Patents

Literature

63results about How to "Solve the insulation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicone rubber-based heat-insulating coating and preparation method thereof

ActiveCN107760194AImprove mechanical propertiesEnhanced interface bindingCoatingsSpecial surfacesFiberRocket

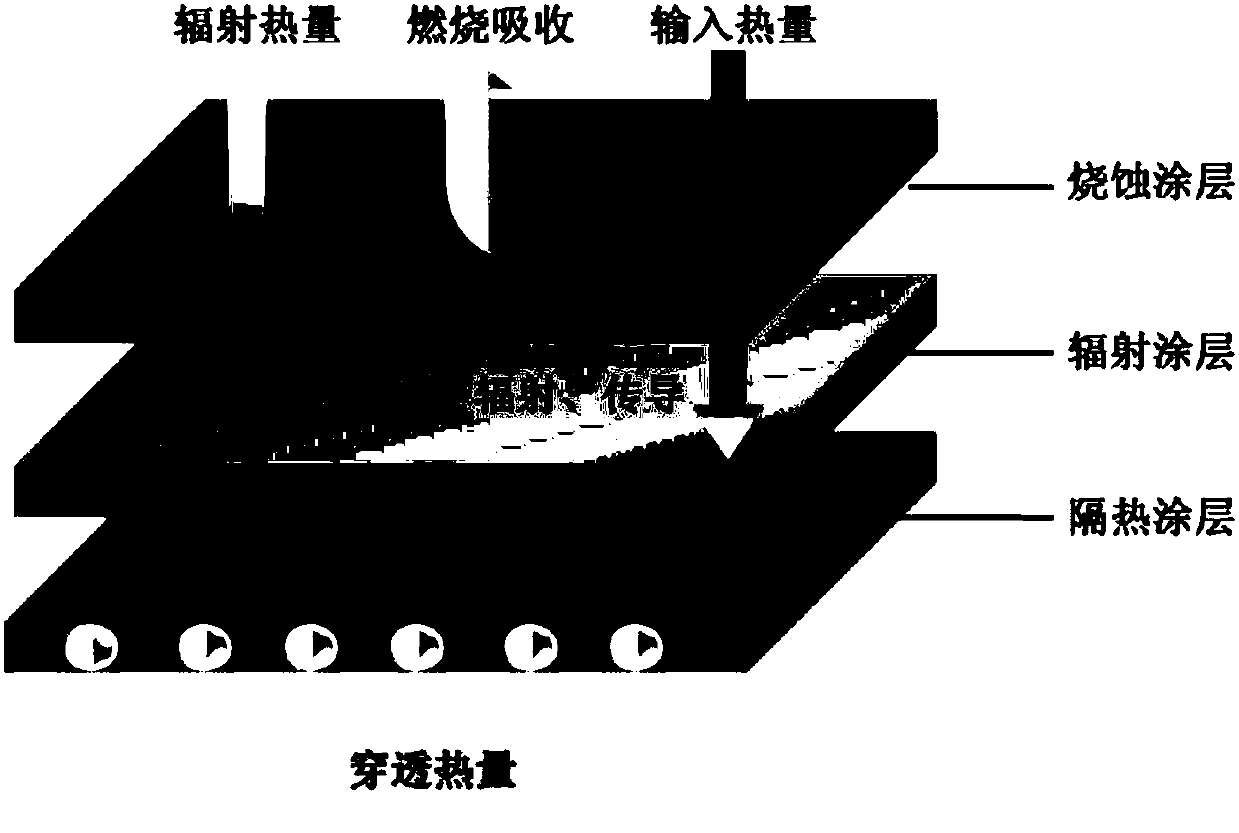

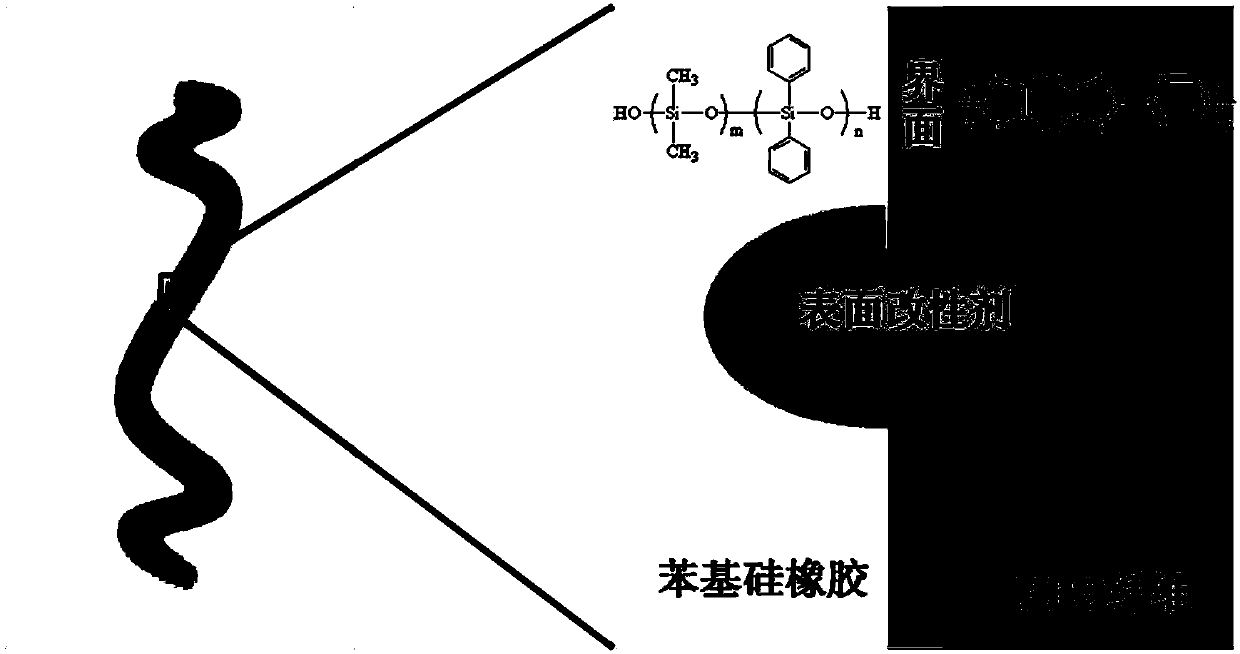

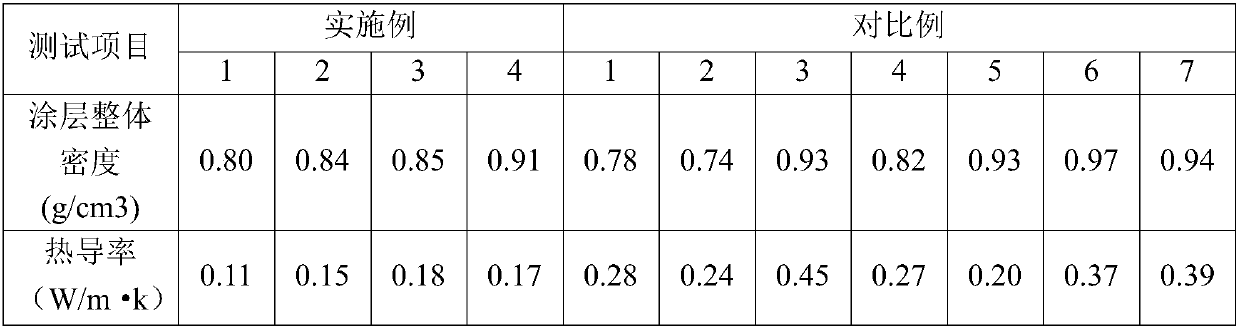

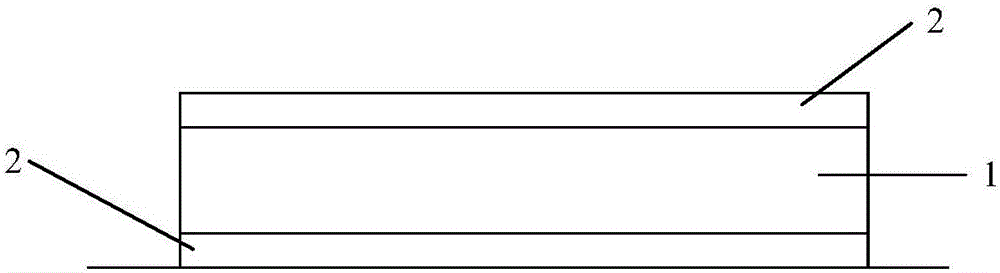

The invention provides a silicone rubber-based heat-insulating coating and a preparation method thereof. The silicone rubber-based heat-insulating coating comprises heat-insulating coating, radiationcoating and ablation coating, wherein the heat-insulating coating is arranged on the surface of a substrate; the radiation coating is arranged between the heat-insulating coating and the ablation coating; the heat-insulating coating, the radiation coating and the ablation coating are silicone rubber-based coating; the radiation coating performing an in-situ ceramization reaction through heat penetrating through the ablation coating; poly-p-phenylene benzobisoxazole fiber is distributed in the ablation coating. The preparation method comprises the steps of preparing the ablation coating, the radiation coating and the heat-insulating coating. Compared with the prior art, the silicone rubber-based heat-insulating coating has the beneficial effects as follows: through use of the poly-p-phenylene benzobisoxazole fiber, the mechanical properties of the ablation coating are improved; through the in-situ ceramization reaction, the high-radiation coating is prepared, and the defects of low mechanical properties and heat-insulating performance of the silicone rubber-based heat-insulating coating are successfully overcome; the silicone rubber-based heat-insulating coating has a wide application prospect in the field of heat protection of structural surfaces of rocket-carrying and missile weapons and the like.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

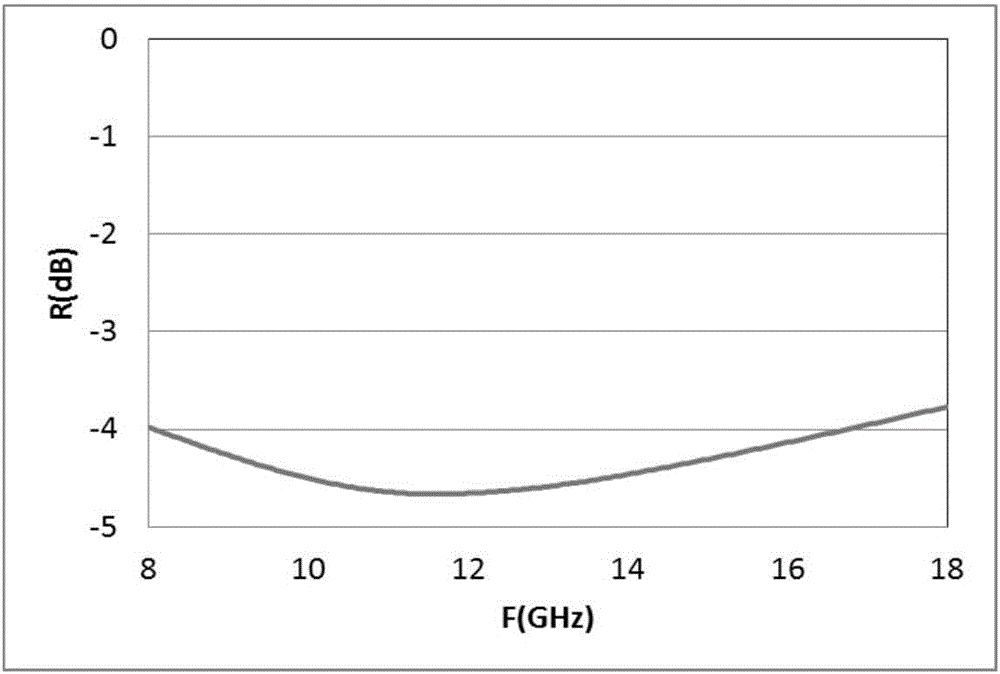

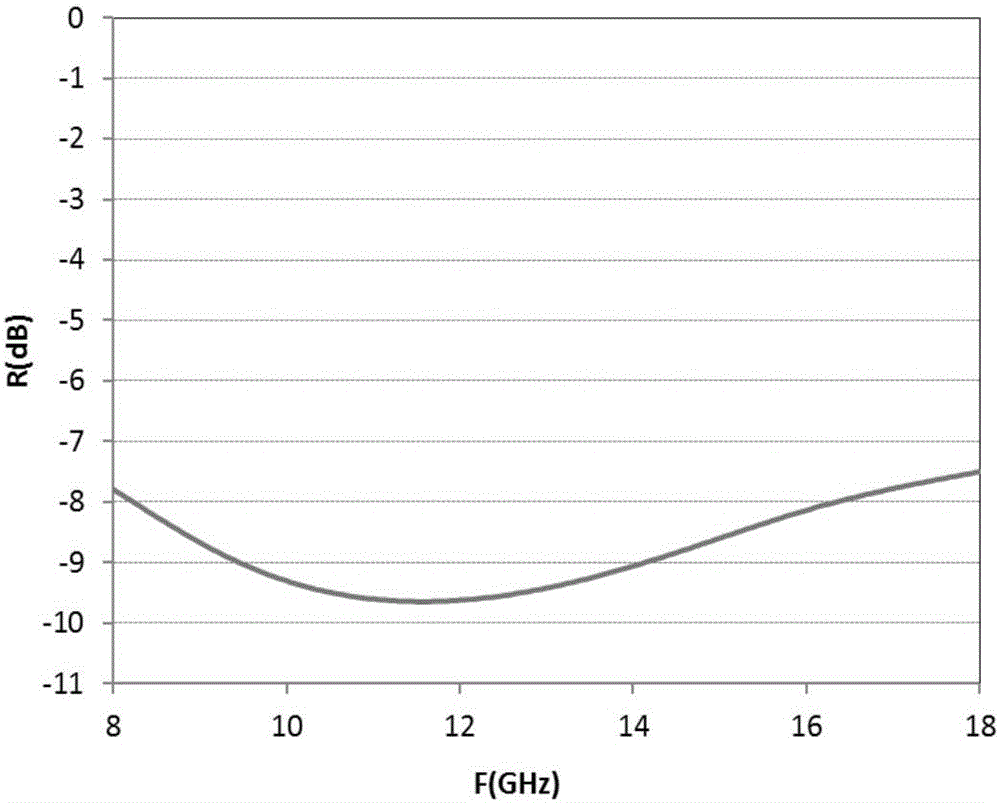

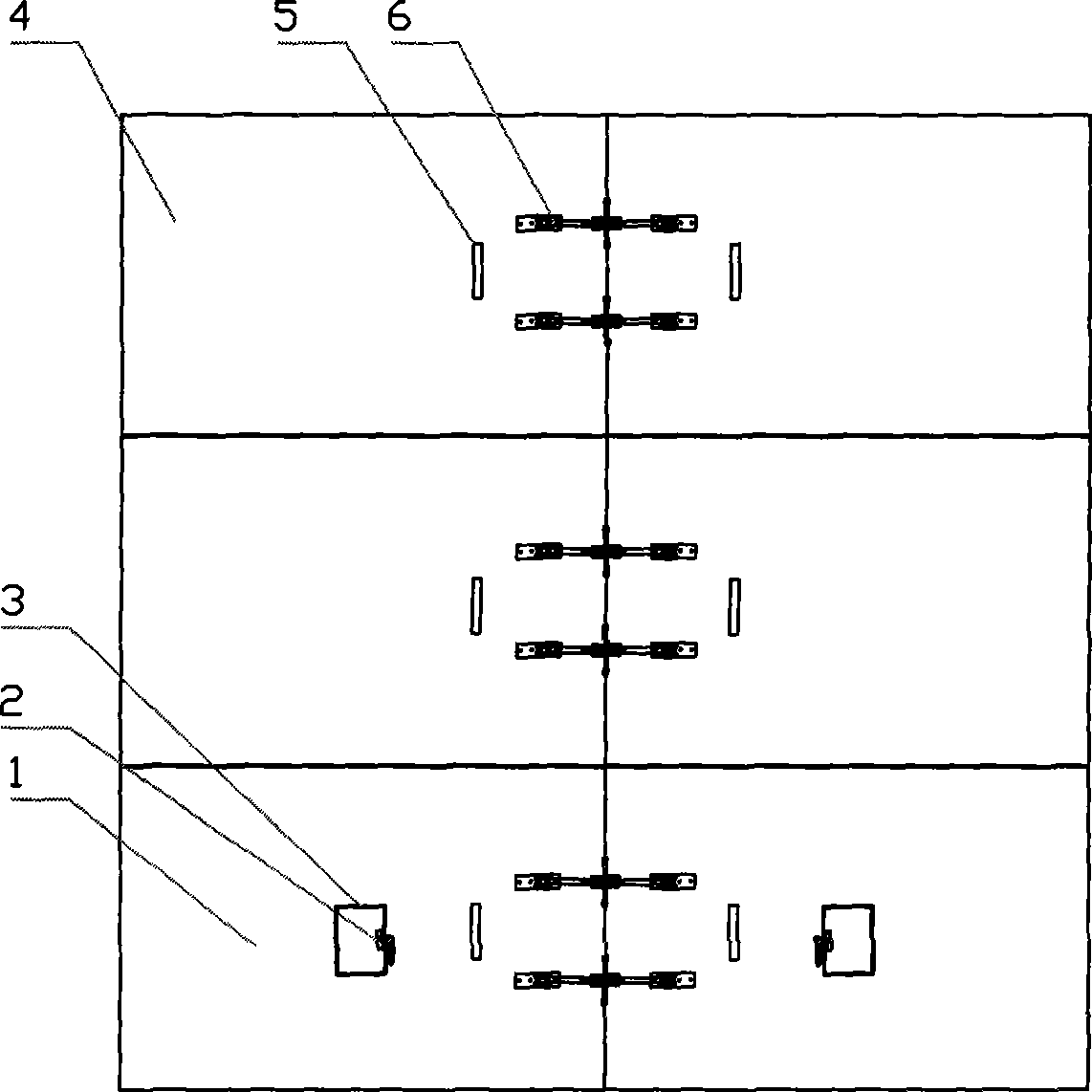

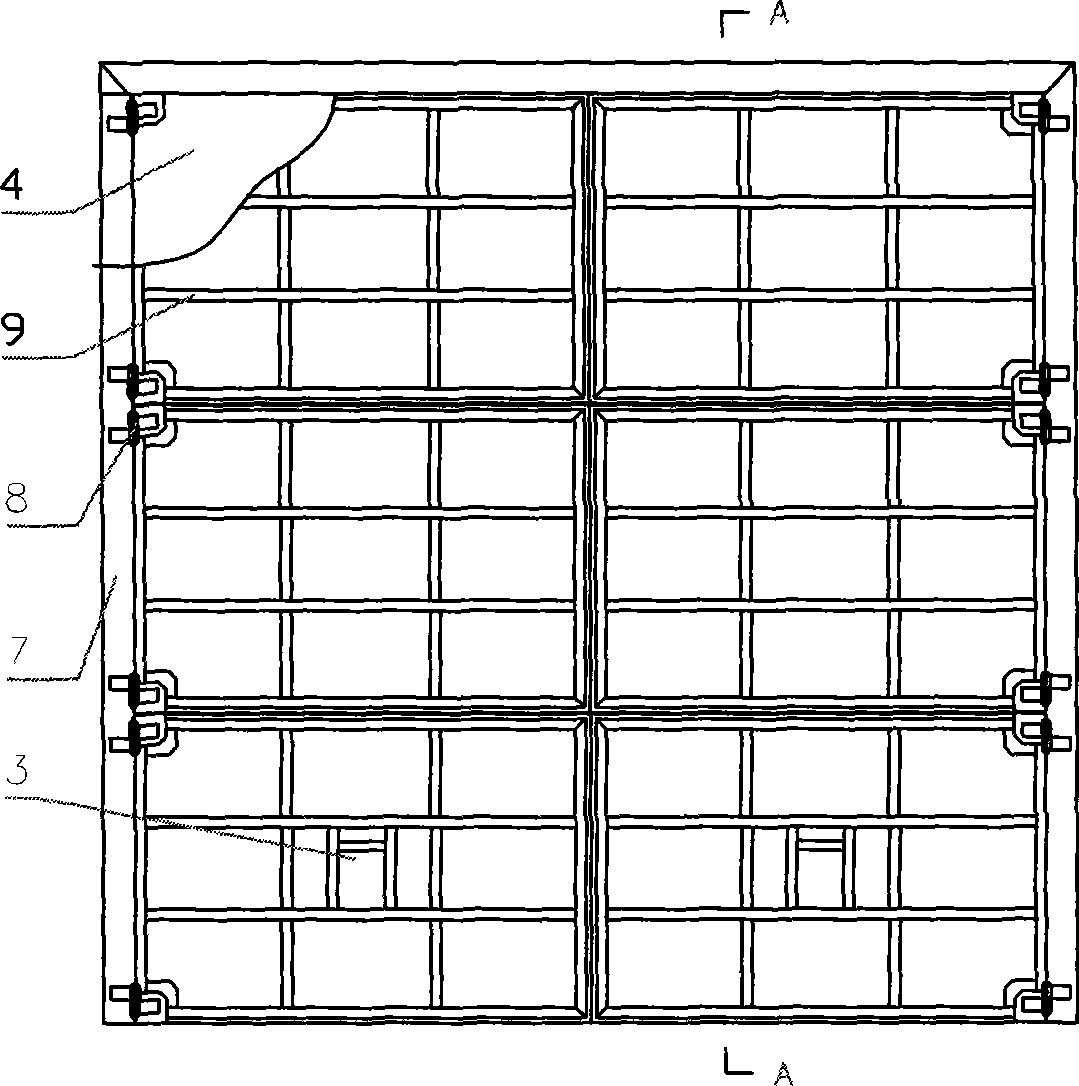

High temperature-resistant electromagnetic wave-absorbing coating and use thereof

ActiveCN106497313ASolve the insulation performanceSolve Oxidation ProblemsFireproof paintsRadiation-absorbing paintsRadarThermal insulation

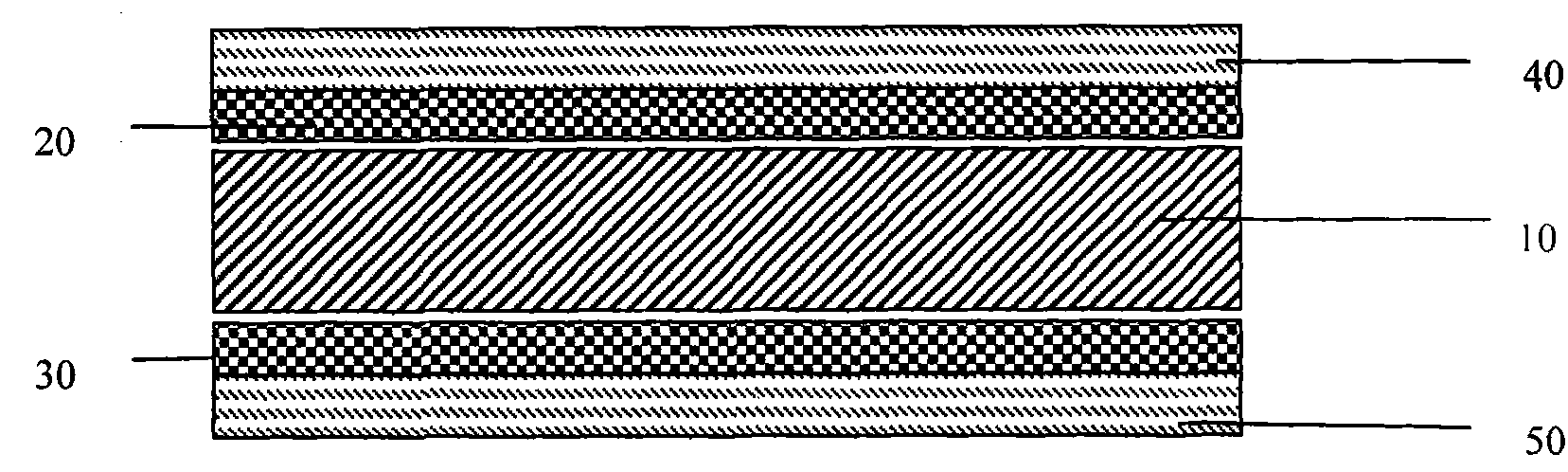

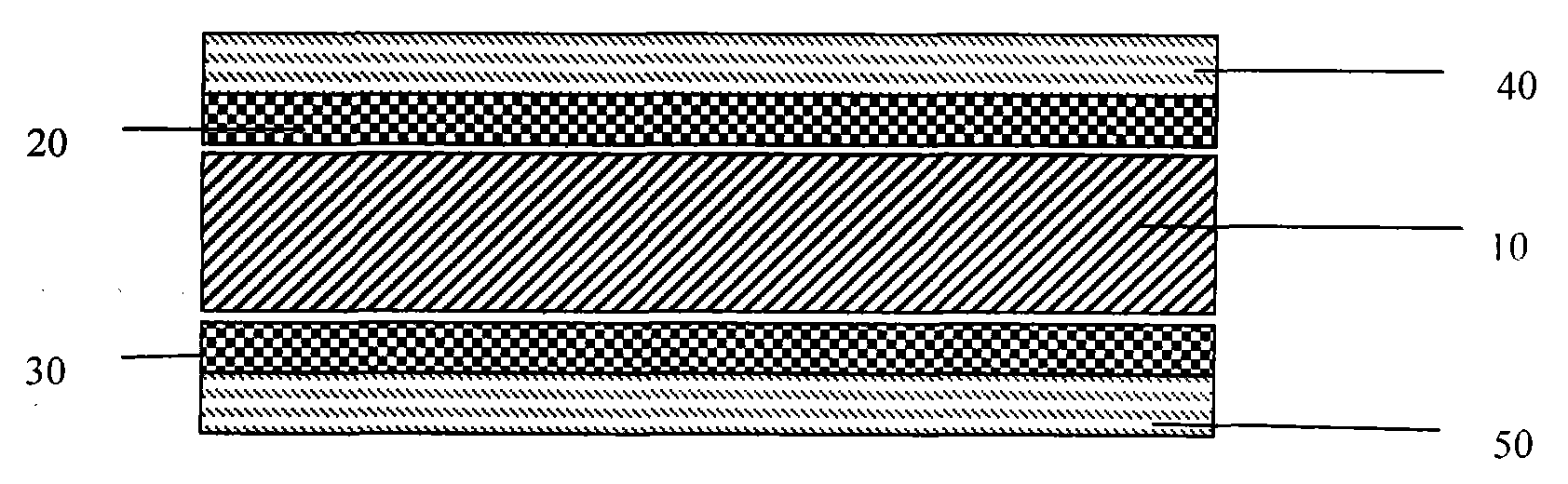

The invention belongs to the technical field of electronic materials and relates to a high temperature-resistant electromagnetic wave-absorbing coating and its use in aircraft stealth. The high temperature-resistant electromagnetic wave-absorbing coating comprises at least one wave absorbing layer (1) coating a substrate and two thermal insulation oxygen barrier layers (2). The two thermal insulation oxygen barrier layers (2) are respectively located on the upper and lower surfaces of the wave absorbing layer (1). The wave absorbing layer (1) comprises a high temperature resistant absorbent and a high temperature resistant resin as main components, and has functions of absorbing electromagnetic wave and resisting oxidation. The thermal insulation oxygen barrier layer (2) mainly comprises a high temperature resistant resin and a filler, reduces the temperature of the wave absorbing layer (1) at a high temperature and blocks direct contact between the wave absorbing layer (1) and air. The high temperature-resistant electromagnetic wave-absorbing coating can be applied to the outer surface of an aircraft and realize radar stealth of a target in a high temperature environment.

Owner:NAT UNIV OF DEFENSE TECH

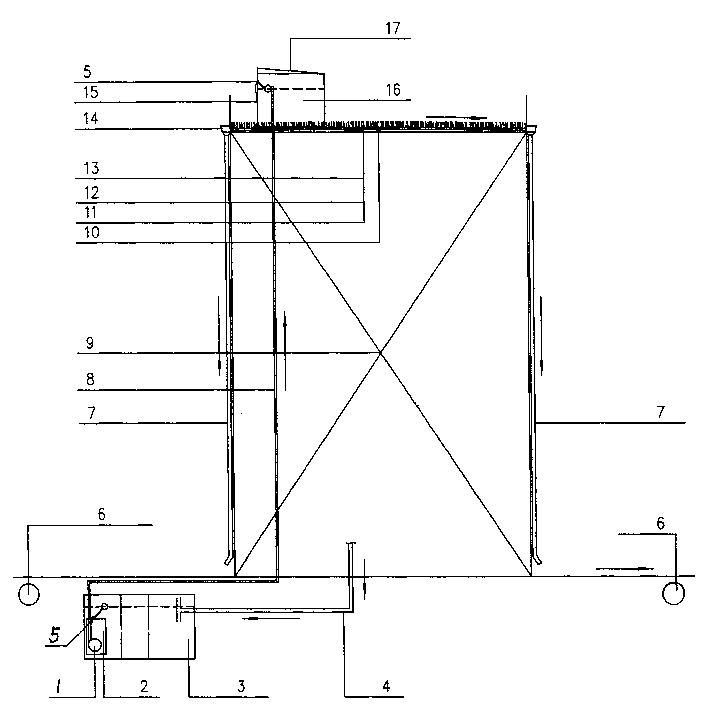

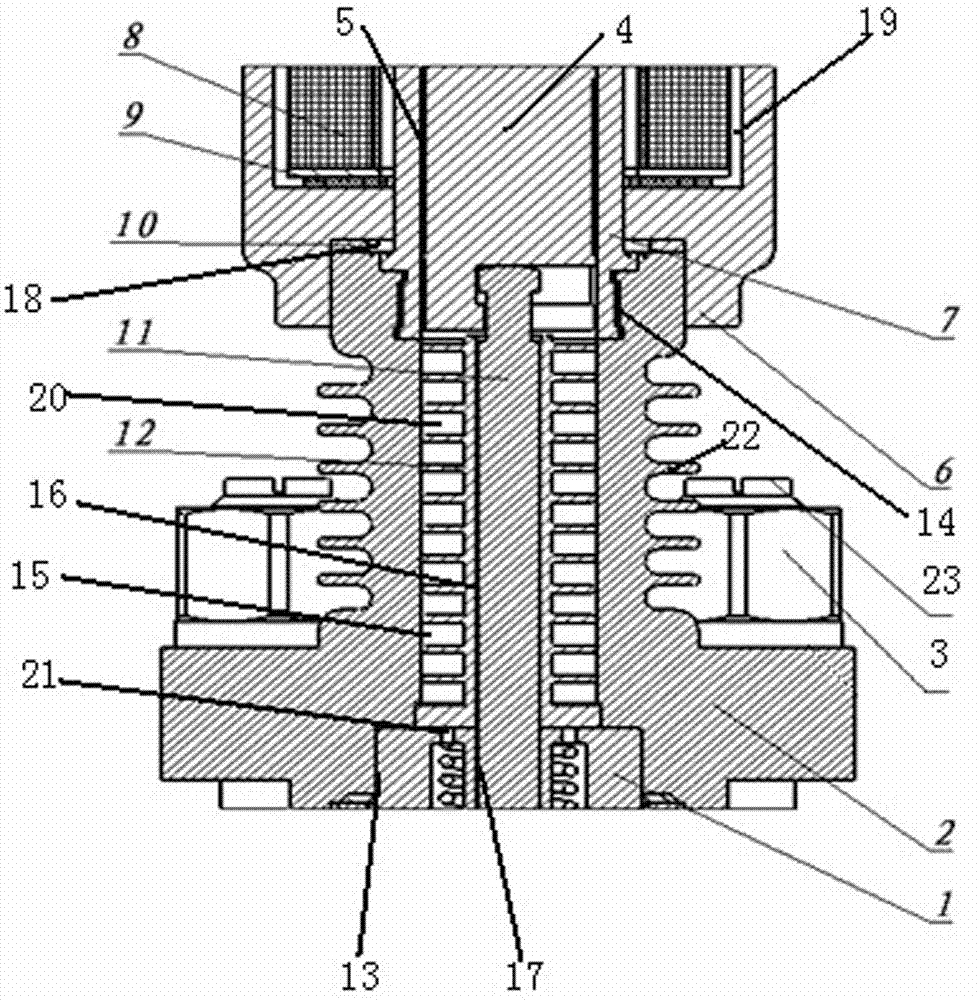

Air sealed door for grain depot

InactiveCN101387181AReasonable structureImprove air tightnessSealing arrangementsWar-like protectionEngineeringSquare meter

The invention relates to an airtight door for a granary, which relates to a grain baffle door for a large-scale granary. The airtight door for the granary is characterized in that a left door leaf and a right door leaf are angulated at an included angle of between 130 and 145 DEG after closing, and are divided into three layers respectively, namely six door plates (1); single-hole semicircular gland strips (11) are arranged between an upper door plate (1) and a lower door plate (1) and between the door plates (1) and a door frame (7); a two-hole flat circular gland strip (17) is arranged between a left door plate (1) and a right door plate (1); bearings (22) are arranged between upper hinges (26) and lower hinges (25) of the door frame (7) and the door plates (1); and each layer of the door plates is uniformly provided with two pairs of locking devices (6) which consist of handwheels (14), lock sleeve screws (13), lock catch screws (15), pedestals (16) provided with hooks, and pedestals (12) provided with suspension loops. The airtight door for the granary is reasonable in structure, is safe and durable, and is lightweight, portable, quick and stable in opening and closing a lock; and the side pressure is more than 20 tons per square meter, and the time for airtight semi-attenuation from 500 Pa to 250 Pa is more than 25 minutes. Moreover, the airtight door for the granary can be widely used for the large-scale granary the heat preservation and heat insulation effects of which meet the requirement of transport and storage of the grain in controlled atmosphere.

Owner:上海粮油仓储有限公司

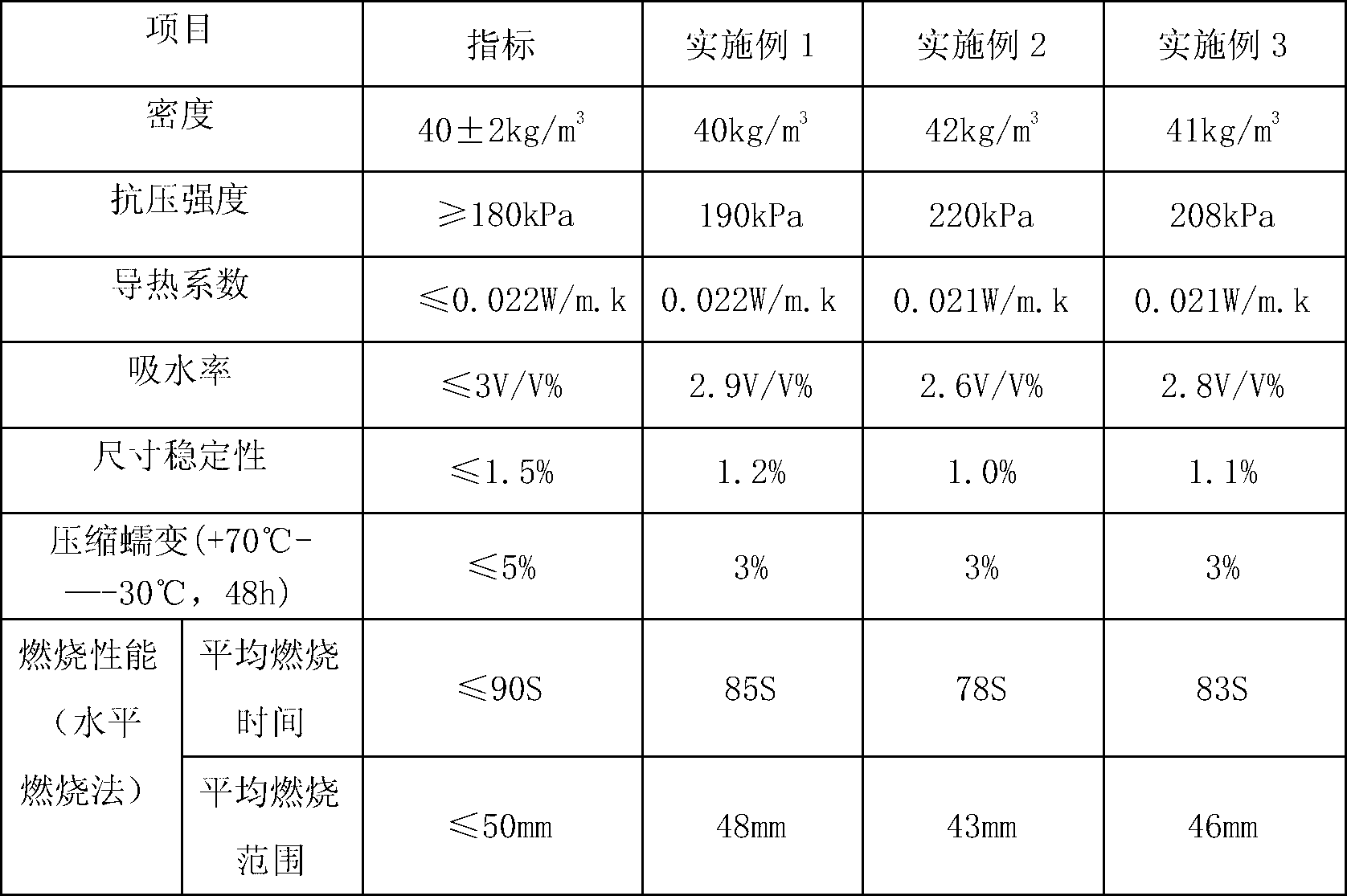

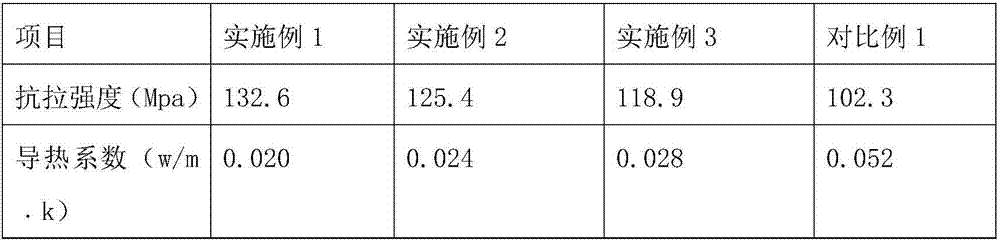

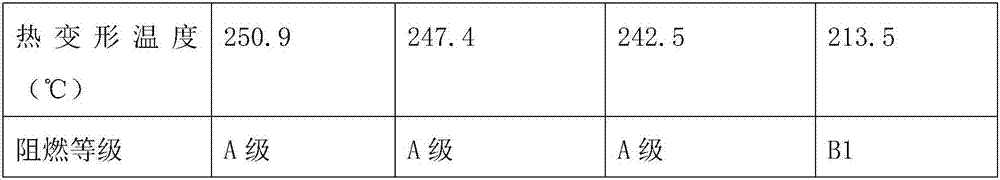

Combination material of insulation boards for producing building outer walls and preparation method thereof

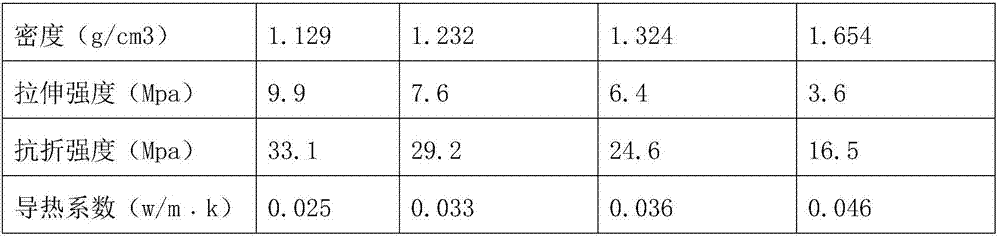

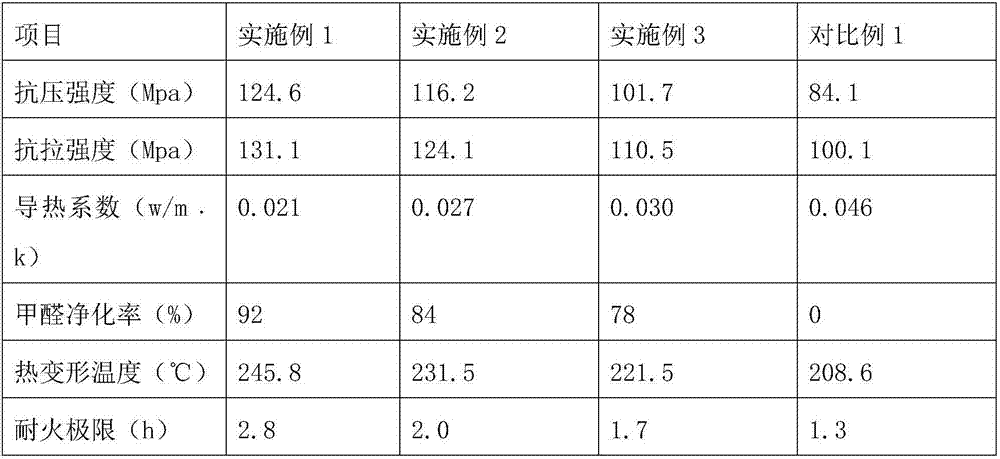

The invention relates to a combination material of polyurethane insulation boards for producing building outer walls by using a continuous method and a preparation method thereof. The combination material is composed of a component A and a component B, a weight ratio of the component A to the component B is 1:1-1.3, wherein the component A is composed of the following components, by weight, of 20-40% of polyether polyol A, 15-35% of polyether polyol B, 10-20% of polyether polyol C, 1.0-3.0% of foam stabilizer, 1.0-3.0% of chemical foaming agent, 10-20% of physical foaming agent, 0.5-3.5% of catalytic agent and 10-20% of fire retardant, and the component B is polymethyl polyphenyl polyisocyanates. The preparation method of the combination material comprises stirring and mixing all components in the component A in proportion, and then mixing the component A with the component B. Polyurethane foams made of the combination material are low in heat conductivity coefficient, good in leakproofness, excellent in flame retardant property, good in product stability and capable of completely meeting requirements for polyurethane outer wall boards.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

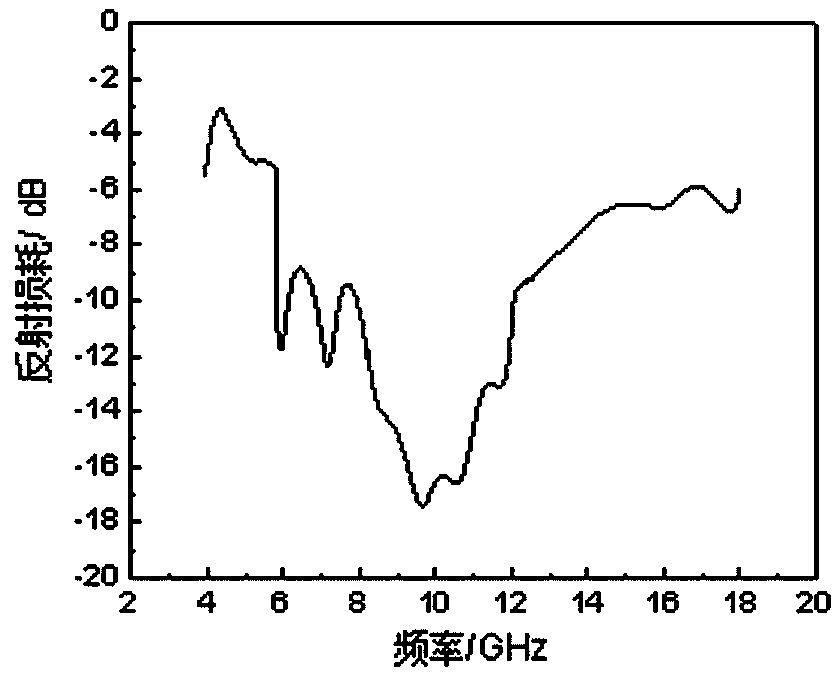

Preparation method of graphene-based light heat-insulating wave-absorbing material

ActiveCN110951455ASatisfy the anti-deformation abilityFulfil requirementsOther chemical processesChemical industryHeat managementMagnetite Nanoparticles

The invention relates to the technical field of a preparation method of graphene-based light heat-insulating wave-absorbing material and particularly relates to a preparation method of a graphene-based light heat-insulating wave-absorbing material. According to the preparation method, the magnetic nanoparticles and graphene are compounded, the light composite heat-insulating wave-absorbing material is prepared through the technological processes of pretreatment, graphene oxide surface modification, graphene oxide aqueous solution preparation, composite aerogel synthesis and the like. The powder is simple in preparation process, low in production cost and convenient for industrial production, the prepared heat-insulating wave-absorbing material has excellent electromagnetic wave absorptionperformance in a frequency band range of 2GHz to 18GHz, meanwhile, the heat insulation effect can be comparable with that of polymer foam commonly used in the current building field, the efficient heat preservation and heat insulation and a good electromagnetic wave absorption function of a single light material can be achieved, and material technical support is provided for heat management and electromagnetic environment purification of buildings.

Owner:NO 33 RES INST OF CHINA ELECTRONICS TECHNOOGY GRP

High heat flux density resisting thermal protection material and preparation method thereof

ActiveCN108867029ASolve the problem of poor resistance to damageSolve the problem of heat protectionCarbon fibresLayered productsHeat fluxHigh density

The invention relates to a high heat flux density resisting thermal protection material and a preparation method thereof and belongs to the field of inorganic functional materials. According to the preparation method of the high heat flux density resisting thermal protection material disclosed by the invention, a second carbon fiber layer with a low thermal conductivity and a low density is prepared on one side of a first carbon fiber layer with a high thermal conductivity and a high density to form an integrated whole fabric, and an upper layer and a lower layer of the integrated whole fabrichave different attributes; the integrated whole fabric is shaped and reinforced, and the first carbon fiber layer is treated in a high heat conduction and compaction mode, so that a heat prevention and insulation integrated light thermal protection material prepared from a low-density thermal-insulation bottom layer and a high heat flux density resisting compact surface layer with high mechanicalproperty is formed; thus, the two problems of heat prevention and heat insulation under the high heat flux density are simultaneously solved; furthermore, the problem that a light thermal protectionmaterial has poor damage resistance. The thermal protection material disclosed by the invention has the advantages of simple structure, no mechanical connection and high reliability, and the highest heat flux density resisting capacity can reach 2.0 MW / m<2> or more.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Energy-saving transformer substation

InactiveCN101192743AReduce energy consumptionSolve the insulation performanceSubstation/switching arrangement detailsDistribution substationsEngineeringEnergy consumption

Owner:SHANGHAI ELECTRIC POWER DESIGN INST +1

Pipe made from copolymer of PVC/ acrylonitrile butadiene - styrene, and preparation method

InactiveCN1872529AAccelerated corrosionImprove heat resistanceSynthetic resin layered productsLaminationPolymer sciencePolyvinyl chloride

A polyvinyl chloride (PVC) / acrylonitrile-butadiene-styrene copolymer (ABS) tube is composed of an external hard PVC layer, an internal ABS layer, and a thermofusible adhesive layer as sandwich layer. It is prepared by three layers coextruding out method, which includes such steps as extruding out PVC-U layer by primary extruder while extruding internal ABS layer and adhesive sandwich layer by two secondary extruders, passing than through a common shaping die, sizing, cooling, winding, and packing.

Owner:金德管业集团有限公司

Heat insulating strip for aluminum alloy doors and windows, and production method thereof

InactiveCN107163562ASolve the strength problemSolve the insulation performancePhenol formaldehyde resinGraphite

The invention provides a heat insulation strip for aluminum alloy doors and windows and a preparation method thereof, and relates to the technical field of engineering plastics production. The heat insulation strip for aluminum alloy doors and windows includes the following raw materials in parts by weight: nylon resin, neoprene rubber, polyester Vinyl chloride resin, phenolic resin, glass fiber, ceramic fiber, fly ash, asbestos powder, floating beads, aerogel, graphite powder, lignin, toughening agent, coupling agent, antioxidant, light stabilizer, heat stabilizer The preparation method comprises the following steps: (1) weighing raw materials; (2) pretreatment; (3) preparing mixed pellets; (4) drying; (5) shaping. The invention solves the problems of low tensile strength, poor thermal insulation performance, poor fireproof performance and poor thermal stability of existing heat insulation strips used for aluminum alloy doors and windows.

Owner:肥西县碧涛建材有限公司

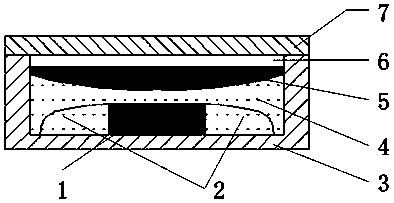

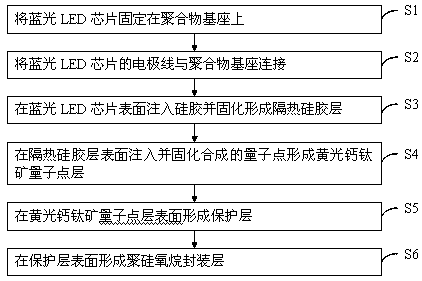

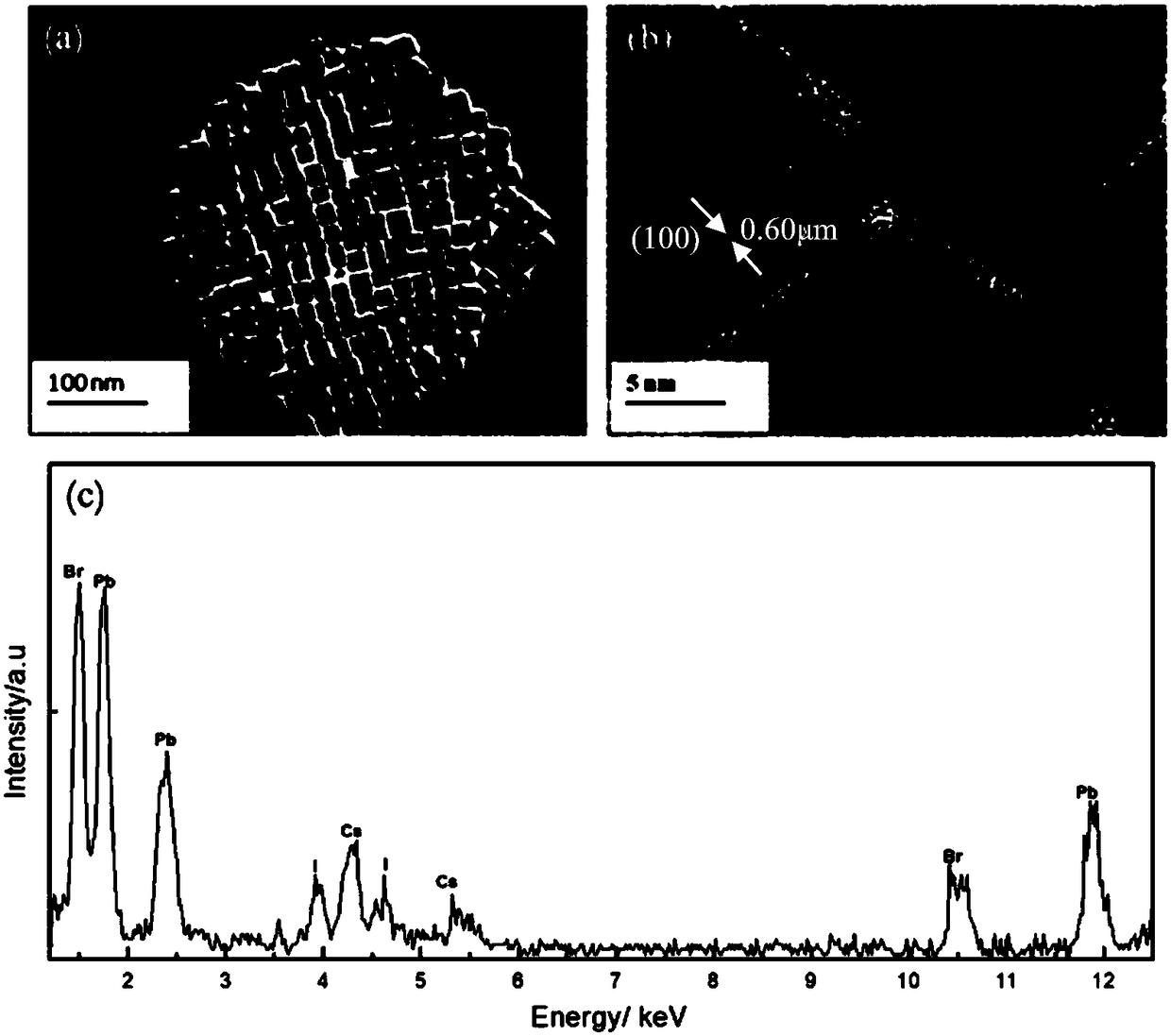

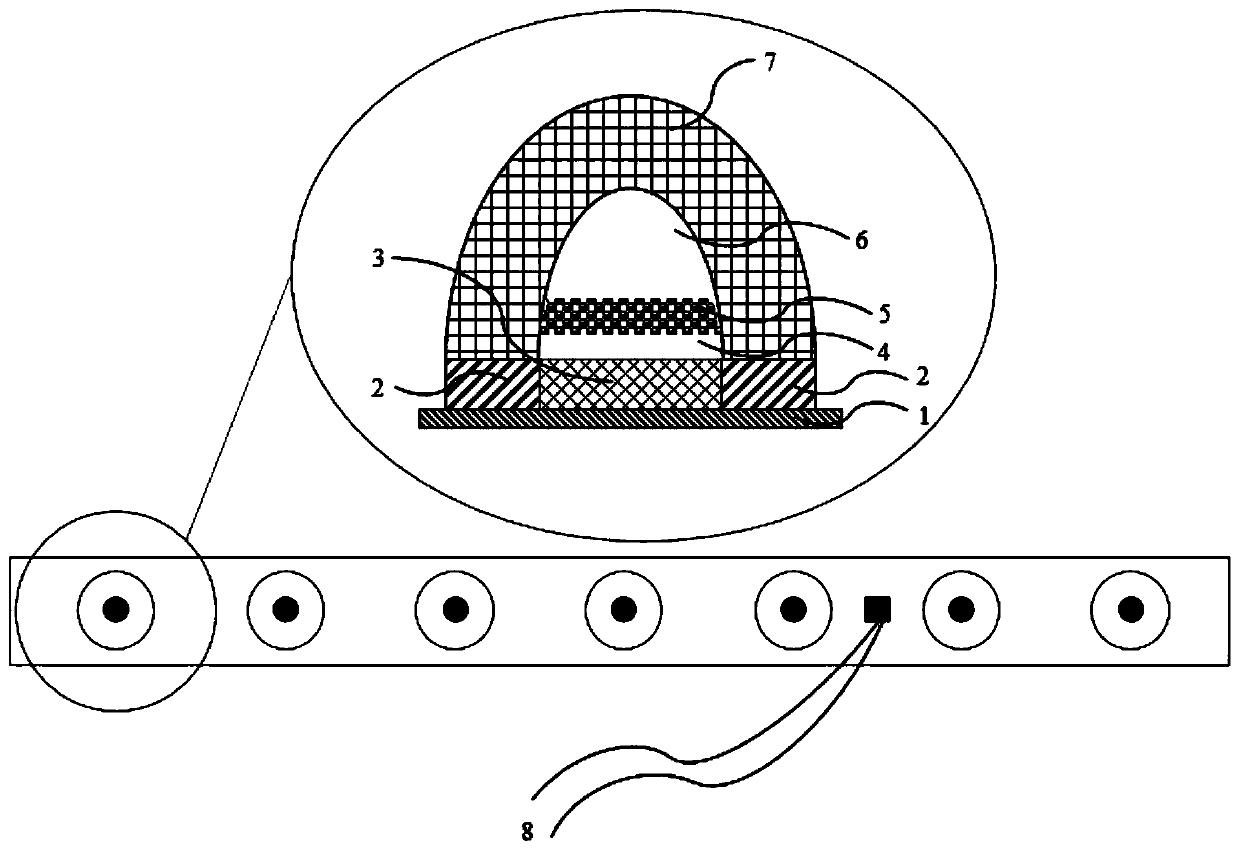

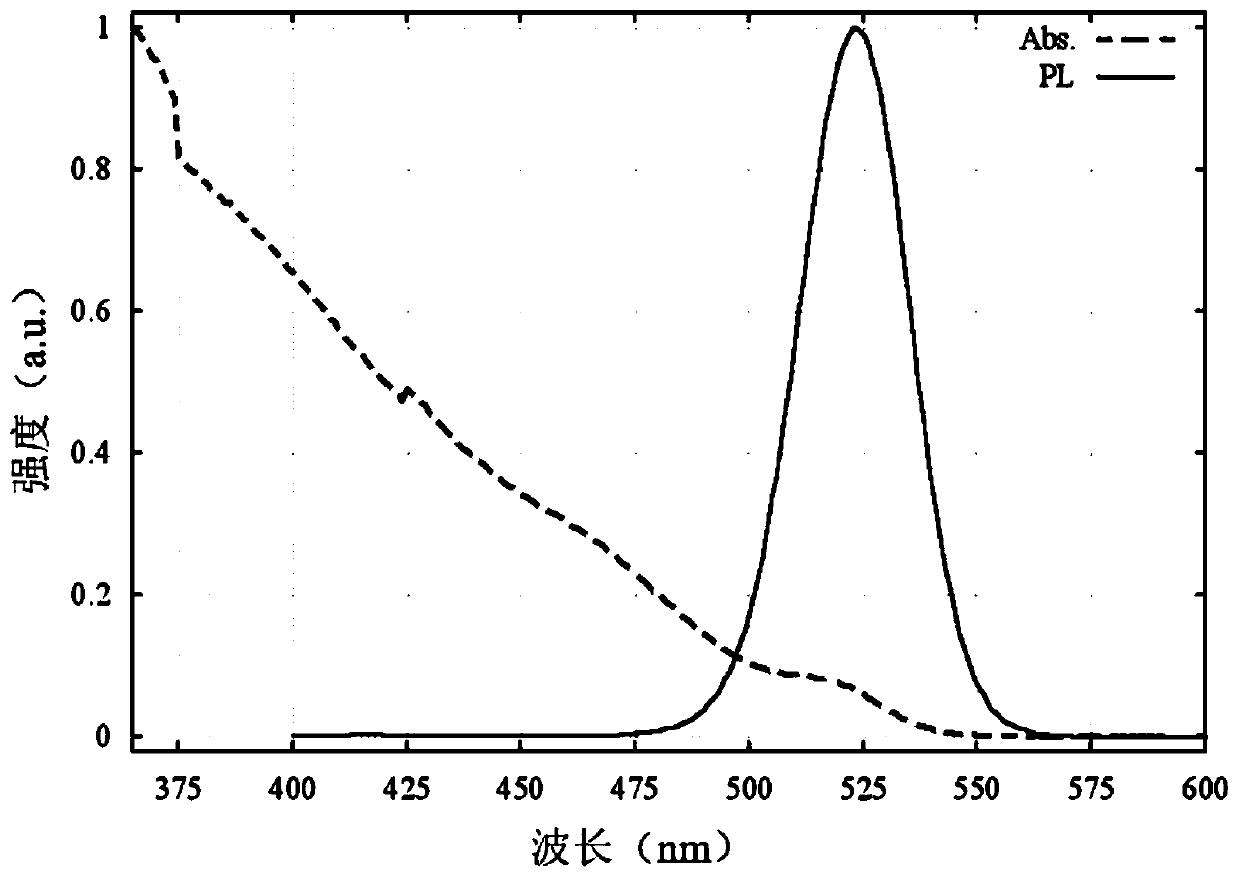

Yellow-light LED packaging structure and packaging method

InactiveCN108548105AHigh color purityImprove stabilityElectric lightingSpectral modifiersQuantum dotEngineering

The invention discloses a yellow-light LED packaging structure and a packaging method. The yellow-light LED packaging structure comprises a blue-light LED chip, a polymer foundation, an electrode wire, thermal insulating silica gel layers, yellow-light perovskite quantum dot layers, protective layers and polysiloxane packaging layers, wherein the polymer foundation is used for fixing the blue-light LED chip and comprises a base and fences arranged around the base, and the blue-light LED chip is fixed on the base; the electrode wire is connected with the blue-light LED chip and the polymer foundation; the thermal insulating silica gel layers are cured around the blue-light LED chip and on the upper surface of the blue-light LED chip; the yellow-light perovskite quantum dot layers are curedon the surfaces of the thermal insulating silica gel layers; the protective layers deposited on the surfaces of the yellow-light perovskite quantum dot layers; and the polysiloxane packaging layers are arranged on the surfaces of the protective layers. Thus, high-stability half-peak width and narrow yellow-light perovskite type quantum dot LED is obtained.

Owner:NANCHANG UNIV

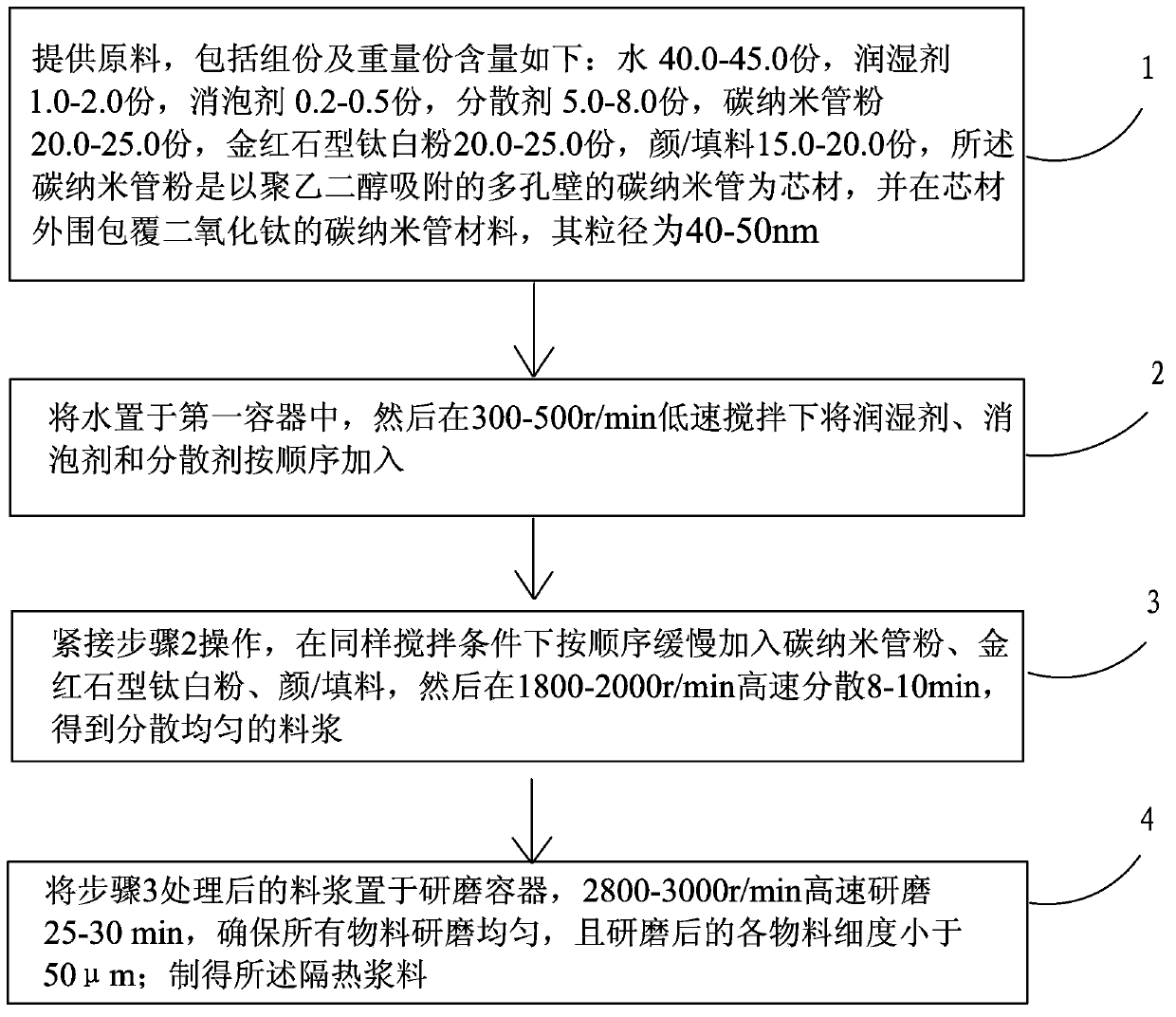

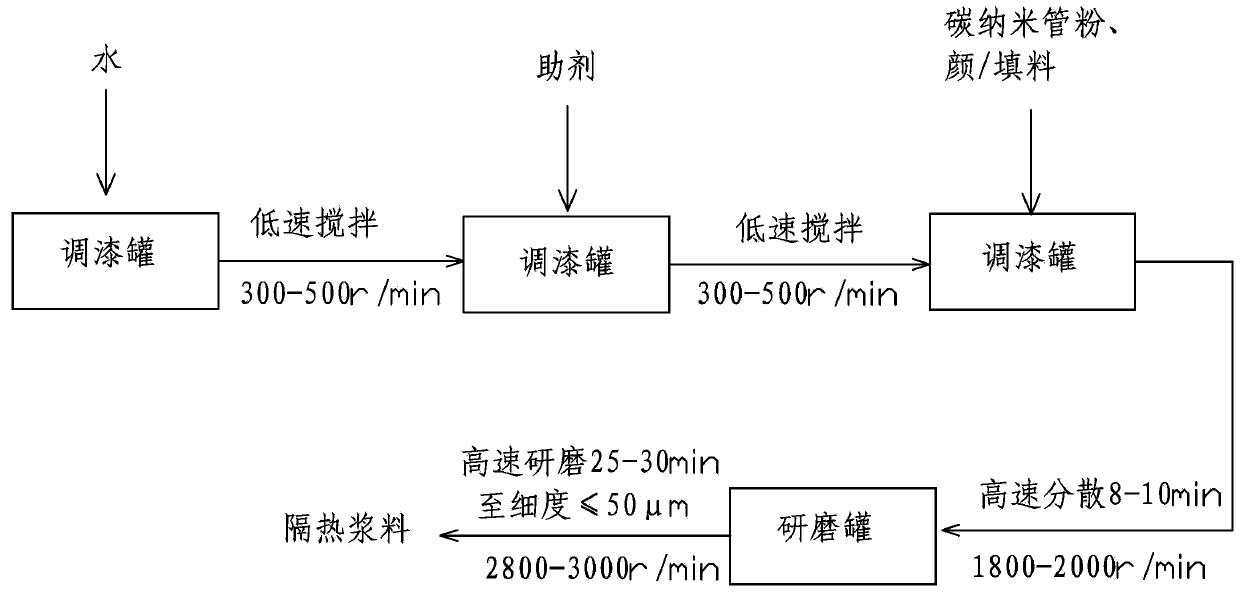

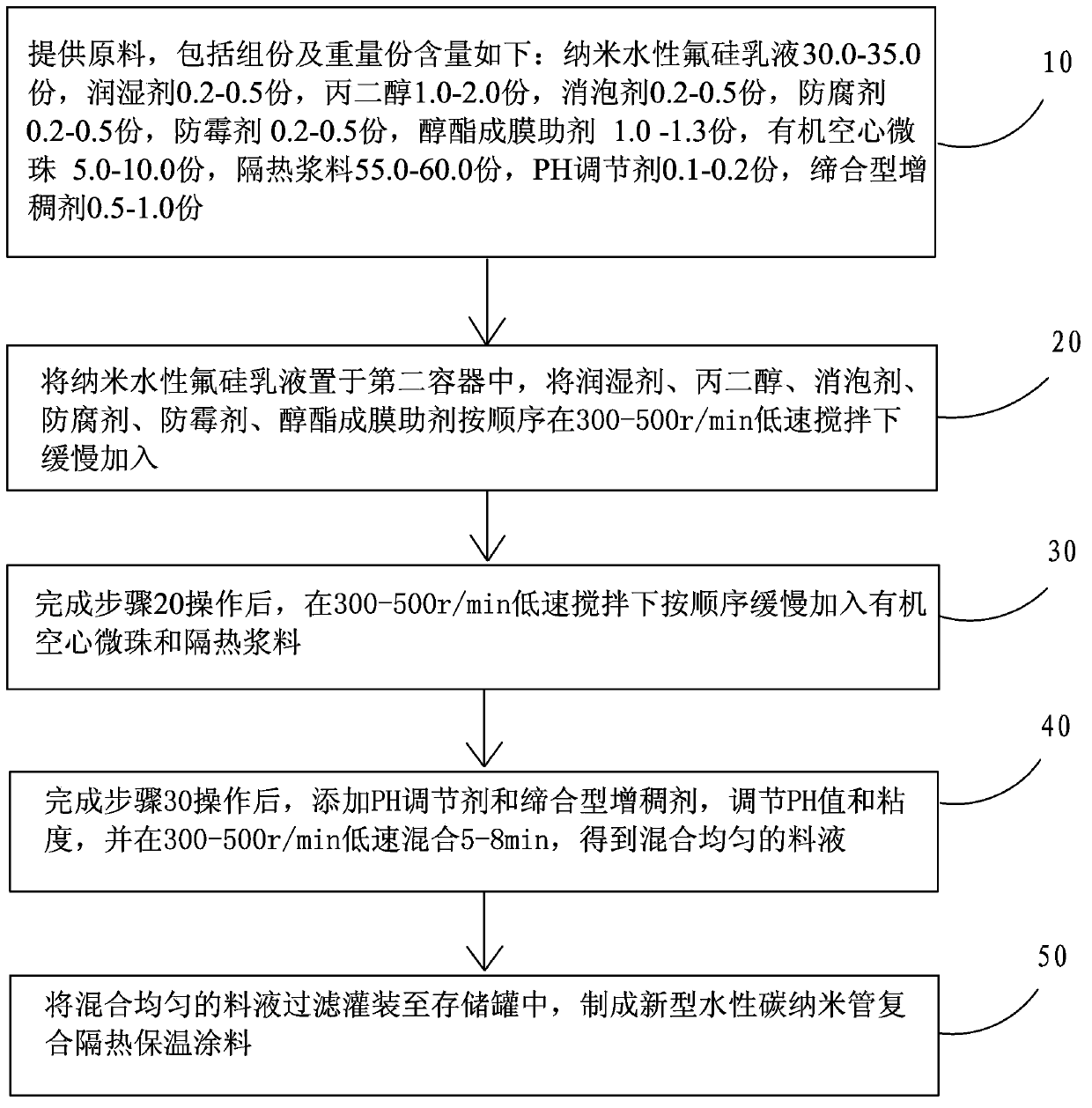

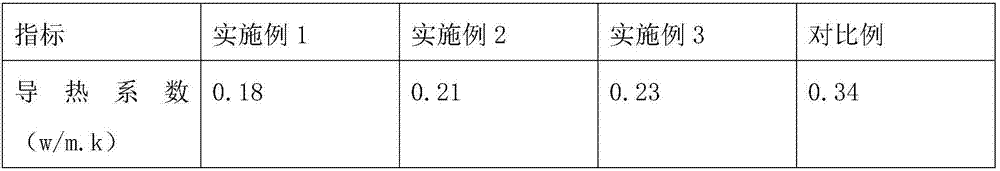

Thermal insulation slurry and novel aqueous carbon nanotube composite thermal insulation coating using thermal insulation slurry and preparation method thereof

ActiveCN103360858AImprove insulation effectSuper aging resistanceReflecting/signal paintsEmulsionThermal insulation

The invention provides a thermal insulation slurry and a novel aqueous carbon nanotube composite thermal insulation coating using the thermal insulation slurry and a preparation method thereof. Carbon nanotube powder in the thermal insulation slurry uses a polyethylene glycol-adsorbed porous-wall carbon nanotube as a core material, titanium dioxide is coated over the core material, and as an important component of the thermal insulation slurry, the carbon nanotube powder enables the thermal insulation slurry to have integrated multiple thermal insulation modes. The novel aqueous carbon nanotube composite thermal insulation coating uses a carbon nanotube material of a special structure in the thermal insulation slurry as a thermal insulation material and a nanometer aqueous fluoro-silicone emulsion as a film forming substance, so the prepared novel aqueous carbon nanotube composite thermal insulation coating has protruding thermal insulation performance and good stability and application properties. The preparation method for the novel aqueous carbon nanotube composite thermal insulation coating has the advantages of simple and easily available construction equipment and simple technological operation; and the coating prepared by using the method has protruding thermal insulation performance and good stability and application properties.

Owner:SHENZHEN SUNRISE NEW ENERGY CO LTD

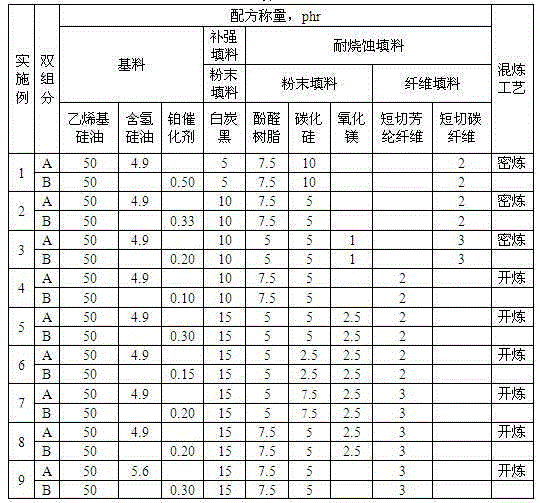

Addition-type room temperature vulcanized silicone rubber external heat-resistant material for engine and preparation method thereof

InactiveCN106609040ASolve the insulation performanceSolve the shortcomings of small molecules produced by the condensation of condensation-type silicone rubberMissileEngineering

The invention provides an addition-type room temperature vulcanized silicone rubber external heat-resistant material for an engine and a preparation method thereof. The material is prepared from 100 parts by weight of base rubber, 4-6 parts by weight of a crosslinking agent, 0.1-0.4 parts by weight of a catalyst, 20-40 parts by weight of a reinforcing filler and 20-40 parts by weight of an ablation-resistant filler. The material solves the problem that the existing resin material in the missile engine external heat-resistant field has poor heat-insulating properties and the condensed silicone rubber polycondensation produces a small molecule. Through use of a large amount of the ablation-resistant filler in the base of the addition-type room temperature vulcanized silicone rubber, good mechanical and ablation performances are obtained. The addition-type room temperature vulcanized silicone rubber external heat-resistant material can be used in the field of missile engine external heat resistance.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

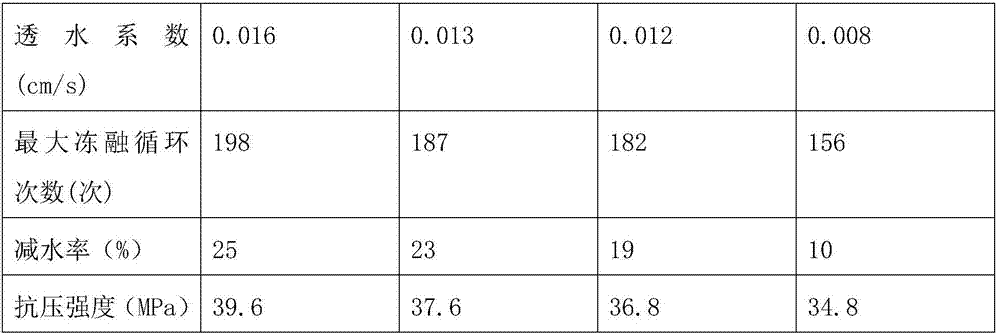

Eco-friendly pavior brick and preparation method thereof

InactiveCN107056199ASolve the problem that waste cannot be reusedSolve the insulation performanceSingle unit pavingsCeramicwareBrickSurface layer

The invention provides an eco-friendly pavior brick and a preparation method thereof, and relates to the technical field of pavior brick production. The pavior brick comprises a surface layer and a base layer, wherein the surface layer is prepared from, by weight, 15-27 parts of cement, 15-30 parts of grit, 5-7 parts of macadam, 30-40 parts of industrial waste cinder granules, 12-16 parts of waste ceramic particles, 3-6 parts of silica fume, 5-10 parts of coal ash, 3-10 parts of lime, 2-4 parts of air-entraining agents, 1.5-2.5 parts of waterproof agents, 0.3-0.5 part of antifreezing agents, 0.4-0.6 part of water reducing agent, 0.3-0.5 part of pigment powder and 1-3 parts of water; the base layer is prepared from, by weight, 16-18 parts of cement, 18-22 parts of grit, 17-25 parts of macadam and 2-3 parts of water; the preparation method includes the steps of (1) the preparation of surface layer ingredients, (2) preparation of base layer dosing, (3) molding, demoulding, stacking and maintaining; the eco-friendly pavior brick and the preparation method thereof solve the problems of unavailable recycling of wastes, poor heat insulation property, low water permeability and freezing resistance, a bad effect of reducing water and low compressive strength in the prior art.

Owner:合肥慧林建材有限公司

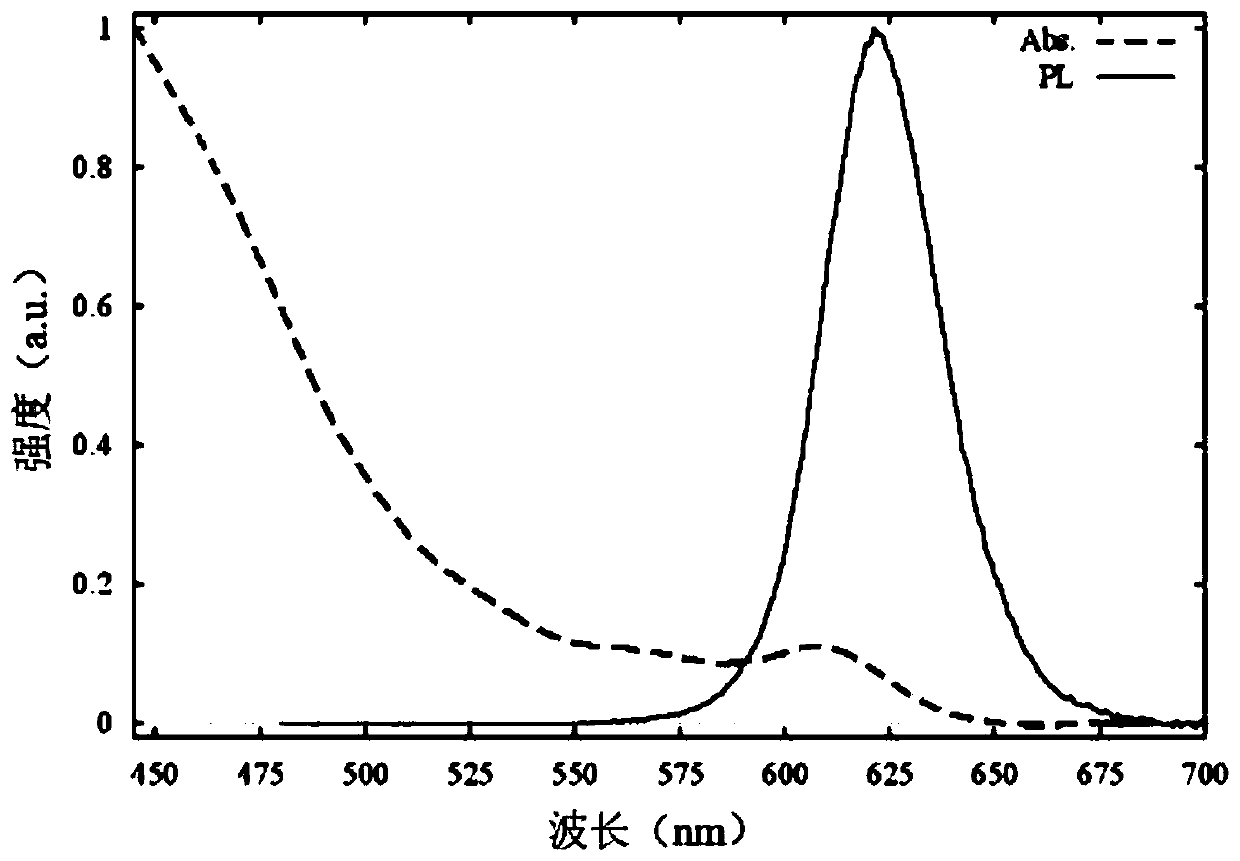

Quantum dot LED package structure and packaging method

ActiveCN109755357AImprove stabilitySolve the insulation performanceSemiconductor devicesInsulation layerQuantum dot

The invention discloses a quantum dot LED package structure and a packaging method. The package structure comprises the following parts of blue LED chips; a strip substrate for fixing the blue LED chips; an electrode connecting the blue LED chips and the strip substrate; an AB adhesive insulation layer cured on the upper surfaces of the blue LED chips; a quantum dot layer cured on the upper surface of the AB adhesive insulation layer; an AB adhesive protective layer cured on the upper surface of the quantum dot layer; a PMMA lens encapsulation layer covering the blue LED chips, the electrode,the AB adhesive insulation layer, the quantum dot layer and the AB adhesive protective layer and sealing the above components with the strip substrate; and a common electrode disposed on the strip substrate and connecting respective blue LED chips in series. By providing a lens encapsulation layer and a double-layer protective rubber layer, the invention can block the invasion of the quantum dot layer and the LED chips by the external water and oxygen, which provides an environment for isolating water and oxygen for quantum dots and is beneficial to improving the luminous efficiency and service life of the quantum dots.

Owner:SOUTH CHINA NORMAL UNIVERSITY

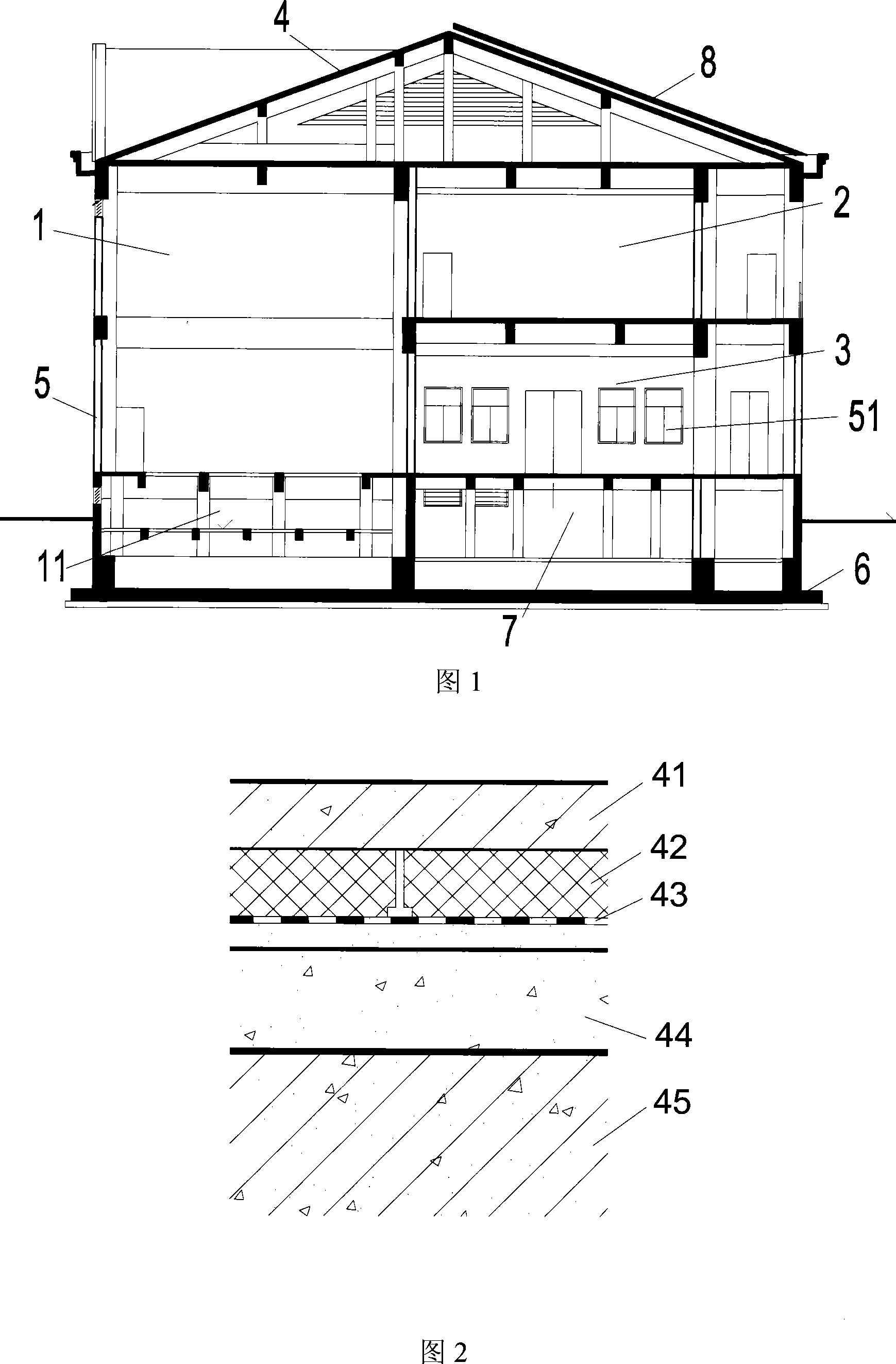

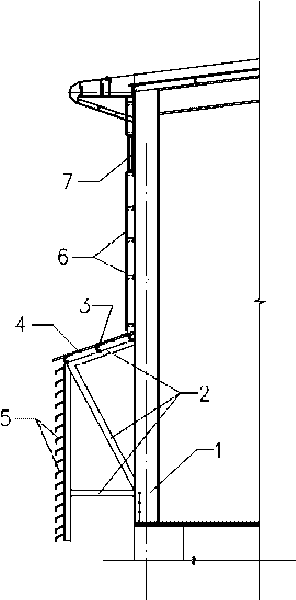

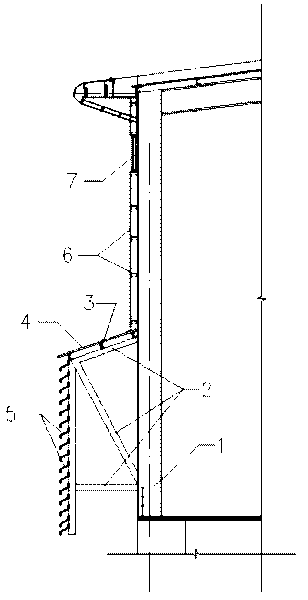

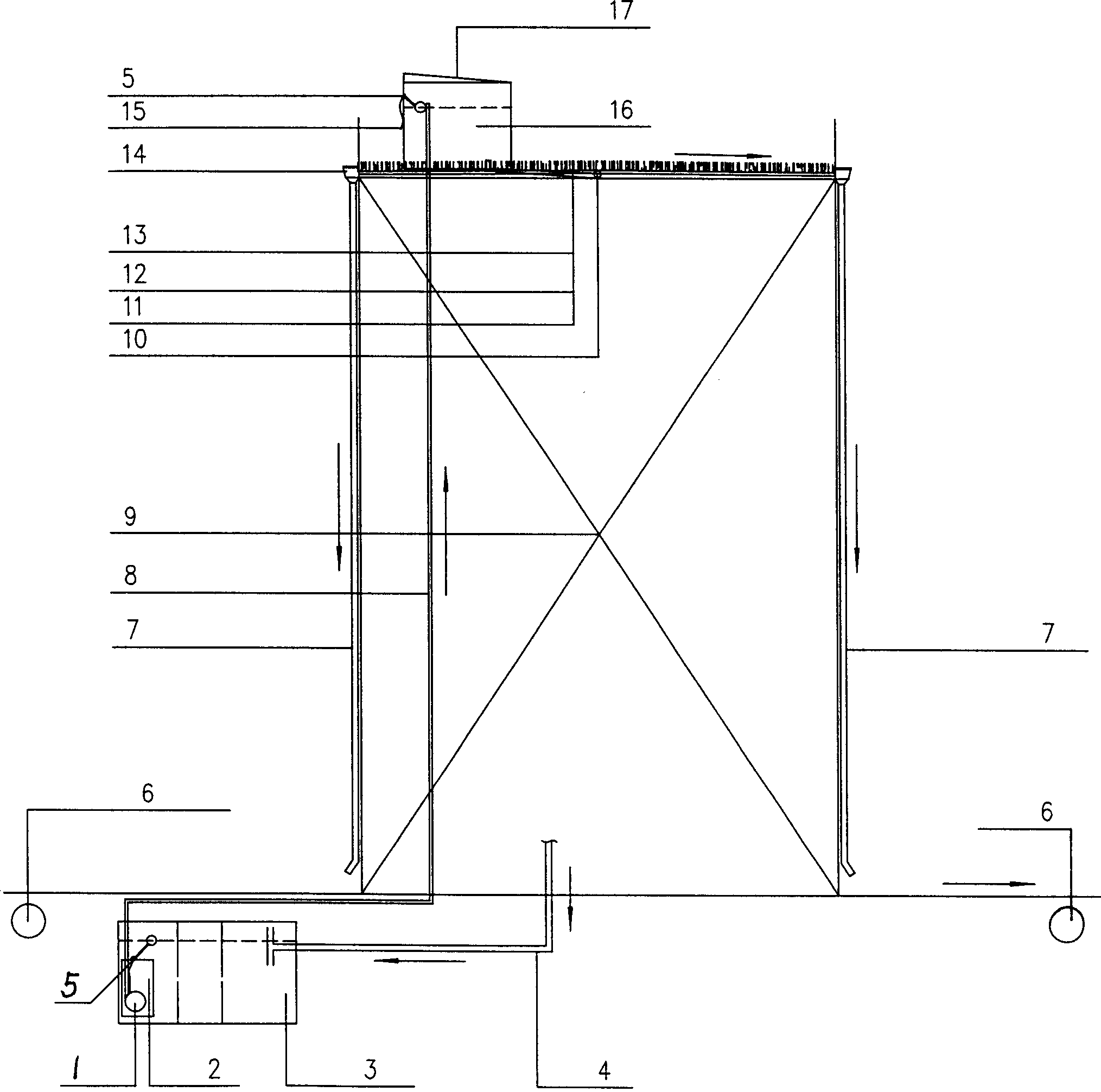

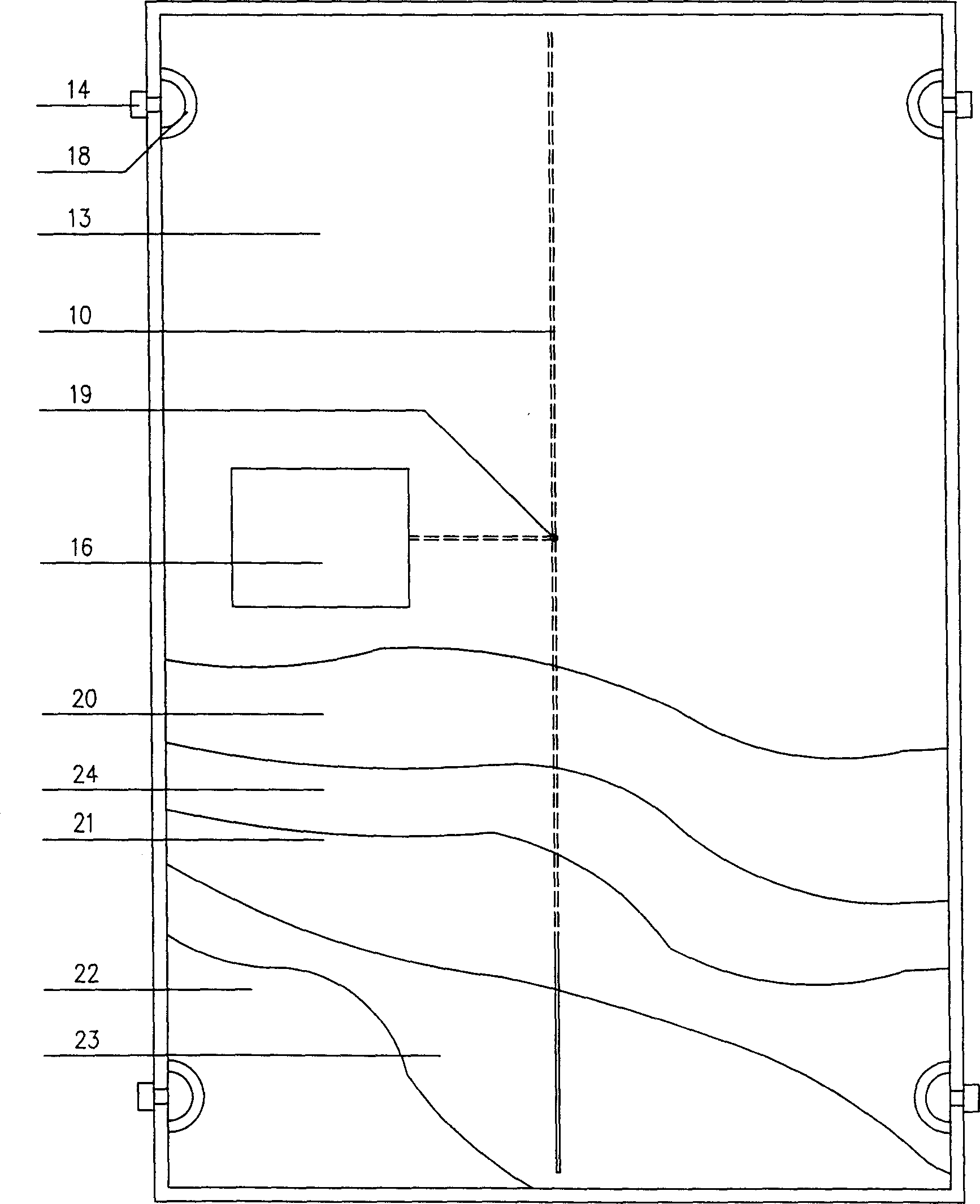

Mill construction of overhanging type air inlet ventilation outer wall

InactiveCN101761252AImprove ventilationSpeed up the flowWallsBuilding insulationsWorking environmentArchitectural engineering

The invention discloses a mill construction of an overhanging type air inlet ventilation outer wall, which comprises a mill steel column (1). A big overhanging type open air inlet steel support (2) is connected below the lower neutralizing interface of the outer side of the mill steel column (1); the top surface of the big overhanging type open air inlet steel support (2) is provided with a baffle; the outer side of the big overhanging type open air inlet steel support (2) is provided with a rain-proof louvre blade (5); the outer side of the upper part of the mill steel column (1) is connected with an upper outer wall; and the upper outer wall is provided with a lighting arrangement near the position of a cornice. Firstly, the invention can enable the ventilation rate in a mill to be increased a lot, thereby ensuring the mill to have air with relatively stable flowing, secondly, the invention can avoid the increase of heat in a heat production workshop due to the perpendicular incidence of sunlight, and thirdly, the invention can lower the temperature of the surface of equipment in the heat production workshop, improve the work environment of the equipment in the workshop and prolong the service life of the equipment.

Owner:GUIYANG MAGNESIUM ALUMINUM DESIGN & RES INST CO LTD

Water purifying plant for buildings

InactiveCN1415560AEasy to useReduce production operating costsEnergy based wastewater treatmentBiological water/sewage treatmentReclaimed waterSewage

A water cleaning facility for building is composed of separating unit, water regulating unit, diffusing unit, cleaning unit and water collecting unit for drainging the reclaimed water. The septic tank, immersible pump, water supply pipe, sewage tank, diffusing pipe and roof region for planting are included.

Owner:孙王虎

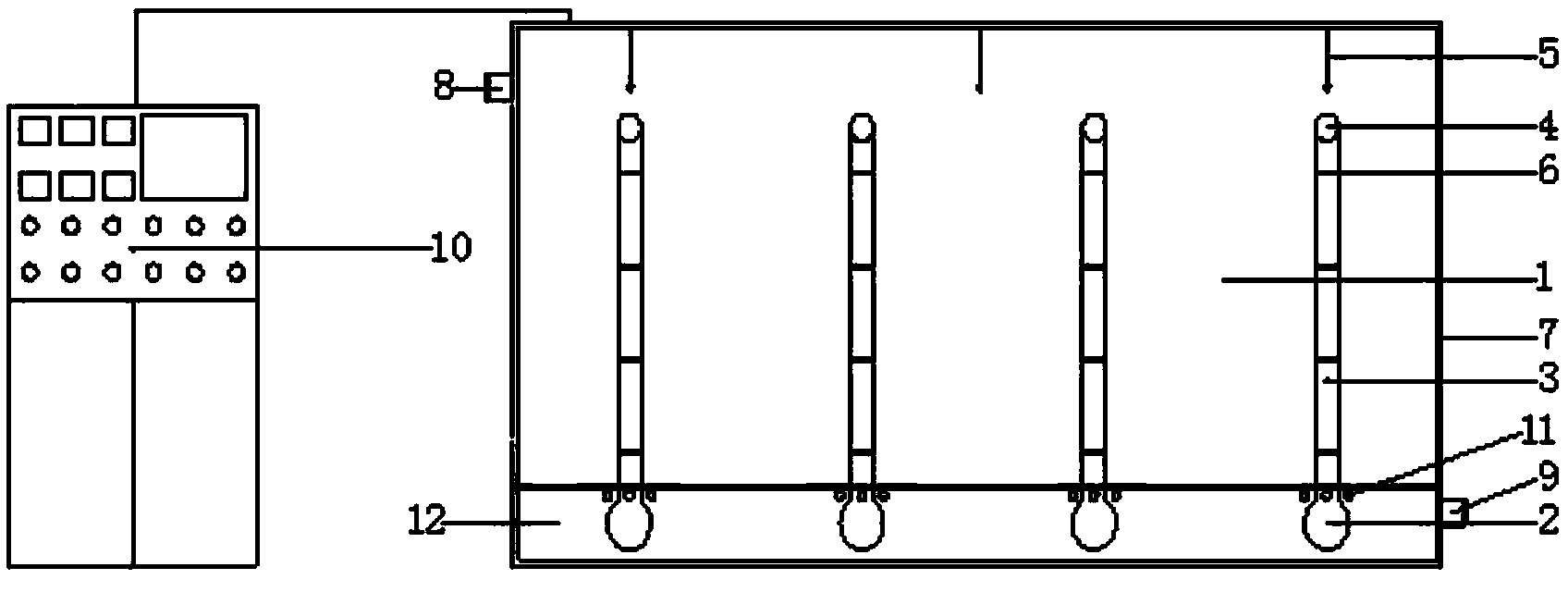

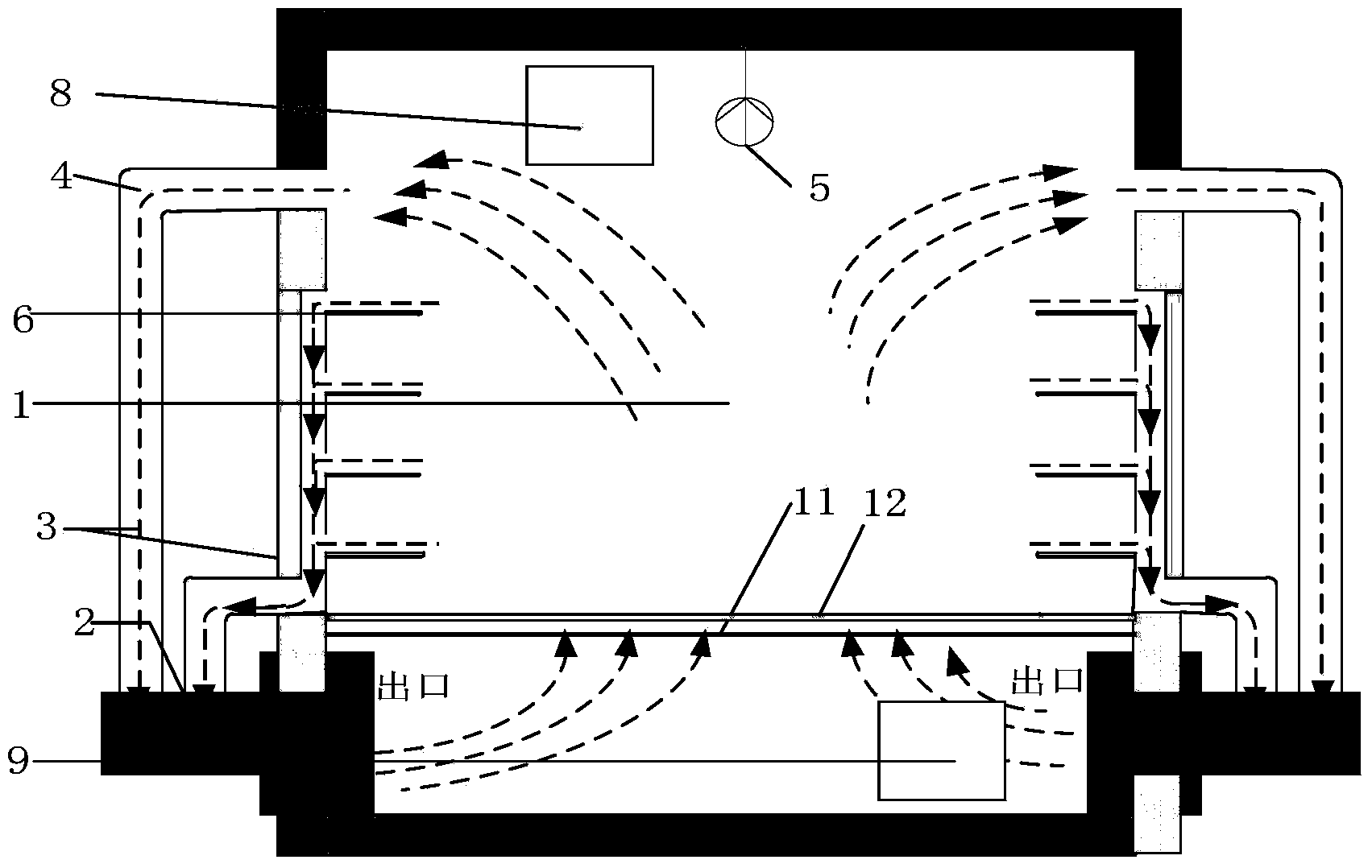

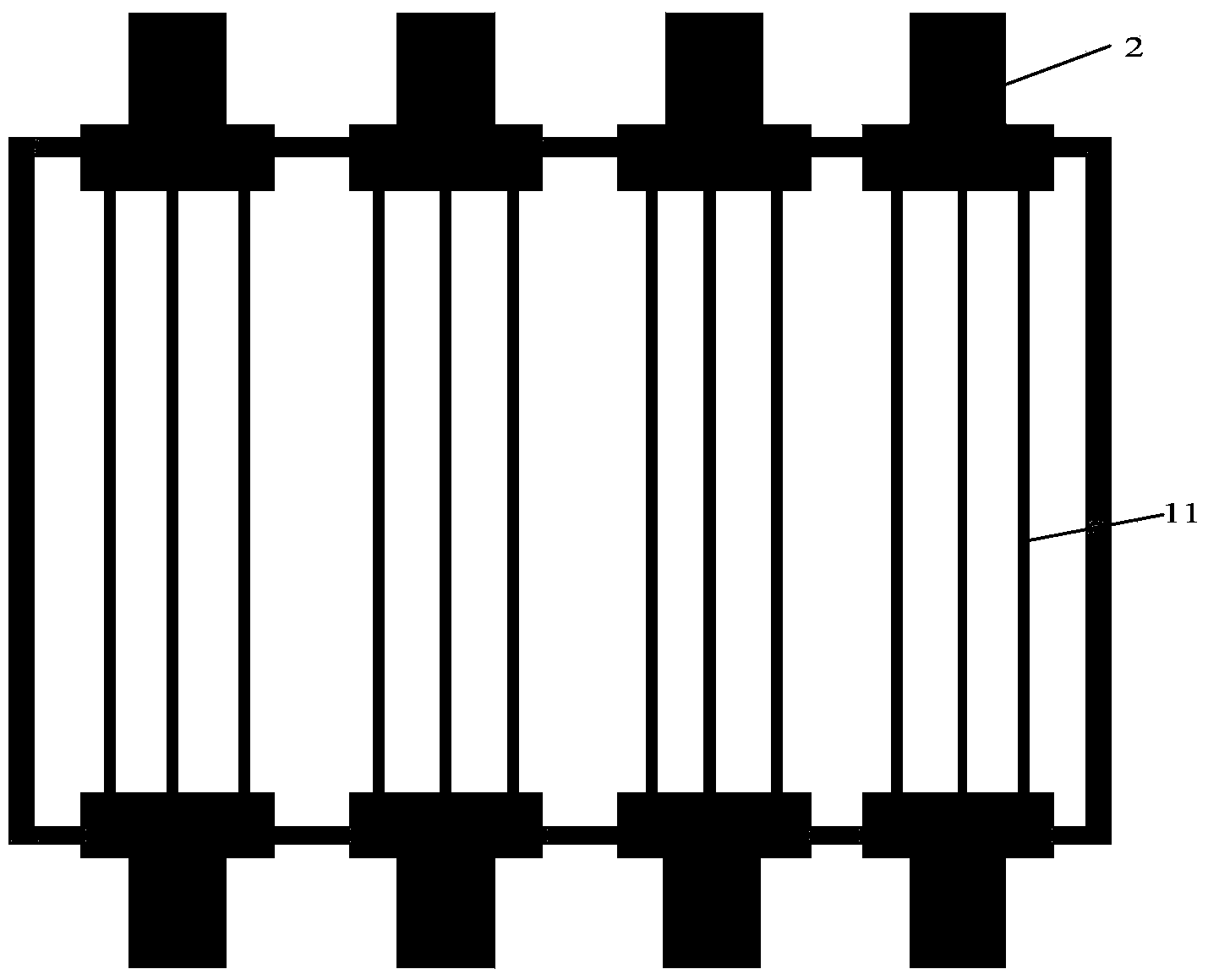

Electric-heating air-circulating-type drying box

ActiveCN103776242AAvoid uneven heatingHeat size controllableDrying gas arrangementsDrying chambers/containersElectric heatingEngineering

The invention provides an electric-heating air-circulating-type drying box which comprises a box body, a heating bar and an air circulating unit. The upper end of the box body is provided with an air outlet, the lower end of the box body is provided with an air inlet, the air outlet and the air inlet are provided with a first axial flow fan and a second axial flow fan respectively, sliding channels are arranged in the box body, swinging plates are arranged on the sliding channels, the air circulating unit comprises a first return pipeline, a second return pipeline, a third axial flow fan and a fourth axial flow fan, the side face of the box body is sequentially provided with an upper air outlet hole, a lower air outlet hole and an air inlet hole from top to bottom, the upper air outlet hole is located between the inner wall of the upper portion of the box body and the uppermost-layer sliding channel, the lower air outlet hole is located below the bottommost-layer sliding layer, and the air inlet hole is located below the lower air outlet hole. The drying box is safe and quick to use and easy to control; the box body is made of stainless steel; a control system is arranged outside separately and is convenient to repair and maintain; the double-channel axial fans are used, an air flow system is manufactured manually, and heating efficiency is doubled.

Owner:HARBIN ENG UNIV

Heat insulation pad

ActiveCN110356591AIncrease stiffnessAchieve high thermal resistanceCosmonautic vehiclesCosmonautic thermal protectionTitanium alloyComposite structure

The invention provides a heat insulation pad. The heat insulation pad is positioned between a low-temperature assembly and a high-temperature assembly, and comprises an upper titanium alloy cap, a polyimide column and a lower titanium alloy cap; a structure can be realized by embedding the polyimide column into the upper titanium alloy cap and the lower titanium alloy cap, and can also be realizedby embedding the upper titanium alloy cap and the lower titanium alloy cap in the polyimide column, and are fixedly connected through screws, when in a unstressed mode, a gap is reserved between theupper titanium alloy cap and the lower titanium alloy cap, and a gap value between the upper titanium alloy cap and the lower titanium alloy cap is 0 after the screws are screwed according to the 80%pre-tightening force. The heat insulation pad provided in the application adopts the heat insulation pad with a titanium alloy and polyimide composite structure, the rigidity is provided through the titanium alloy, the structure size is kept stable, thermal resistance is provided through polyimide and a separation interface, and finally large thermal resistance, high rigidity and high size stability of the heat insulation pad are realized.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Carbon fiber composite material for high-temperature environment and preparation thereof

PendingCN112409787AAvoid problems with poor mixing uniformityThe problem of poor mixing uniformity is overcomeSynthetic resin layered productsResin-Based CompositeBoron nitride

The invention relates to an enhanced heat-resistant carbon fiber composite material and a product thereof. The enhanced heat-resistant carbon fiber composite material is prepared from the following raw materials: a composite resin base material prepared from a first composite resin composition, a second composite resin composition and an auxiliary agent 1; and a graphene nanosheet selected from nitride particles of silicon nitride or boron nitride; and a corresponding auxiliary agent 2. The carbon fiber composite material prepared by the preparation method of the invention not only has excellent mechanical properties, but also has the advantages of excellent heat resistance, heat insulation, processing formability and the like, and is particularly suitable for manufacturing heat insulationdevices in a high-temperature heat radiation environment.

Owner:NANJING XIAOZHUANG UNIV

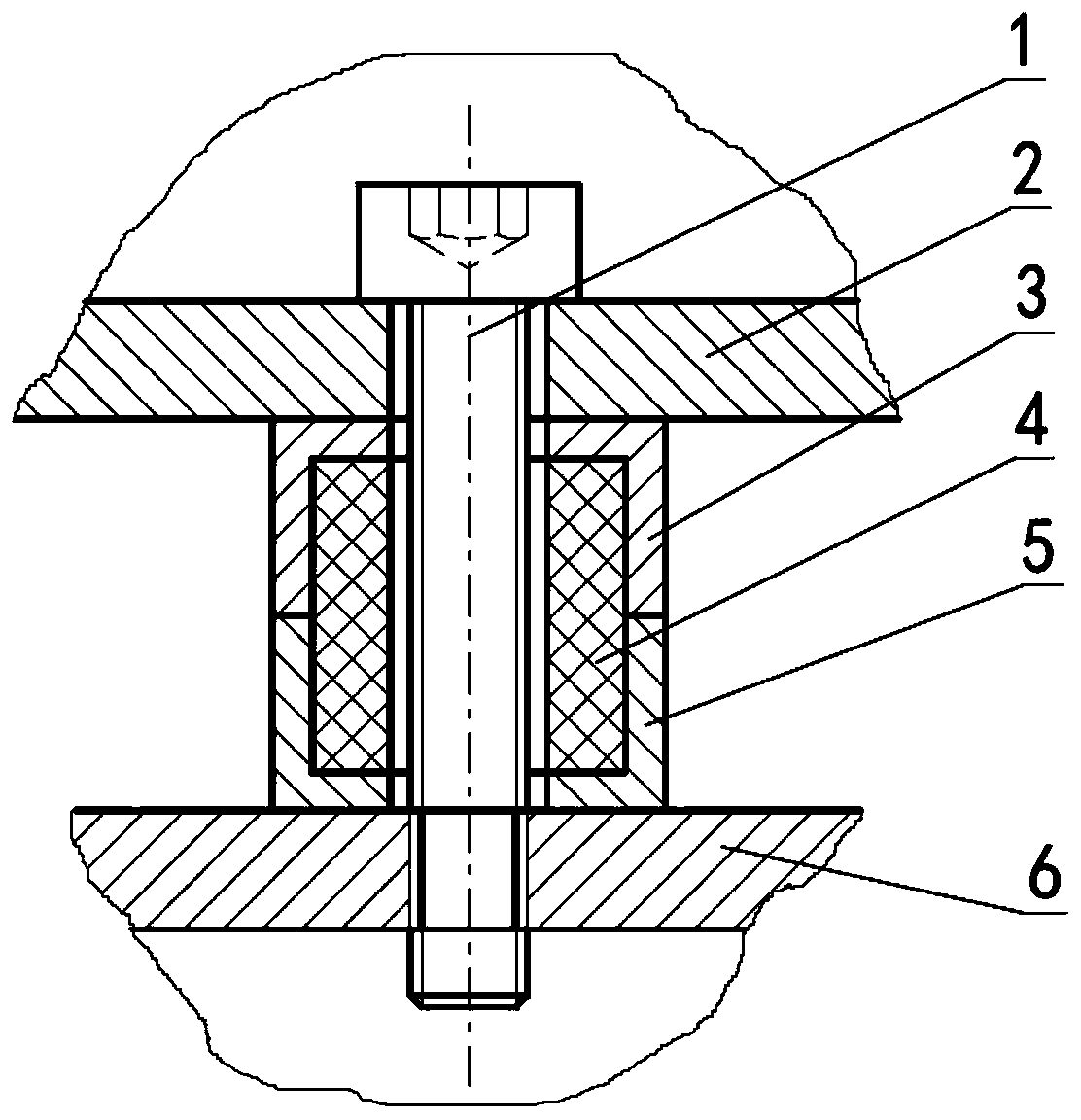

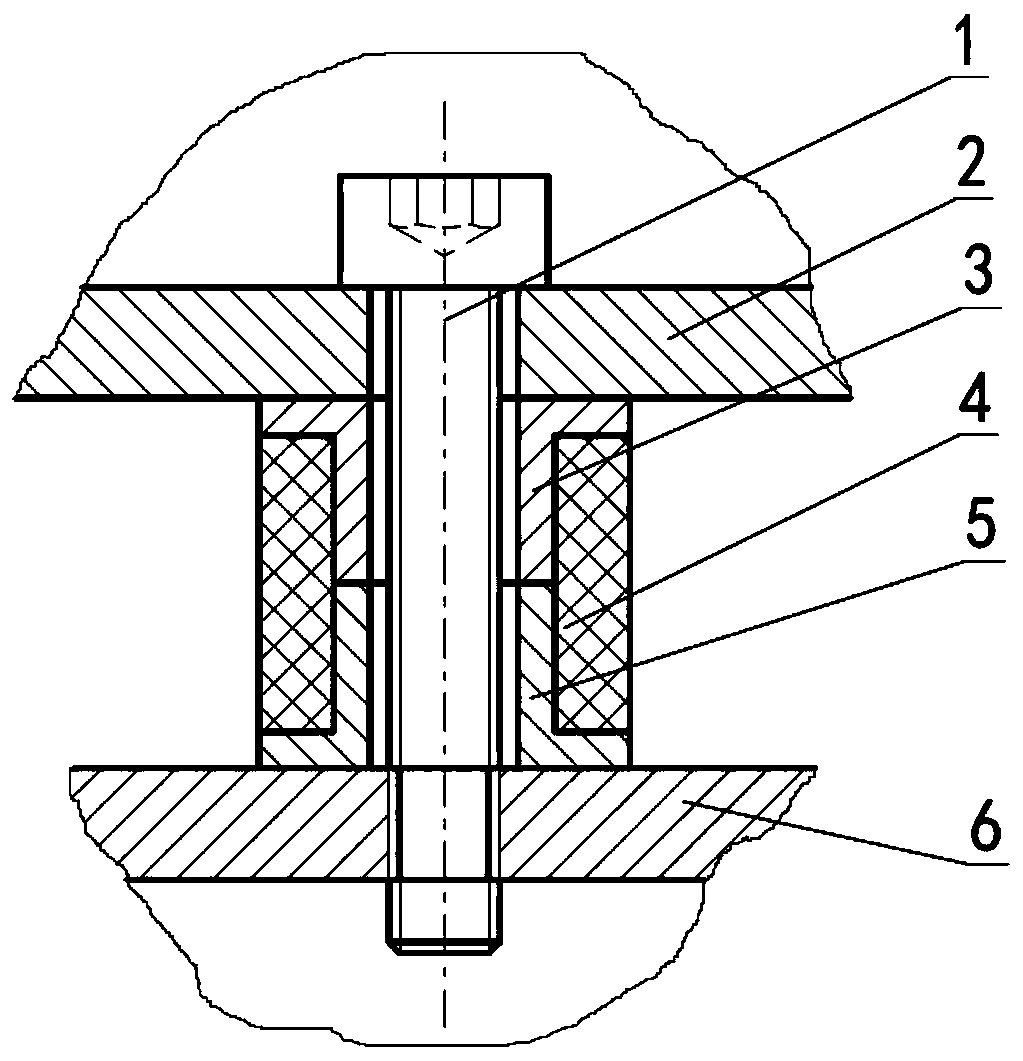

High temperature and high pressure resistance electromagnetism driving stop valve inner screen outer dissipation heat insulation device

ActiveCN103759066AGuaranteed functionMaintain propertiesSpindle sealingsValve members for heating/coolingSolenoid valveEngineering

A high temperature and high pressure resistance electromagnetism driving stop valve inner screen outer dissipation heat insulation device comprises a guiding body, a valve bush, a coil outer housing, a nonmagnetic tube, a coil component, a valve rod, a moving magnet and a heat insulation sleeve, wherein a guiding body groove is formed in the lower end face of the valve bush, a nonmagnetic tube inserting hole with an inner thread is formed in the outer end of the valve bush, a heat insulation sleeve through hole is formed in the center of the valve bush, the heat insulation sleeve is installed in the heat insulation sleeve through hole, the heat insulation sleeve is provided with a first valve rod through hole, the guiding body is provided with a second valve rod through hole, the guiding body is installed in the guiding body groove, the valve rod is installed in the first valve rod through hole and the second valve rod through hole, the coil outer housing is installed at the upper end of the valve bush, the coil outer housing is connected with the valve bush through threads, the nonmagnetic tube is installed in an inner cavity of the coil outer housing, the lower end of the nonmagnetic tube is connected with the nonmagnetic tube inserting hole at the upper end of the valve bush through threads, and the moving magnet is installed in the nonmagnetic tube. The high temperature and high pressure resistance electromagnetism driving stop valve inner screen outer dissipation heat insulation device is large in heat dissipation area, good in heat dissipation effect, and strong in heat insulation function, and thereby can improve safety and reliability of a whole electromagnetism driving stop valve.

Owner:ANSHAN SOLENOID VALVE +1

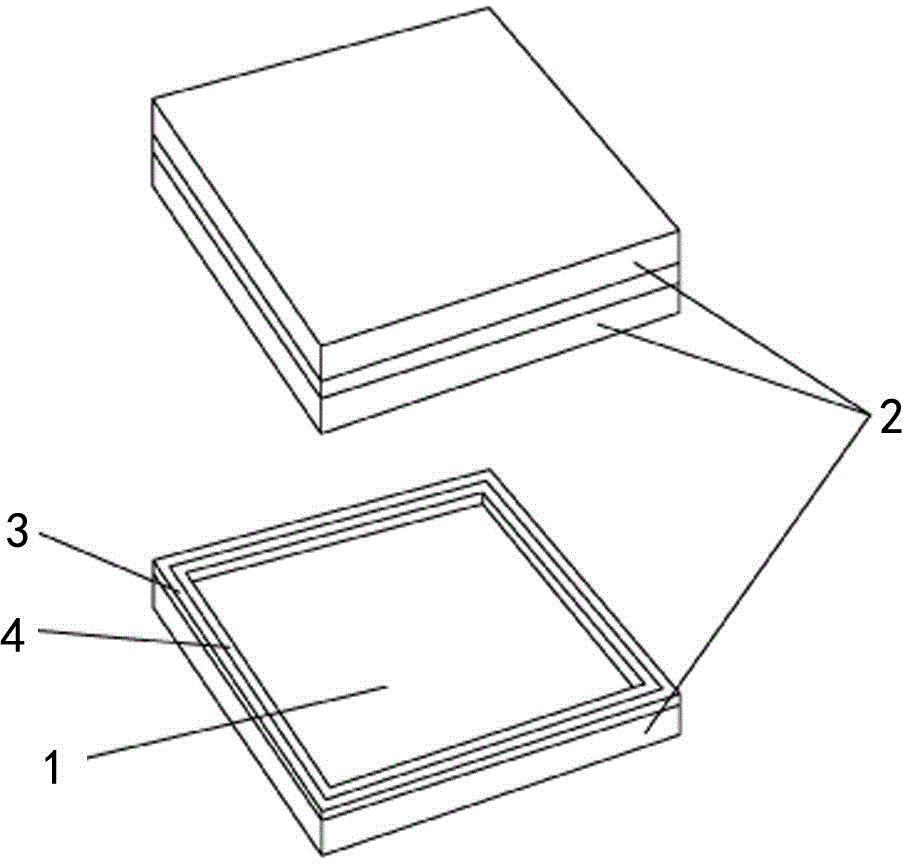

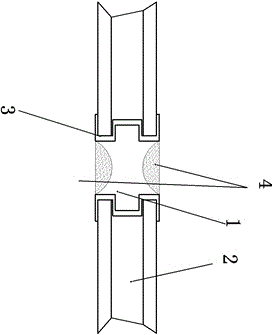

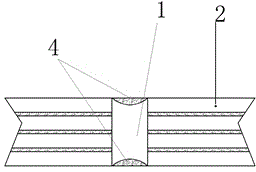

Frameless composite heat-insulation fireproof glass splicing structure

InactiveCN104441842APrevent crossfireGuaranteed fire resistance and heat insulationBuilding componentsGlass/slag layered productsOptoelectronics

The invention relates to the field of fireproof glass and particularly relates to a frameless composite heat-insulation fireproof glass splicing structure. The frameless composite heat-insulation fireproof glass splicing structure has the advantages of good fireproof and heat-insulation performances of fireproof glass, omitting of a framework structure and enhancement of transparent beautiful effect of the fireproof glass. The frameless composite heat-insulation fireproof glass splicing structure comprises at least two pieces of fireproof glass substrates; the fireproof glass substrates are arranged in parallel; a heat-insulation pressing strip is arranged between the adjacent edges of each fireproof glass substrate; a sealed containing cavity is formed by each heat-insulation pressing strip and the adjacent fireproof glass substrate, and is filled with at least two sealing glue layers and at least one transparent fireproof glue layer; and the transparent fireproof glue layer is arranged between the two sealing glue layers.

Owner:余永翀

Sports shoes and preparation method thereof

InactiveCN107057134ASolve prone to breakageSolve quality and weightFootwearPolyvinyl alcoholStearic acid

The invention provides a pair of sports shoes and a preparation method thereof and relates to the technical field of shoes. The pair of sports shoes is prepared from, by weight, 250-280 parts of natural rubber, 100-200 parts of butadiene styrene rubber, 50-100 parts of polyurethane rubber, 600-700 parts of rock flour, 60-80 parts of zinc oxide, 3-5 parts of stearic acid, 4-8 parts of sulphur, 10-14 parts of ointment, 16-24 parts of floating beads, 16-40 parts of aerogel, 40-60 parts of formalized polyvinyl alcohol fiber, 29-35 parts of aromatic polyamide fiber, 5-9 parts of foaming agent, 3-7 parts of rubber accelerator, 3-5 parts of plasticizer, 7-9 parts of light stabilizer, 3-9 parts of heat stabilizer, 2-6 parts of lubricating agent and 4-8 parts of coupling agent. The preparation method includes the following steps that 1, raw materials are weighed; 2, the raw materials are put in a rubber mixing mill; 3, upper molds, bottom molds and shoe trees are manufactured; 4, foaming molding is performed; 5, the shoe trees, the upper molds and the bottom molds are taken out. The problem that existing sports shoes easily break and have heavy weight, poor toughness and poor heat preservation and insulation effect is solved.

Owner:合肥博创机械制造有限公司

Energy-saving and environmental composite door and window profile and production method thereof

InactiveCN107141725ASolve the strength problemSolve the insulation performanceFire retardantAntioxidant

The invention provides an energy-saving and environmental composite door and window profile and a production method thereof and relates to the field of building materials. The energy-saving and environmental composite door and window profile is composed of raw materials including, by weight part, 50-60 parts of vinyl resin, 35-45 parts of halogenated unsaturated polyester, 22-36 parts of glass fiber felt, 13-31 parts of metal fiber, 12-18 parts of ceramic fiber, 15-21 parts of bamboo charcoal powder, 9-17 parts of nano titanium dioxide, 23-35 parts of aerogel, 13-23 parts of phenolic foam, 11-15 parts of polyamide fiber, 0.2-0.6 part of fire retardant, 0.3-0.5 part of coupling agent, 0.3-0.7 part of antioxidant and 0.2-0.4 part of flow modifier. The preparation method of the energy-saving and environmental composite door and window profile comprises the following steps of (1) weighing out the raw materials; (2) preparing the aerogel and the glass fiber felt; (3) mixing the raw materials and performing pulling and extruding molding. The energy-saving and environmental composite door and window profile and the production method thereof solve the problems of low strength, poor heat insulating effects, low heat resistance and poor environmental effects of existing composite door and window profiles.

Owner:HEFEI YIZHI DOORS & WINDOWS CO LTD

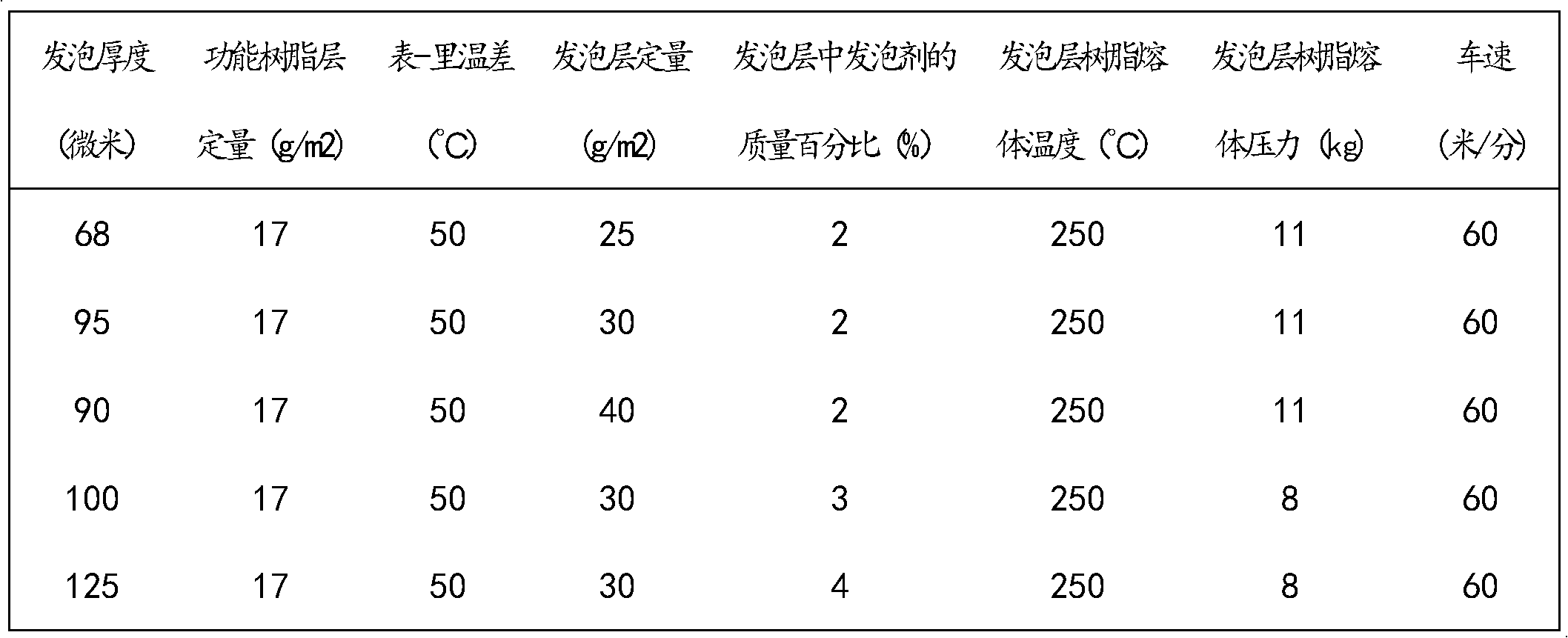

A kind of composite foam paper product and its preparation method and application

InactiveCN102277792ASolve the insulation performanceEasy to recycle and decomposeSpecial visual effect coatingsCoatingsProduction linePolyolefin

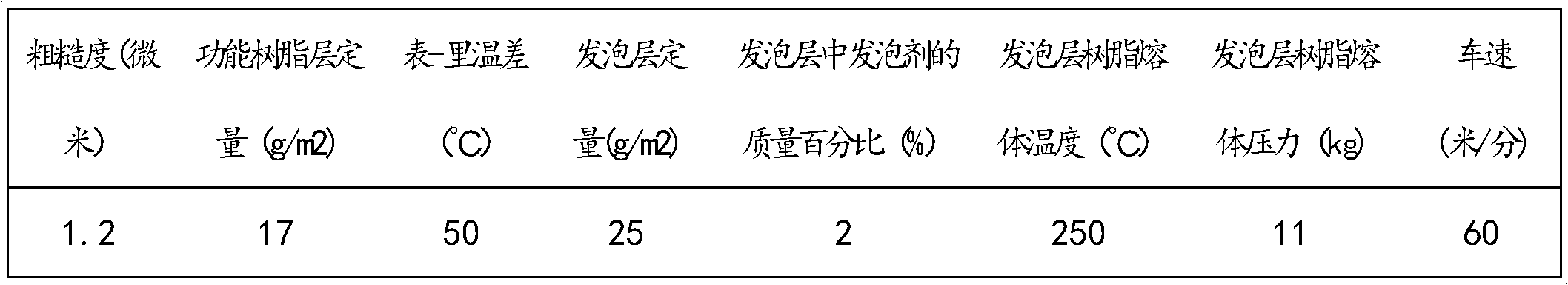

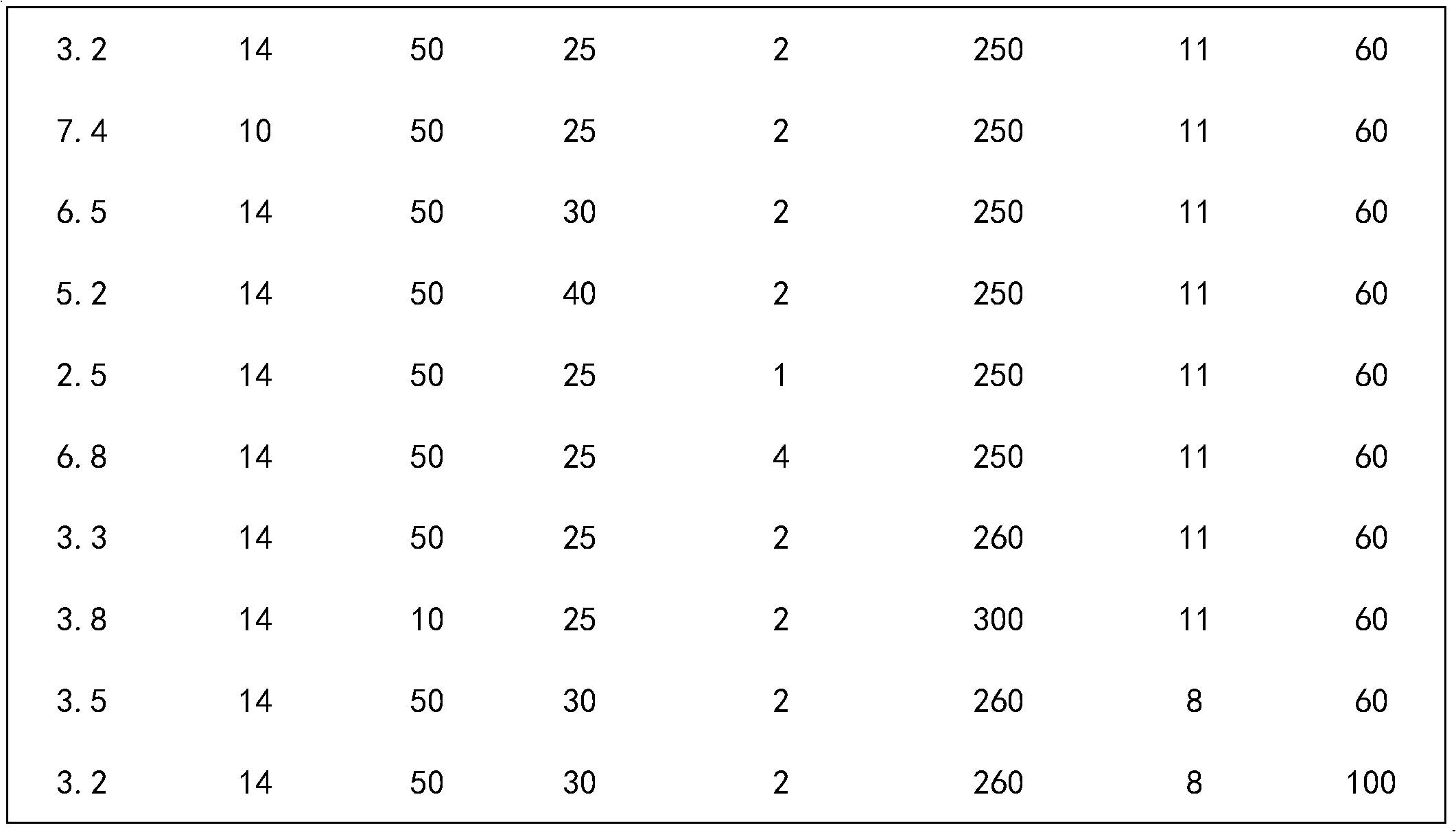

The invention provides a composite foamed paper product and its preparation method and application. The composite foamed paper product is mainly composed of a foam layer and a paper layer, wherein the material of the foam layer is 93-99% (w / w ) composite resin composed of polyolefin resin and 1-7% (w / w) foaming agent, the foaming layer is compounded and fixed with the paper layer through an extrusion coating process; the preparation method is according to 20-450 g / square Rice paper as the base material, 20-40 g / m2 composite resin as the foam layer, through the multi-layer composite cast extrusion production line at a melt temperature of 240-320 ° C, resin melt pressure 4-11KG, speed 50 - Under the processing condition of 120 m / min, composite resin and paper are compounded and processed; this paper product overcomes the problems of poor heat insulation and cushioning performance of paper and rough foaming and printing in the existing process, and can be used in food and industrial products Widely used in packaging and publishing printing fields.

Owner:刘天树

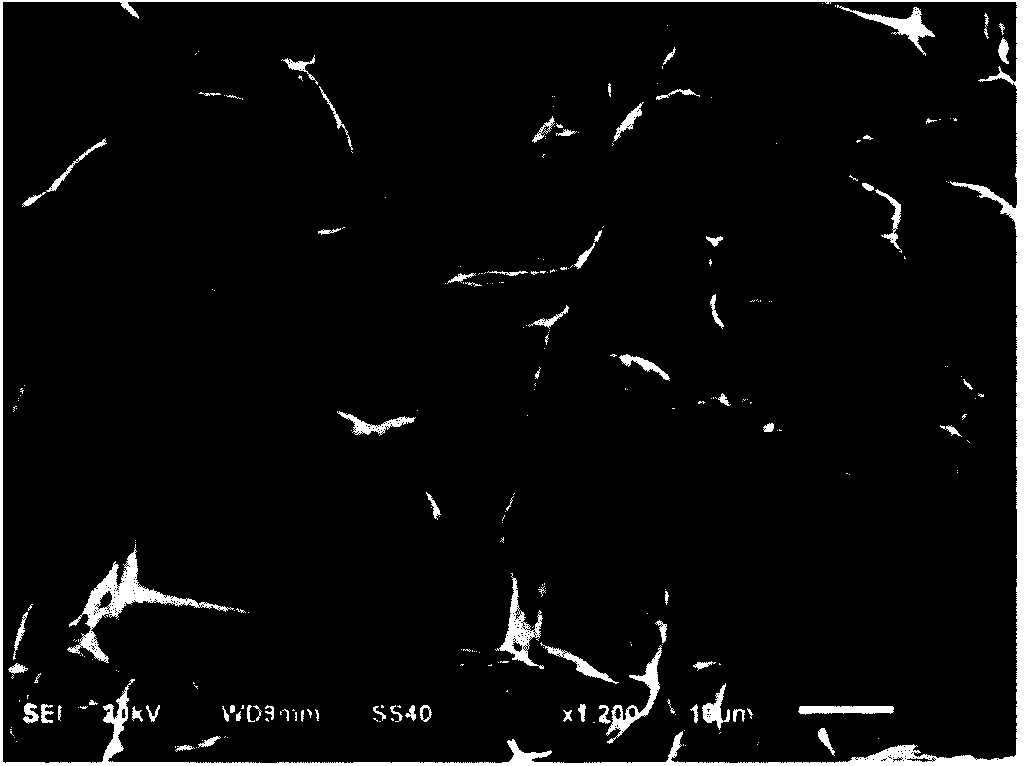

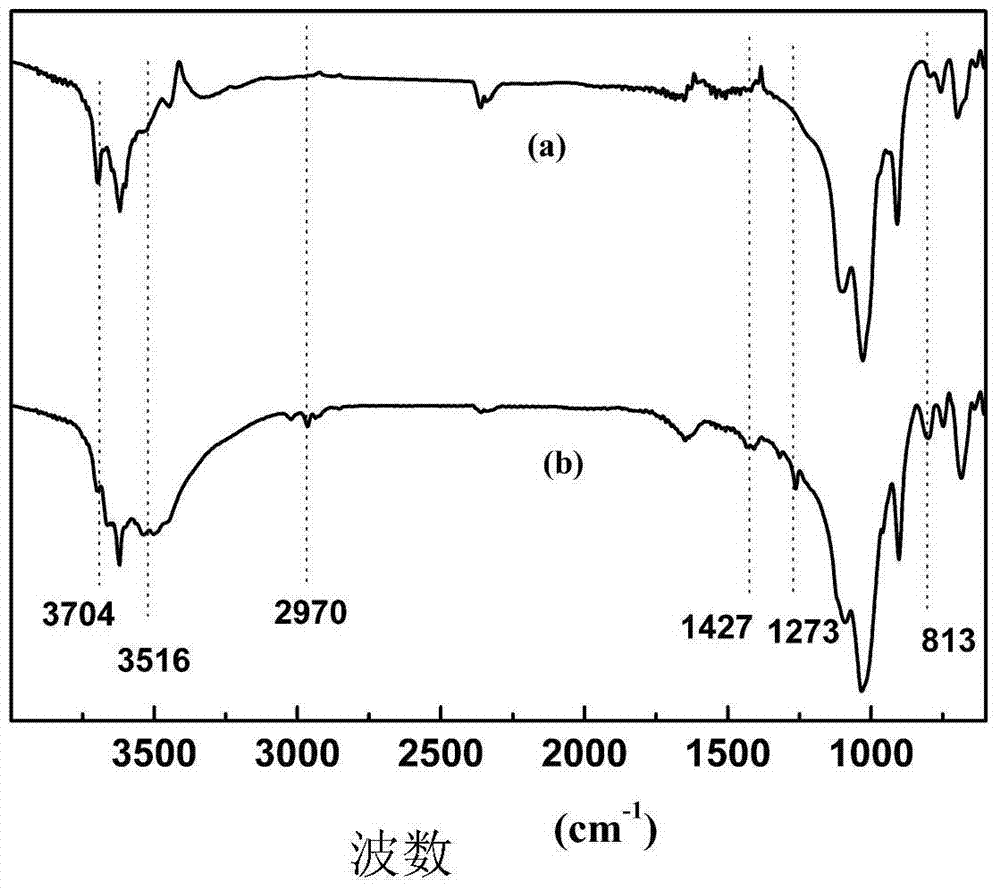

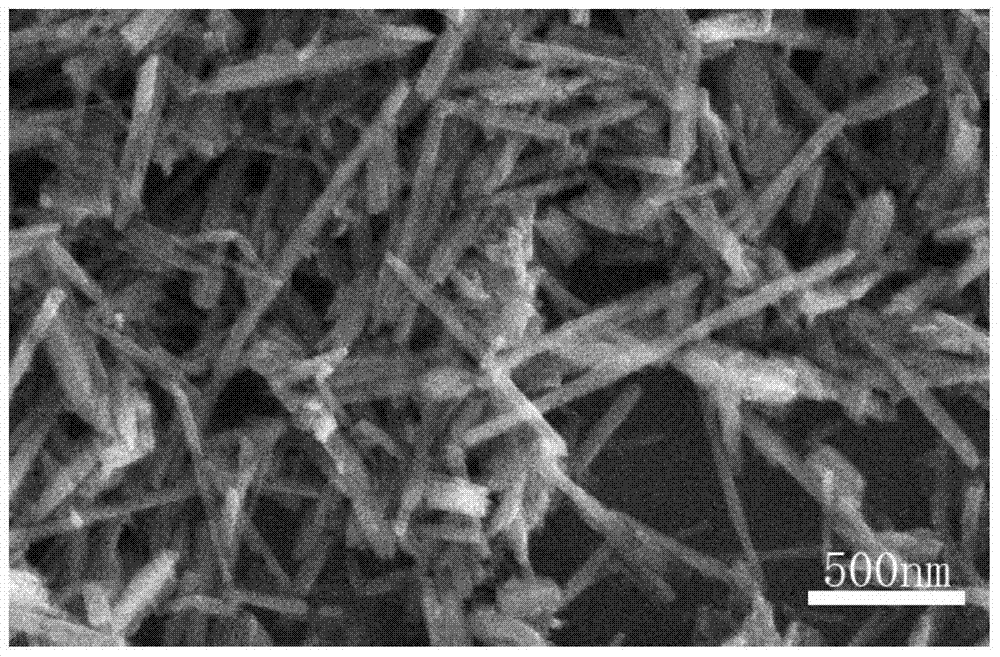

A kind of high-strength, high heat insulation silica airgel and preparation method thereof

InactiveCN105565774BImprove mechanical propertiesSolve the insulation performanceCeramicwareHalloysitePorosity

The invention discloses high-strength high-thermal-insulation silica aerogel and a preparation method thereof. The preparation method comprises the following steps: modifying halloysite with amino-terminated polysiloxane; adding ethyl orthosilicate, absolute ethyl alcohol, hydrochloric acid, dimethyl formamide and ammonium hydroxide to ensure a reaction and obtain gel; finally, carrying out carbon dioxide supercritical extraction to obtain the silica aerogel. As hollow natural clay fiber halloysite which is high in mechanical strength, low in thermal conductivity and high in thermal stability is taken as a reinforcing phase, the silica aerogel prepared according to the preparation method is relatively high in porosity, relatively low in density, excellent in mechanical property, favorable in heat-insulating property and relatively high in heat resistance.

Owner:TIANJIN CHENGJIAN UNIV

Composite phase change material composition for window frame

InactiveCN109337652ASolve cold insulationSolve the insulation performanceWindow/door framesHeat-exchange elementsStart timePolyolefin

The invention provides composite phase change material composition for a window frame. The composite phase change material composition is prepared from polyolefin, phthalate, a hydrocarbon mixture, acarbon material, a silicate material, a resin material and a polymer. The material composition can absorb or release a large amount of heat on the premise of unchanged size and unchanged performance in a phase change process, so that product performance stability is guaranteed, the problems about cold insulation and heat insulation of the window frame are solved, indoor temperature equalization ofa building is realized, indoor temperature fluctuation is reduced, start times of an air conditioner are reduced, energy consumption of the building is reduced remarkably, and energy using efficiencyis increased.

Owner:FOSHAN UNIVERSITY +1

Preparation method of compound acrylate resin coating for heat isolation and corrosion protection of pipeline

InactiveCN107916034ASolve corrosionSolve the insulation performanceAnti-corrosive paintsIsolation effectMicrosphere

The invention discloses a preparation method of a compound acrylate resin coating for heat isolation and corrosion protection of a pipeline. The preparation method has the advantages that the acid andalkaline modification is performed on the basis of lanthanum oxide and cerium oxide, so that the anti-corrosive property and anti-aging property are improved; the rare earth ions can form coordination bonds with polarity groups of hydroxyl groups, hydroxymethyl groups and the like in the molecules of the base material, so that the coating can produce coordination polymerizing and drying, and thequick dryness of a paint film is improved; a superfine silicon dioxide aerogel is respectively subjected to hydrophobic and hydrophilic modification by trimethylchlorosilane and 3-aminopropylsilanetriol, the hydrophobic groups and hydrophilic groups are respectively grafted to the surface of the superfine silicon dioxide aerogel, the good compatibility with the compound base material is realized,the microsphere is tightly bonded with the base material, the interface heat drag is smaller than the air heat drag, and the heat isolation effect is improved; a chlorosulfonated polyethylene emulsionand a styrene-acrylic emulsion are compounded, so that the anti-aging property and the anti-corrosive property of the coating are improved.

Owner:安徽铭能保温科技有限公司

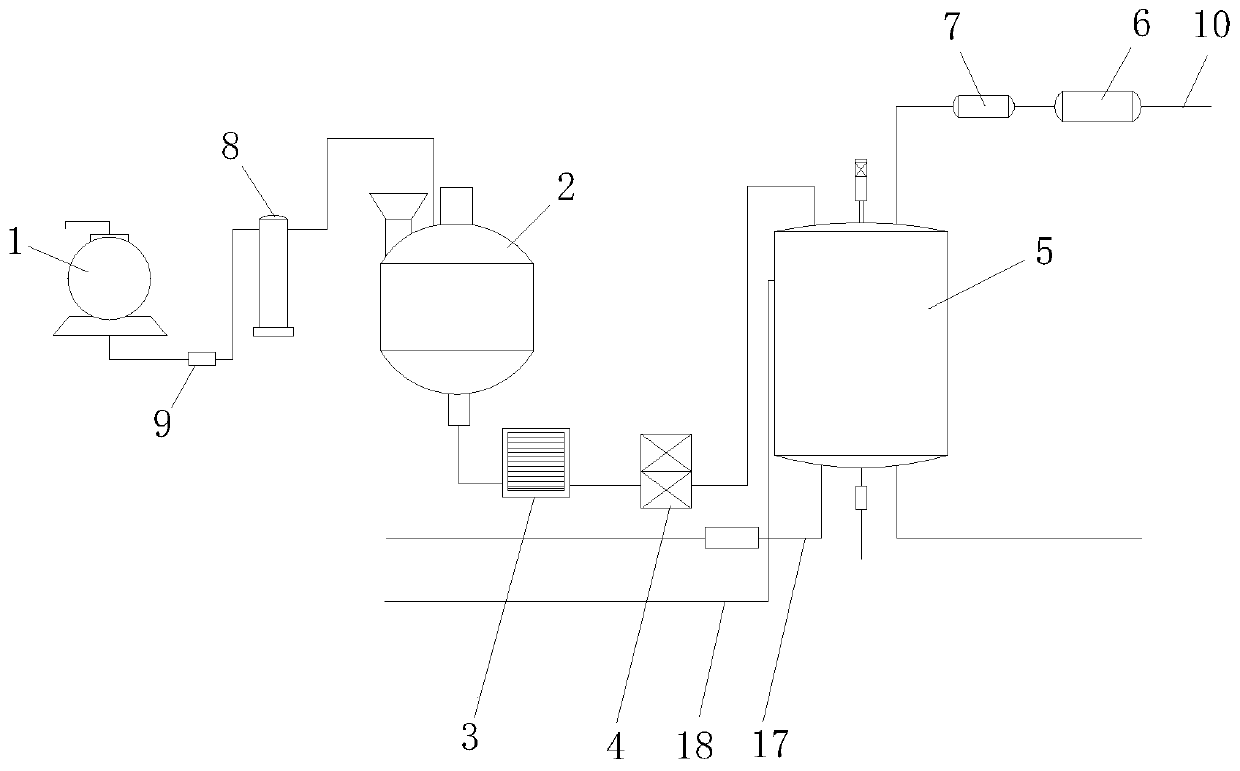

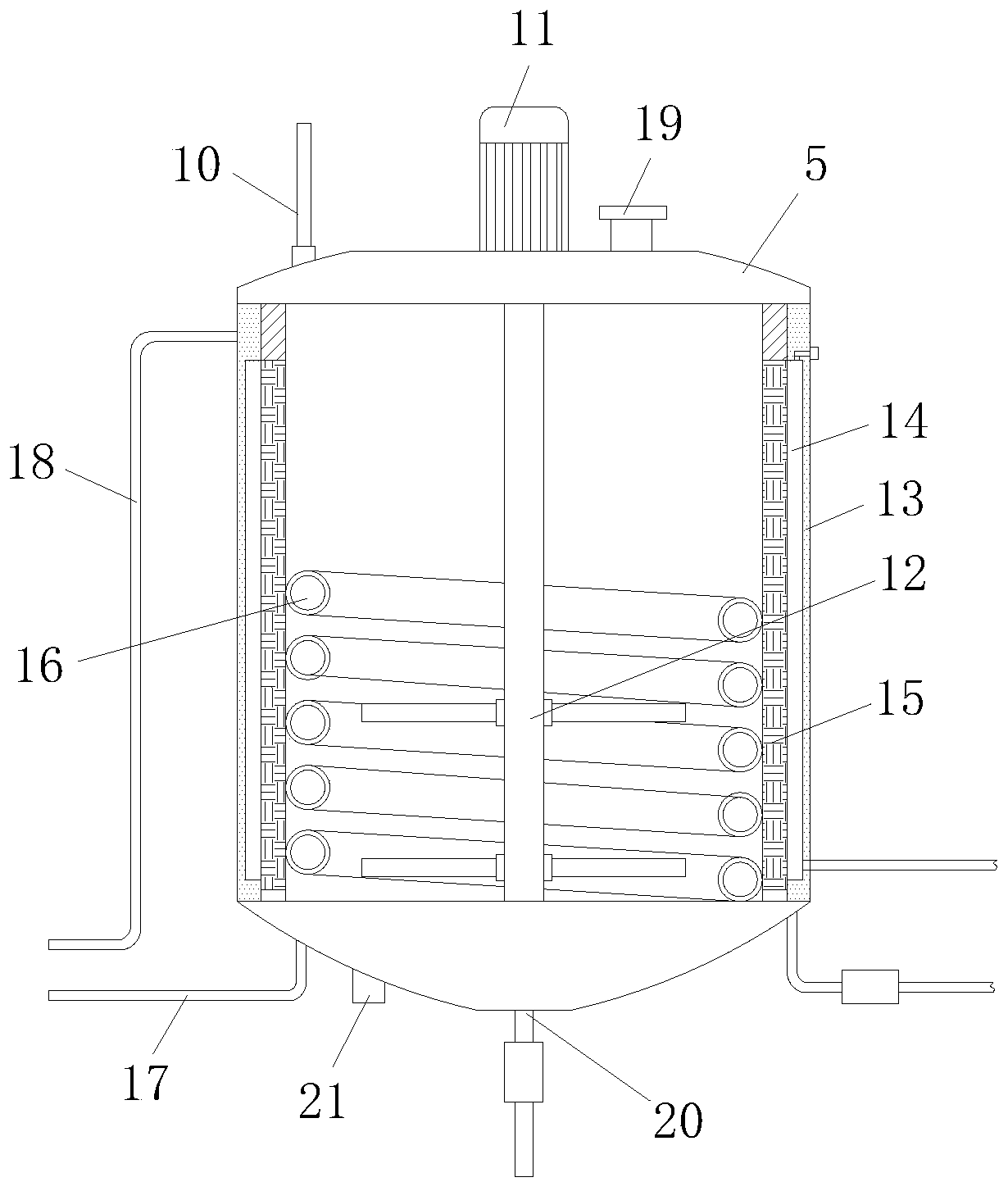

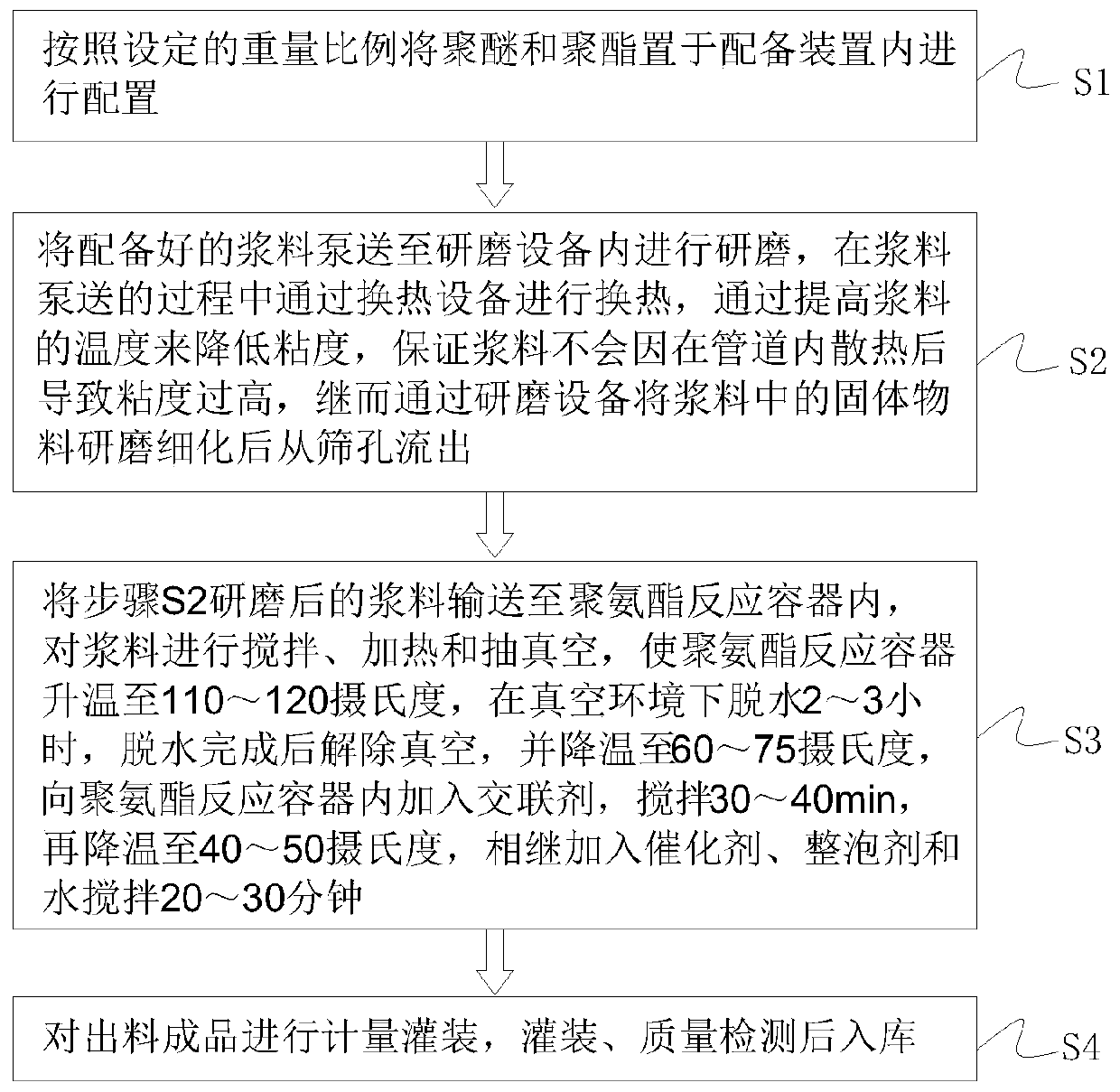

Polyurethane composition for wood-like spraying all-water foaming system as well as preparation method and equipment

InactiveCN110951019ALower component costsImprove performancePolyurea/polyurethane coatingsChemical/physical/physico-chemical stationary reactorsPolyesterPolymer science

The invention discloses a polyurethane composition for a wood-like spraying all-water foaming system. The polyurethane composition is prepared from the following components in parts by weight: 85 parts of polyether; 15 parts of polyester; 3-5 parts of a cross-linking agent; 1 to 5 parts of a catalyst; 2-5 parts of a foam stabilizer; and 1-1.5 parts of water. The preparation method of the polyurethane composition comprises the following steps: S1, raw material preparation; S2, heat exchange and grinding; and S3, dehydration, stirring and reaction; and S4, metering, filling and detecting. The invention also provides preparation equipment of the polyurethane composition for the wood-like spraying all-water foaming system. According to the invention, the polyurethane composition, the preparation method and the equipment are synchronously improved, so that the component cost of the polyurethane composition spraying material is reduced, the comprehensive performance is improved, the sprayingperformance is good, the texture formed by a coating layer is clear, the production cost is reduced, the market demand can be met, and the large-scale popularization and application are facilitated.

Owner:清远市蓝林新材料有限公司

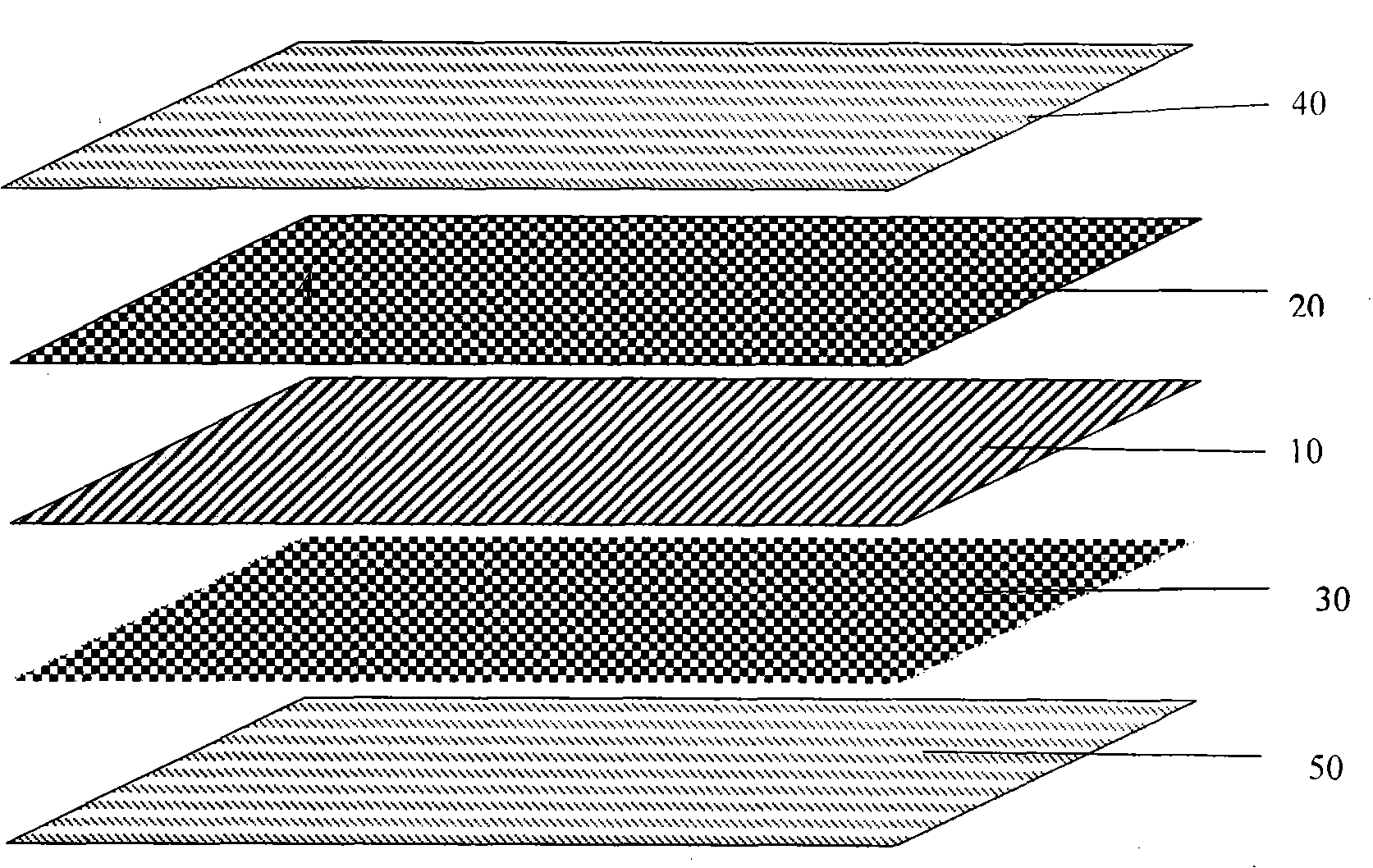

Sound insulating pad-top cover reinforcing beam for car roof and preparation method thereof

ActiveCN102029951ASolve the sound insulationSolve the insulation performanceVehicle componentsEngineeringKraft paper

The invention discloses a sound insulating pad-top cover reinforcing beam for a car roof and a preparation method thereof. Particularly, a polyurethane (PU) foam board (10) is used as a base material, two pieces of double-side film coated kraft paper (40) and (50) are attached to both sides of the PU foam board, proper environment-friendly PU adhesive layers (20) and (30) are attached between the double-side film coated kraft paper and the base material, wherein the double-side film coated kraft paper is manufactured by respectively applying high-temperature resistant adhesive films evenly on both sides of the kraft paper, and the sound insulating pad-top cover reinforcing beam for a car roof is manufactured by forming in a hot mold. The product has no deformation, light weight and favorable sound absorbing, heat insulating, flame retarding and reinforcing performances.

Owner:YANTAI ZHENGHAI HIGH TECH

Wall building material and preparing method thereof

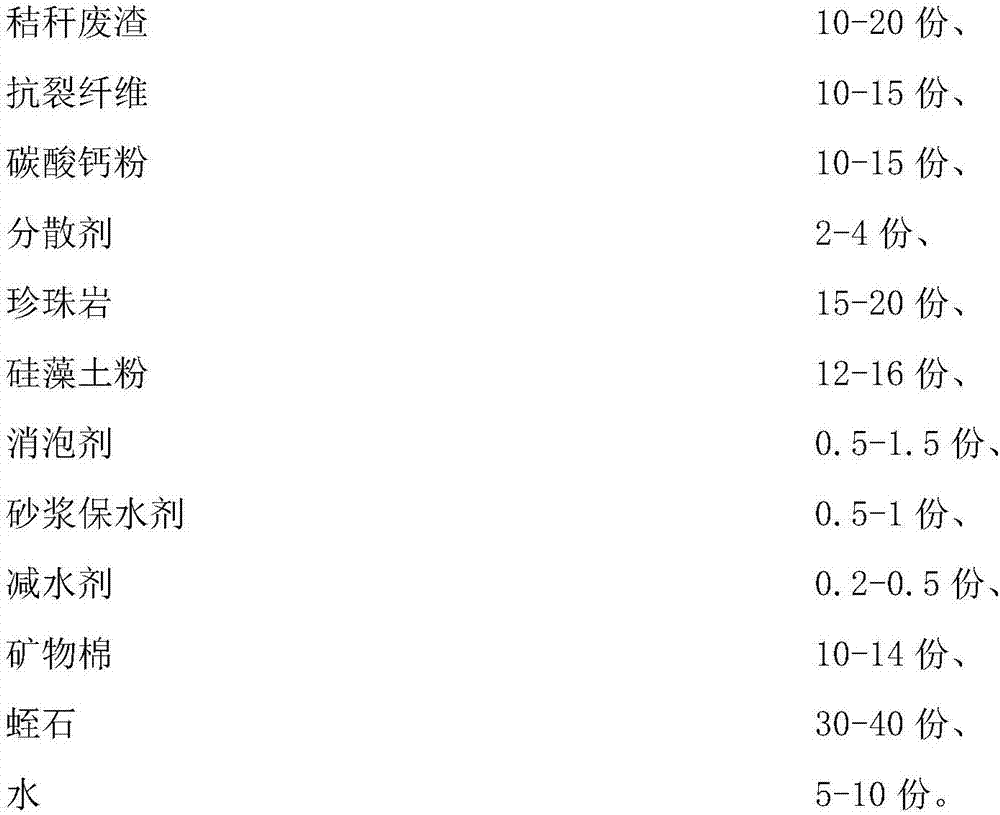

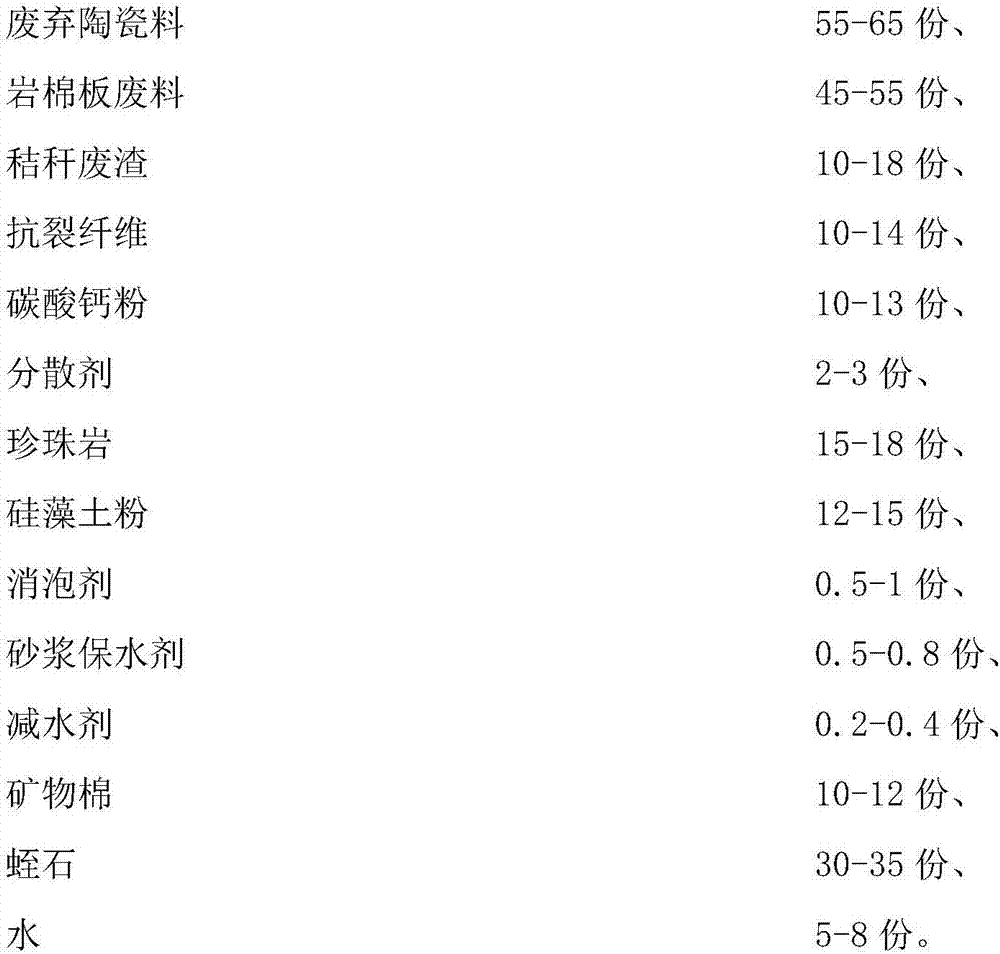

InactiveCN107082622ASolve the insulation performanceSolve the strength problemFiberAbsorption effect

The invention provides a wall building material and a preparing method thereof, and relates to the field of building materials. The wall building material is prepared from, by weight, 55-70 parts of abandoned ceramic materials, 45-60 parts of rock wool board waste materials, 10-20 parts of straw waste residue, 10-15 parts of anti-crack fiber, 10-15 parts of calcium carbonate powder, 15-20 parts of perlite, 12-16 parts of diatomite powder, 0.5-1.5 parts of defoaming agent, 0.5-1 part of mortar water-retaining agent, 0.2-0.5 part of water reducing agent,10-14 parts of mineral wool, 30-40 parts of vermiculite, 5-10 parts of water, and 2-4 parts of dispersing agent. The preparing method of the wall building material comprises the first step of weighing, by weight, the abandoned ceramic materials, the rock wool board waste materials, the straw waste residue, the anti-crack fiber, calcium carbonate powder, perlite, diatomite powder, the defoaming agent, the mortar water-retaining agent, water reducing agent, the mineral wool, and vermiculite into an agitator to be stirred so that a solid mixture can be obtained; the second step of adding the water and dispersing agent into the solid mixture, and stirring the mixture for 20-30 min to make the mixture mixed uniform. The wall building material has the advantages of being good in heat preservation and heat insulation effect, high in intensity, high in waste reutilization rate, good in sound absorption effect, and high in corrosion resistance.

Owner:肥西县碧涛建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com