Cerium oxide-zirconium oxide-based composite oxide and preparation method thereof

A composite oxide, zirconia-based technology, applied in catalyst activation/preparation, chemical instruments and methods, separation methods, etc., can solve the problems of reduced specific surface area and low OSC value of cerium-zirconium composite oxides, and achieve excellent dispersion , the effect of high oxygen storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

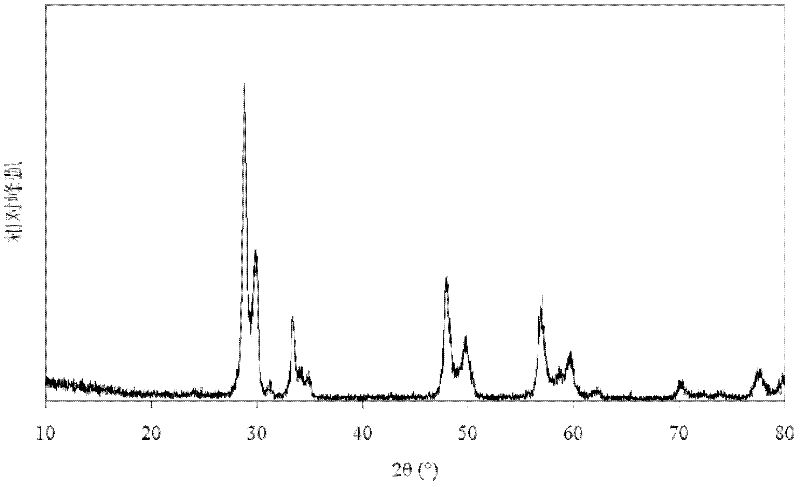

Embodiment 1

[0035] Take by weighing 70g ceria, be dissolved completely by the nitric acid of 65wt% by concentration; Take by weighing 348g zirconium nitrate (Zr(NO 3 ) 4 ·5H 2 O, corresponding to 100g ZrO 2 ), add 1000mL deionized water to dissolve completely; weigh 126g Ce(NO 3 ) 3 ·6H 2 O (corresponding to ceria content of 50g), add 500mL deionized water to dissolve; after stirring and mixing the three solutions prepared above, the Ce-containing 3+ with Ce 4+ A mixed solution of cerium and zirconium with a ratio of about 40:60;

[0036] Add sodium hydroxide solution (concentration is 10wt%) in gained cerium-zirconium mixed solution, stir gained mixed solution vigorously simultaneously, when solution pH reaches about 6, suspend adding alkali, this moment in solution Ce 4+ and Zr 4+ All have basically completely precipitated into cerium hydroxide (wherein cerium mainly exists in the form of +4 valence) and zirconium hydroxide, and the mixed turbid solution of cerium hydroxide and ...

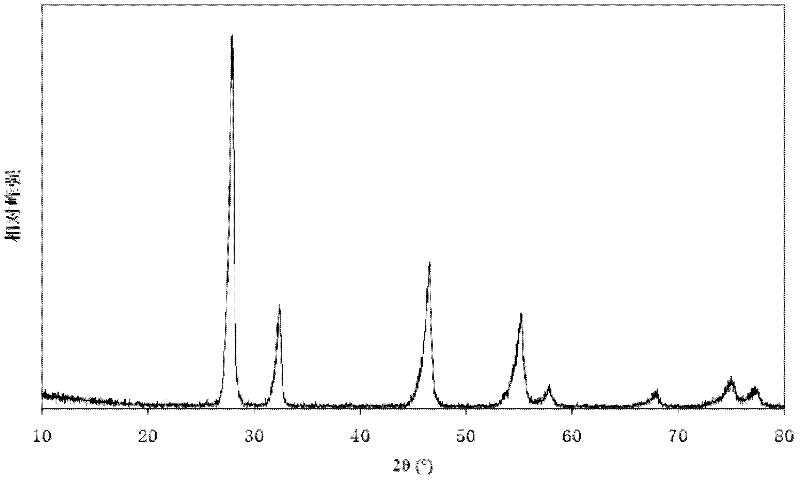

Embodiment 2

[0039] Take by weighing 140g ceria, be dissolved completely by the sulfuric acid of 40wt% by concentration; Take by weighing 432.9g zirconium sulfate (Zr(SO 4 ) 2 4H 2 O, corresponding to 150g ZrO 2 ), add 1000mL deionized water to dissolve completely; weigh 124.2g Ce 2 (SO 4 ) 3 ·8H 2 O (corresponding to ceria content of 60g), add 600mL deionized water to dissolve; after stirring and mixing the three solutions prepared above, the Ce-containing 3+ with Ce 4+ The ratio is a 30:70 mixed solution of cerium and zirconium;

[0040] Slowly add ammonia solution (concentration is 30wt%) in the obtained cerium-zirconium mixed solution, while vigorously stirring the gained mixed solution, when the solution pH reaches about 6.5, suspend adding alkali, this moment in the solution Ce 4+ and Zr 4+ All have basically completely precipitated into cerium hydroxide (wherein cerium mainly exists in the form of +4 valence) and zirconium hydroxide, and the mixed turbid solution of cerium ...

Embodiment 3

[0043] Take by weighing 80g ceria, be that the nitric acid of 65wt% is dissolved completely by concentration; Take by weighing 348g zirconium nitrate (Zr(NO 3 ) 4 ·5H 2 O, corresponding to 100g ZrO 2 ), add 1000mL deionized water to dissolve completely; weigh 50.4g Ce(NO 3 ) 3 ·6H 2 O (corresponding to cerium oxide content of 20g), add 200mL deionized water to dissolve, then weigh 368g Al(NO 3 ) 3 9H 2 O (corresponding to Al 2 o 3 content of 50g) was dissolved in 500mL deionized water; after stirring and mixing the four solutions prepared above, the Ce-containing 3+ with Ce 4+ A mixed solution of cerium, zirconium and aluminum in a ratio of 20:80;

[0044] Slowly add sodium hydroxide solution (concentration is 10wt%) in the obtained cerium-zirconium-aluminum mixed solution, stir the gained mixed solution simultaneously, when solution pH reaches about 6, suspend adding alkali, this moment in the solution Ce 4+ and Zr 4+ All have basically completely precipitated in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com