Low-temperature SCR (Selective Catalytic Reduction) catalyst and preparation method thereof

An SCR catalyst and catalyst technology, applied in the field of denitration, can solve the problem that the carrier is difficult to load active components, and achieve the effect of improving the catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] 1. MnO 2 Preparation of:

[0035] According to relevant information reports: Manganese oxide is a variable price oxide. There are four different preparation methods, and the properties of manganese oxide obtained by different methods and different pH values are also different. We use the following method to synthesize manganese oxide:

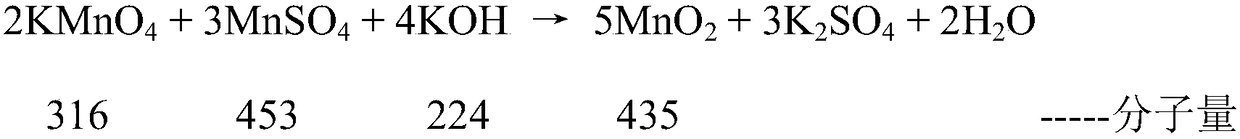

[0036] The principle of the reaction is:

[0037]

[0038] Specific steps are as follows:

[0039] (1) Dissolve 15.8g potassium permanganate and 12.4g potassium hydroxide in 300ml deionized water, stir and dissolve, and record it as liquid A;

[0040] (2) 13g manganese sulfite is dissolved in 200ml deionized water to make liquid B;

[0041] (3) Slowly add liquid B to liquid A dropwise under the conditions of normal temperature, normal pressure and strong stirring;

[0042] (4) After the addition is completed, age for 30min, then filter and wash to the filtrate without sulfate ions (using BaCl 2 solution detection);

[0043] ...

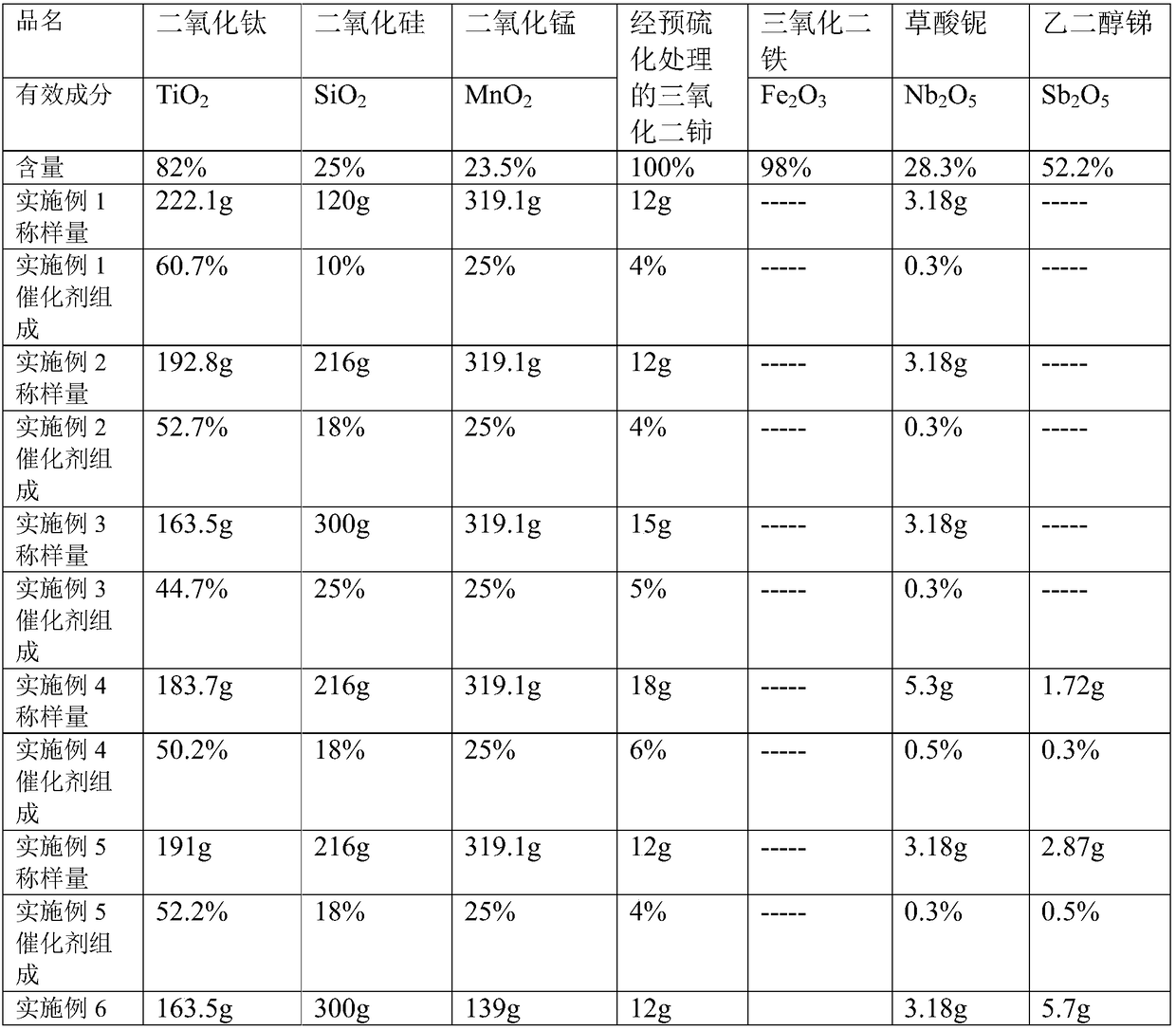

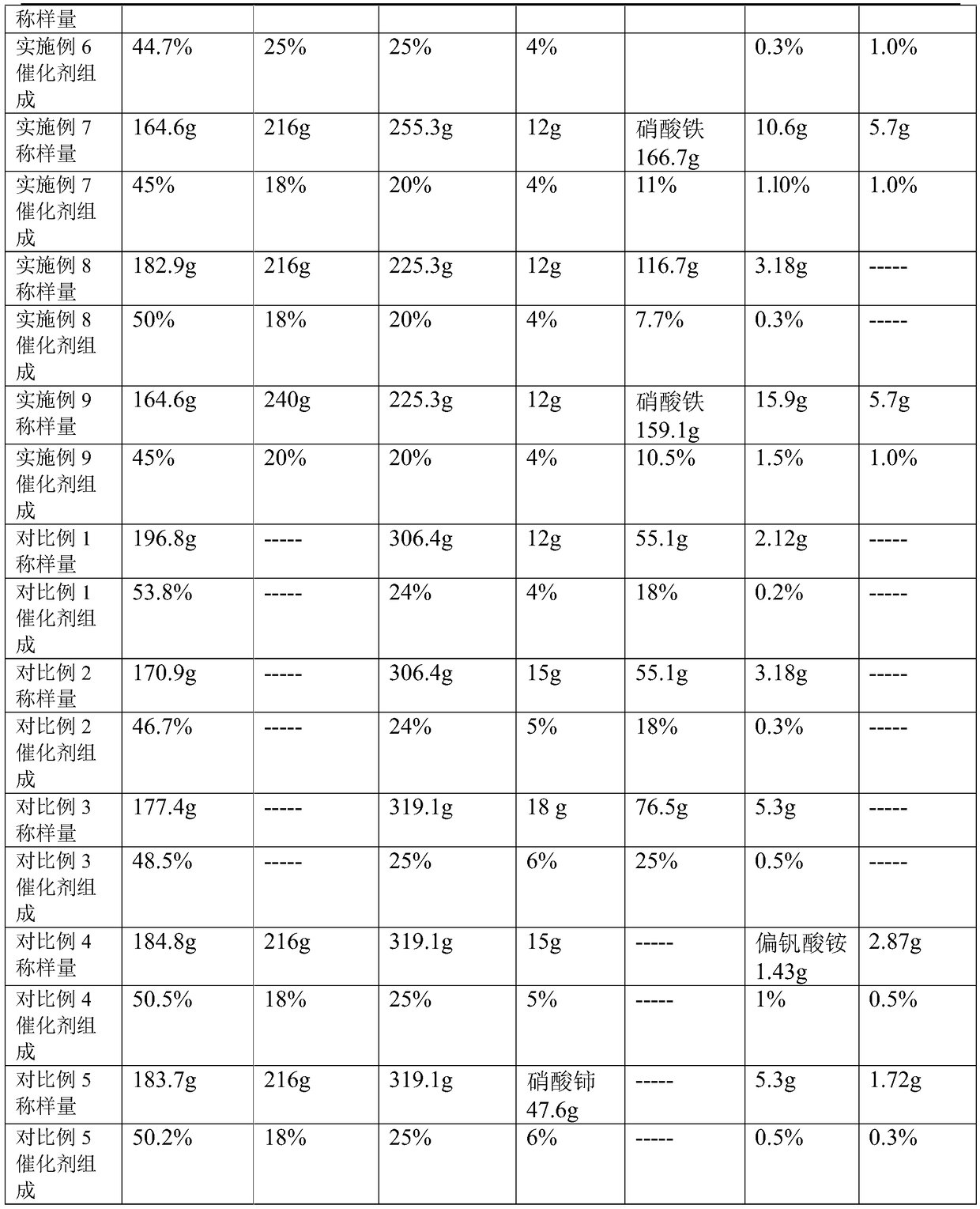

Embodiment 1

[0054] A preparation method of a low-temperature SCR catalyst in this embodiment comprises the following steps:

[0055] (1) Weigh the prepared raw materials: 319g of manganese dioxide, 120g of silicon dioxide, 12g of presulfurized cerium oxide, 3.18g of niobium oxalate and 222.1g of titanium dioxide, put them into the kneader, and then add the formed Lubricant (stearic acid) 2.25g, release agent (glycerin) stearic acid 2.25g, defoamer (lactic acid) 0.3g, binder (hydroxymethylcellulose, CMC) 3.75g, polyethylene oxide (PEO) 3.75g and an appropriate amount of deionized water, and then fully kneaded until the hand feeling can be extruded into a strip of ∮ 3mm in the extruder (that is, the catalyst precursor);

[0056] (2) The catalyst precursor was first dried at 105°C, and then activated at 350°C. According to the indication of the differential thermal analyzer and the actual measurement, the drying time of the catalyst precursor at 105°C was 24 hours, and at 350°C The activati...

Embodiment 2

[0064] A preparation method of a low-temperature SCR catalyst in this embodiment comprises the following steps:

[0065] (1) Weigh the prepared raw materials: 319g of manganese dioxide, 216g of silicon dioxide, 12g of presulfurized cerium oxide, 3.18g of niobium oxalate and 192.8g of titanium dioxide, put them into the kneader, and then add the formed Lubricant (stearic acid) 2.25g, release agent (glycerin) stearic acid 2.25g, defoamer (lactic acid) 0.3g, binder (hydroxymethylcellulose, CMC) 3.75g, polyethylene oxide (PEO) 3.75g and an appropriate amount of deionized water, and then fully kneaded until the hand feeling can be extruded into a strip of ∮ 3mm in the extruder (that is, the catalyst precursor);

[0066] (2) The catalyst precursor was first dried at 105°C, and then activated at 350°C. According to the indication of the differential thermal analyzer and the actual measurement, the drying time of the catalyst precursor at 105°C was 24 hours, and at 350°C The activati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com