Patents

Literature

41 results about "Cerium(III) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cerium(III) oxide, also known as cerium oxide, cerium trioxide, cerium sesquioxide, cerous oxide or dicerium trioxide, is an oxide of the rare-earth metal cerium. It has chemical formula Ce₂O₃ and is gold-yellow in color.

Optical glass

InactiveCN1450010AHigh coefficient of thermal expansionPrecise without migrationOptical elementsLithium oxideSilicic acid

The present invention relates to an optical glass using silicic acid group as main body, said optic glass has high expansion coefficient, high Young modulus, excellent weatherability and high transmissivity in the infrared wave zone. Said glass composition contains (mole%) 36-66% of silicon dioxide, 0-12% of aluminium oxide, 0-6% of boric oxide, 0-10% of magnesium oxide, 0-16% of calcium oxide, 0-16% of strontium oxide, 0-16% of baria, 0-8% of zinc oxide, 0-32% of lithium oxide, 0-25% of sodium oxide, 0-25% of potassium oxide, 0-20% of cesium oxide, 0-6% of phosphorus pentoxide, 0-8% of scandium oxide and others.

Owner:PICVUE OPTOELECTRONICS INT

Cerium oxide-zirconium oxide-based composite oxide and preparation method thereof

ActiveCN102513085AGood dispersionImprove oxygen storage capacityCatalyst carriersInternal combustion piston enginesCeriumComposite oxide

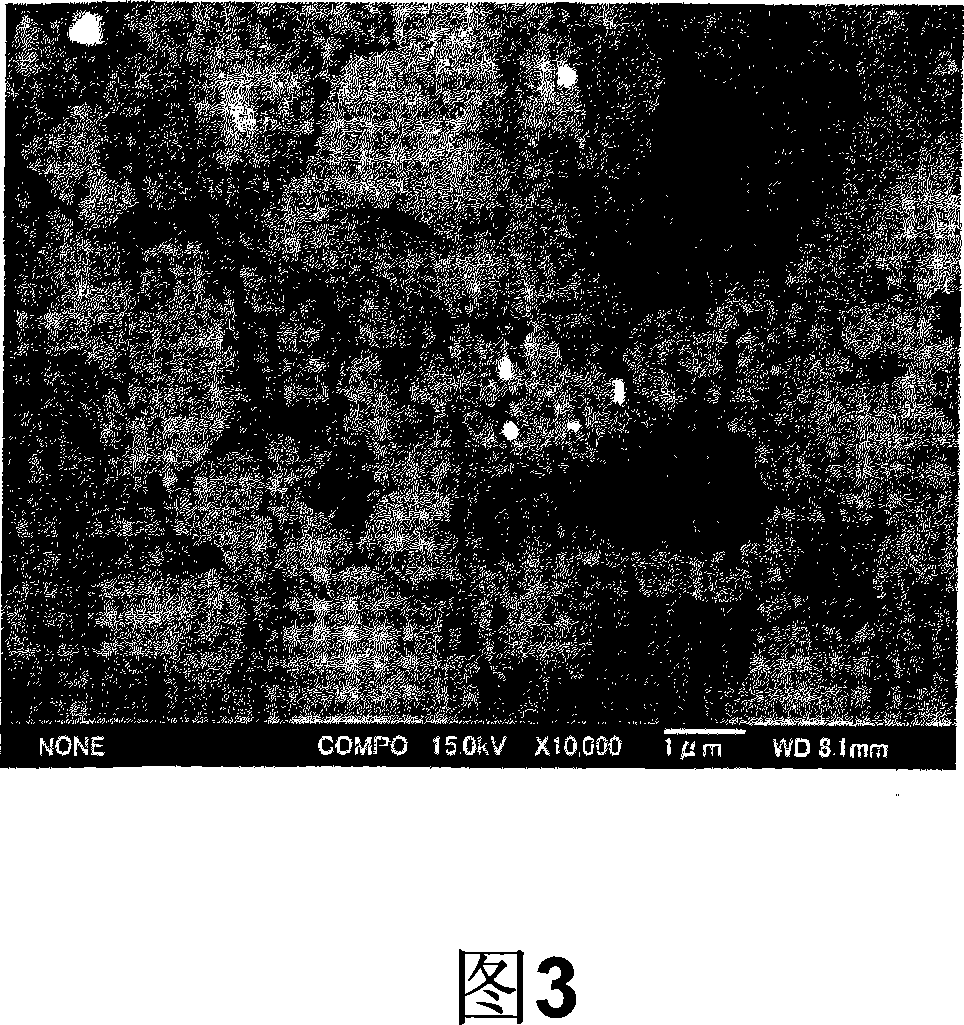

The invention provides a cerium oxide-zirconium oxide-based composite oxide and a preparation method of the cerium oxide-zirconium oxide-based composite oxide. The cerium oxide-zirconium oxide-based composite oxide is a mixture of CeO2 and ZrO2, wherein the mass ratio between the CeO2 and the ZrO2 is 45:55-70:30. Ce3+ and Ce4+ formation potential of hydrogen (pH) values of hydroxide precipitationis different ,firstly, mixing Ce4+ and Zr4+ in the mixed solution in a way of coprecipitation, and then precipitating Ce3+; and the solid solution of cerium zirconium and the composition of cerium oxide on the surface of the solid solution of the cerium zirconium can be simultaneously realized by high-temperature roasting. The cerium oxide-zirconium oxide-based composite oxide has excellent dispersive action for precious metal platinum and high oxygen storage capacity (OSC), and thus can be applied to catalyst promoter or catalyst carrier of automobile exhaust three-way catalyst (TWC).

Owner:方复(上海)新材料科技有限公司

Cerium oxide and zirconium oxide based sosoloid catalyst, preparation method and application thereof

InactiveCN101607195AImprove catalytic performanceImprove thermal stabilityDispersed particle separationCatalyst activation/preparationZirconium hydrideCerium(IV) oxide

The invention relates to a catalytic material for purifying tail gas of an automobile, in particular to a cerium oxide and zirconium oxide based sosoloid catalyst, a preparation method and application thereof. The cerium oxide and zirconium oxide based sosoloid catalyst comprises 50-79.5wt% of zirconium oxide, 20-49.5wt% of cerium oxide and 0.5-25wt% of oxides of other elements, wherein the zirconium oxide, the cerium oxide and the oxides of other elements is present in a sosoloid form, and the oxides of other elements are one or more oxides of lanthanons except cerium. The preparation method is as follows: continuous coprecipitation is carried out on zirconium oxychloride, saline solution of cerium and saline solution of lanthanons except cerium to obtain the cerium oxide and zirconium oxide based sosoloid catalyst. In the invention, by adding the zirconium oxide and the oxides of the lanthanons except cerium, the prepared cerium oxide and zirconium oxide based sosoloid catalyst has favorable catalytic performance and greatly improved thermal stability. The preparation method can prepare the cerium oxide and zirconium oxide based sosoloid catalyst under relatively lower temperature and normal pressure.

Owner:顾冬萍

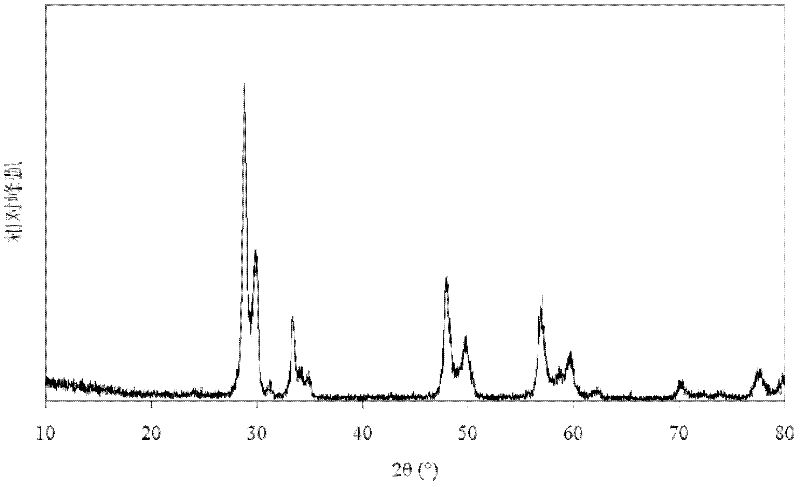

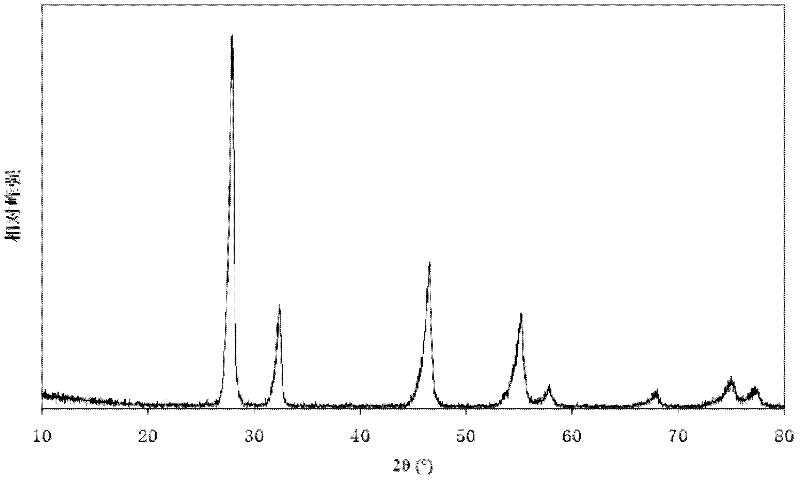

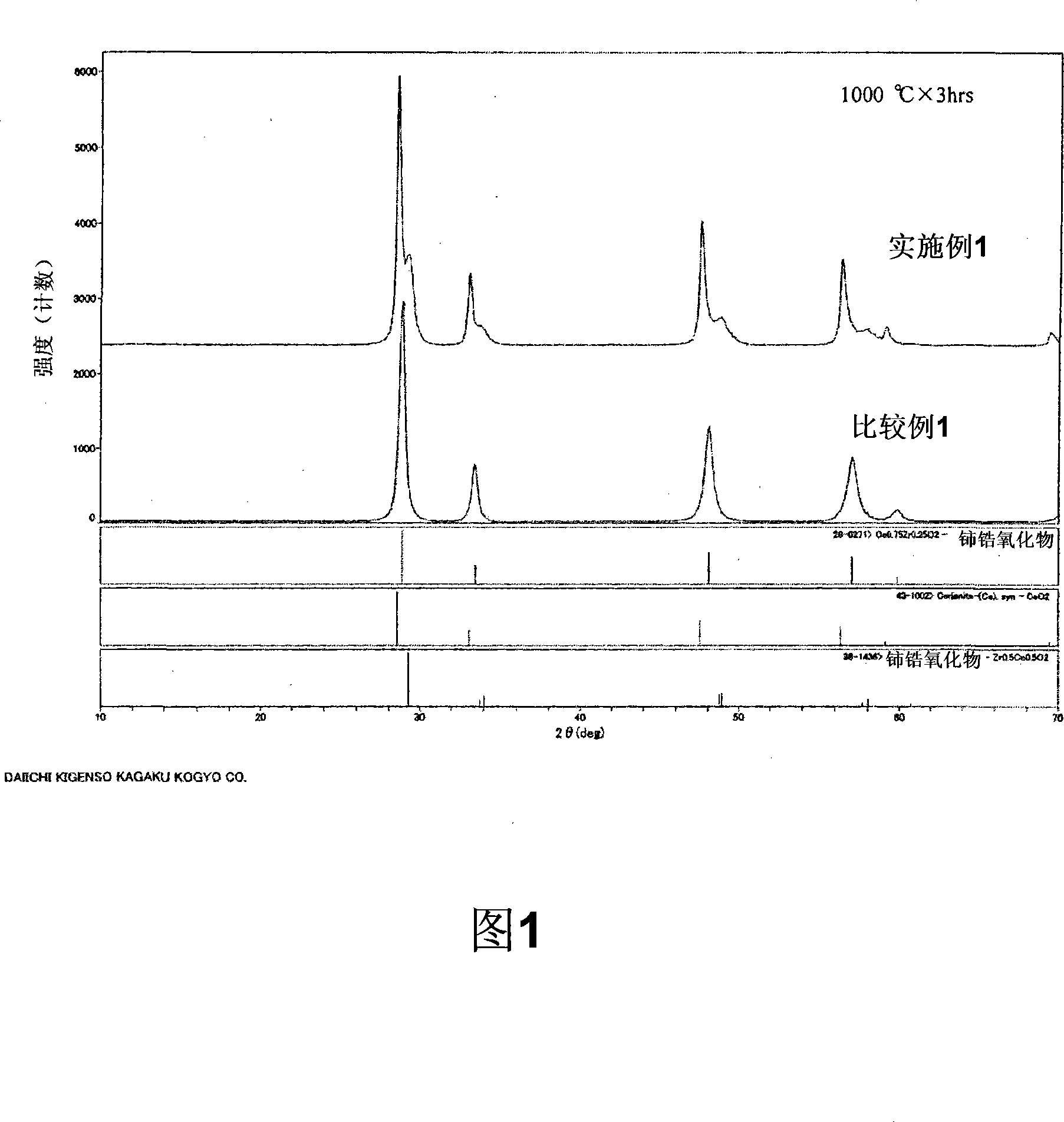

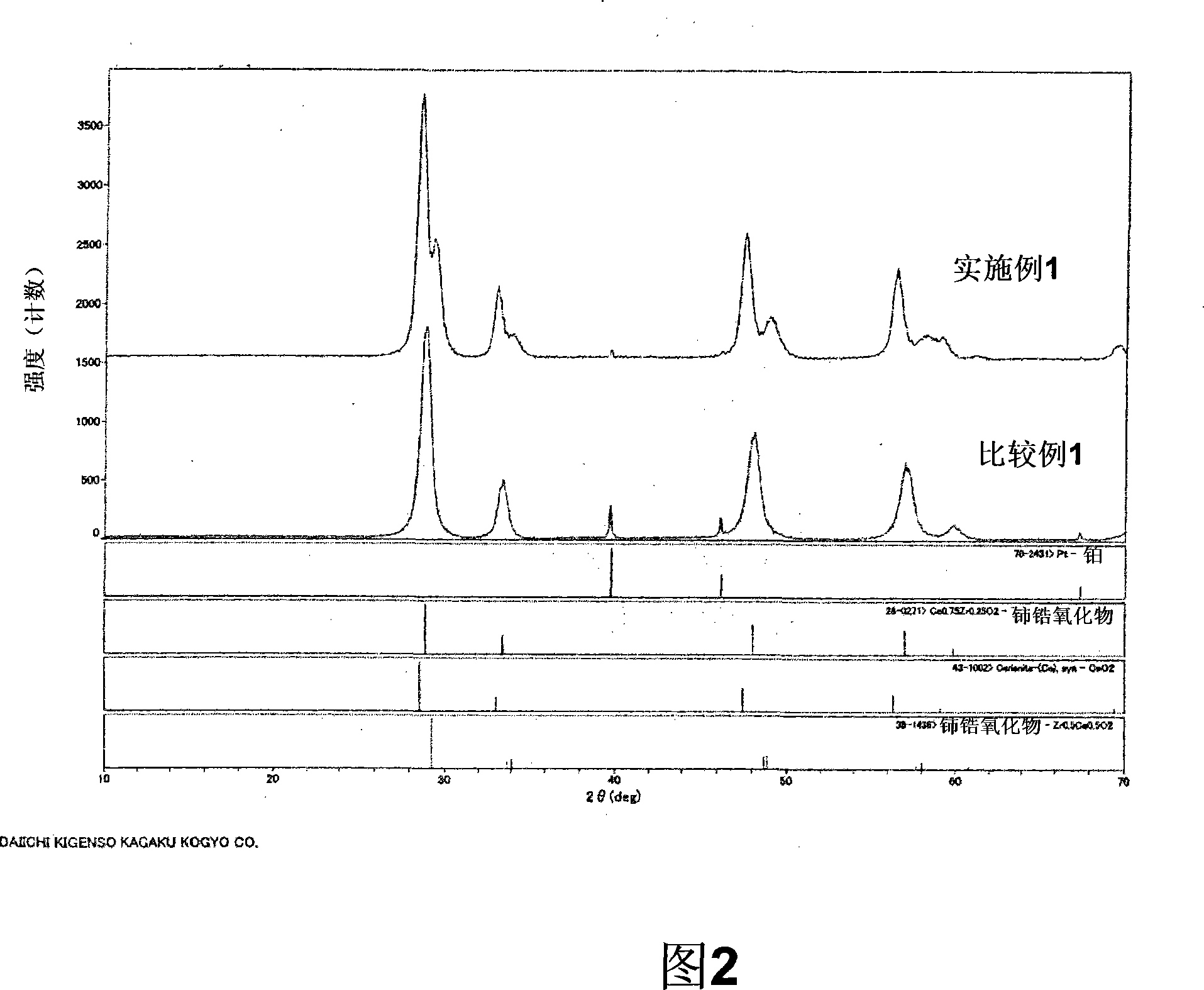

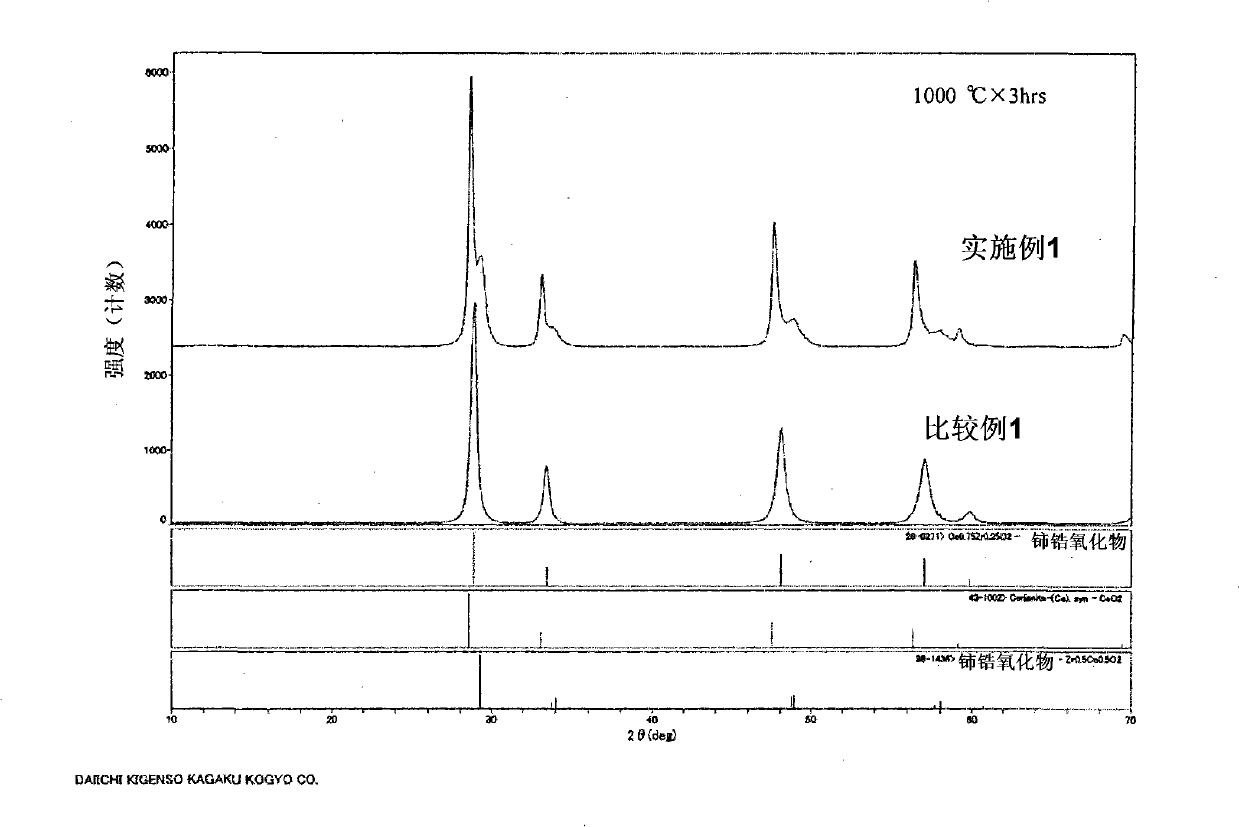

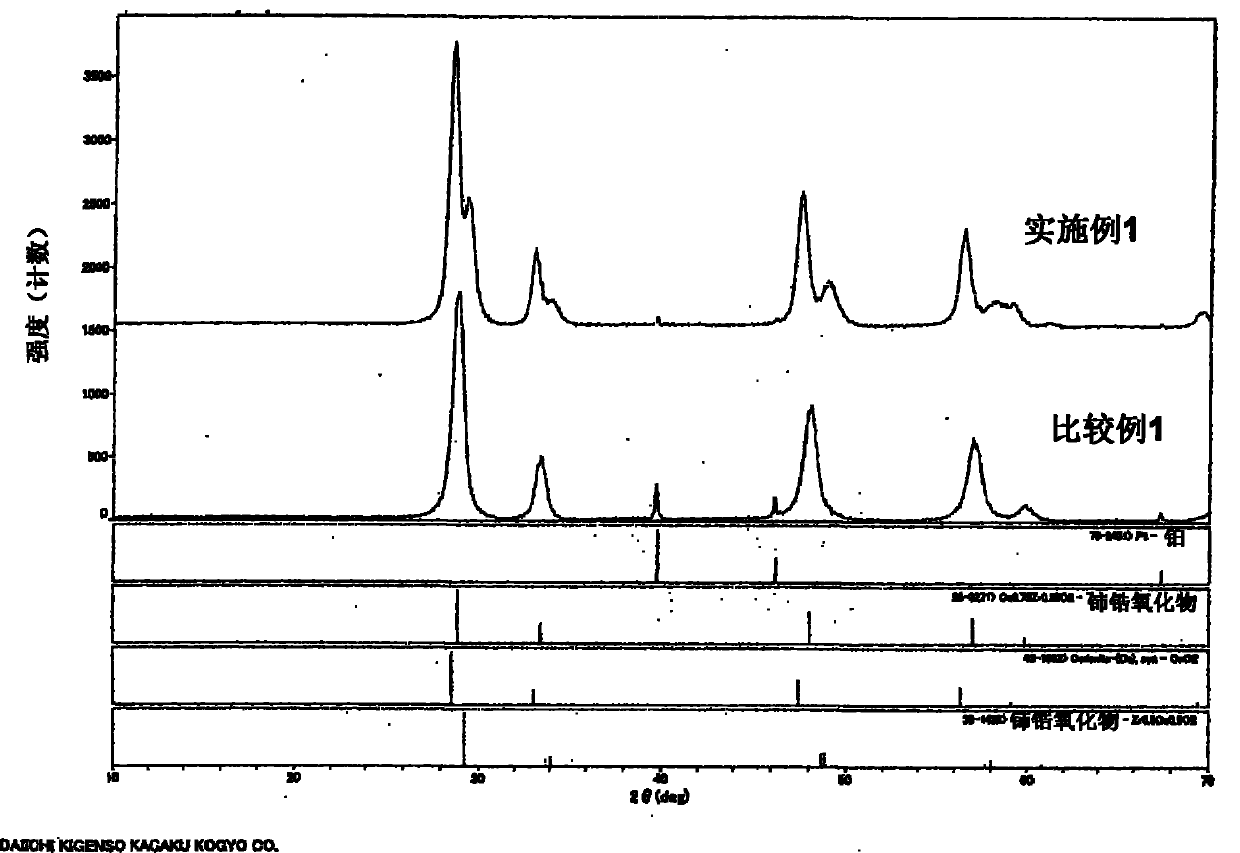

Cerium oxide-zirconium oxide-based mixed oxide and method for producing thereof

ActiveCN101096012AGood dispersionEasy to prepareCatalyst carriersInternal combustion piston enginesZirconium hydridePlatinum

The present invention provides a cerium oxide-zirconium oxide-based mixed oxide having superior platinum dispersibility and a suitable OSC, and a simple production process thereof. The cerium oxide-zirconium oxide-based mixed oxide comprises cerium oxide and zirconium oxide, wherein (1) the weight ratio of CeO 2 : ZrO 2 is 60:40 to 90:10, and (2) the cerium oxide and the zirconium oxide are present as a mixture, the zirconium oxide being composed of a solid solution in which tetragonal or cubic zirconium oxide contains cerium.

Owner:DAIICHI KIGENSO KAGAKU KOGYO CO LTD

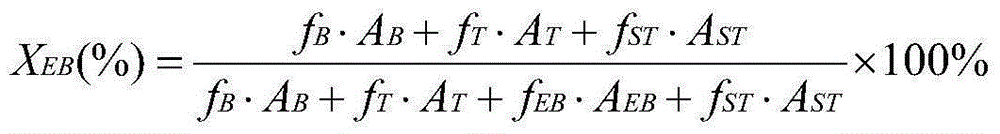

Preparation method of catalyst for styrene preparation by ethylbenzene dehydrogenation

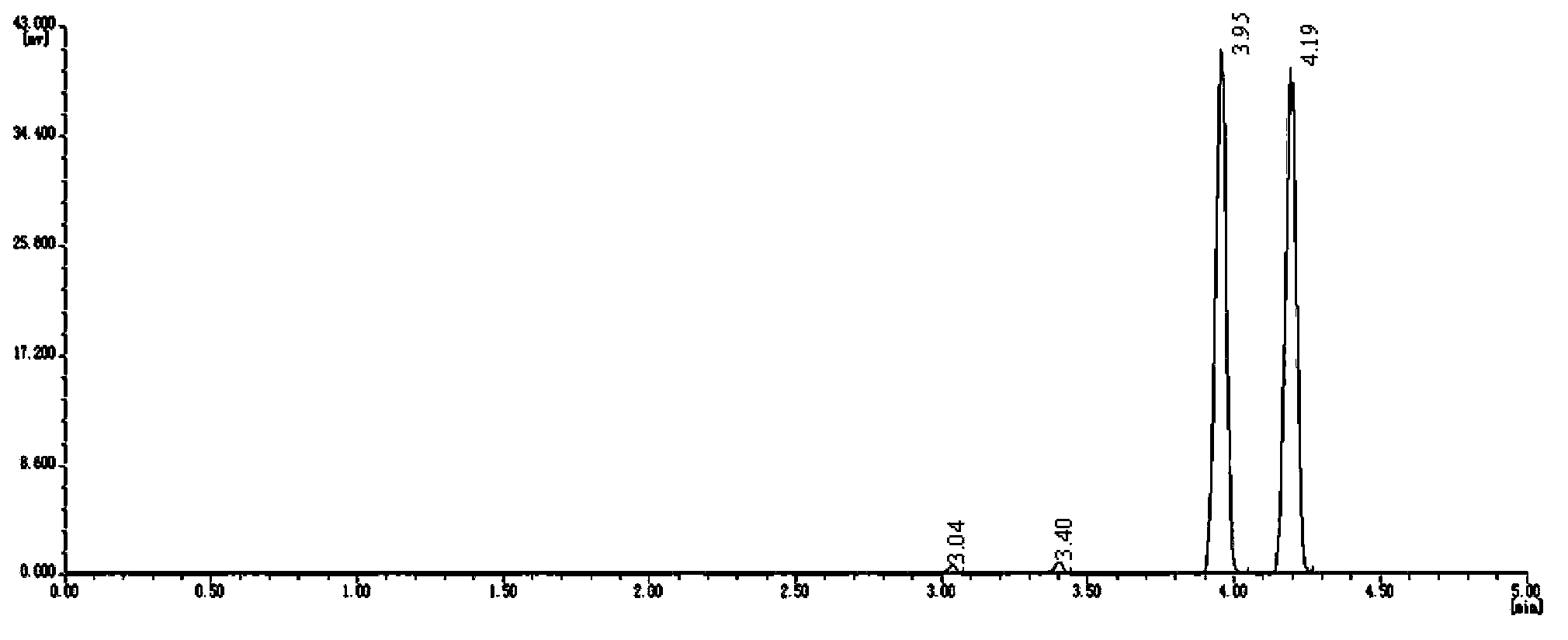

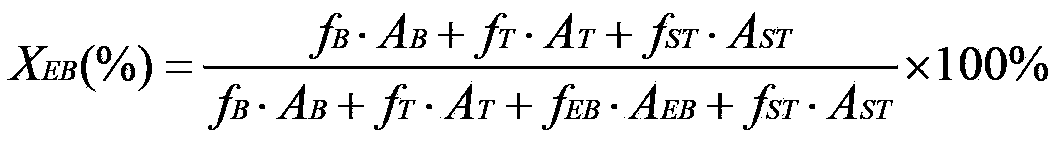

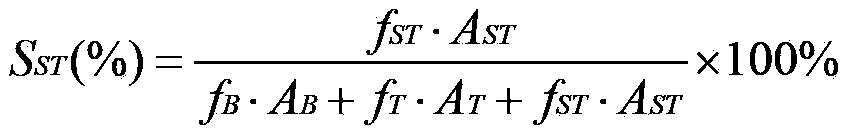

Relating to a catalyst, the invention provides a preparation method of a catalyst for styrene preparation by ethylbenzene dehydrogenation. The catalyst has high crushing strength, large aperture and small specific surface area, and also has high catalytic activity in ethylbenzene dehydrogenation reaction under a low water ratio condition. The catalyst for styrene preparation by ethylbenzene dehydrogenation is a composite oxide of iron, potassium, magnesium, cerium and molybdenum. The method includes:1) preparation of nano-Ce2O3; and 2) preparation of the catalyst. According to a technical scheme, self-made nano-dicerium trioxide is adopted, and cerium nitrate and nano-dicerium trioxide in a proper ratio are introduced into the catalyst as the cerium source. The prepared catalyst has large aperture, small specific surface area and high crushing strength, and can maintain high catalytic activity under a low water-oil ratio condition.

Owner:XIAMEN UNIV

Method for preparing rare-earth-doped manganese-zinc ferrite material

InactiveCN109553408AChanging grain boundary compositionChange ionic valencePolyvinyl alcoholRare earth

The invention relates to the technical field of magnetic materials, and discloses a method for preparing a rare-earth-doped manganese-zinc ferrite material, comprising the steps of adding manganese oxide, zinc oxide and iron oxide as main components to a ball mill and conducting ball milling to obtain a mixture A; pre-firing the mixture A, and then conducting cooling to room temperature to obtaina pre-fired material; adding the pre-sintered material, vanadium oxide, niobium oxide, bismuth trioxide, molybdenum oxide, phosphorus pentoxide, copper oxide and a composite rare earth additive into aball mill, and conducting secondary ball milling and drying to obtain a mixture B, wherein the composite rare earth additive is composed of cerium oxide, yttrium oxide and lanthanum oxide; adding a polyvinyl alcohol solution to the mixture B, conducting mixing and granulation, and then conducting sieving by a sieve of 40-80 mesh, so as to obtain pellets; adding the pellets into a molding machinefor pressing, so as to obtain a blank; and sintering the blank and conducting cooling. The rare-earth-doped manganese-zinc ferrite material prepared by the method of the invention has high initial magnetic conductivity and saturation magnetic flux density.

Owner:ZHONGDE ELECTRONICS

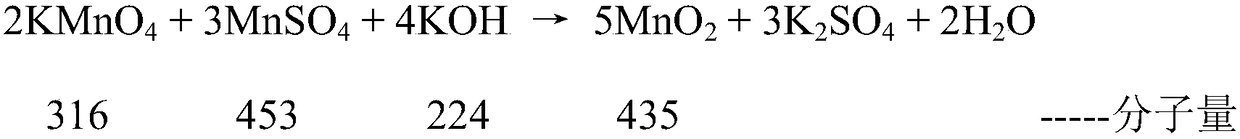

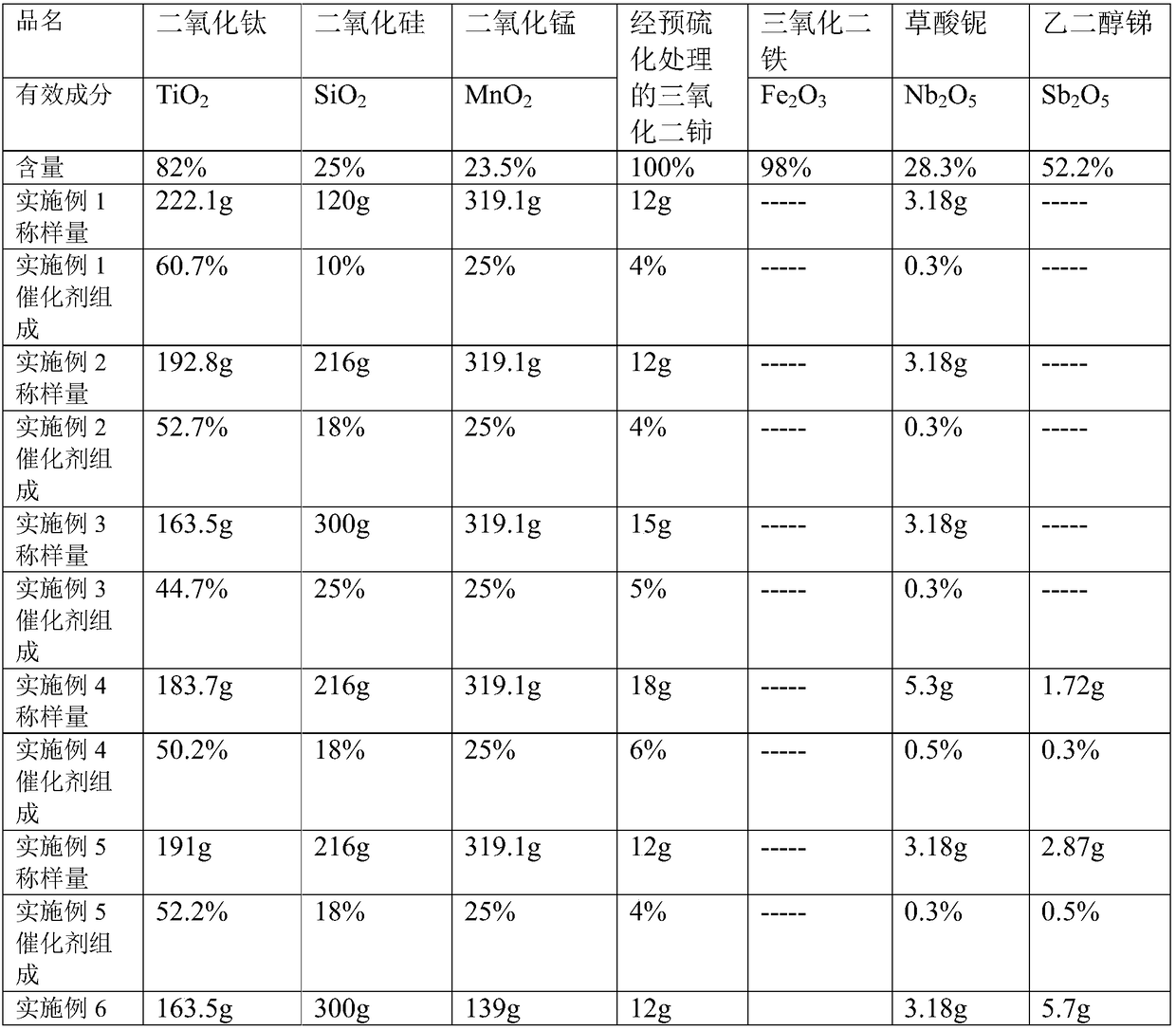

Low-temperature SCR (Selective Catalytic Reduction) catalyst and preparation method thereof

InactiveCN108940266AMultiple catalytic active centersHigh catalytic activityHeterogenous catalyst chemical elementsDispersed particle separationWater vaporSesquioxide

The invention discloses a low-temperature SCR (Selective Catalytic Reduction) catalyst and a preparation method thereof. The catalyst comprises a carrier and active ingredients supported on the carrier, wherein the carrier is a complex of titania and silica, and the active ingredients include manganese oxide and cerium sesquioxide subjected to prevulcanization treatment. The silica is added into the titania, so that the specific surface area of the carrier reaches 160-170m<2> / g, the pore volume reaches 0.4cm<3> / g, the carrier can load more active ingredients after the specific surface area andpore volume are increased, and more catalytically active centers exist, so that the catalytic activity of the low-temperature SCR catalyst can be effectively improved. Moreover, due to the addition of the silica, the water resistance of the low-temperature SCR catalyst disclosed by the invention can be enhanced, and the low-temperature activity of the low-temperature SCR catalyst disclosed by theinvention is improved, so that the low-temperature SCR catalyst disclosed by the invention also has excellent denitration efficiency on flue gas containing 15% of water vapor under the low-temperature condition (100-120 DEG C).

Owner:沈炳龙

Preparation method for water-based fluorescence enhanced anti-forgery ink

The invention relates to a preparation method for water-based fluorescence enhanced anti-forgery ink. The present water-based ink cannot realize the characteristics of fluorescence enhancement, restraining and impeding effects for fluorescence attenuation, long fluorescence anti-forgery time, excellent hiding effect, and the like. The preparation method provided by the invention comprises the following steps: firstly, reacting cerium oxide with hydrochloric acid, thereby obtaining solid-state cerous chloride; preparing a cerous chloride alcohol solution, a phenanthroline alcohol solution and an acetylacetone alcohol solution; successively adding the phenanthroline alcohol solution and the acetylacetone alcohol solution into the cerous chloride alcohol solution; filtering and drying, thereby obtaining a complex of transition metal cerium; uniformly mixing and stirring the complex of transition metal cerium, resin and fluorescent powder, and then adding emulsifying agent, pigment, de-foaming agent, dispersing agent, antibacterial agent, wetting agent and flatting agent; and quickly stirring and repeatedly grinding, thereby obtaining the water-based fluorescence enhanced anti-forgery ink. According to the preparation method provided by the invention, the water-base resin is taken as a connecting material, thereby being non-toxic and pollution-free. The preparation method provided by the invention is simple and reliable and can be applied to industrial production.

Owner:海宁鼎丞智能设备有限公司

Comprehensive anti-corrosion coating with alloy co-doping, Dacromet and sealing layer

ActiveCN106009794AImprove anti-corrosion performanceHigh surface hardnessSolid state diffusion coatingAnti-corrosive paintsEpoxyPolyethylene glycol

The invention discloses a comprehensive anti-corrosion coating with alloy co-doping, Dacromet and a sealing layer. The comprehensive anti-corrosion coating comprises an alloy co-doping agent, a Dacromet coating and a sealing liquid, wherein the alloy co-doping agent comprises zinc powder, aluminum powder, alumina powder, nickel powder, dicerium trioxide powder and ammonium chloride; the Dacromet coating comprises a component A and a component B; the component A comprises zinc sheets, aluminum sheets, deionized water and fatty alcohol-polyoxyethylene ether; the component B comprises an amorphous composite molybdate compound, barium acid salt, hydrogen peroxide and hydrogen peroxide; the component A and the component B are mixed in a mass ratio of 1:(15-25); the sealing liquid comprises a front pre-prepared component and a curing reaction component; the front pre-prepared component comprises a mixture of a normal-temperature curing agent, an ethanol solution with the volume concentration being 50-80%, glycerin, zinc sheets and aluminum sheets; the curing reaction component is epoxy resin emulsion; the front pre-prepared component and the curing reaction component are mixed in a mass ratio of 2:(2-3).

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

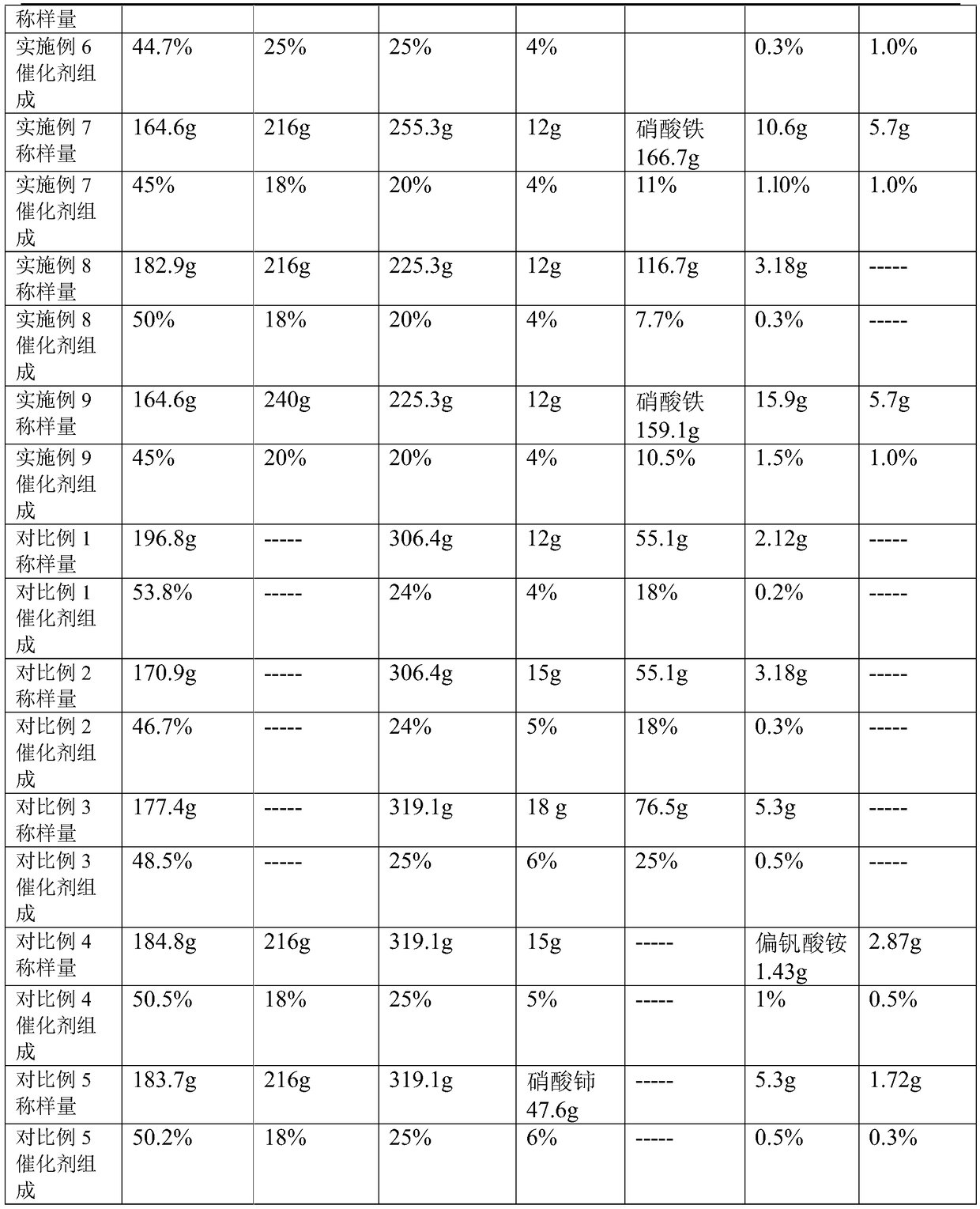

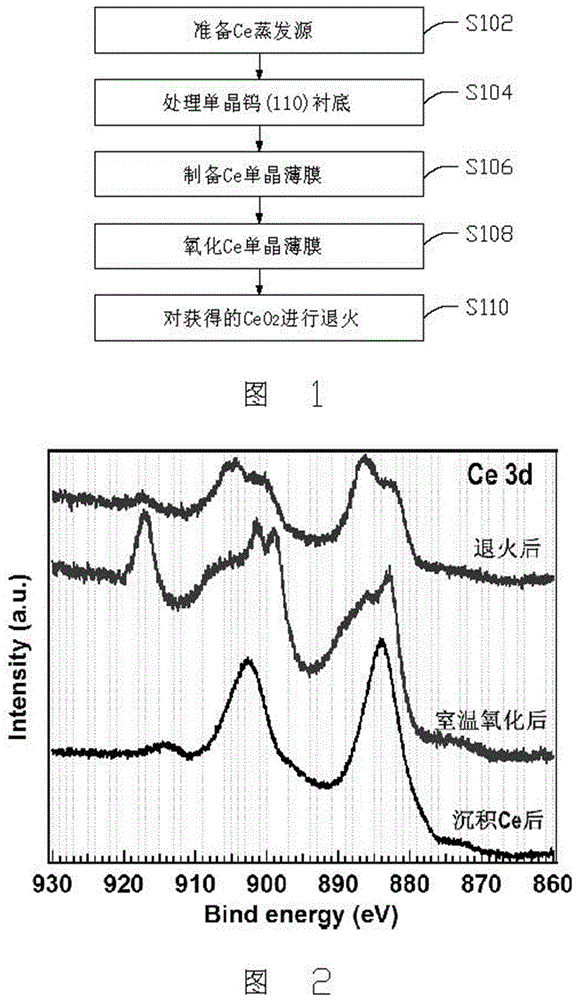

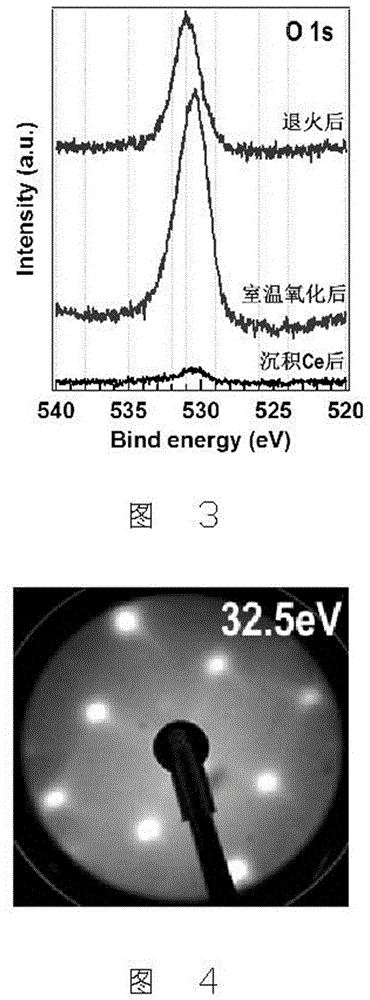

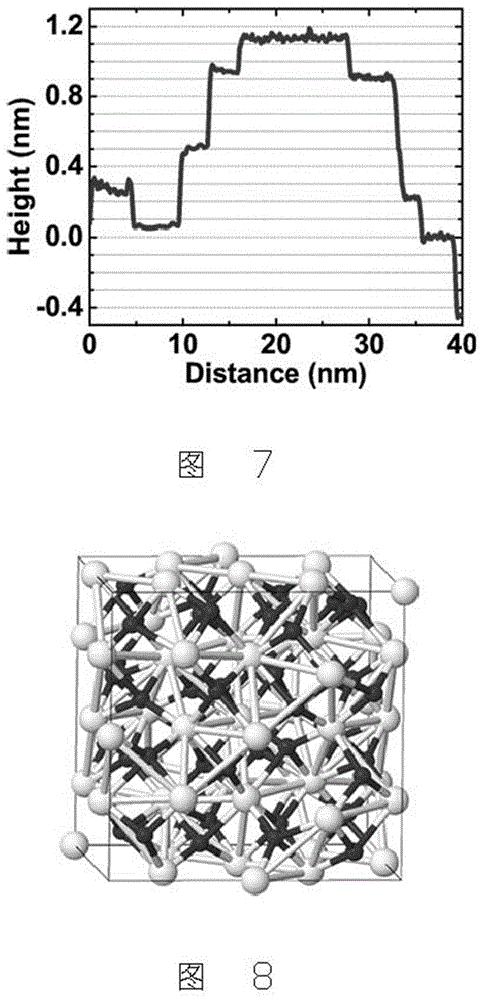

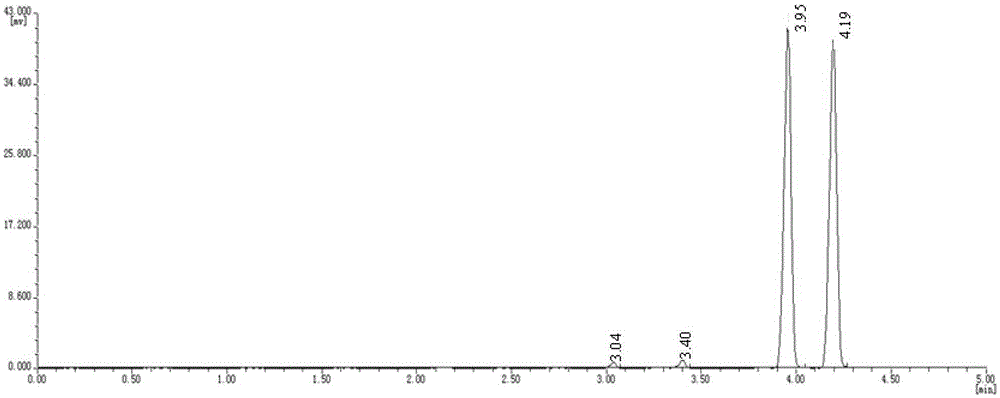

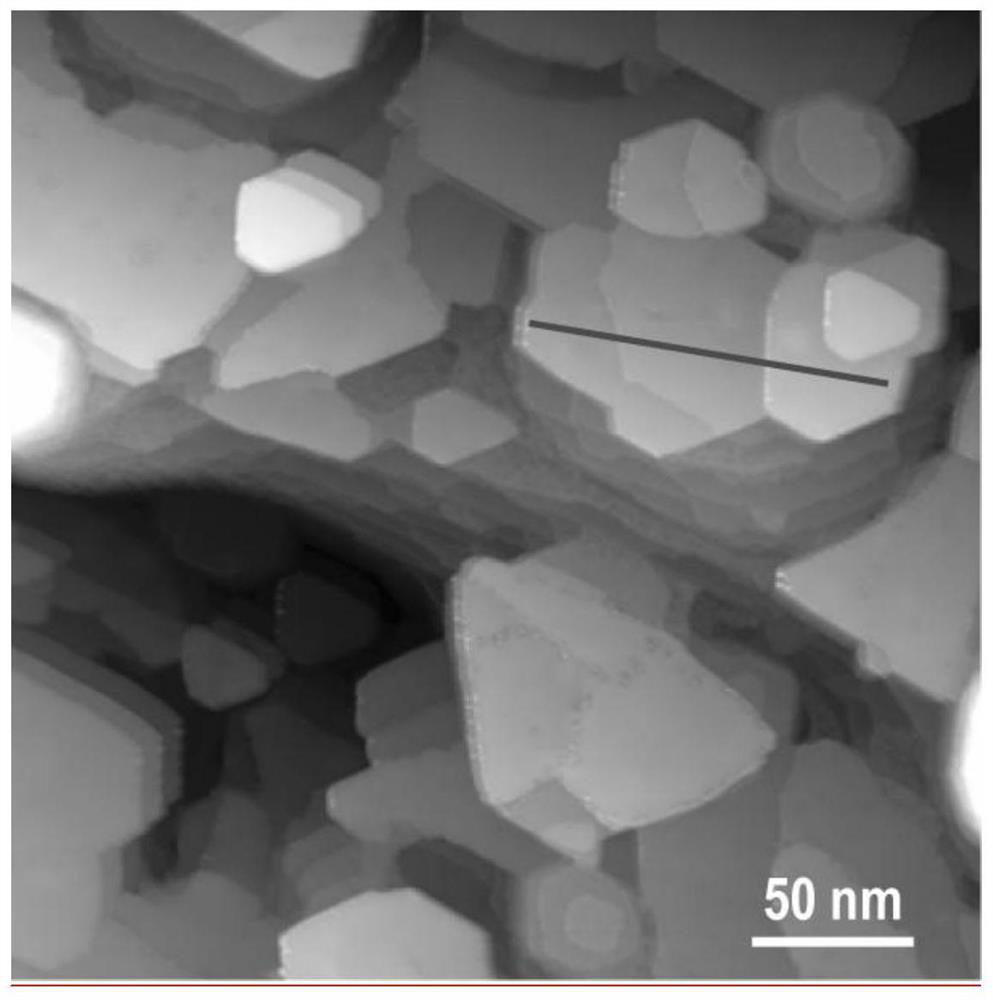

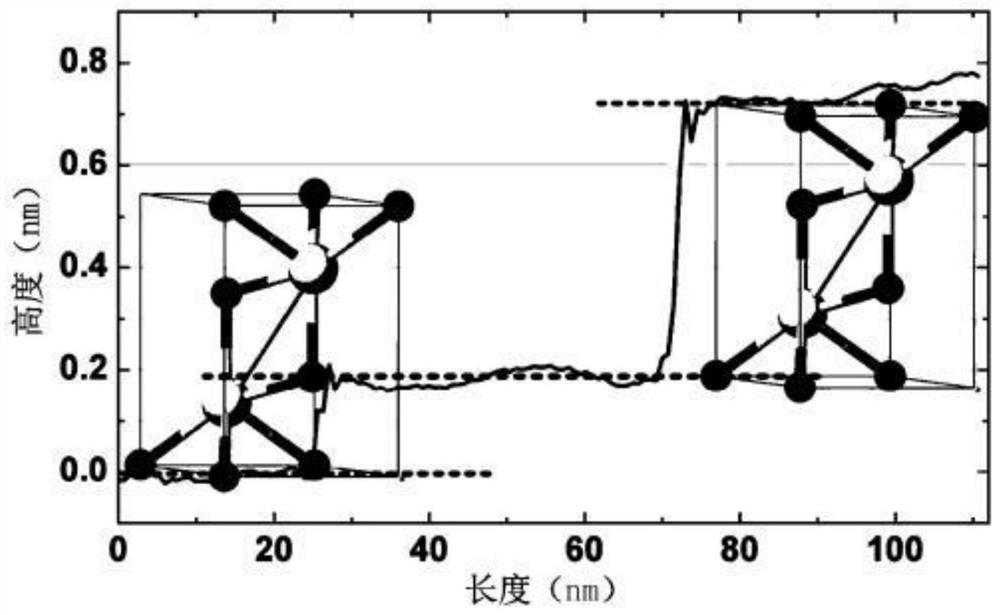

Preparation method for cubic-phase dicerium trioxide single-crystal thin film

The invention belongs to the field of preparation of thin films, and discloses a preparation method for a cubic-phase dicerium trioxide single-crystal thin film. According to the invention, dicerium trioxide has a structure of (Mn0.5Fe0.5)2O3, and a space group of 206. The method comprises the following steps: taking a single-crystal tungsten (110) substrate, and subjecting the surface of the single-crystal tungsten (110) substrate to cleaning treatment so as to obtain an atomic-scale flat surface; taking a cerium (Ce) evaporation source, and depositing cerium (Ce) on the surface of the treated single-crystal tungsten (110) substrate so as to obtain a cerium (Ce) single-crystal thin film with a thickness of 2 to 5 nanometers on the surface of the treated single-crystal tungsten (110) substrate; oxidizing the cerium (Ce) single-crystal thin film at a room temperature so as to obtain cerium dioxide (CeO2); and subjecting cerium dioxide (CeO2) to annealing treatment in a vacuum environment with an annealing temperature of 900 DEGC and an annealing time of 15 to 30 minutes so as to obtain the dicerium trioxide (Ce2O3) single-crystal thin film of a (001) plane. The cubic-phase dicerium trioxide (Ce2O3) single-crystal thin film of the (001) plane obtained by using the method provided by the invention is a supplement to a conventional catalytic model system.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Bright red cubic zirconium oxide crystal

InactiveCN107937982ASolve the puzzle where Big Red can't be coloredUnique formulaPolycrystalline material growthBy pulling from meltCeriumYttrium

The invention relates to a bright red cubic zirconium oxide crystal. The bright red cubic zirconium oxide crystal is prepared from the following formula raw materials: 89 to 94 percent of zirconium dioxide, 3 to 8 percent of yttrium oxide, 1.5 to 3 percent of rare earth dicerium trioxide or cerium dioxide and 1.5 to 4 percent of neodymium oxide. The bright red cubic zirconium oxide crystal can beprepared by the steps of mixing the above formula raw materials uniformly, placing the mixture into a crucible, smelting, performing crystal pulling and cooling. The formula is unique, the special formula and the proportion of a coloring agent are selected, the problem that the bright red cannot be colored when the raw materials are at high temperature of 2700 DEG C is solved successfully, the blank that no cubic zirconium oxide crystal serves as nature-imitated ruby is filled, and when the bright red cubic zirconium oxide crystal is used for producing the nature-imitated ruby, the color is beautiful and bright and the nature-imitated ruby can be compared favorably with the natural ruby.

Owner:冯春生

A kind of preparation method of ethylbenzene dehydrogenation styrene catalyst

Relating to a catalyst, the invention provides a preparation method of a catalyst for styrene preparation by ethylbenzene dehydrogenation. The catalyst has high crushing strength, large aperture and small specific surface area, and also has high catalytic activity in ethylbenzene dehydrogenation reaction under a low water ratio condition. The catalyst for styrene preparation by ethylbenzene dehydrogenation is a composite oxide of iron, potassium, magnesium, cerium and molybdenum. The method includes:1) preparation of nano-Ce2O3; and 2) preparation of the catalyst. According to a technical scheme, self-made nano-dicerium trioxide is adopted, and cerium nitrate and nano-dicerium trioxide in a proper ratio are introduced into the catalyst as the cerium source. The prepared catalyst has large aperture, small specific surface area and high crushing strength, and can maintain high catalytic activity under a low water-oil ratio condition.

Owner:XIAMEN UNIV

Preparation method of compound acrylate resin coating for heat isolation and corrosion protection of pipeline

InactiveCN107916034ASolve corrosionSolve the insulation performanceAnti-corrosive paintsIsolation effectMicrosphere

The invention discloses a preparation method of a compound acrylate resin coating for heat isolation and corrosion protection of a pipeline. The preparation method has the advantages that the acid andalkaline modification is performed on the basis of lanthanum oxide and cerium oxide, so that the anti-corrosive property and anti-aging property are improved; the rare earth ions can form coordination bonds with polarity groups of hydroxyl groups, hydroxymethyl groups and the like in the molecules of the base material, so that the coating can produce coordination polymerizing and drying, and thequick dryness of a paint film is improved; a superfine silicon dioxide aerogel is respectively subjected to hydrophobic and hydrophilic modification by trimethylchlorosilane and 3-aminopropylsilanetriol, the hydrophobic groups and hydrophilic groups are respectively grafted to the surface of the superfine silicon dioxide aerogel, the good compatibility with the compound base material is realized,the microsphere is tightly bonded with the base material, the interface heat drag is smaller than the air heat drag, and the heat isolation effect is improved; a chlorosulfonated polyethylene emulsionand a styrene-acrylic emulsion are compounded, so that the anti-aging property and the anti-corrosive property of the coating are improved.

Owner:安徽铭能保温科技有限公司

Modified colemanite and melamine polyphosphate flame-retardant synergistic corrosion-resistant coating

InactiveCN106752421AImprove flame retardant performanceImprove aging resistanceFireproof paintsChloropene polymer coatingsColemaniteTemperature resistance

The invention discloses modified colemanite and melamine polyphosphate flame-retardant synergistic corrosion-resistant coating. The modified colemanite and melamine polyphosphate flame-retardant synergistic corrosion-resistant coating is prepared from the following raw materials in parts by weight: 60 to 65 parts of chlorosulfonated polyethylene rubber latex, 35 to 40 parts of neoprene latex, 7 to 8 parts of polyoxyethylene aliphatic alcohol ether, a proper amount of deionized water, 2.5 to 3 parts of a silane coupling agent KH 560, 2 to 3 parts of lanthanum oxide, 1.5 to 2 parts of dicerium trioxide, a proper amount of a nitric acid solution at the concentration of 65 percent by weight, an ammonium bicarbonate solution at the concentration of 50 percent by weight, 10 to 12 parts of rutile type titanium dioxide, 1.5 to 2 parts of polyalkylene glycol, 2 to 3 parts of sodium-based montmorillonite, 4 to 5 parts of melamine polyphosphate, 4 to 5 parts of colemanite, 1 to 1.5 parts of oleic acid and a proper amount of absolute ethanol. The composition emulsion has flame retardance, high-temperature resistance and excellent adhesive force; a paint film is tough and anti-ageing; the process is simple and convenient in industrial control; and the corrosion-resistant coating is applied to surface corrosion prevention of metal equipment, pipelines, cylinders and the like, and prolongs the service time of equipment.

Owner:闻承岳

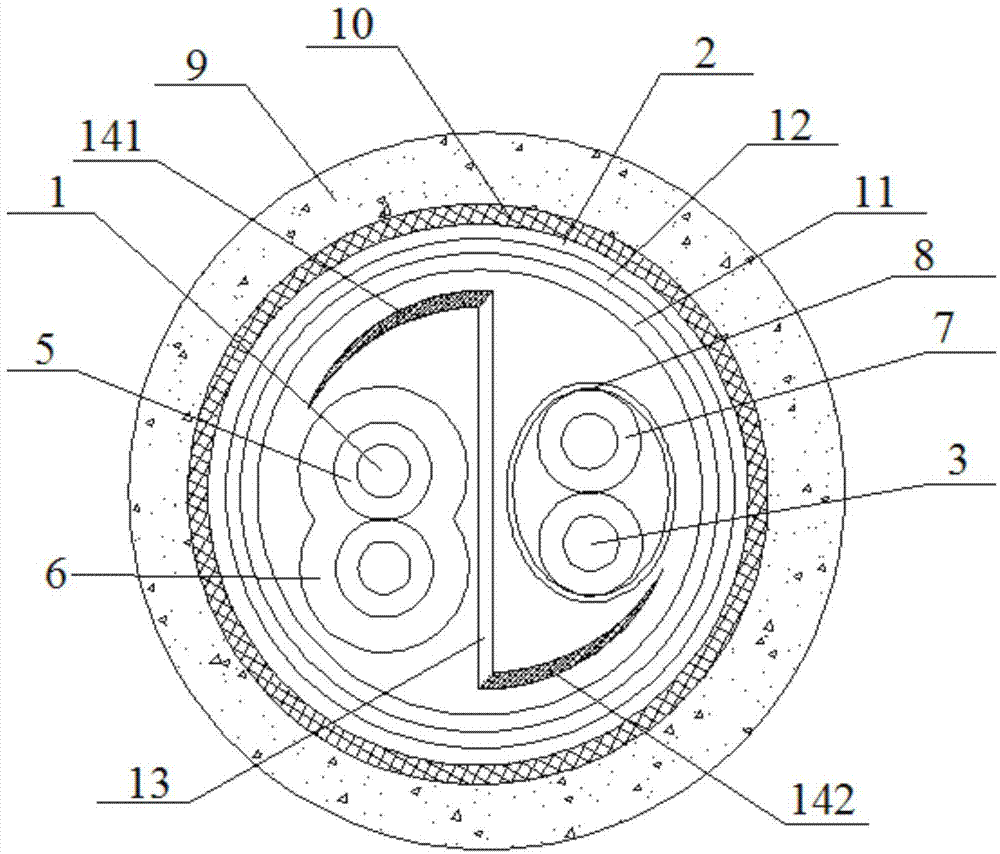

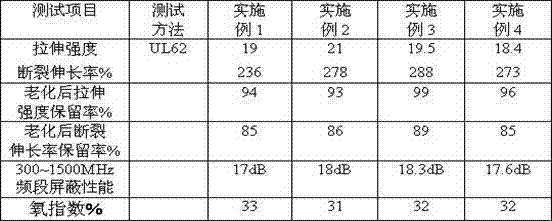

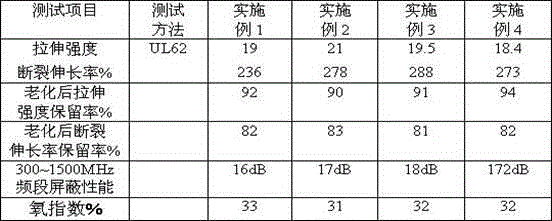

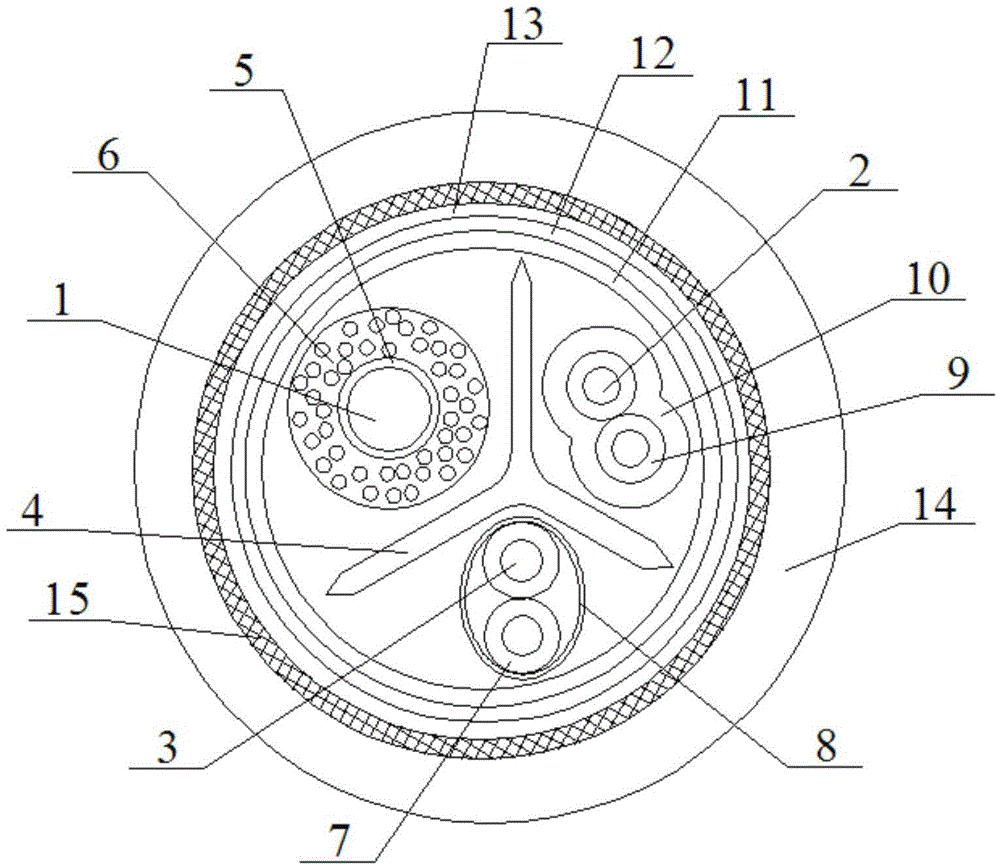

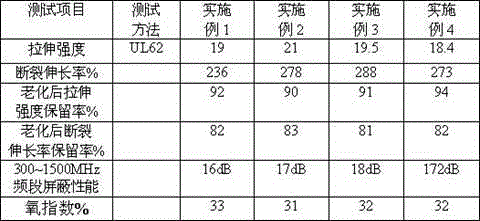

Heat-resisting type communication power source flexible cable

InactiveCN104766650AExcellent electromagnetic wave shielding performanceImprove balanceClimate change adaptationPower cables with screens/conductive layersPolyesterSesquioxide

The invention discloses a heat-resisting type communication power source flexible cable. The heat-resisting type communication power source flexible cable comprises two power copper wires and two data copper wires, wherein a separating plate is located between an inner sheath layer and a single-surface aluminum foil layer, a first lateral empennage part and a second lateral empennage part are arranged at the two ends of the separating plate respectively and located on the left and right sides of the separating plate respectively, and the separating plate is of a spiral structure in the length extending direction; the single-surface aluminum foil layer, the inner sheath layer and a filling rope surface are wrapped with a polyester belt layer; the outer surface of an inflaming retarding layer is wrapped with a shielding sheath layer, and the shielding sheath layer is composed of, by weight parts, PVC resin, ethylene-vinyl acetate copolymer, di-iso-decylphthalate, polythiophene, siloxane, cerium sesquioxide, antimonous oxide and asbestos wool. The electromagnetic wave shielding performance of a data cable is improved, the heat-resisting type communication power source flexible cable further has good tensioning and tearing strength physical mechanical performance, and the flame retardant property is further improved.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

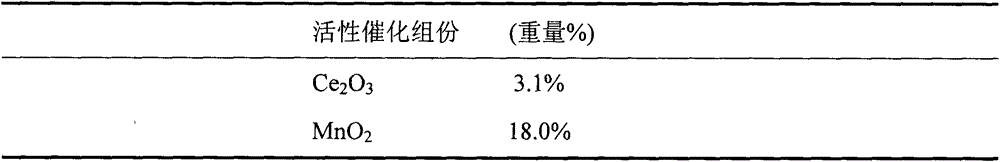

Catalyst for preparing p-nitroacetophenone by oxidizing 4-nitroethylbenzene and preparation method of catalyst

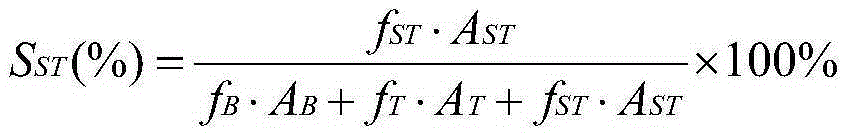

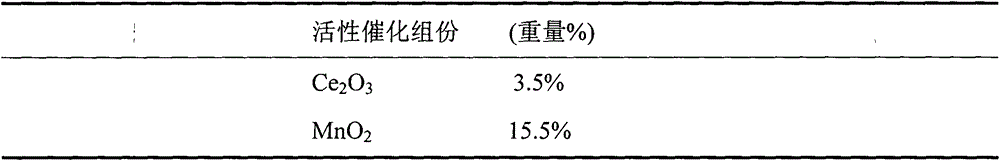

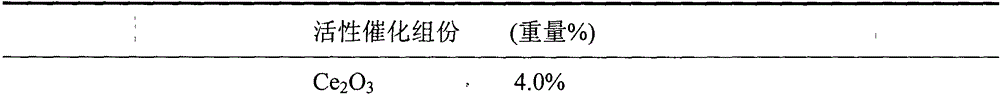

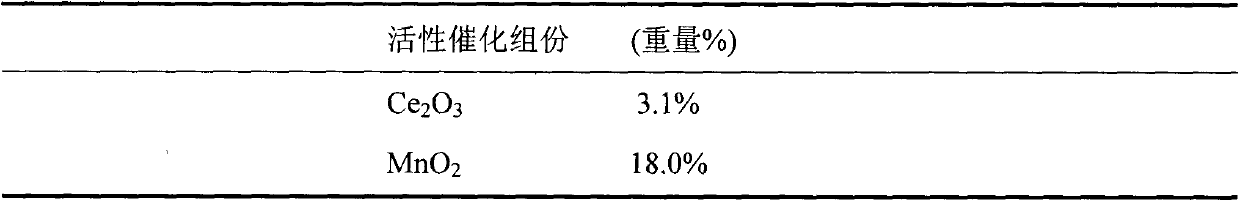

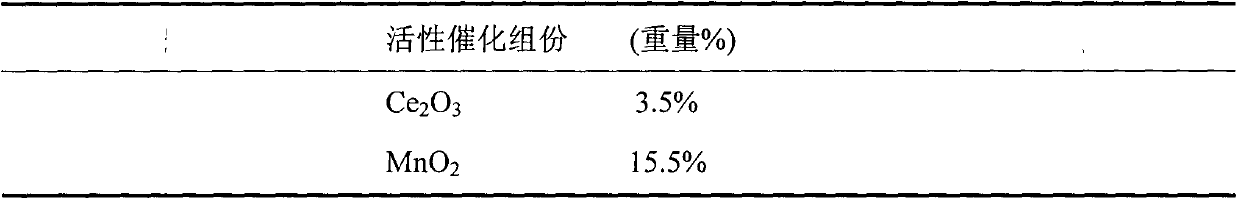

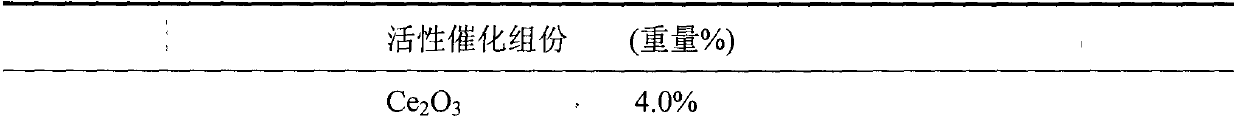

The invention provides a catalyst for preparing p-nitroacetophenone by oxidation of p-nitroethylbenzene and a preparation method thereof, which is a kind of catalyst with clay and talc as the main constituent raw materials, adding cerium (+3 valence), manganese (+2 )’s hydroxide is wet-milled in a ball mill to a powder particle size of less than 320 mesh, and a binder with MC or PVA as the main component is added, and the honeycomb ceramic blank is produced through the process of extrusion molding, which is fired at 1240-1280°C prepared catalyst. The catalyst includes active catalytic components cerium oxide, manganese dioxide and a ceramic carrier. Ce of the present invention 2 o 3 -MnO 2 / The honeycomb ceramic catalyst with ceramic carrier has the characteristics of good catalytic effect and long service life. The method is used to prepare p-nitroacetophenone by catalyzing p-nitroethylbenzene with pure oxygen, and the yield of p-nitroacetophenone is above 65%.

Owner:YANCHENG INST OF IND TECH

Wear-resistance-enhanced anticorrosive paint formed by compounding silicon nitride and epoxy ethylene

InactiveCN106497244AImprove flame retardant performanceImprove aging resistanceFireproof paintsChloropene polymer coatingsAmmonium Hydrogen CarbonatePolyacrylamide

The invention discloses wear-resistance-enhanced anticorrosive paint formed by compounding silicon nitride and epoxy ethylene resin. The wear-resistance-enhanced anticorrosive paint is prepared from the following raw materials in parts by weight: 60 to 65 parts of chlorosulfonated polyethylene latex, 35 to 40 parts of polychloroprene latex, 7 to 8 parts of polyoxyethylene aliphatic alcohol ether, a proper amount of deionized water, 2.5 to 3 parts of a silane coupling agent KH560, 2 to 3 parts of lanthanum oxide, 1.5 to 2 parts of dicerium trioxide, a proper amount of nitric acid solution with the concentration of 65 wt percent, a proper amount of ammonium hydrogen carbonate solution with the concentration of 50 wt percent, 10 to 12 parts of rutile titanium dioxide powder, 1.5 to 2 parts of polyacrylamide, 8 to 9 parts of epoxy ethylene resin, 6 to 7 parts of nano silicon nitride, 0.2 to 0.3 part of an accelerant DM, 0.2 to 0.3 parts of epoxy soybean oil, 2 to 2.5 parts of active magnesium oxide and 0.4 to 0.5 part of barium petroleum sulfonate. The paint disclosed by the invention has good anticorrosive property, environment-friendliness and wear-resistance, and the utilization period and the anticorrosive period are prolonged, so that the cost is reduced and the anticorrosive efficiency is improved.

Owner:闻承岳

Composite chlorosulfonated polyethylene anticorrosive paint doped with highly thermal-conductive filler

InactiveCN106497245AImprove flame retardant performanceImprove aging resistanceFireproof paintsChloropene polymer coatingsHexagonal boron nitrideSilanes

The invention discloses a composite chlorosulfonated polyethylene anticorrosive paint doped with highly thermal-conductive filler. The anticorrosive paint is prepared from the following raw materials (by weight): 60-65 parts of chlorosulfonated polyethylene latex, 35-40 parts of neoprene latex, 7-8 parts of polyoxyethylene aliphatic alcohol ether, a proper amount of deionized water, 2.5-3 parts of a silane coupling agent KH560, 2-3 parts of lanthana, 1.5-2 parts of dicerium trioxide, a proper amount of a nitric acid solution with concentration of 65wt%, an ammonium bicarbonate solution with concentration of 50wt%, 10-12 parts of rutile titanium dioxide, 0.9-1.1 parts of a dispersant NNO, 6-7 parts of hexagonal boron nitride, 3-4 parts of multiwalled carbon nanotube, a proper amount of isopropanol and 0.16-0.18 part of a titanate coupling agent TC-2. The prepared paint has excellent anticorrosive effect and heat-radiation and cooling effect, and can avoid fatigue, efflorescence, corrosion and tarnishing of the metal structural material due to long-term thermal expansion and cold contraction.

Owner:闻承岳

Modified anticorrosive chlorosulfonated polyethylene coating with polyaniline loaded on surfaces of zeolite molecular sieves

InactiveCN106566326AImprove flame retardant performanceImprove aging resistanceFireproof paintsChloropene polymer coatingsLanthanumAniline

The invention discloses a modified anticorrosive chlorosulfonated polyethylene coating with polyaniline loaded on the surfaces of zeolite molecular sieves. The coating is made of, by weight, 60-65 parts of chlorosulfonated polyethylene latex, 35-40 parts of neoprene latex, 7-8 parts of polyoxyethylene fatty alcohol ether, an appropriate amount of deionized water, 2.5-3 parts of silane coupling agents KH560, 2-3 parts of lanthanum oxides, 1.5-2 parts of cerous oxides, an appropriate amount of nitric acid solutions with the concentration being 65wt%, an appropriate amount of ammonium bicarbonate solutions with the concentration being 50wt%, 10-12 parts of rutile titanium dioxides, 1-1.2 parts of silicone emulsion, 2-3 parts of aniline, 0.1-0.12 part of ammonium persulfate, 4-5 parts of the zeolite molecular sieves, 0.3-0.4 part of sodium dodecyl benzene sulfonate and an appropriate amount of absolute ethyl alcohol. The manufactured coating has the advantages that an technology and equipment are simple, industrial production is easy, product construction is convenient, and the adhesive force and the quick-drying performance are excellent. The coating can be used on the surface of steel body structure and chemical pipeline equipment and has good preservative effect.

Owner:闻承岳

Chlorosulfonated polyethylene anti-corrosion coating with nano ferrite graphene composite material

InactiveCN106634244AImprove flame retardant performanceImprove aging resistanceFireproof paintsChloropene polymer coatingsCeriumSodium hydroxide

The invention discloses a chlorosulfonated polyethylene anti-corrosion coating with a nano ferrite graphene composite material. The chlorosulfonated polyethylene anti-corrosion coating is prepared from the following raw materials in parts by weight: 60-65 parts of chlorosulfonated polyethylene latex, 35-40 parts of neoprene latex, 7-8 parts of polyoxyethylene aliphatic alcohol ether, a proper amount of deionized water, 2.5-3 parts of a silane coupling agent KH560, 2-3 parts of lanthanum oxide, 1.5-2 parts of cerium sesquioxide, a proper amount of a 65wt% nitric acid solution, a 50wt% ammonium bicarbonate solution, 10-12 parts of rutile titanium dioxide, 1-1.5 parts of dipropylene glycol monomethyl ether, 2-2.5 parts of simethicone, 2.7-3 parts of ferric trichloride hexahydrate, 1.2-1.3 parts of cobalt chloride hexahydrate, 4-5 parts of graphene oxide, 0.1-0.12 part of sodium thiosulfate, a proper amount of absolute ethyl alcohol and a proper amount of a 10wt% sodium hydroxide solution. The chlorosulfonated polyethylene anti-corrosion coating disclosed by the invention has good atmosphere aging resistance, corrosion resistance and electromagnetic shielding property.

Owner:闻承岳

Cerium oxide-zirconium oxide-based mixed oxide and method for producing thereof

ActiveCN101096012BGood dispersionEasy to prepareCatalyst carriersInternal combustion piston enginesPlatinumMixed oxide

Owner:DAIICHI KIGENSO KAGAKU KOGYO CO LTD

Chlorosulfonated ethylene composite anticorrosive paint with organic montmorillonite modified zinc powder

InactiveCN106752420AImprove quick-dry performanceAccelerated corrosionFireproof paintsChloropene polymer coatingsPotassium hydroxideRutile

The invention discloses chlorosulfonated ethylene composite anticorrosive paint with organic montmorillonite modified zinc powder. The composite anticorrosive paint is prepared from the following raw materials in parts by weight: 60 to 65 parts of chlorosulfonated polyethylene latex, 35 to 40 parts of neoprene latex, 7 to 8 parts of polyoxyethylene aliphatic alcohol ether, a proper amount of deionized water, 2.5 to 3 parts of silane coupling agents KH560, 2 to 3 parts of lanthanum oxide, 1.5 to 2 parts of cerous oxide, a proper amount of nitric acid solution with the concentration being 65 weight percent, ammonium bicarbonate solution with the concentration being 50 weight percent, 10 to 12 parts of rutile titanium dioxide, 1 to 1.5 parts of methyl acrylate, 0.8 to 1 part of sodium hexametaphosphate, 6 to 7 parts of flake zinc powder, 3 to 4 parts of organic montmorillonite, 8 to 9.5 parts of silica sol and 1 to 1.2 parts of potassium hydroxide. The prepared paint has the advantages that the mechanical property is excellent; the advantages of good surface adhesion force on the surface of metal, high covering capability, high floating capability and high shielding capability are prominent; the anticorrosion performance is excellent; the process is simple; the industrial control is convenient; the paint is worthy of being popularized.

Owner:闻承岳

Production raw material and preparation method of a disc insulator with good insulation performance

ActiveCN113416057BImprove insulation performanceImprove body strengthInsulatorsCeramic materials productionGlazeCerium

Owner:萍乡强盛电瓷制造有限公司

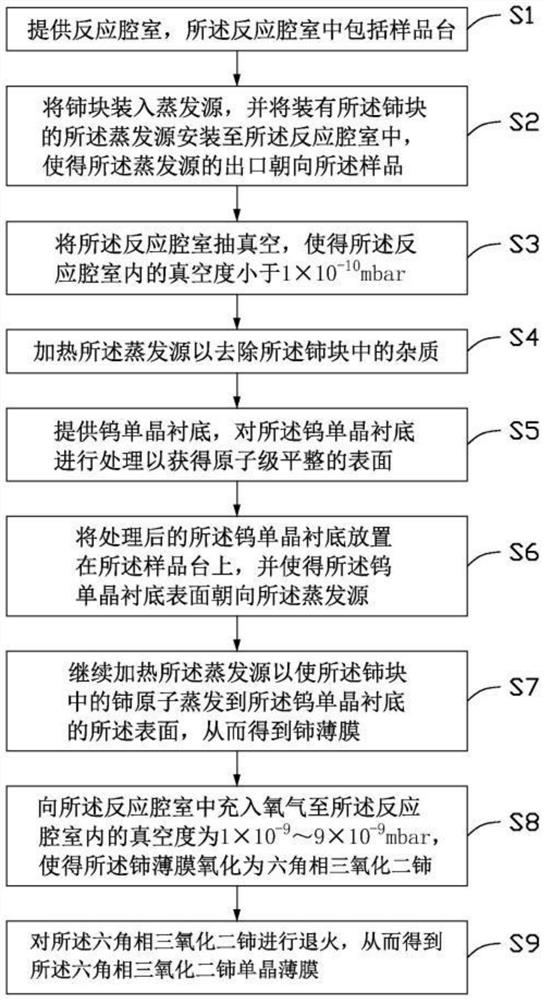

Preparation method of hexagonal-phase dicerium trioxide monocrystal film

InactiveCN114457407AHigh purityPolycrystalline material growthFrom solid stateCeriumPhysical chemistry

The invention provides a preparation method of a hexagonal-phase dicerium trioxide monocrystal film, which comprises the following steps: providing a reaction chamber which comprises a sample table; loading the cerium block into an evaporation source; the reaction chamber is vacuumized; heating the evaporation source; the method comprises the following steps: providing a tungsten single crystal substrate, and processing the tungsten single crystal substrate to obtain an atomic level flat surface; the processed tungsten single crystal substrate is placed on the sample table; continuously heating the evaporation source to obtain a cerium film; oxygen is filled into the reaction chamber, so that the cerium film is oxidized into hexagonal-phase dicerium trioxide; and carrying out annealing on the hexagonal-phase dicerium trioxide so as to obtain the hexagonal-phase dicerium trioxide single crystal thin film. The hexagonal-phase dicerium trioxide single crystal film prepared by the method is relatively high in purity.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Catalyst for preparing p-nitroacetophenone by oxidation of p-nitroethylbenzene and preparation method thereof

The invention provides a catalyst for preparing p-nitroacetophenone by oxidizing 4-nitroethylbenzene and a preparation method of the catalyst. The method comprises the steps that clay and talc serve as the main raw materials, hydroxides of cerium (+3) and manganese (+2) are subjected to wet milling in a ball mill till the particle sizes are smaller than 320 meshes, an adhesive taking MC or PVA as the main component is added, a honeycomb greenware is produced through a technological process of extrusion molding, and the catalyst is obtained through firing at 1,240 DEG C to 1,280 DEG C. The catalyst comprises active catalytic components of cerium oxide, manganese dioxide and a ceramic carrier. The honeycomb ceramic catalyst of the Ce2O3-MnO2 and ceramic carrier has the advantages of being good in catalytic effect and long in service life. The catalyst is used for preparing p-nitroacetophenone by conducting pure oxygen catalyzing on 4-nitroethylbenzene, and the yield of p-nitroacetophenone is 65% or above.

Owner:YANCHENG INST OF IND TECH

Modified zinc oxide antibiosis and mildew-resistance enhanced chlorosulfonated polyethylene anticorrosion coating

InactiveCN106497246AImprove flame retardant performanceImprove aging resistanceFireproof paintsAntifouling/underwater paintsZinc nitrateCorrosion

The invention discloses a modified zinc oxide antibiosis and mildew-resistance enhanced chlorosulfonated polyethylene anticorrosion coating, which is prepared from the following raw materials (by weight): 60-65 parts of chlorosulfonated polyethylene latex, 35-40 parts of neoprene latex, 7-8 parts of polyoxyethylene aliphatic alcohol ether, a proper amount of deionized water, 2.5-3 parts of a silane coupling agent KH560, 2-3 parts of lanthana, 1.5-2 parts of dicerium trioxide, a proper amount of a nitric acid solution with concentration being 65 wt%, an ammonium bicarbonate solution with concentration being 50 wt%, 10-12 parts of rutile titanium dioxide, 2-3 parts of aluminium triphosphate, 5-6 parts of cassia oil, 3-4 parts of barium metaborate, 3-4 parts of zinc nitrate, 3-4 parts of hexamethylene tetramine, 4-5 parts of stearic acid and a proper amount of anhydrous ethanol. The prepared composite anticorrosion coating is full water-borne and environment friendly, has good synergistic effect of various components, has short film-forming drying time, good hardness, corrosion resistance, weather resistance and excellent film adhesion, and can be used for anticorrosion of outdoor pipelines, metal machinery equipment and chemical equipment.

Owner:闻承岳

Production raw material and preparation method of disc-shaped insulator with good insulating property

ActiveCN113416057AImprove insulation performanceImprove body strengthInsulatorsCeramic materials productionSesquioxideGlaze

The invention provides a production raw material and a preparation method of a disc-shaped insulator with good insulating property, and relates to the technical field of power equipment. According to the production raw material and the preparation method of the disc-shaped insulator with good insulating property, a main body raw material of the disc-shaped insulator comprises the following raw materials in parts by mass: 15 to 25 parts of aluminum oxide, 10 to 15 parts of high-potassium feldspar, 40 to 60 parts of clay, 0.1 to 1 part of lanthanum oxide, 0.1 to 1 part of cerium sesquioxide, 0.1 to 0.88 part of praseodymium oxide, 15 to 18 parts of nacrite and 15 to 18 parts of garnet. A disc-shaped insulator main body glaze raw material comprises the following raw materials in parts by mass: 15-20 parts of quartz, 2-5 parts of talc, 18-27 parts of kaolin, 1-3 parts of copper oxide, 1-3 parts of ferric oxide and 0.1-1 part of rare earth oxide. The processed insulator can have good mechanical strength, meanwhile, the processed insulator has good insulativity in use, long-term use of the insulator can be guaranteed, and the insulator is worthy of being vigorously popularized.

Owner:萍乡强盛电瓷制造有限公司

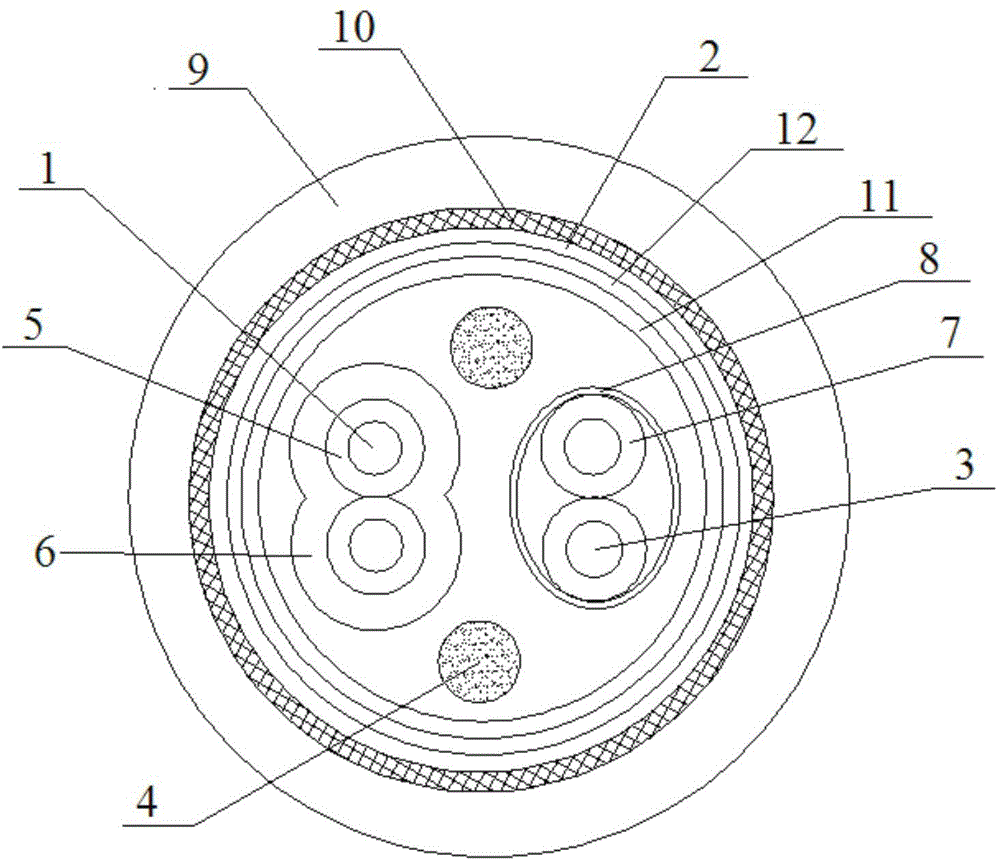

Hybrid cable integrating electric power and data transmission

ActiveCN104835559AImprove crosslink strengthExcellent electromagnetic wave shielding performancePower cables including communication wiresPower cables with screens/conductive layersPolyesterCopper conductor

The invention discloses a hybrid cable integrating electric power and data transmission. The cable comprises two electric power copper conductors and two data copper conductors. The two data copper conductors are respectively wrapped by a shielding insulating layer. A single-sided aluminum foil layer wraps the outer surfaces of the two shielding insulating layers. A polyester tape layer wraps surfaces of the single-sided aluminum foil layer, an inner sheath layer, and a filling rope. A double-sided aluminum foil layer wraps the outer surface of the polyester tape layer. A flame-retardant layer wraps the outer surface of the double-sided aluminum foil layer. An outer sheath layer wraps the outer surface of the flame-retardant layer. The shielding insulating layer contains PVC resin, ethylene-vinyl acetate copolymer, isodecyl phthalic acid, polythiophene, siloxane, fumed silica, cerium oxide, antimonous oxide, and asbestos wool. The cable improves reflection and absorption of low-frequency electromagnetic waves, and has good physical and mechanical property of stretching and tearing strength while improving crosstalk and signal attenuation, and improves flame retardation performance.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

An alloy co-infiltrating dacromet and sealing layer comprehensive anti-corrosion coating

ActiveCN106009794BImprove anti-corrosion performanceHigh surface hardnessSolid state diffusion coatingAnti-corrosive paintsPolyethylene glycolGlycerol

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Integrated data cable for telecommunication power source

InactiveCN106297978AExcellent electromagnetic wave shielding performanceImproved near-end crosstalk (NEXT) performanceInsulated cablesInsulated conductorsCopper wireCerium

The invention discloses an integrated data cable for a communication power source. The integrated data cable comprises an aluminum core, two electric power copper wires, two data copper wires and a herringboned frame; two data copper wires are respectively wrapped with a shielding insulated layer; and an insulating foamed layer, a single-sided aluminum foil layer and an inner sheath layer are respectively located in the first cavity, second cavity and third cavity of the herringboned frame. The shielding insulated layer is composed of the following components by weight: 100 parts of PVC resin; 40 to 60 parts of ethylene-vinyl acetate copolymer; 10 to 12 parts of isodecyl phthalate; 15 to 20 parts of polythiophene; 5 to 10 parts of siloxane; 20 to 25 parts of fumed silica; 0.5 to 1 part of cerium(III) oxide; and 5 to 10 parts of antimony(III) oxide. With the integrated data cable of the invention adopted, the reflection and absorption of low-frequency electromagnetic waves can be improved, the problem of crosstalk and signal attenuation can be solved, and the crosslinking strength of base materials is improved. The integrated data cable has better physical and mechanical properties such as high tensile and tearing strength.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com