dissolve 1.68g potassium hydroxide in 120ml methanol to prepare potassium hydroxide solution;

[0095] 3) Add the zirconium nitrate solution dropwise to the potassium hydroxide solution, control the reaction temperature to 35°C, and the stirring rate to be 600r / min. Use potassium hydroxide solution to adjust and control the final pH of the reaction system to 5;

[0096] 4) After reaching the final pH requirement of the reaction system, the temperature is increased to 55°C and aged for 4 hours;

[0097] 5) Filter the solution and then wash and purify with water to obtain a filter cake;

[0098] 6) The purified filter cake was ultrasonically dispersed in 15.2 g of water, transferred to an autoclave, and hydrothermally treated at 220° C. for 3 hours to obtain a t...

Embodiment 3

[0101] A method for preparing transparent nano-zirconia liquid dispersion, including the following steps:

[0102] 1) Dissolve 2.1 g of zirconium oxychloride octahydrate in 70 ml of water to prepare a zirconium oxychloride solution;

[0103] 2) Dissolve 0.24g of sodium hydroxide in 50ml of water to prepare a sodium hydroxide solution;

[0104] 3) Add the sodium hydroxide solution dropwise to the zirconium oxychloride solution, control the reaction temperature to 20°C, the stirring rate to 500r / min, and use the sodium hydroxide solution to adjust and control the final pH of the reaction system to 2;

[0105] 4) After reaching the final pH requirement of the reaction system, the temperature is increased to 70°C and aged for 1 hour;

[0106] 5) Transfer the solution to a dialysis bag for washing and purification;

[0107] 6) Transfer the purified reaction solution to an autoclave, hydrothermally heat it at 190°C for 12 hours, adjust the concentration by rotary evaporation, and obtain a tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com