Environment-friendly material and preparation method thereof

A technology of environmentally friendly materials and raw materials, applied in the field of building materials, can solve the problems of high thermal insulation and environmental protection requirements, and achieve the effects of light weight, low thermal conductivity, and improved compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

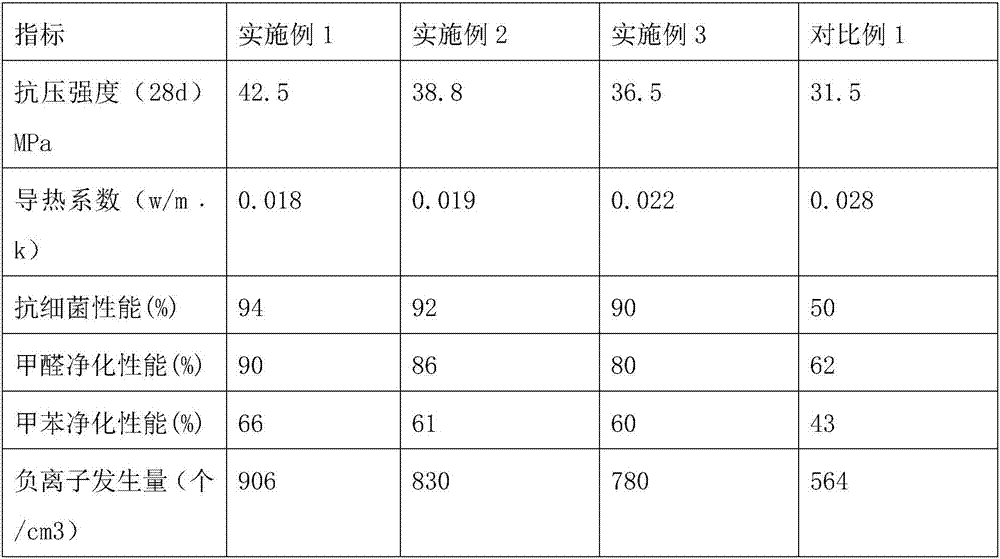

Examples

Embodiment 1

[0030] An environmentally friendly material, including the following raw materials with a weight of kg: 32kg of expanded perlite, 15kg of magnesium oxide, 17kg of cement, 18kg of urea-formaldehyde resin, 0.75kg of sodium dodecylbenzenesulfonate, 4kg of negative ion additives, 13kg of quartz sand, and 18kg of vermiculite , 10kg of bentonite, 14kg of diatomite, 15kg of nano titanium dioxide, 13kg of floating beads, 9kg of sepiolite powder, 14kg of synthetic fiber, 135kg of bamboo charcoal, 0.3kg of retarder, 0.4kg of foaming agent, 0.6kg of water reducing agent and 7kg of water .

[0031] Synthetic fibers are polyacrylonitrile fibers.

[0032] The cement is ordinary Portland cement.

[0033] The retarder is sodium tripolyphosphate.

[0034] The blowing agent is sodium bicarbonate.

[0035] The water reducer is a polycarboxylate water reducer.

[0036] A kind of preparation method of environment-friendly material, comprises the following steps:

[0037] (1) Take the raw mate...

Embodiment 2

[0042] An environmentally friendly material, including the following raw materials: 30kg of expanded perlite, 10kg of magnesium oxide, 14kg of cement, 15kg of urea-formaldehyde resin, 0.5kg of sodium dodecylbenzenesulfonate, 3kg of negative ion additives, 11kg of quartz sand, 14kg of vermiculite, 8kg of bentonite, 12kg of diatomite, 13kg of nano titanium dioxide, 12kg of floating beads, 8kg of sepiolite powder, 13kg of synthetic fiber, 11kg of bamboo charcoal, 0.2kg of retarder, 0.1kg of foaming agent, 0.3kg of water reducer and 5kg of water.

[0043] Synthetic fibers are polyacrylonitrile fibers.

[0044] The cement is ordinary Portland cement.

[0045] The retarder is sodium tripolyphosphate.

[0046] The blowing agent is sodium bicarbonate.

[0047] The water reducer is a polycarboxylate water reducer.

[0048] A kind of preparation method of environment-friendly material, comprises the following steps:

[0049] (1) Take the raw material according to the weight of the e...

Embodiment 3

[0054] An environmentally friendly material, including the following raw materials: 34kg of expanded perlite, 20kg of magnesium oxide, 20kg of cement, 21kg of urea-formaldehyde resin, 1kg of sodium dodecylbenzenesulfonate, 5kg of negative ion additives, 15kg of quartz sand, 22kg of vermiculite, bentonite 12kg, diatomaceous earth 16kg, nano titanium dioxide 17kg, floating beads 14kg, sepiolite powder 10kg, synthetic fiber 15kg, bamboo charcoal 15kg, retarder 0.4kg, foaming agent 0.7kg, water reducer 0.9kg and water 9kg.

[0055] Synthetic fibers are polyacrylonitrile fibers.

[0056] The cement is ordinary Portland cement.

[0057] The retarder is sodium tripolyphosphate.

[0058] The blowing agent is sodium bicarbonate.

[0059] The water reducer is a polycarboxylate water reducer.

[0060] A kind of preparation method of environment-friendly material, comprises the following steps:

[0061] (1) Take the raw material according to the weight of the environmental protection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com