High-temperature rare earth oxide laser crystal and preparation method thereof

A technology of rare earth oxides and laser crystals, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., to achieve the effects of less cracking, high transparency, and short cycle times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

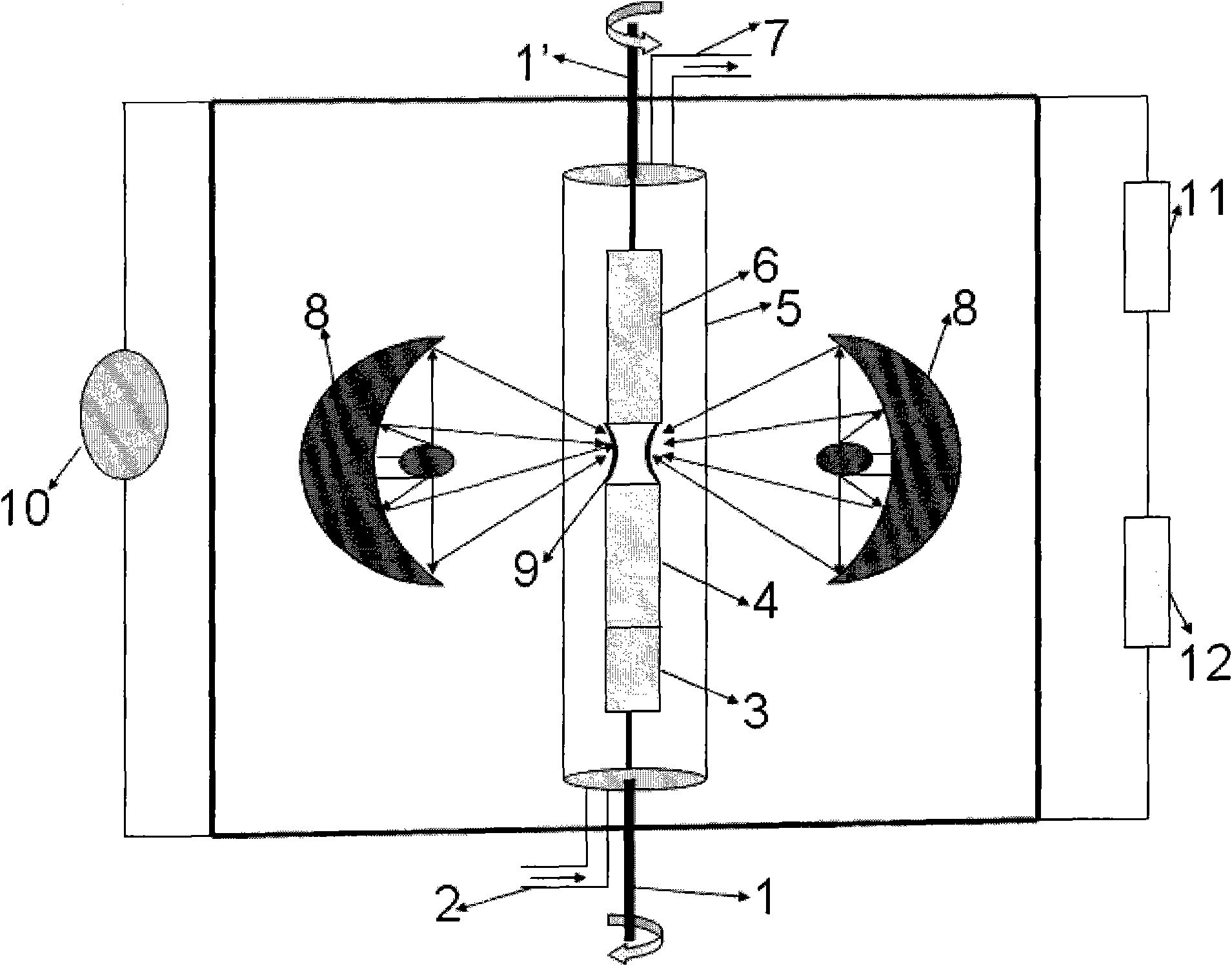

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Nd:Lu 2 o 3 the crystal

[0039] Preparation (Nd x Lu 1-x ) 2 o 3 , the specific chemical equation is: xNd 2 o 3 +(1-x)Lu 2 o 3 =(Nd x Lu 1-x ) 2 o 3

[0040] The raw material that present embodiment adopts is Nd 2 o 3 and Lu 2 o 3 , take x=0.01 in the matching ratio, and set Nd 2 o 3 (4N) and Lu 2 o 3 (5N) The raw material is properly dried in the air, then strictly weighed according to the stoichiometric ratio, and fully mixed, put into a Pt crucible and sintered at 1000-1100°C for 8 hours, and the obtained polycrystalline material is ground into a fine powder with an average particle size The diameter is 4μm. Take 30g and 15g of polycrystalline materials and put them into two long balloons respectively, compact them with glass rods, vacuumize them and put them under hydrostatic pressure of 68KN for 1 minute to make 2 round rods with the same diameter. is 10mm, the lengths are 80mm and 40mm respectively, and then sintered in a rotary s...

Embodiment 2

[0042] Example 2: Nd:Sc 2 o 3 the crystal

[0043] Preparation (Nd x sc 1-x ) 2 o 3 , chemical equation: xNd 2 o 3 +(1-x)Sc 2 o 3 =(Nd x sc 1-x ) 2 o 3

[0044] The raw material that present embodiment adopts is Nd 2 o 3 and Sc 2 o 3 , take x=0.01 in the matching ratio, and set Nd 2 o 3 (4N) and Sc 2 o 3 (5N) high-purity raw materials, dried properly in the air, then strictly weighed according to the stoichiometric ratio, and fully mixed, put into a Pt crucible and sintered at 1000-1100°C for 8 hours, and the obtained polycrystalline material was ground into fine powder, with an average particle size of 4 μm.

[0045] According to the method of Example 1, two polycrystalline material rods were prepared and loaded into the floating zone growth furnace, and the temperature was raised until the lower end of the upper material rod and the upper end of the seed crystal rod melted, and the contact began to grow, and the growth temperature range was 2400-2500 ° ...

Embodiment 3

[0046] Example 3: Yb:Lu 2 o 3 the crystal

[0047] Preparation (Yb x Lu 1-x ) 2 o 3 , chemical equation: xYb 2 o 3 +1-xLu 2 o 3 =(Yb x Lu 1-x ) 2 o 3

[0048] The raw material that present embodiment adopts is high-purity Yb 2 o 3 and Lu 2 o 3 , take x=0.05 in the matching ratio, and Yb 2 o 3 (4N) and Lu 2 o 3 (5N) high-purity raw materials, dried properly in the air, then strictly weighed according to the stoichiometric ratio, and fully mixed, put into a Pt crucible and sintered at 1000-1100°C for 8 hours, and the obtained polycrystalline material was ground into fine pink.

[0049] According to the method of Example 1, two polycrystalline material rods were prepared and loaded into a floating zone growth furnace, and the rest of the growth conditions were the same as in Example 1. After the growth, cool down to room temperature for five hours. The crystals taken out from the floating zone furnace are colorless and transparent. Hereafter Yb:Lu 2 o 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com