New construction process of self-adhesive rubber anticorrosive lining

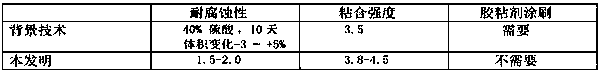

A kind of anti-corrosion lining, self-adhesive technology, applied in the direction of adhesive type, adhesive, non-polymer adhesive additives, etc., can solve the problem of adhesive flammability and harmful gas volatilization, adhesive bonding performance and corrosion resistance performance Stability, poor adhesion performance and other problems, to achieve the effect of improving performance and rubber lining construction quality, eliminating health and safety hazards, and filling the gaps in process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: A self-adhesive rubber anti-corrosion lining (parts by weight): 100 parts of corrosion-resistant rubber, 200-280 parts of tackifier, 280-380 parts of softener, 50-80 parts of reinforcing aid, 0.5 parts of vulcanizing agent -1.0 parts, 1.5-2.5 parts of anti-aging agent A, 1.5 parts of anti-aging agent B, 0.5-2.0 parts of accelerator, the error range of the above ingredients is controlled within 5%.

[0022] The corrosion-resistant rubber refers to butyl rubber.

[0023] The tackifier refers to phenolic resin.

[0024] The softener refers to polyisobutylene.

[0025] The reinforcing agent is carbon black.

[0026] The vulcanizing agent refers to sulfur.

[0027] The anti-aging agent A refers to ketamine.

[0028] The anti-aging agent B refers to polyphenols; the accelerator refers to a thiuram accelerator.

Embodiment 2

[0029] Example 2: A method of making a self-adhesive rubber anti-corrosion lining, 1) 100 parts of corrosion-resistant rubber, 200-280 parts of tackifier, 50-80 parts of reinforcing aid, 0.5-1.0 parts of vulcanizing agent, anti-aging Add 1.5-2.5 parts of agent A, 1.5 parts of anti-aging agent B, and 0.5-2.0 parts of accelerator according to a certain order of addition (rubber→tackifier+reinforcing agent→anti-aging agent+vulcanizing agent+tackifier→accelerator) Mix evenly in the rubber internal mixer, unload and park, then add 280-380 parts of softener to the rubber intermeshing mixing equipment, stir and mix evenly to make semi-finished products for use; 2) Semi-finished products pass through the extruder Applied on one side of the qualified rubber lining film and rolled up, it becomes a single-sided self-adhesive rubber anti-corrosion lining film. The tackifier is added twice and the total amount added does not exceed 280 parts.

[0030]

Embodiment 3

[0031] Example 3: A new construction process for self-adhesive rubber anti-corrosion lining

[0032] 1) For the acceptance of sand blasting and derusting equipment, the surface of the equipment to be lined with rubber should meet the technical requirements for rubber lining;

[0033] 2) Lofting: cutting and lofting according to the surface shape of the rubber-lined equipment and the rubber-lined process, the lofting requires accurate, reasonable, and even arrangement of materials, and minimizes seams;

[0034] 3) Lining: Align the placed film with the lining part of the equipment, then slowly pull out the release paper on the film, and press the film while pulling the release paper, so as to complete the lining of the entire film;

[0035] The seam direction of the film lining should be determined according to the equipment structure: the seam direction of the equipment connection pipe or the inner wall should follow the flow direction of the medium; the seam direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com