Preparation method of hexagonal-phase dicerium trioxide monocrystal film

A technology of cerium oxide and single crystal thin film, which is applied in chemical instruments and methods, single crystal growth, single crystal growth, etc. It can solve the problems of less research, inability to exist and preserve stably, and difficulty, and achieve high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

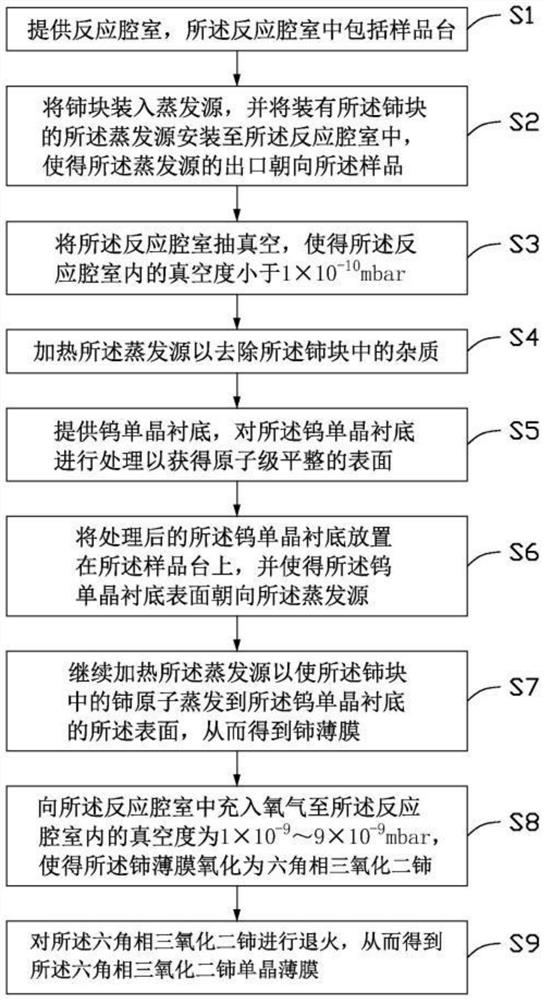

[0030] see figure 1 , a preferred embodiment of the present invention provides a hexagonal phase cerium oxide (space group is P-3m1, lattice constant is a=b=0.394nm, c=0.51nm, α=β=90°, γ=120 °) the preparation method of monocrystalline thin film, comprises the following steps:

[0031] In step S1, a reaction chamber is provided, and the reaction chamber includes a sample stage.

[0032] In step S2, the cerium block is loaded into the evaporation source, and the evaporation source with the cerium block is installed in the reaction chamber so that the outlet of the evaporation source faces the sample stage.

[0033] In this embodiment, before loading the cerium block into the evaporation source, the cerium block is cleaned to remove thicker oxide impurities on the surface of the cerium block. The cerium block is a high-purity cerium block.

[0034] In this embodiment, the container filled with the cerium block in the evaporation source is a crucible. It can be understood tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com