Heat-resisting type communication power source flexible cable

A communication power supply and flexible cable technology, which is applied in the direction of insulated cables, power cables with shielding layers/conductive layers, cables, etc., can solve problems such as mutual interference, mutual adhesion of cable sheaths, and influence on cable electrical performance, and achieve high cable balance performance and reliability, good RL and NEXT performance, and enhanced electromagnetic wave shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

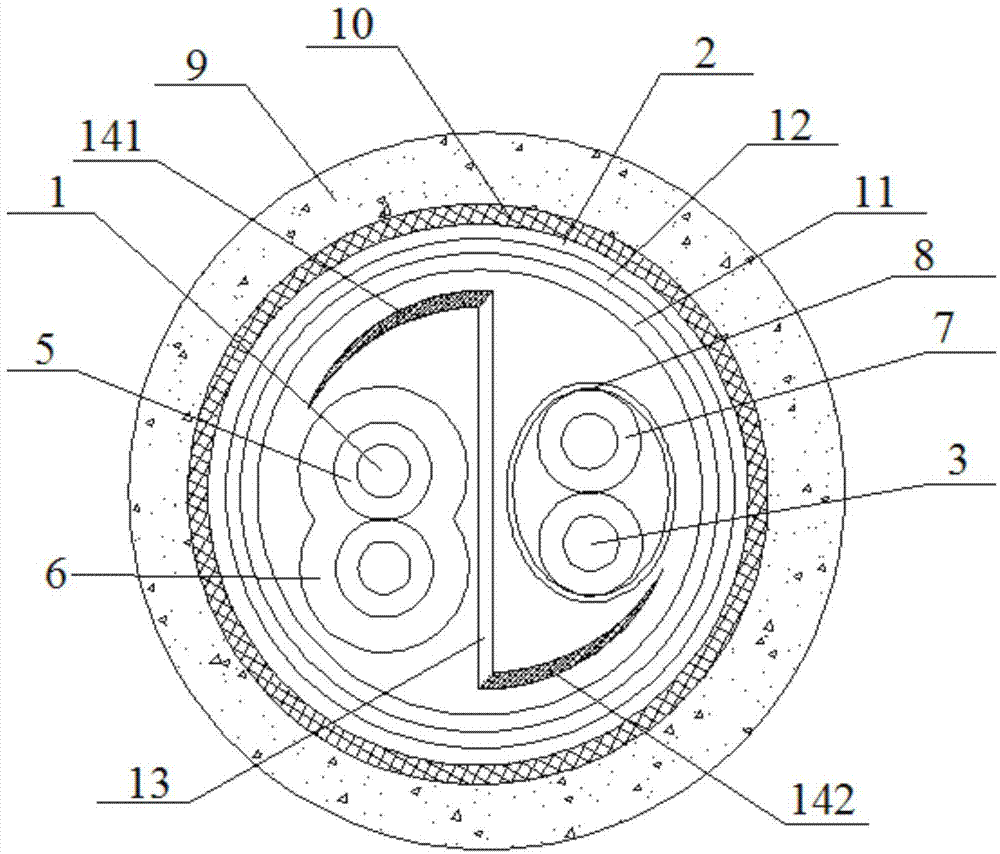

[0038] Embodiment. A heat-resistant communication power supply flexible cable, comprising: two power copper wires 1, two data copper wires 3 and a filling rope 4;

[0039] Each of the two power copper wires 1 is coated with an insulating layer 5, the two insulating layers 5 are placed in parallel and placed in the shape of "∞", and an inner sheath layer 6 is covered on the surface of the two insulating layers 5 ;

[0040] Each of the two data copper wires 3 is coated with an insulating layer 7, and a single-sided aluminum foil layer 8 covers two outer surfaces of the insulating layer 7;

[0041] A partition 13 is located between the inner sheath layer 6 and the single-sided aluminum foil layer 8, and the two ends of the partition 13 respectively have a first side empennage part 141 and a second side empennage part 142, and the first side empennage part 141 , The second side empennage portion 142 is respectively located on the left side and the right side of the partition 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com