Dispersing aid and carbon nanotube dispersion liquid and conductive slurry thereof

A dispersing aid, carbon nanotube technology, applied in the direction of carbon nanotubes, conductive materials dispersed in non-conductive inorganic materials, nanocarbons, etc., can solve the problems of poor dispersion effect, easy agglomeration and precipitation, etc., to improve production. Efficiency, long-lasting adsorption, low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

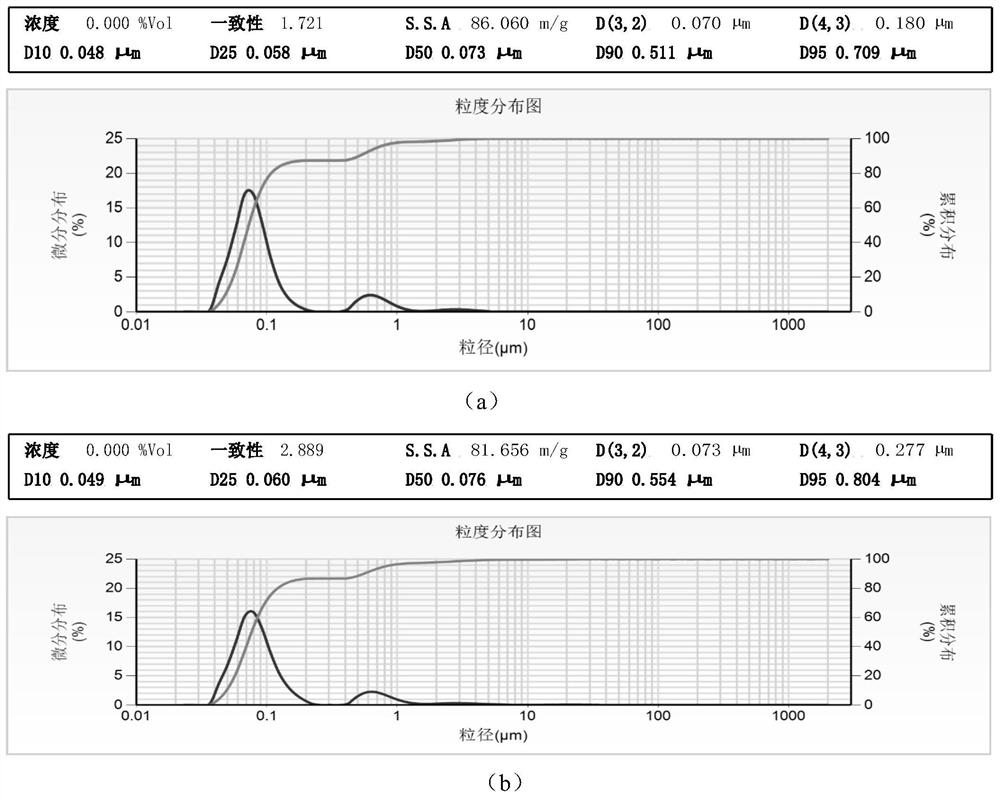

[0093] The high-solid aqueous carbon nanotube dispersion provided in this example is prepared by the following method:

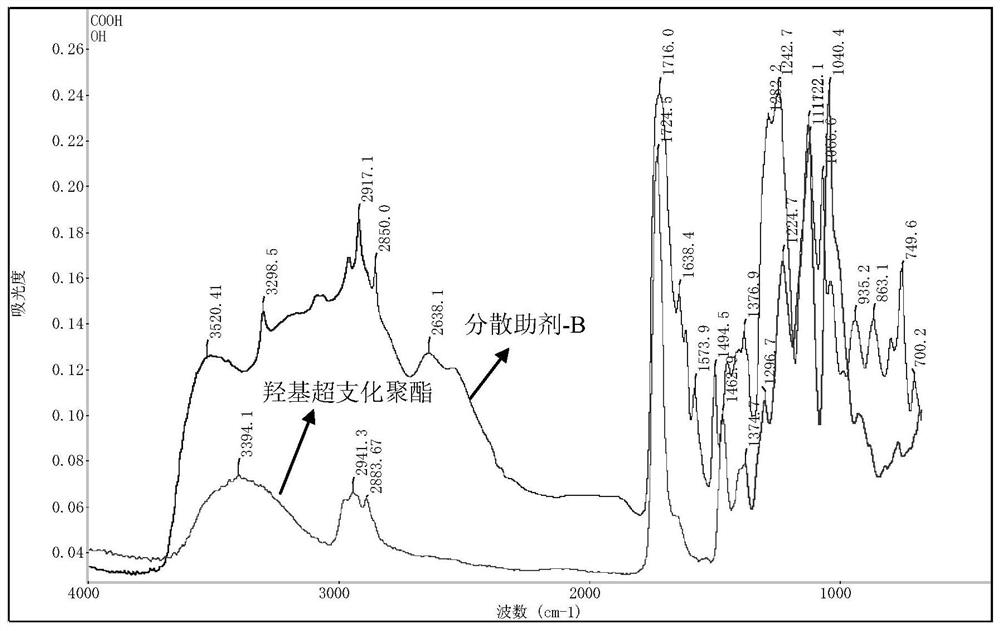

[0094] (1) Preparation of dispersing aid

[0095] Add 35g of hydroxyl hyperbranched polyester and dissolve it in 300mL of DMF in a four-necked flask with a stirrer, condenser, thermometer and nitrogen inlet, heat to make it dissolve completely, and add a certain amount of ( The molar ratio of acid anhydride to hydroxyl hyperbranched polyester is 7:1) of phthalic anhydride and 0.5g of catalyst N,N-dimethylbenzylamine. After it dissolves, the temperature is raised to 95°C, and the reaction reaches the theoretical acid value (initial Half of the acid value), after steaming off part of the solvent, the reaction temperature was lowered to 50°C, and then the system was neutralized with 30wt% sodium hydroxide aqueous solution to a pH value of 7.0-8.0, and finally a yellow transparent solution with a solid content of 40% was obtained , that is, a solution containin...

Embodiment 2

[0103] The high-solid aqueous carbon nanotube dispersion provided in this example is prepared by the following method:

[0104] (1) Preparation of dispersing aid

[0105] Add 35g hydroxyl hyperbranched polyester and dissolve in 300mL DMF in the four-necked flask that has stirrer, condensation tube, thermometer and nitrogen inlet, heating makes it dissolve completely, under the protection of passing into nitrogen, add a certain amount (acid anhydride The molar ratio of dodecenyl succinic anhydride and trimellitic anhydride to the hydroxyl hyperbranched polyester is 5:1) (the molar ratio of dodecenyl succinic anhydride and trimellitic anhydride is 1:2) and 0.8 g catalyst N,N-dimethylbenzylamine, after it dissolves, heat up to 110°C, react to the theoretical acid value (half of the initial acid value), evaporate part of the solvent and lower the reaction temperature to 50°C, then use 30wt% Aqueous sodium hydroxide solution neutralizes the reactant solution to a pH value of 7.0-8...

Embodiment 3

[0115] This example provides water-based carbon nanotube conductive paste, which is prepared by the following method:

[0116] The water-based carbon nanotube dispersion liquid 66.5g that embodiment 2 makes, 14g water-based polyurethane resin (30% solid content) are mixed, disperse 30 minutes at a high speed with 600rpm in the high-speed disperser, then add the fluid that total mass is 1.2g Leveling agent and anti-settling agent (the mass ratio of leveling agent and anti-settling agent is 2.5:1), mechanically stirred at 300rpm for 10 minutes, and the final product water-based carbon nanotube conductive paste was obtained after standing for defoaming.

[0117] The water-based carbon nanotube conductive paste is coated into a sample film of 20 cm × 30 cm by scrape coating process, and the surface of the sample film is observed. The surface is uniform and there is no obvious shrinkage cavity. The film thickness measured by the height gauge is 10+ / - 1 micron, measured with a squar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com