Sound insulating pad-top cover reinforcing beam for car roof and preparation method thereof

A technology for strengthening beams and sound insulation pads, applied in vehicle parts, transportation and packaging, etc., can solve the problems of heavy product weight, high labor intensity and high cost, and achieve the effect of low labor intensity of workers, ensuring product quality and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

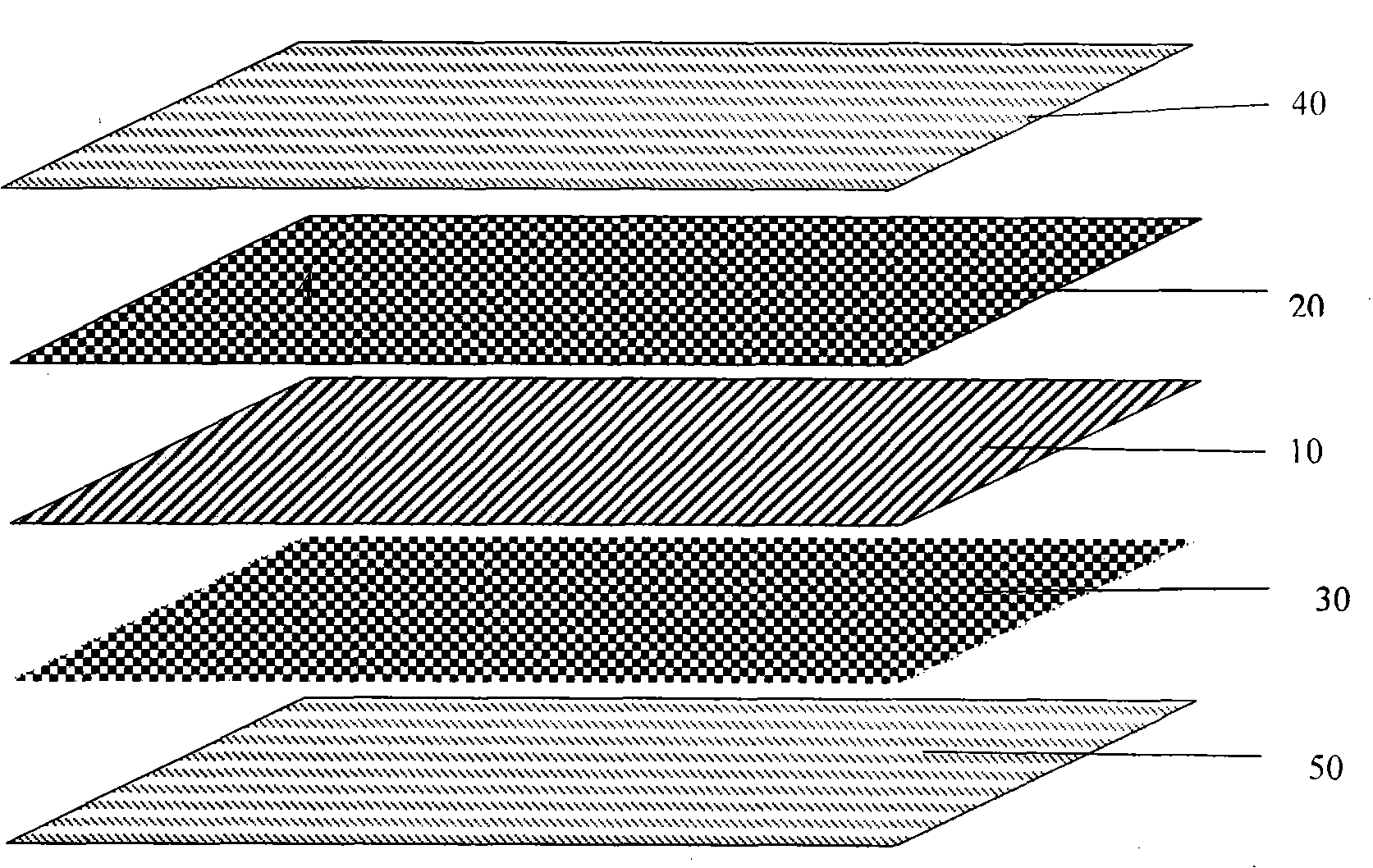

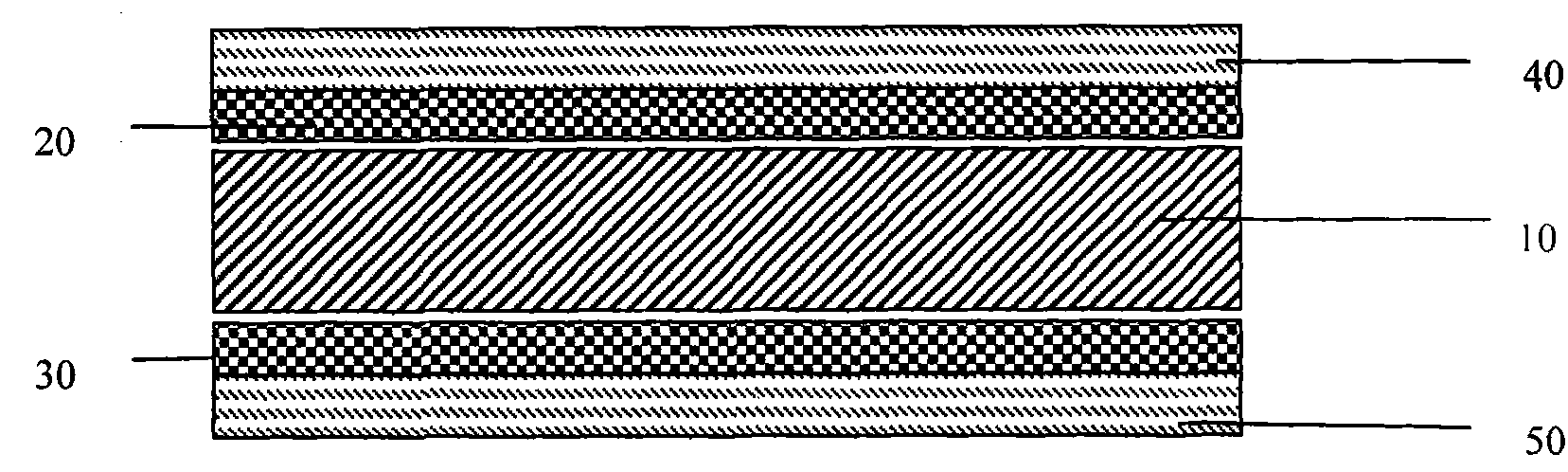

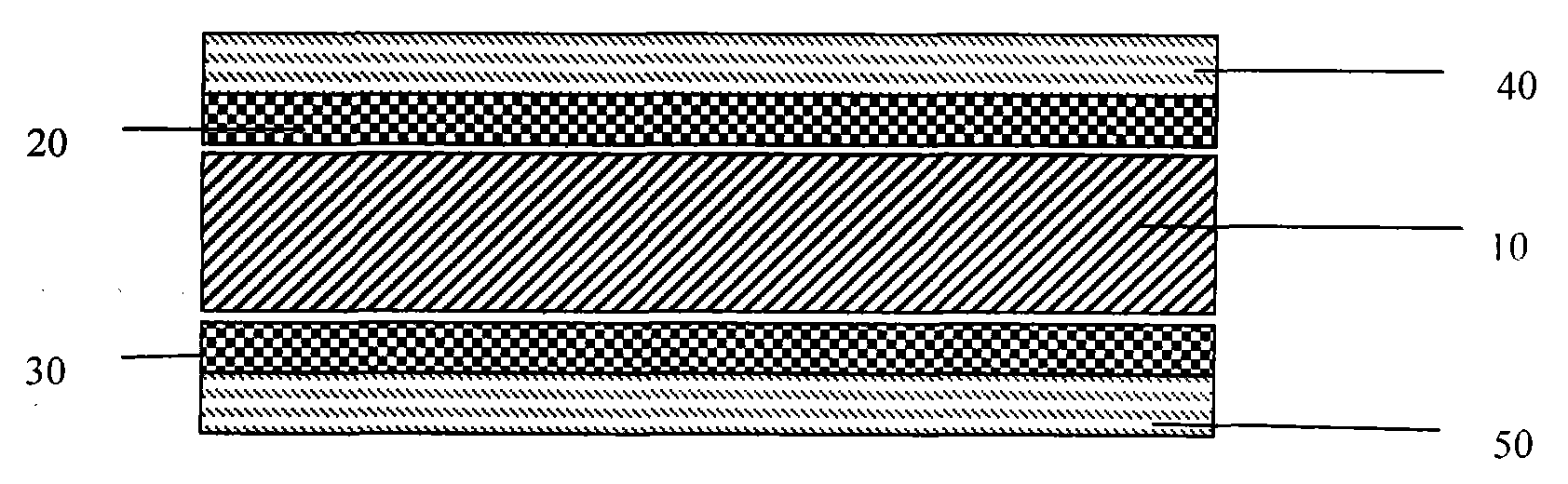

[0017] Example 1, see figure 1 , 2 , taking Magotan CC sound insulation pad-top cover reinforcement beam as an example, the specification of sound insulation pad-top cover reinforcement beam: L850*W629*T6.5mm; put the base material-PU foam board into the roller rubber with double-sided gluing function Glue inside the machine, rubber roller temperature: 30°C, rubber roller height: 5.5mm, double-sided uniform roller glue volume: 34g / m2, the glue used is environmentally friendly polyurethane glue, and the PU foam board that has been glued by the roller is sprayed on both sides 16g / m2 demineralized water containing curing agent, the curing agent is triethylenediamine in the amine curing agent, the dosage is 0.2-1% of the weight of the demineralized water; the PU foam board and the lower surface are covered with double-sided coating film Kraft paper, double-sided coated kraft paper is made by conventional technology, that is, a layer of high-temperature resistant adhesive film is ...

Embodiment 2

[0018] Example 2, see figure 1 , 2 , taking Xinbaolai sound insulation pad-top cover reinforcement beam as an example, the specification of sound pad-top cover reinforcement beam 2: L764*W398*8.5mm, put the base material-PU foam board into the roller glue with double-sided gluing function Glue on the machine, the temperature of the rubber roller is 50°C, the height of the rubber roller is 7.5mm, and the amount of glue on both sides is 44g / m2. 20g / m2 demineralized water containing curing agent, spread double-sided coated kraft paper on the lower and lower sides of the PU foam board sprayed with demineralized water, the double-sided coated kraft paper is made by conventional technology Both sides are evenly coated with a layer of high-temperature resistant adhesive film, placed in a hot mold for compression molding, mold temperature: 90°C, the production process adopts two-stage deflation and pressure holding technology, pressure holding delay Ⅰ: 12S, mold opening and deflation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com