Novel stainless steel color-coated steel plate

A technology for color-coated steel and stainless steel, applied in the field of steel plate printing, can solve the problems of easy falling off or discoloration, insufficient adsorption force, easy corrosion and rust, etc. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

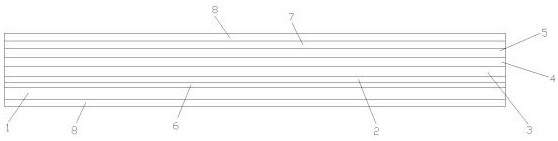

[0014] Embodiments of the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments.

[0015] see figure 1 As shown in combination, a new type of stainless steel color-coated steel plate includes a stainless steel substrate 1, and the upper surface of the stainless steel substrate 1 is covered with a protective layer 7, a passivation layer 5, a laser layer 4, a color coating layer 3, and a hot-melt adhesive layer in sequence. 2 and pickling layer 6, the color coating 3 includes a front topcoat 3-1 and a front primer 3-2, the stainless steel substrate 1 is sprayed with an atomized layer 8 on both sides, the The pickling layer 6 is obtained by removing the surface oxide layer by soaking the pickling solution in hot rolling. The pickling solution can be hydrochloric acid and sulfuric acid, and the hot melt adhesive layer 2 is evenly applied on the pickling layer 6 by a roller. On the surface, the hot melt adhesive layer 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com