Method for preparing low-temperature denitration composite catalyst by adopting ultrasonic treatment and step-by-step impregnation method

A composite catalyst and low-temperature denitrification technology, which is applied in separation methods, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of active substances falling off easily, and achieve the effect of improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

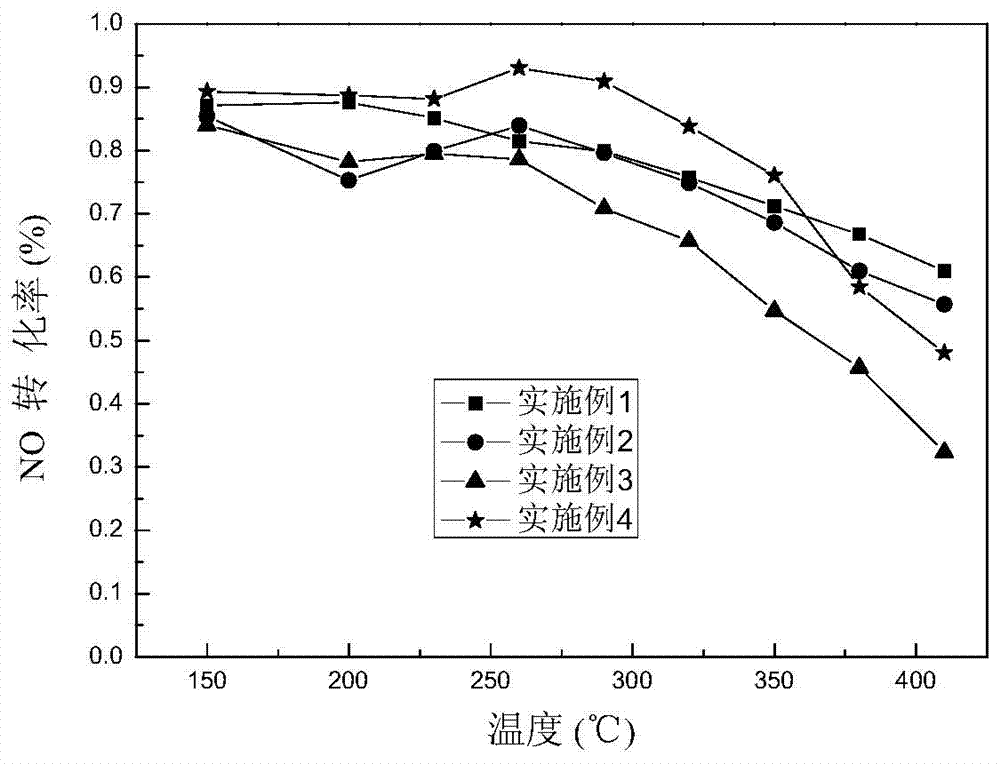

Embodiment 1

[0024] A. First, 2g of oxalic acid is completely dissolved in 50g of water by ultrasound for 10min, then 0.0514g of ammonium metavanadate is added, and it is completely dissolved by ultrasound for 10min, then 0.2625g of ammonium tungstate is added, and it is completely dissolved by ultrasound for 10min. Use after it turns dark green.

[0025] B. Add 4g of titanium dioxide powder into another 250ml beaker containing 50ml of water, stir evenly, then add 3.579g of 50wt% manganese nitrate solution, 0.76g of cerium nitrate and 1.01g of ferric nitrate, and use ultrasound for 10min to completely dissolve, Stir.

[0026] C. Add the prepared vanadium-tungsten solution to the above solution, put it on the electric heating mantle and stir at 120°C for 2 hours to react.

[0027] D. Put the stirred sample into an oven set at a temperature of 120°C for drying.

[0028] E. After grinding the dried powder, screen out 20-40 mesh and calcinate at 400°C for 3 hours.

[0029] A high-efficiency...

Embodiment 2

[0031] A. First, 2g of oxalic acid is completely dissolved in 50g of water by ultrasonication for 10min, then 0.1542g of ammonium metavanadate is added, which is completely dissolved by ultrasonication for 10min, then 0.4374g of ammonium tungstate is added, which is completely dissolved by ultrasonication for 10min and stirred to form a vanadium-tungsten solution. Use after it turns dark green.

[0032] B. Add 4g of titanium dioxide powder into another 250ml beaker containing 50ml of water, stir evenly, then add 3.579g of 50wt% manganese nitrate solution, 0.76g of cerium nitrate and 1.01g of ferric nitrate, and use ultrasound for 10min to completely dissolve, Stir.

[0033] C. Add the prepared vanadium-tungsten solution to the above solution, put it on the electric heating mantle and stir at 120°C for 2 hours to react.

[0034] D. Put the stirred sample into an oven set at a temperature of 120°C for drying.

[0035] E. After grinding the dried powder, screen out 20-40 mesh a...

Embodiment 3

[0038] A. First, 2g of oxalic acid is completely dissolved in 50g of water by ultrasonication for 10min, then 0.2572g of ammonium metavanadate is added, which is completely dissolved by ultrasonication for 10min, then 0.4374g of ammonium tungstate is added, which is completely dissolved by ultrasonication for 10min and stirred to form a vanadium-tungsten solution. Use after it turns dark green.

[0039] B. Add 4g of titanium dioxide powder to another 250ml beaker containing 50ml of water, stir evenly, then add 7.158g of 50wt% manganese nitrate solution, 1.52g of cerium nitrate and 2.02g of ferric nitrate, and use ultrasound for 10min to completely dissolve, Stir.

[0040] C. Add the prepared vanadium-tungsten solution to the above solution, put it on the electric heating mantle and stir at 120°C for 2 hours to react.

[0041] D. Put the stirred sample into an oven set at a temperature of 120°C for drying.

[0042] E. After grinding the dried powder, screen out 20-40 mesh and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com