Hard-film rust-preventative oil

A technology of anti-rust oil and hard film, which is applied in the direction of anti-corrosion coatings, coatings, rosin coatings, etc. It can solve the problems of anti-rust lubricants such as poor resistance to humidity and heat and salt spray, and achieve good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

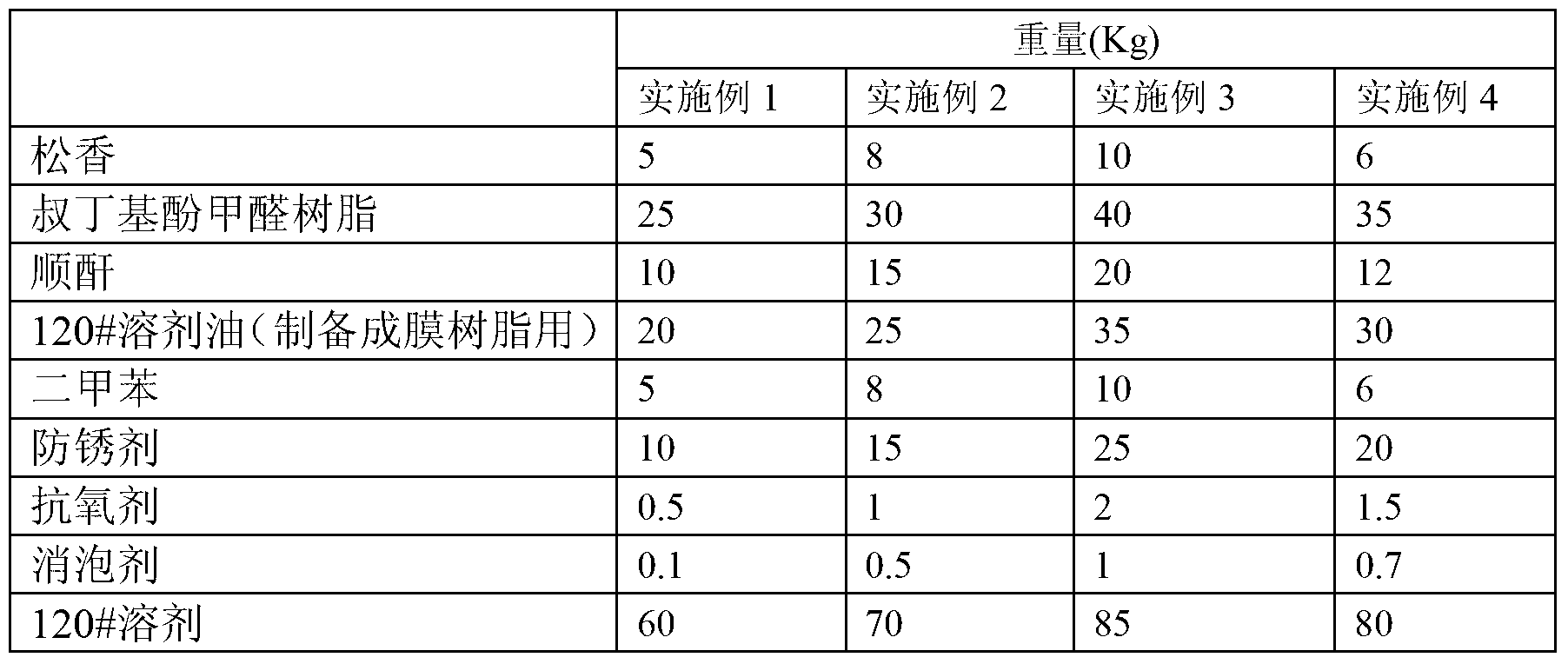

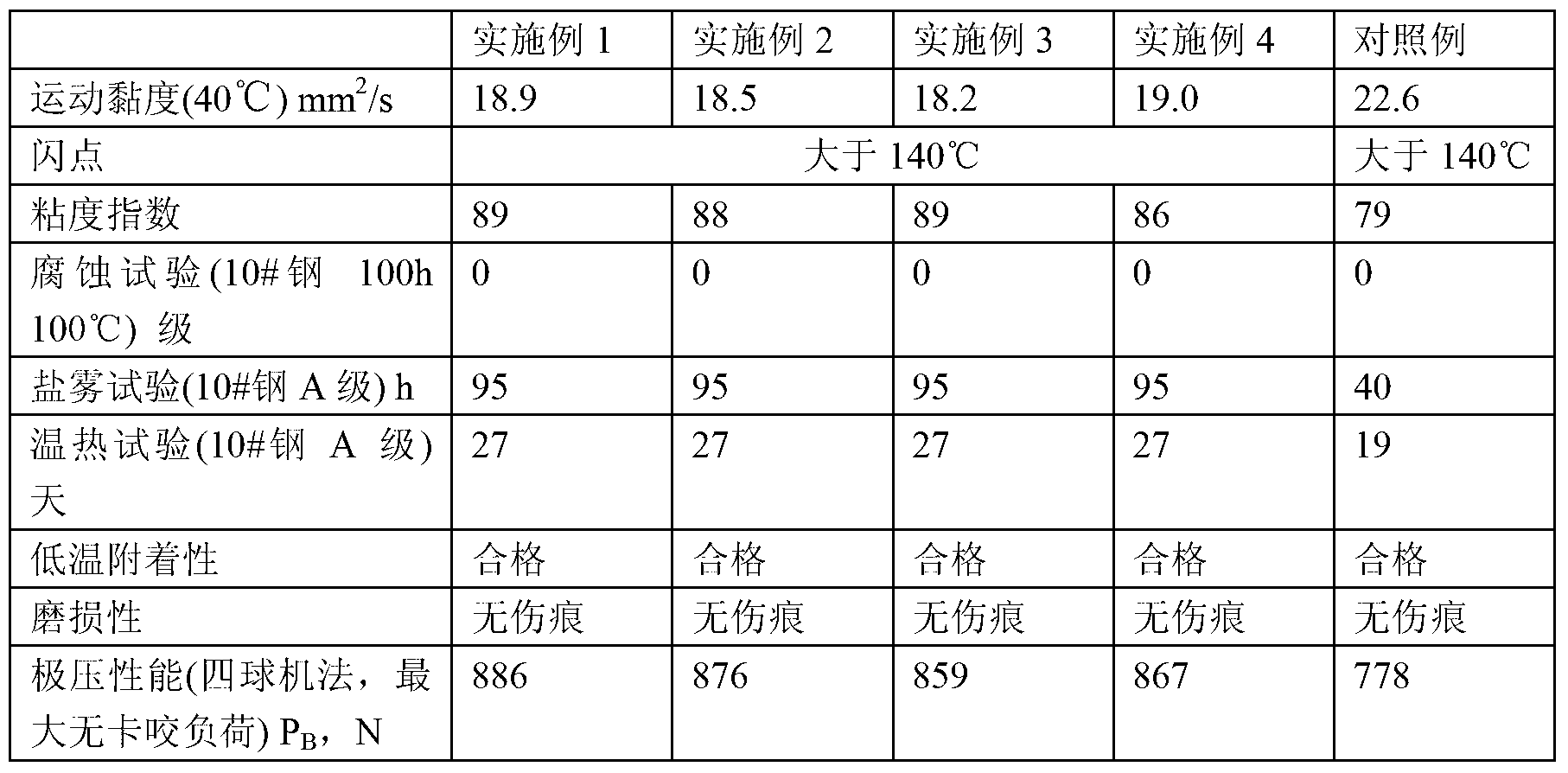

Examples

Embodiment 1

[0019] S1: Put rosin and maleic anhydride into the reactor, raise the temperature to 95±2°C, stir, add xylene and tert-butylphenol formaldehyde resin in turn, raise the temperature to 150±2°C, and keep it for 1.5 hours;

[0020] S2: Cool to 85±2°C, add 120# solvent oil, stir well to obtain film-forming resin;

[0021] S3: Put benzotriazole, 2,6-di-tert-butyl-p-cresol, and 120# solvent into the reaction kettle, raise the temperature to 50±2°C, and stir for 1 hour;

[0022] S4: Add film-forming resin and silicone, stir well, cool, filter, and obtain.

Embodiment 2

[0024] The difference from Example 1 is that in step S3, put the oxidized petroleum tallow barium soap, tetrakis-[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, and 120# solvent Put it into a reaction kettle, raise the temperature to 50±2°C, and stir for 1 hour; in step S4, add film-forming resin and ethanol, stir well, cool, and filter to obtain.

Embodiment 3

[0026] The difference from Example 1 is: in step S3, 10 parts of oxidized petroleum tar barium soap, 15 parts of benzotriazole, 2,6-di-tert-butyl-p-cresol, and 120# solvent are put into the reaction kettle, Raise the temperature to 50±2°C and stir for 1 hour; in step S4, add film-forming resin and silicone, stir evenly, cool, and filter to obtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com