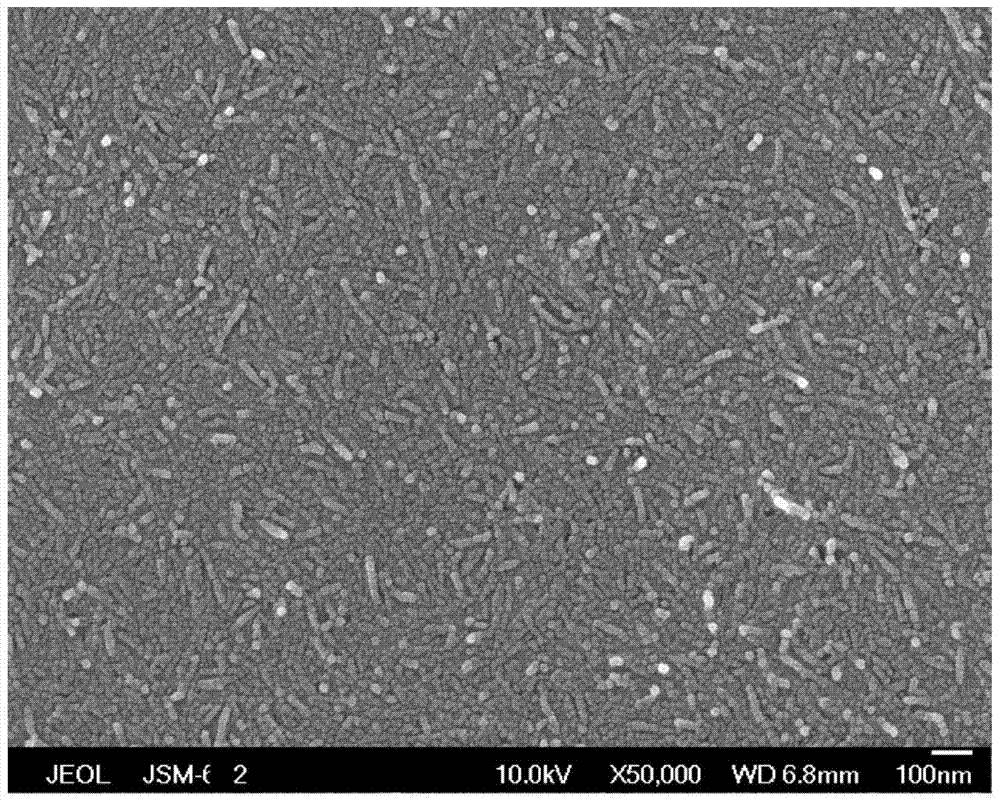

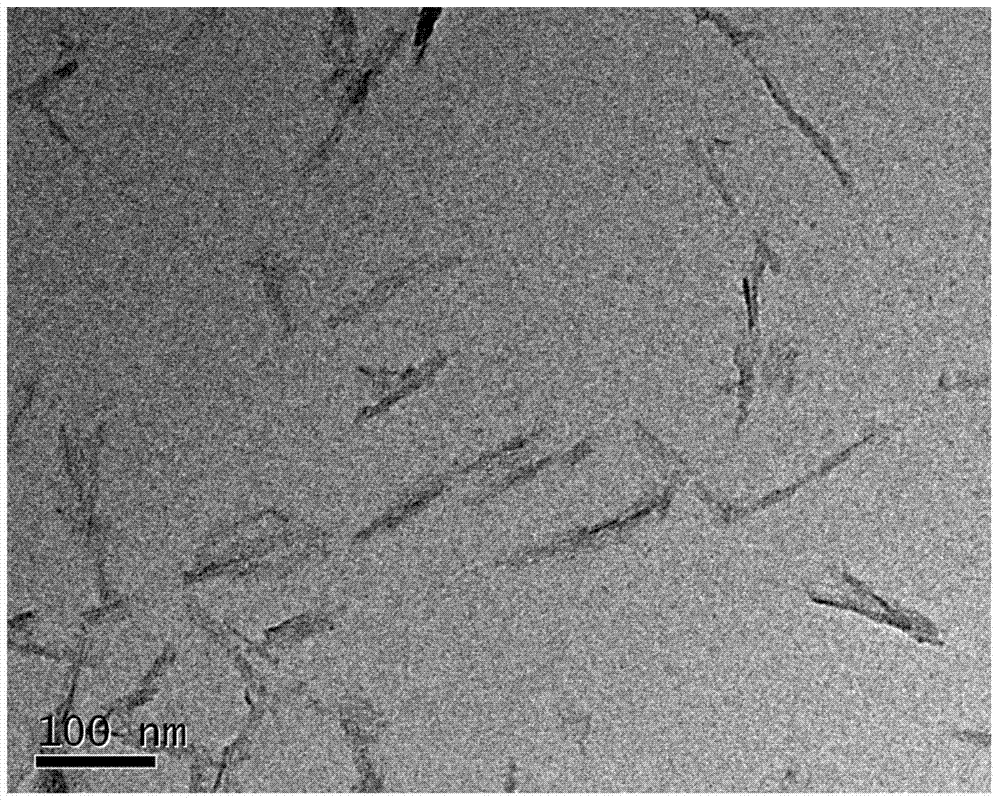

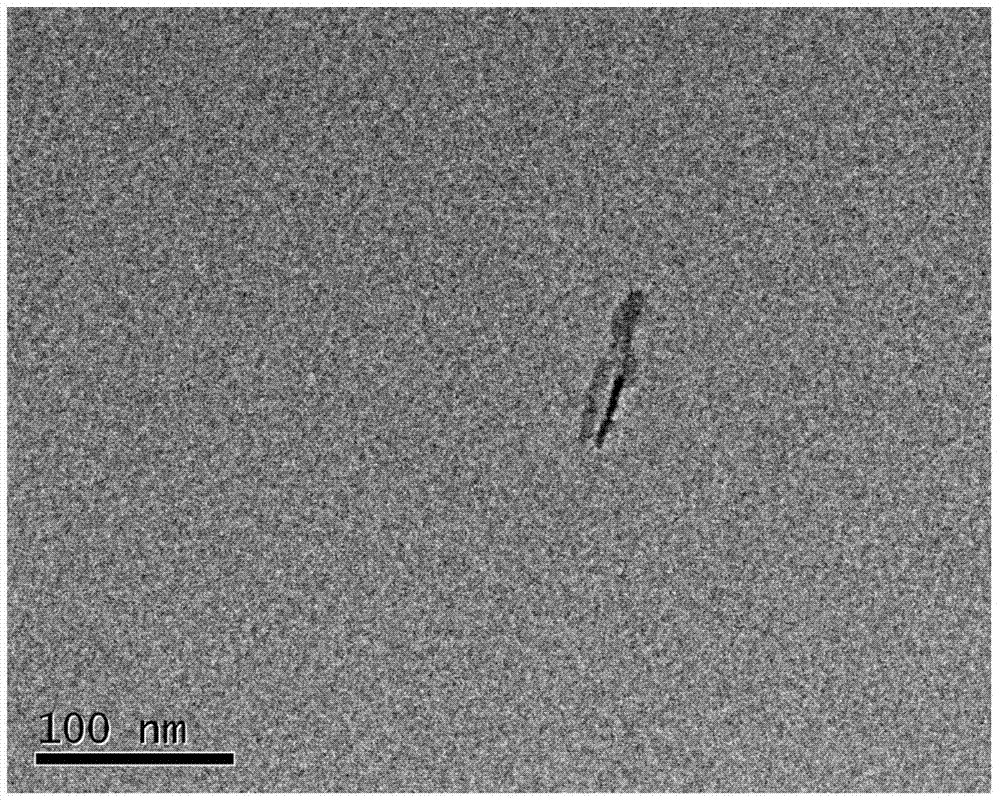

A kind of transparent aluminum hydroxide liquid phase dispersion and its preparation method and application

A technology of aluminum hydroxide and liquid phase dispersion, which is applied in the field of nanomaterials, can solve the problems of easy agglomeration and poor dispersion of particles, achieve uniform particle size distribution, small particle size, and reduce the chance of collision or agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A preparation method of a transparent aluminum hydroxide liquid phase dispersion, comprising the following steps:

[0050] 1) 3.8g aluminum nitrate nonahydrate was dissolved in 50g ethanol to obtain aluminum nitrate solution;

[0051] 2) 2.2g potassium hydroxide is dissolved in 30g ethanol, makes potassium hydroxide solution;

[0052] 3) After the aluminum nitrate solution is stirred evenly, potassium hydroxide solution is added dropwise, the reaction temperature is controlled to be 20° C., the stirring rate is 300 r / min, and the final pH value of the reaction system is adjusted and controlled to be 11 with potassium hydroxide solution;

[0053] 4) After reaching the final pH requirement of the reaction system, continue aging at constant temperature for 1 hour;

[0054] 5) Pour out the solution and let it stand for 1 hour, filter the solution and wash with water to obtain a filter cake;

[0055] 6) Ultrasonic disperse the washed filter cake in 6.4 g of water to obtain...

Embodiment 2

[0058] A preparation method of a transparent aluminum hydroxide liquid phase dispersion, comprising the following steps:

[0059] 1) 7.2g aluminum chloride hexahydrate was dissolved in 150g water to obtain aluminum chloride solution;

[0060] 2) 3.9g sodium hydroxide is dissolved in 160g water, makes sodium hydroxide solution;

[0061] 3) After stirring the aluminum chloride solution evenly, add sodium hydroxide solution dropwise, control the reaction temperature to 30°C, and the stirring rate to 500r / min, adjust and control the final pH value of the reaction system to 8.5 with sodium hydroxide solution;

[0062] 4) After reaching the final pH requirement of the reaction system, heat up to 70°C and age for 2 hours;

[0063] 5) Pour out the solution and let it stand for 8 hours, filter the solution and wash with water and ethanol to obtain a filter cake;

[0064] 6) ultrasonically disperse the washed filter cake in 41.8 g of ethanol to obtain a transparent and stable aluminum...

Embodiment 3

[0068] A preparation method of a transparent aluminum hydroxide liquid phase dispersion, comprising the following steps:

[0069] 1) Dissolve 34.2g of iron-free aluminum sulfate in 120g of methanol to prepare aluminum sulfate solution;

[0070] 2) 20.7g potassium hydroxide was dissolved in 60g methanol to obtain potassium hydroxide solution;

[0071] 3) After the aluminum sulfate solution is stirred evenly, potassium hydroxide solution is added dropwise, the reaction temperature is controlled to be 40° C., the stirring rate is 450 r / min, and the final pH value of the reaction system is adjusted and controlled to be 10 with potassium hydroxide solution;

[0072] 4) After reaching the final pH requirement of the reaction system, heat up to 60°C and age for 4 hours;

[0073] 5) Pour out the solution and let it stand for 5 hours, filter the solution and wash with water and ethyl acetate to obtain a filter cake;

[0074] 6) Ultrasonic disperse the washed filter cake in 15.6 g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com