Fabricated wall for hospital

A prefabricated, hospital technology, applied in the direction of wall, thermal insulation, fire prevention, etc., can solve the problems of easy breeding of bacteria on the surface of the wall, insufficient functions of embedded equipment, affecting the sound insulation effect of the wall, etc., to achieve convenient and fast installation, good thermal insulation, The effect of shortening construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

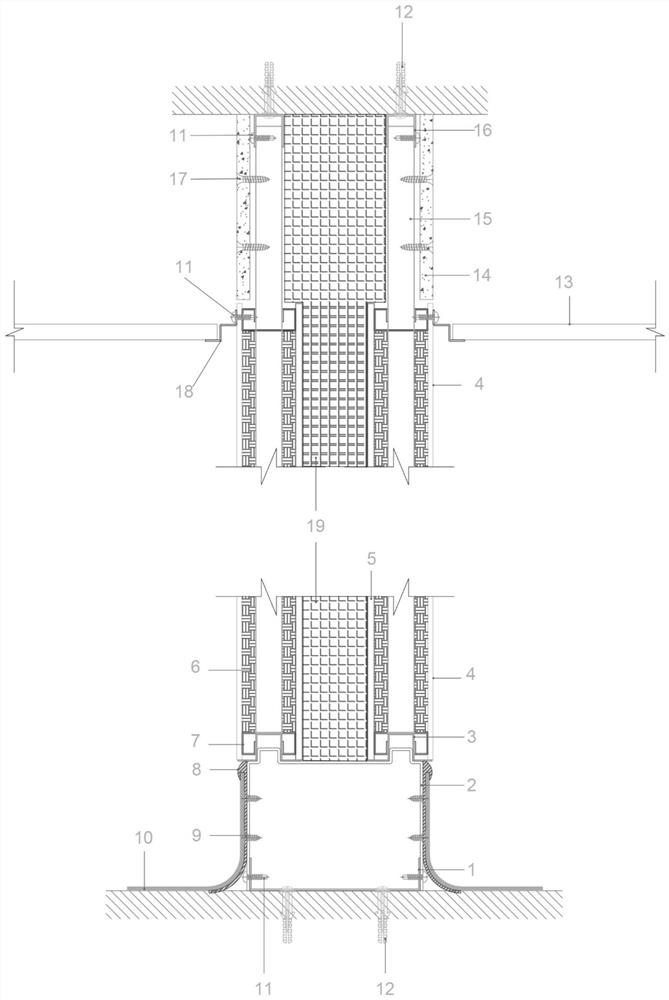

[0047] The present invention improves the sound insulation layer 19 to solve the problem that the current material of the sound insulation layer 19 is sound insulation cotton, which is usually filled into the inner cavity of the wall by filling, so as to achieve a sound insulation effect, but this method requires cost Large manpower and material resources, and in the filling process, the sound insulation material is a light-weight floc, which may cause uneven dispersion in the cavity of the wall through the filling method, affecting the sound insulation effect of the overall wall;

[0048] see Figure 5 and Figure 6 As shown, the specific improvement of the sound insulation layer 19 is: the sound insulation material is respectively loaded into the upper filling plate 26 and the lower filling plate 27, so that when the wall is installed, it can be installed in the wall as a whole, so that It can effectively solve the inconvenience of installation and the problem that the soun...

Embodiment 3

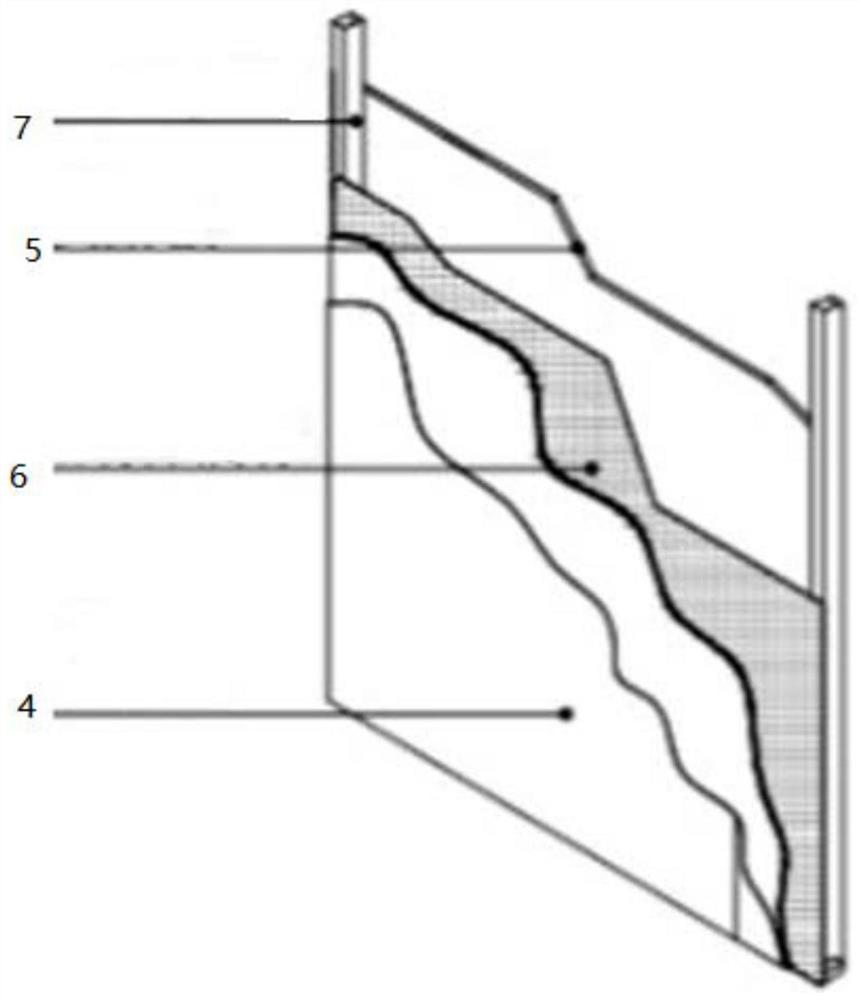

[0053] see Figure 7 As shown, both sides of the adjusting plate 30 are slidingly connected with the inner wall of the lower filling plate 27, wherein one end of the adjusting plate 30 is connected with the sliding plate 32, and the sliding plate 32 extends into the side wall cavity of the lower filling plate 27, and is connected with the lower filling plate. 27 is slidingly connected, and a screw rod 33 is vertically arranged in the inner cavity of the side wall of the lower filling plate 27, and the screw rod 33 runs through a plurality of slide plates 32 in turn, and the top end of the screw rod 33 extends to the top inner cavity of the lower filling plate 27, And be connected with connector 29;

[0054] When in use, the drive motor of the peripheral device is connected to the connector 29, and then the screw rod 33 is driven to rotate forward and reverse, so that the slide plate 32 moves up and down along the lower filling plate 27, and drives the adjustment plate 30 to mo...

Embodiment 4

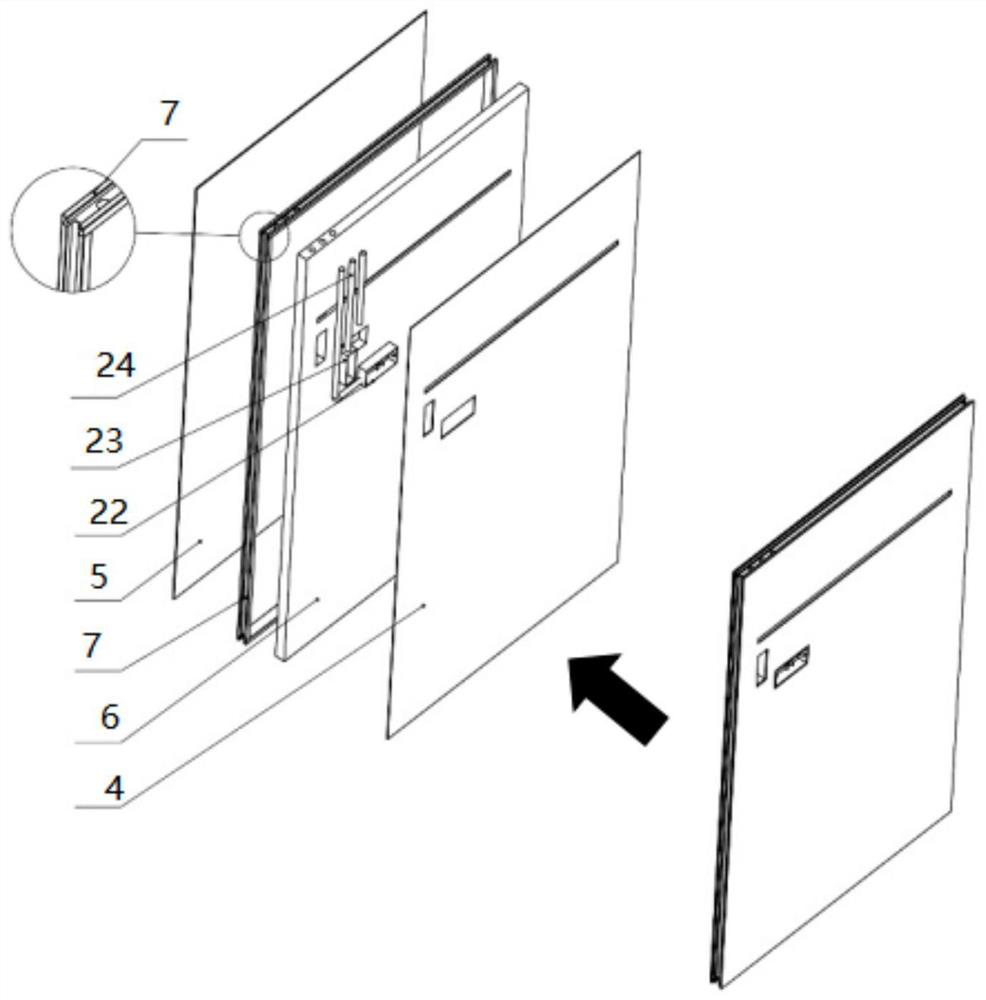

[0057] see Figure 8-11 As shown, the upper filling plate 26 is connected with the lower filling plate 27 through the connector 29, the bottom sides of the upper filling plate 26 are respectively provided with plugs 35, the bottom of the plug 35 is provided with a mounting groove, and the two sides of the mounting groove are provided with a limiting plate 41, the limit plate 41 is slidably connected in the installation groove through the limit rod 42, the spring 43 is connected between the two sets of limit plates 41, the side of the limit plate 41 away from the spring 43 is provided with a pin block 36, and the connector 29 A mounting hole 39 adapted to the plug 35 is provided on the top, and the pin block 36 is a hemispherical structure;

[0058] When installing the upper filler plate 26 and the lower filler plate 27, the plug 35 at the bottom of the upper filler plate 26 is correspondingly inserted into the mounting hole 39 in the connector 29, and when the plug 35 reaches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com