Modified starch-chitosan copolymer flocculating agent and preparation method thereof

A chitosan copolymer and flocculant technology, applied in the field of modified starch-chitosan copolymer flocculant and its preparation, can solve the problems of low solubility and poor flocculation performance, and achieve strong applicability and excellent environmental friendliness. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

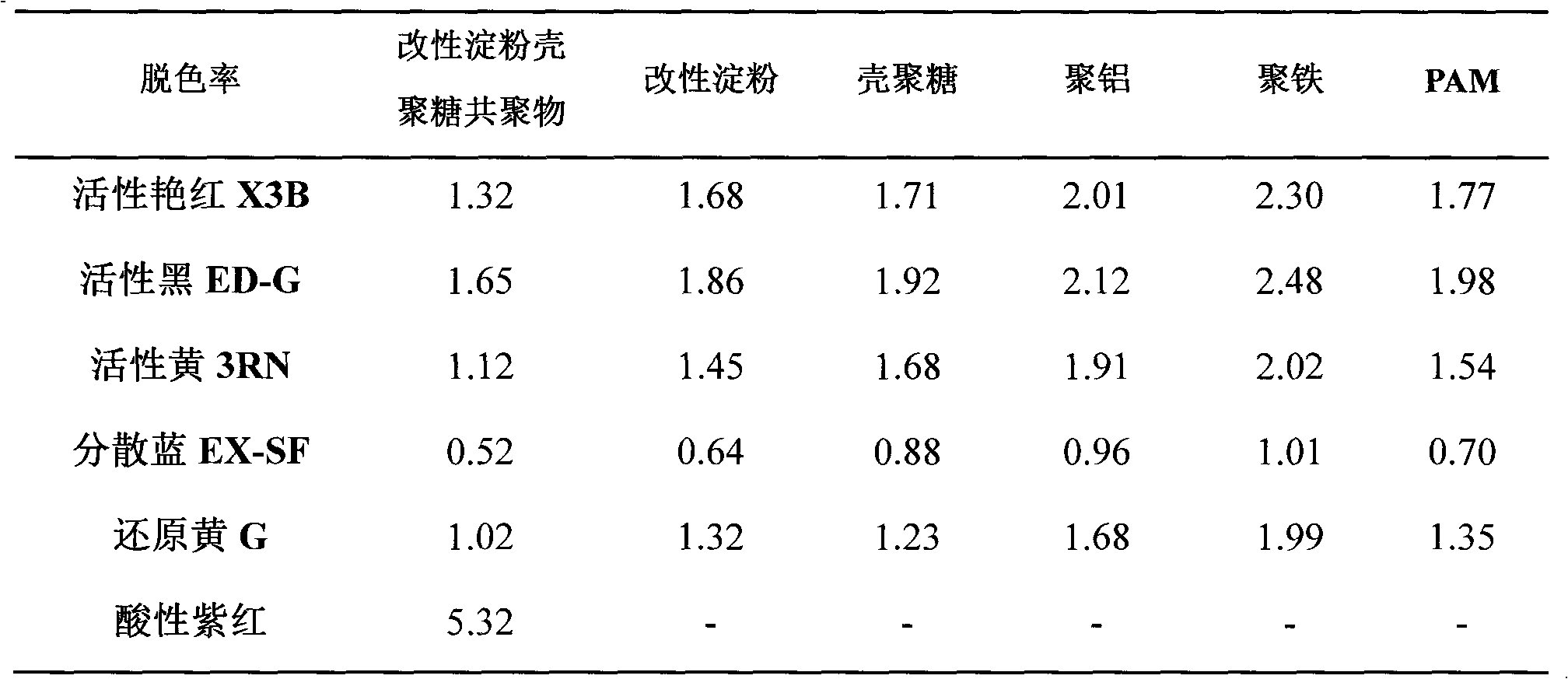

[0028] Embodiment one, with the non-ionic modified starch prepared by graft polymerization with acrylamide: chitosan mass ratio is 2: 1, at 75 ℃, reaction 12h, initiator initiator cerium ammonium nitrate consumption accounts for total mass When it is 0.5%, it is prepared, dried and crushed to 200 mesh for later use. Through the flocculation test of the dye wastewater (1L) prepared in the laboratory, the chromaticity is 1000 times, and the decolorization rate reaches 90%. The situation of the added quality is shown in Table 1.

[0029] The situation of adding quality is shown in (Table 1)

[0030]

Embodiment 2

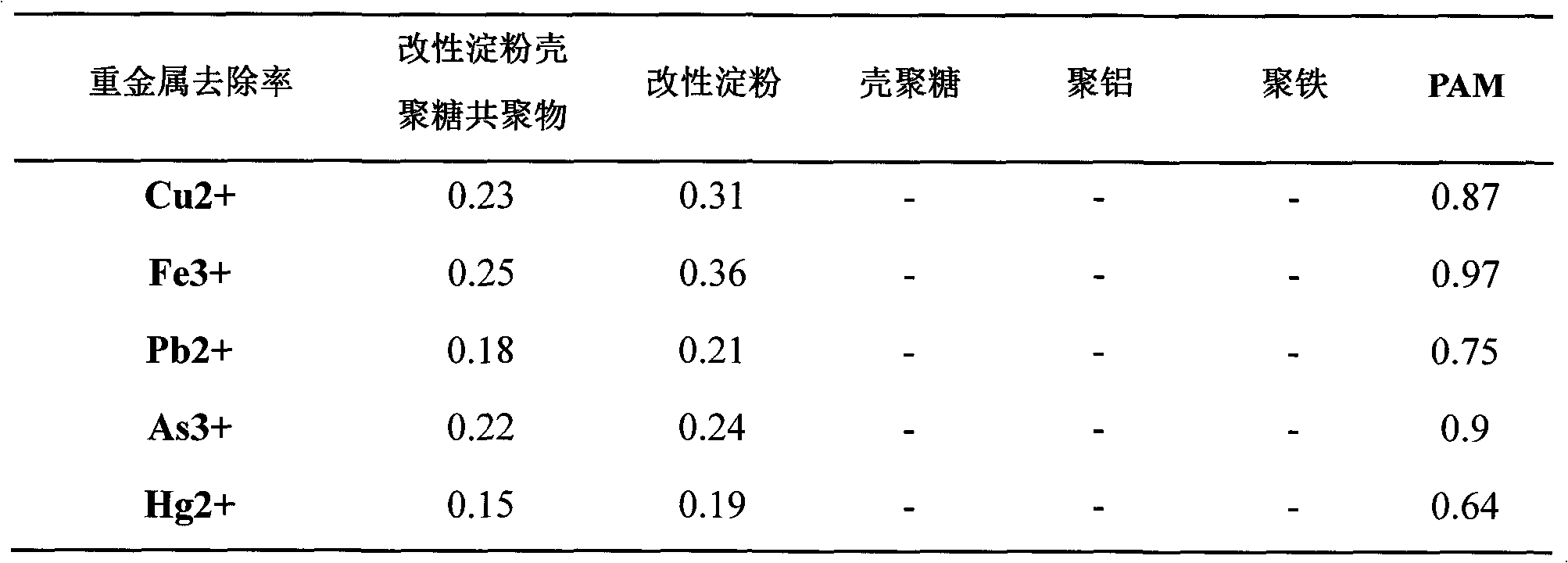

[0031] Embodiment two, with the anionic modified starch prepared with phosphate: chitosan mass ratio is 1: 1, at 75 ℃, reacted 16h, when initiator initiator ammonium cerium nitrate consumption accounts for 0.5% of total mass, Prepared, dried and crushed to 200 mesh for later use. See Table 2 for the quality of flocculant added to achieve 99% ion removal rate by testing the ion-containing wastewater (1 L) with an average concentration of 100 mg / L.

[0032]

Embodiment 3

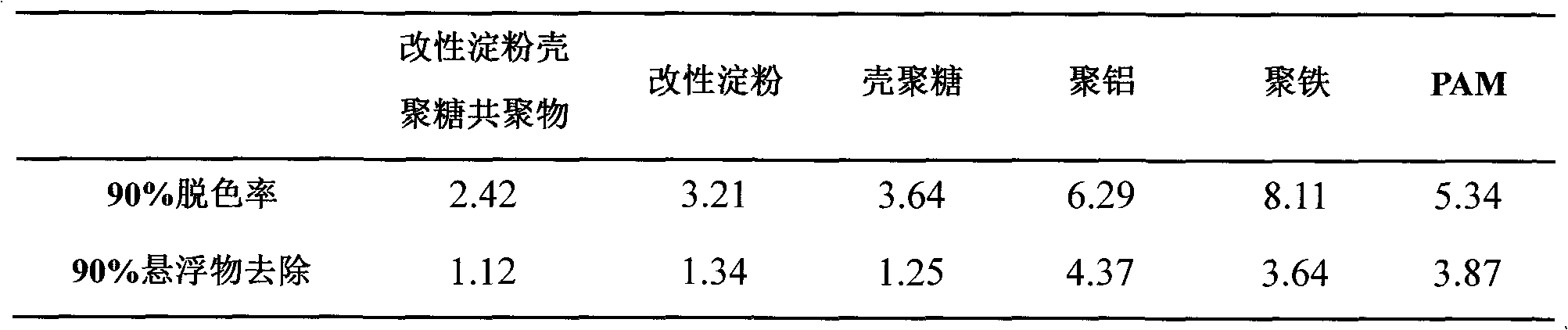

[0033] Embodiment three, with the amphoteric modified starch prepared by sodium tripolyphosphate as esterification agent and urea as catalyst: chitosan mass ratio is 4: 1, at 75 DEG C, reaction 18h, initiator cerium ammonium nitrate consumption accounts for When the total mass is 1%, it is prepared, dried and crushed to 200 mesh for later use. Through the flocculation test on 1L of industrial wastewater containing complex ions (including anions and cations) with a concentration of 100mg / L, see Table 3 for the quality of the dosing to achieve 90% chroma removal and 90% suspended solids removal.

[0034]

[0035] Through the above examples, compared with conventional inorganic flocculants and organic flocculants, it has obvious advantages in the removal of the chromaticity of wastewater, the removal of heavy metal ions, and the removal of suspended solids in water; compared with simple modified starch and chitosan Compared with sugar flocculants, copolymer flocculants can bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com