Silicone rubber-based heat-insulating coating and preparation method thereof

A technology of thermal insulation coating and silicone rubber, which is applied in the field of materials to achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

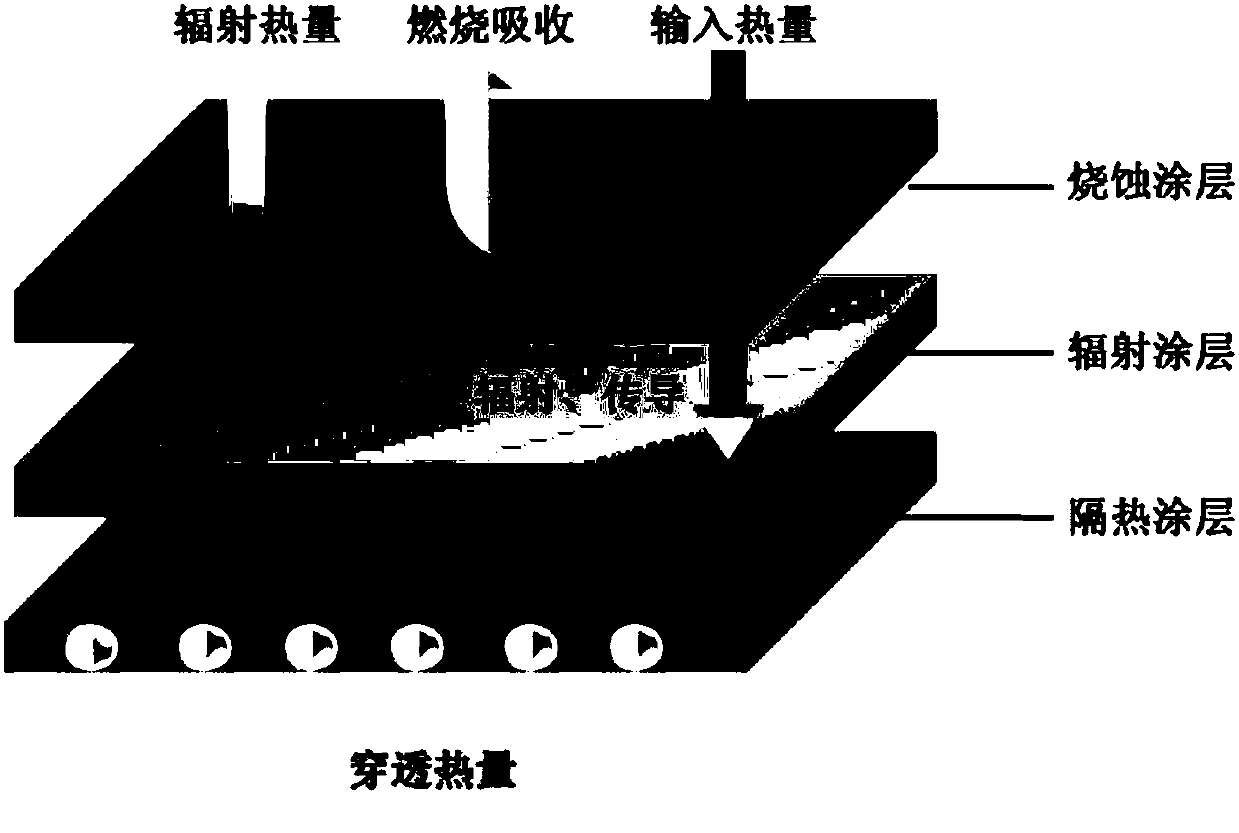

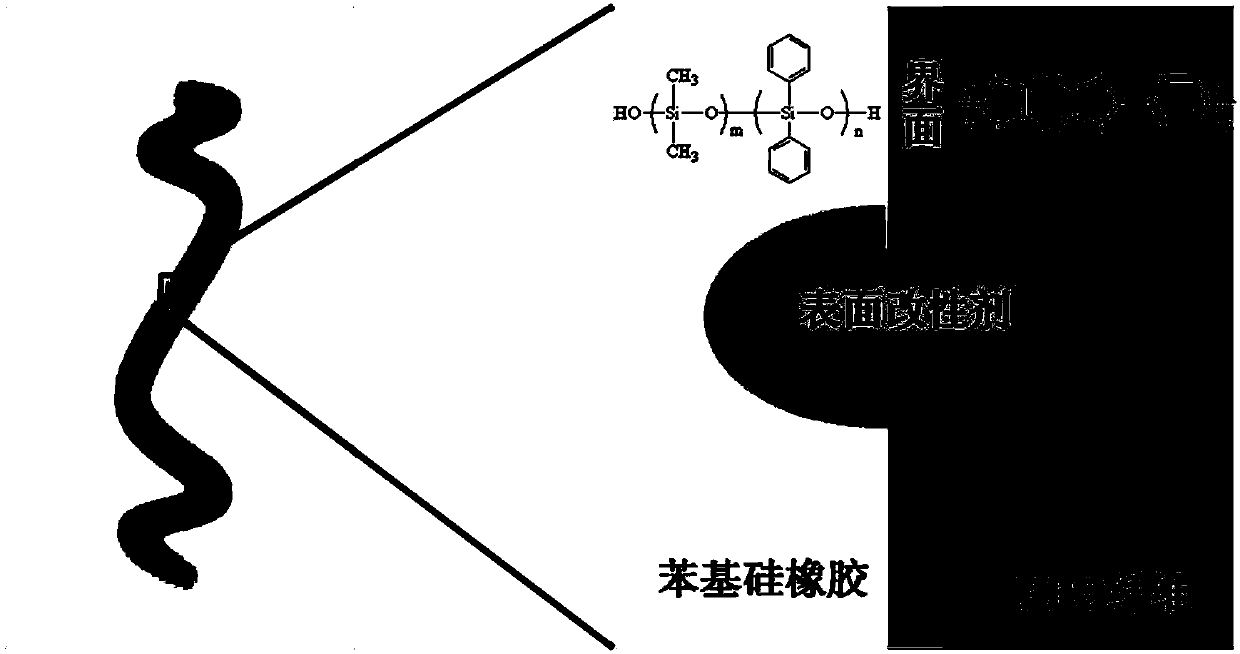

Method used

Image

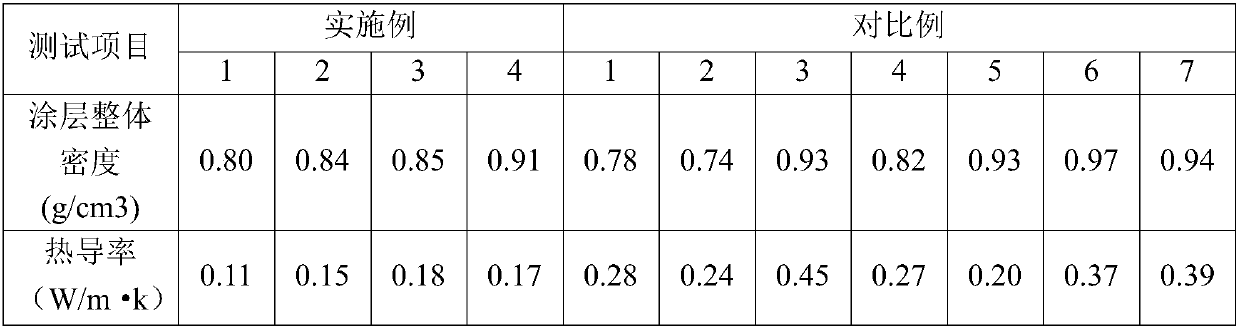

Examples

Embodiment 1

[0037] This embodiment relates to a silicone rubber-based heat-resistant coating, the preparation method of which is as follows:

[0038] (1) Use a degreasing veil dipped in acetone to wipe the surface of the substrate to be sprayed clean, mix 10g of hollow glass microspheres, 2g of γ-aminopropyltriethoxysilane, 20g of white carbon black, and 100g of raw methyl silicone rubber , 3g ethyl orthosilicate, 1g dibutyltin dilaurate and 200g toluene are mixed and stirred, and after stirring, filter with 30-40 mesh metal mesh, and spray the filtrate on the surface of the substrate with a spray gun at a pressure of 0.5MPa to obtain silicone rubber Base thermal insulation coating, the thickness of the thermal insulation coating is controlled at 5mm;

[0039] (2) 15g mica, 5g silica powder, 20g white carbon black, 100g silicon mass fraction are 33% phenyl silicone rubber raw rubber, 3g tetraethyl orthosilicate, 1g dibutyltin dilaurate and 200g toluene are mixed and stirred , after stirr...

Embodiment 2

[0042] This embodiment relates to a silicone rubber-based heat-resistant coating, the preparation method of which is as follows:

[0043] (1) Use a degreasing veil dipped in acetone to wipe the surface of the substrate to be sprayed clean, 20g of hollow phenolic microspheres, 2g of γ-(methacryloyloxy)propyltrimethoxysilane, 20g of white carbon black, 100g Methyl silicone rubber raw rubber, 3g tetraethyl orthosilicate, 1g dibutyltin dilaurate and 200g toluene are mixed and stirred, and after stirring, filter with a 30-40 mesh metal mesh, and spray the filtrate on the base with a pressure of 0.5MPa with a spray gun. On the surface of the material, a silicone rubber-based heat-insulating coating is obtained, and the thickness of the heat-insulating coating is controlled to 0.1mm;

[0044] (2) 30g mica, 8g silica powder, 2g white carbon black, 100g silicon mass fraction are 42% phenyl silicone rubber raw rubber, 3g orthopropyl silicate, 1g dibutyltin dilaurate and 200g toluene are...

Embodiment 3

[0047] This embodiment relates to a silicone rubber-based heat-resistant coating, the preparation method of which is as follows:

[0048] (1) Use a degreasing veil dipped in acetone to wipe the surface of the sprayed substrate, 5g of cork powder, 2g of γ-glycidyl etheroxypropyltrimethoxysilane, 20g of white carbon black, 100g of raw methyl silicone rubber, 3g Ethyl orthosilicate, 1g of dibutyltin dilaurate and 200g of toluene are mixed and stirred, and after stirring, they are filtered with a 30-40 mesh metal mesh, and the filtrate is sprayed on the surface of the substrate with a spray gun at a pressure of 0.5MPa to obtain a silicone rubber substrate. Thermal coating, the thickness of thermal insulation coating is controlled to 2.5mm;

[0049] (2) 25g mica, 10g silica powder, 20g white carbon black, 100g silicon mass fraction are 30% phenyl silicone rubber raw rubber, 3g phenyltrimethoxysilane, 1g dibutyltin dilaurate and 200g toluene are mixed Stir, after stirring, filter w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com