Cerium oxide-zirconium oxide-based mixed oxide and method for producing thereof

A mixed oxide, zirconia-based technology, which is applied in zirconium compounds, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of no OSC and platinum dispersion, and achieve the effect of excellent platinum dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] 280g of 20% cerium nitrate solution (CeO 2 Equivalent to containing 56 g) heated to 85 ℃, then added 624g 25% sodium sulfate solution (Na 2 SO 4 The equivalent weight is 156 g), and it was maintained at 85° C. for 1 hour to obtain a slurry containing cerium sulfate-sodium mixed salt.

[0103] 110g of 20% zirconium nitrate solution (ZrO 2 Equivalent is containing 22g) and 110g 20% cerium nitrate solution (CeO 2 Equivalent is to contain 22g) to join in this alkaline slurry containing cerium sulfate-sodium mixed salt.

[0104] The solution was then neutralized with 500 g of 25% sodium hydroxide. The pH at this point is 12 or higher.

[0105] Continuing, the hydroxide is obtained by filtering and rinsing with water.

[0106] The obtained hydroxide was then fired at 650° C. in air for 5 hours to obtain the oxide.

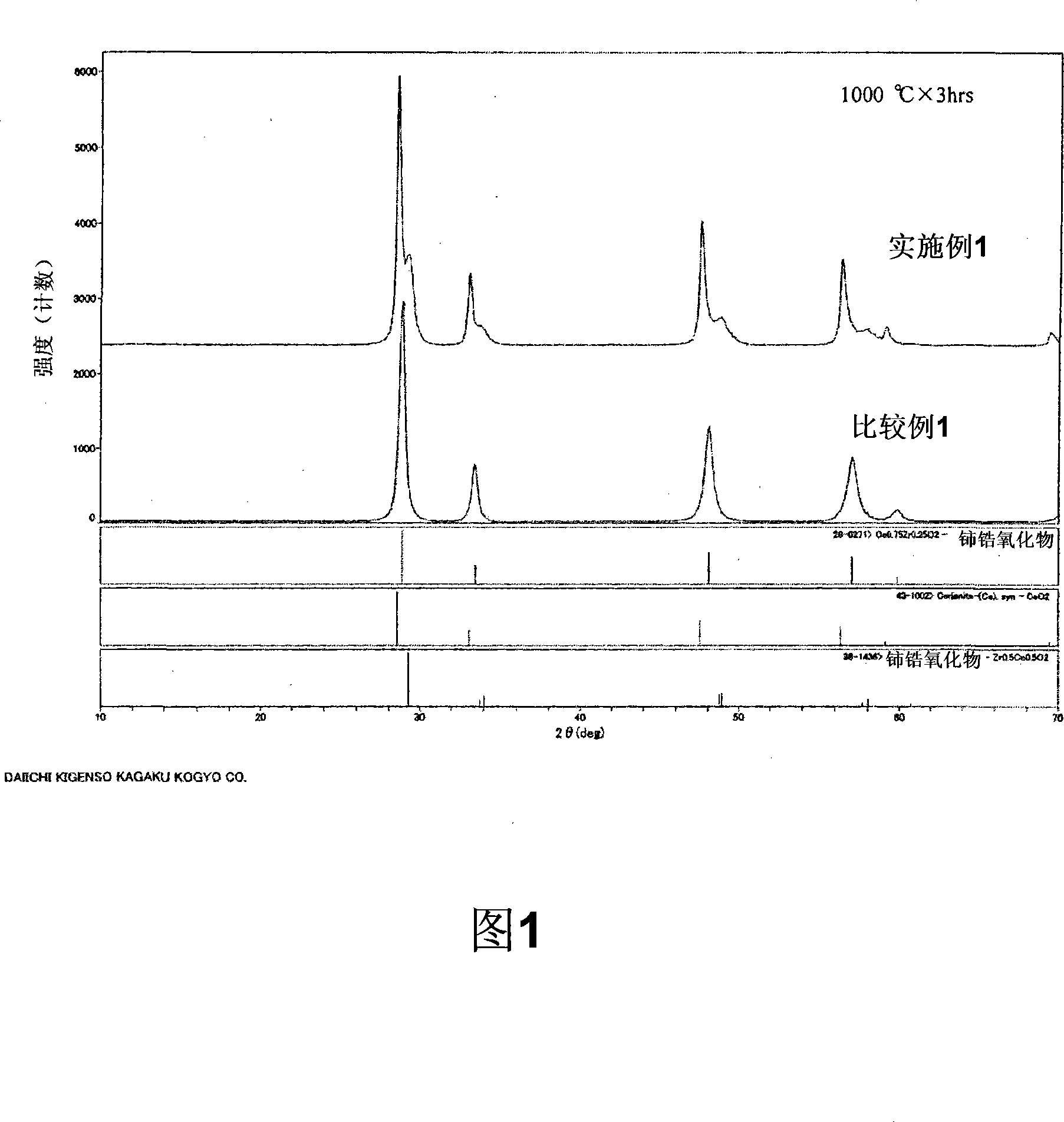

[0107] The X-ray diffraction results of the obtained oxide are shown in FIG. 1 .

[0108] In addition, the specific surface area of the oxide, the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com