Preparation method of catalyst for styrene preparation by ethylbenzene dehydrogenation

A technology for the dehydrogenation of ethylbenzene and styrene, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of low crushing resistance and specific surface area Large, small pore size and other issues, to achieve the effect of high crush resistance, low specific surface area, high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

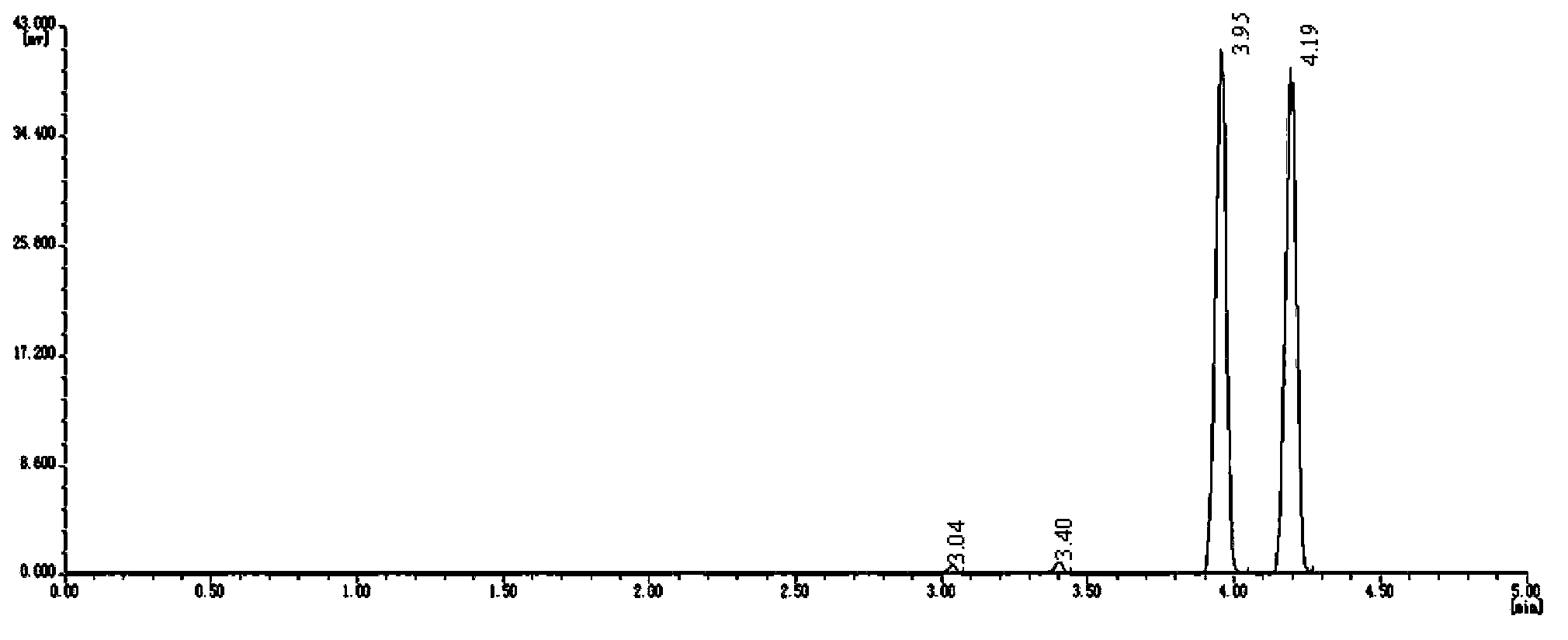

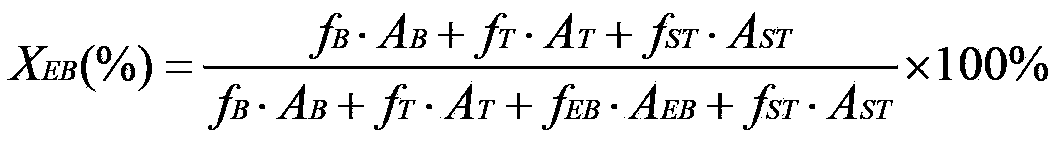

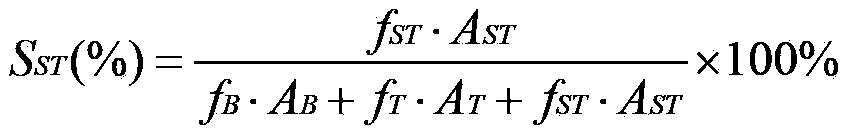

Image

Examples

Embodiment 1

[0037]Dissolve 220.4g of cerium nitrate in 2600mL of water, and add 28% mass fraction of ammonia solution dropwise at a stirring rate of 450r / min until the precipitate disappears to obtain a transparent cerium ammonia complex solution. Add 700mL of 20% mass fraction urea solution dropwise at a rate of 1mL / min; raise the temperature to 60°C, stir at a rate of 500r / min for 8h, wash the precipitate to neutrality after cooling, dry at 120°C for 12h, and then The temperature was raised to 340°C at a rate of °C / min, and fired for 4 hours to obtain the finished nano-cerium oxide.

[0038] 306.8g iron oxide red, 62.2g iron oxide yellow, 36.8g prepared nano-cerium oxide, 11.8g ammonium molybdate, 15.2g magnesium oxide, 16g cement, and 12g carboxymethyl cellulose were stirred in a kneader for 1h; Dissolve 86.2g of potassium carbonate and 32.4g of cerium nitrate in deionized water respectively, pour them into the above mixture, and stir for 0.5h, take out the extruded strands, cut into g...

Embodiment 2

[0041] 306.8g iron oxide red, 62.2g iron oxide yellow, 32.4g nanometer cerium oxide prepared in embodiment 1, 11.8g ammonium molybdate, 15.2g magnesium oxide, 16g cement, 12g carboxymethyl cellulose are stirred in kneader 1h; Dissolve 86.2g of potassium carbonate and 88.4g of cerium nitrate in deionized water respectively, pour them into the above mixture, and stir for 0.5h, take out the extruded strips, cut into granules with a diameter of 3mm and a length of 5-6mm, and put them in Oven, bake at 80°C for 2 hours, bake at 120°C for 2 hours, then place in a muffle furnace, and bake at 800°C for 4 hours to obtain the finished catalyst. The mass percentage of the main active component in the catalyst is Fe 2 o 3 :70.4%,K 2 O: 11.4%, MgO: 3.0%, CeO 2 : 13.4%, MoO 3 : 1.8% (binder not included). The catalyst passed the boiling water and cold water tests. The activity evaluation results of the catalysts are shown in Table 1.

Embodiment 3

[0043] Dissolve 220.4g of cerium nitrate in 2600mL of water, and add 28% mass fraction of ammonia solution dropwise at a stirring rate of 450r / min until the precipitate disappears to obtain a transparent cerium ammonia complex solution. Add 700mL of 20% mass fraction urea solution dropwise at a rate of 1mL / min; raise the temperature to 60°C, stir at a rate of 500r / min for 8h, wash the precipitate to neutrality after cooling, dry at 120°C for 12h, and then The temperature was raised to 380°C at a rate of °C / min, and fired for 4 hours to obtain the finished nano-cerium oxide.

[0044] 280.0g iron oxide red, 56.8g iron oxide yellow, 32.4g prepared nano cerium oxide, 11.8g ammonium molybdate, 15.2g magnesium oxide, 16g cement, and 12g carboxymethyl cellulose were stirred in a kneader for 1h; Dissolve 86.2g of potassium carbonate and 88.4g of cerium nitrate in deionized water respectively, pour them into the above mixture, and stir for 0.5h, take out the extruded strands, cut them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com