Preparation method for cubic-phase dicerium trioxide single-crystal thin film

A technology of cerium oxide and single crystal thin film, which is applied in the direction of chemical instruments and methods, single crystal growth, single crystal growth, etc., and can solve the problems of non-disclosure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

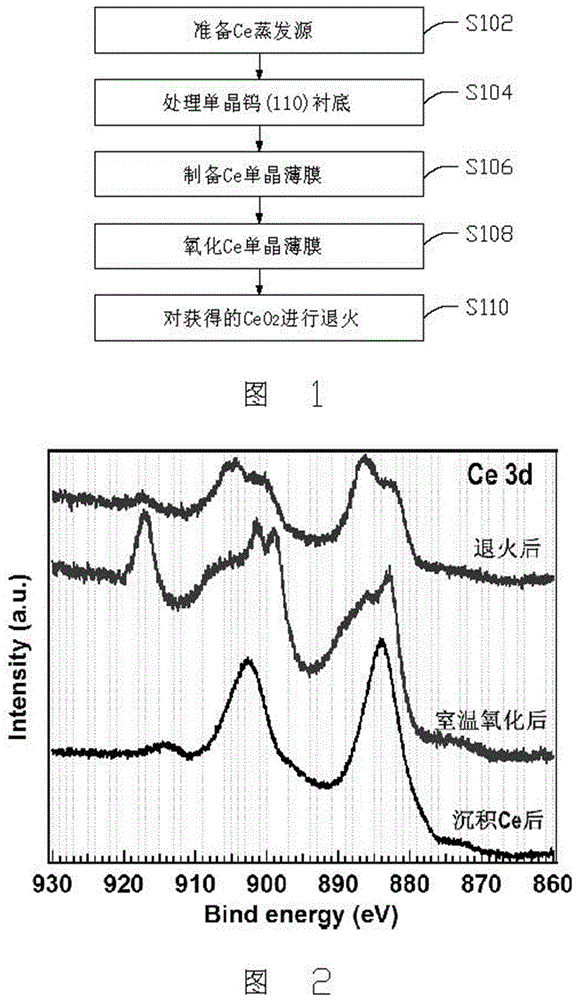

[0034] Please refer to figure 1 , the preparation method of the embodiment of the present invention comprises the following steps:

[0035] S102: Prepare a Ce evaporation source, specifically including:

[0036] a. After removing surface oxides from high-purity Ce rods (the purity of Ce is 99.9%), put them into a tantalum (Ta) crucible and put them into a high-temperature evaporation source;

[0037] b. Put the high-temperature evaporation source into the molecular beam epitaxy system (MBE), and get 2×10 after vacuum baking -10Millibar (mbar) ultra-high vacuum environment;

[0038] c. Gradually raise the temperature of the evaporation source, and degas the Ce source in the tantalum crucible to remove impurities until the temperature rises to 1600°C. After several rounds of degassing, the background vacuum of MBE reaches 5×10 -11 mbar, after trial evaporation of Ce on a clean molybdenum (Mo) plate, use X-ray photoelectron spectroscopy (XPS) to detect the chemical state of Ce...

Embodiment 1

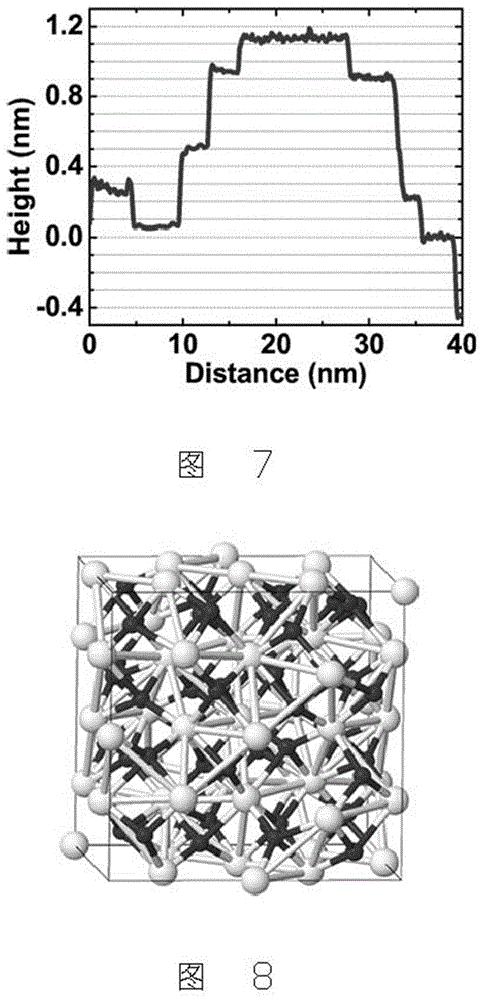

[0049] Ce was deposited on the atomically flat single crystal tungsten (110) surface for about 9 minutes to obtain a Ce single crystal thin film with a thickness of about 2 nm.

[0050] The prepared Ce single crystal thin film was introduced into a high-vacuum fast sampling chamber, and a 1×10 -3 Mbar of high-purity oxygen, oxidized at room temperature for 32 hours, verified by XPS analysis, the main component of the oxidation product is CeO 2 .

[0051] The oxidized CeO 2 Re-introduce into the ultra-high vacuum chamber for annealing treatment, the annealing temperature is 900°C, and the time is 15 minutes.

[0052] The samples were monitored and detected during the preparation process and after the preparation of this example, and the results are as follows:

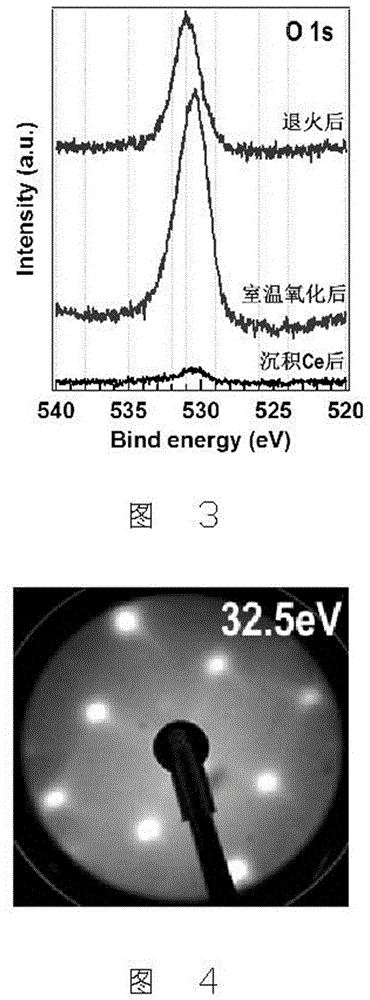

[0053] The chemical state of Ce during the preparation process was monitored by XPS. After depositing Ce film, 1×10 -3 After oxidizing Ce at room temperature under mbar oxygen pressure, after annealing at 900 °C. ...

Embodiment 2

[0056] Ce was deposited on the atomically flat single crystal tungsten (110) surface for about 20 minutes to obtain a Ce single crystal thin film with a thickness of about 5 nm.

[0057] The prepared Ce single crystal thin film is introduced into a high-vacuum rapid sampling chamber, and 1 atmosphere of high-purity oxygen is introduced, and it is oxidized at room temperature for 20 hours. After XPS analysis and verification, the main component of the obtained oxidation product is CeO 2 .

[0058] The oxidized CeO 2 Re-introduce into the ultra-high vacuum chamber for annealing treatment, the annealing temperature is 900°C, and the time is 30 minutes.

[0059] The samples were monitored and detected during the preparation process and after the preparation of this example, and the results are as follows:

[0060] XPS was used to monitor the chemical state of Ce during the preparation process, after oxidation of Ce at room temperature under 1 atmosphere of oxygen pressure, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com