Catalyst for preparing p-nitroacetophenone by oxidation of p-nitroethylbenzene and preparation method thereof

A technology of p-nitroacetophenone and p-nitroethylbenzene, which is applied in the field of catalyst and its preparation, can solve the problems of difficult separation of catalyst and product, difficulty in repeated recycling, and low catalyst efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

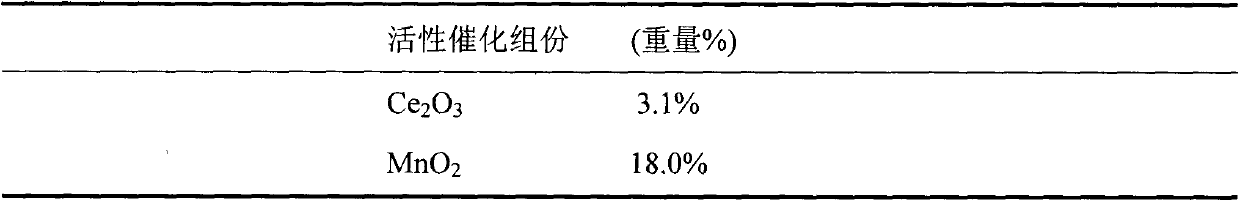

Embodiment 1

[0018] Take by weighing 46g anhydrous cerium trichloride zinc (CeCl 3 ) was dissolved in 250ml of deionized water. After fully dissolving evenly, stir rapidly and add 40% NaOH dropwise to adjust the pH to 12 to obtain a white slurry.

[0019] Weigh 312g manganese sulfate (MnSO 4 ) was dissolved in 1000ml of deionized water. After fully dissolving evenly, stir rapidly and add 40% NaOH dropwise to adjust the pH to 10 to obtain a pink slurry, which was oxidized to a brown slurry.

[0020] Wet grind 660g of clay, 130g of talc and the above two slurries in a ball mill until the powder is less than 320 mesh, add a binder, and go through the extrusion molding process to produce a honeycomb ceramic blank, using a box-type drying furnace at 105°C After drying for 3 hours and firing at 1280°C for 6 hours, the cylindrical honeycomb ceramic catalyst was obtained with a size (mm) of 150×150×300, a number of pores of 25×25, a wall thickness (mm) of 1.0, a pore width of 2.77, and a specific...

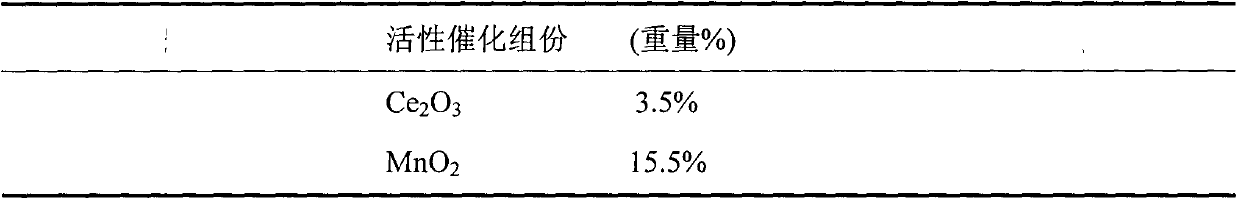

Embodiment 2

[0025] Weigh 52g anhydrous cerium trichloride zinc (CeCl 3 ) was dissolved in 250ml of deionized water. After fully dissolving evenly, stir rapidly and add 40% NaOH dropwise to adjust the pH to 12 to obtain a white slurry.

[0026] Weigh 268g manganese sulfate (MnSO 4 ) was dissolved in 1000ml of deionized water. After fully dissolving evenly, stir rapidly and add 40% NaOH dropwise to adjust the pH to 10 to obtain a pink slurry, which was oxidized to a brown slurry.

[0027] Wet grind 665g of clay, 145g of talc and the above two slurries in a ball mill until the powder is less than 320 mesh, add a binder, and go through the process of extrusion molding to produce a honeycomb ceramic blank, using a box-type drying furnace at 105°C After drying for 3 hours and firing at 1260°C for 6 hours, the cylindrical honeycomb ceramic catalyst was obtained with a size (mm) of 150×150×300, a number of pores of 32×32, a wall thickness (mm) of 1.0, a pore width of 3.66, and a specific surface...

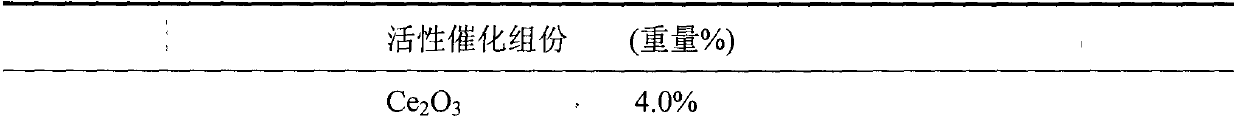

Embodiment 3

[0032] Weigh 60g anhydrous cerium trichloride zinc (CeCl 3 ) was dissolved in 250ml of deionized water. After fully dissolving evenly, stir rapidly and add 40% NaOH dropwise to adjust the pH to 12 to obtain a white slurry.

[0033] Weigh 248g manganese sulfate (MnSO 4 ) was dissolved in 1000ml of deionized water. After fully dissolving evenly, stir rapidly and add 40% NaOH dropwise to adjust the pH to 10 to obtain a pink slurry, which was oxidized to a brown slurry.

[0034] Wet grind 680g of clay, 107g of talc and the above two slurries in a ball mill until the powder is less than 320 mesh, add a binder, and go through the process of extrusion molding to produce a honeycomb ceramic blank, using a box-type drying furnace at 105°C After drying for 3 hours and firing at 1260°C for 6 hours, the cylindrical honeycomb ceramic catalyst was obtained with a size (mm) of 150×150×300, a number of pores of 40×40, a wall thickness (mm) of 0.7, a pore width of 3.03, and a specific surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com