Environment-friendly material capable of purifying air and preparation method thereof

A technology for environmental protection materials and air purification, which is applied in the field of environmental protection materials to achieve the effects of compressive strength, corrosion resistance, high compressive strength, and improved thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

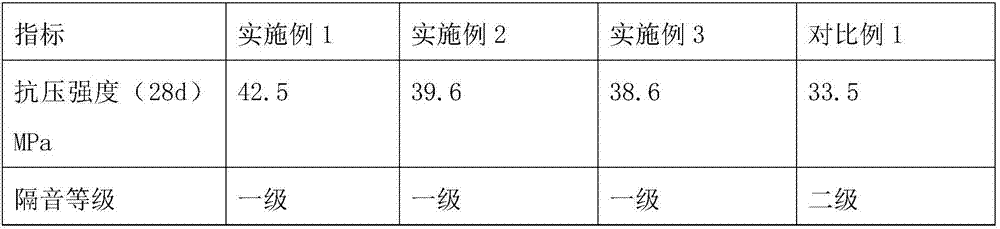

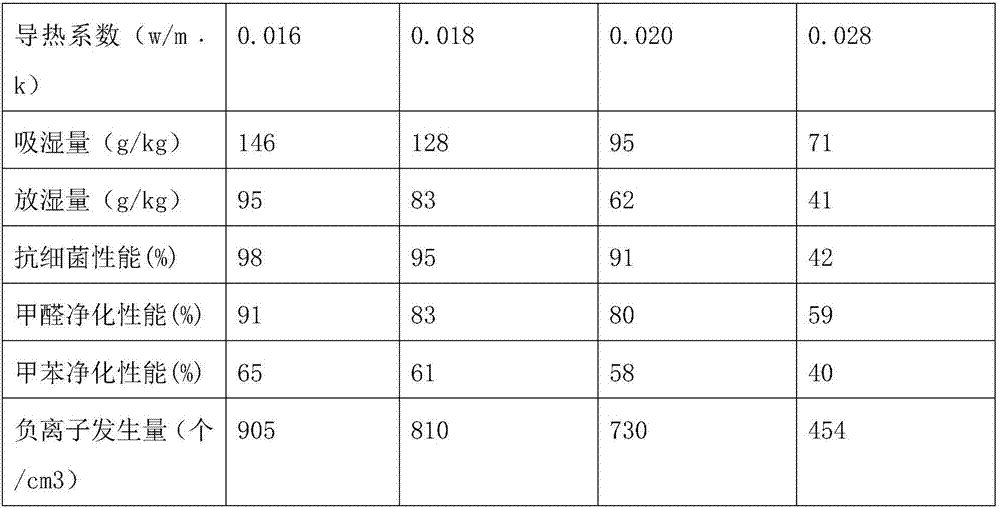

Examples

Embodiment 1

[0035] An environment-friendly material capable of purifying air, characterized in that it comprises the following raw materials in parts by weight: 37.5 parts of expanded perlite, 16 parts of magnesium oxide, 27 parts of cement, 20 parts of urea-formaldehyde resin, and 0.75 parts of sodium dodecylbenzenesulfonate , 4 parts of negative ion additives, 13.5 parts of fine sand, 27 parts of sepiolite, 10 parts of diatomaceous earth, 15 parts of nano zinc oxide, 0.5 parts of silver-loaded zirconium phosphate powder, 13 parts of polyphenylene particles, 15 parts of synthetic fiber, water reducer 0.4 parts and 6 parts of water.

[0036] The air-purifying environment-friendly material prepared under the formula has reached the best in terms of compressive strength, thermal insulation performance, sound insulation effect, respiratory humidity control effect, air purification effect and environmental protection.

[0037] The raw material is added with sepiolite, which has the advantages...

Embodiment 2

[0051] An environment-friendly material capable of purifying air, characterized in that it comprises the following raw materials in parts by weight: 35 parts of expanded perlite, 10 parts of magnesium oxide, 20 parts of cement, 15 parts of urea-formaldehyde resin, and 0.5 part of sodium dodecylbenzenesulfonate , 3 parts of negative ion additives, 12 parts of fine sand, 22 parts of sepiolite, 8 parts of diatomite, 13 parts of nano-zinc oxide, 0.3 parts of silver-loaded zirconium phosphate powder, 12 parts of polyphenylene particles, 13 parts of synthetic fiber, water reducer 0.3 parts and 5 parts water.

[0052] The raw material is added with sepiolite, which has the advantages of thermal insulation and corrosion resistance.

[0053]Diatomaceous earth is added to the raw materials. Diatomaceous earth has a natural microporous structure, which can realize breathing and humidity control. At the same time, it can also absorb toxic and harmful substances in the air such as formalde...

Embodiment 3

[0066] An environment-friendly material capable of purifying air, characterized in that it comprises the following raw materials in parts by weight: 40 parts of expanded perlite, 22 parts of magnesium oxide, 34 parts of cement, 25 parts of urea-formaldehyde resin, and 1 part of sodium dodecylbenzenesulfonate , 5 parts of negative ion additives, 15 parts of fine sand, 32 parts of sepiolite, 12 parts of diatomaceous earth, 17 parts of nano-zinc oxide, 0.7 parts of silver-loaded zirconium phosphate powder, 14 parts of polyphenylene particles, 17 parts of synthetic fiber, water reducer 0.5 parts and 7 parts water.

[0067] The raw material is added with sepiolite, which has the advantages of thermal insulation and corrosion resistance.

[0068] Diatomaceous earth is added to the raw materials. Diatomaceous earth has a natural microporous structure, which can realize breathing and humidity control. At the same time, it can also absorb toxic and harmful substances in the air such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com