Electric-heating air-circulating-type drying box

An air circulation and electric heating technology, applied in the field of drying boxes, can solve the problems of air turbulence, no mention of heat preservation and fireproof and heat insulation functions, inconvenient maintenance and replacement, etc., to achieve uniform and fast heating, and avoid uneven heating , the effect of controllable heat size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

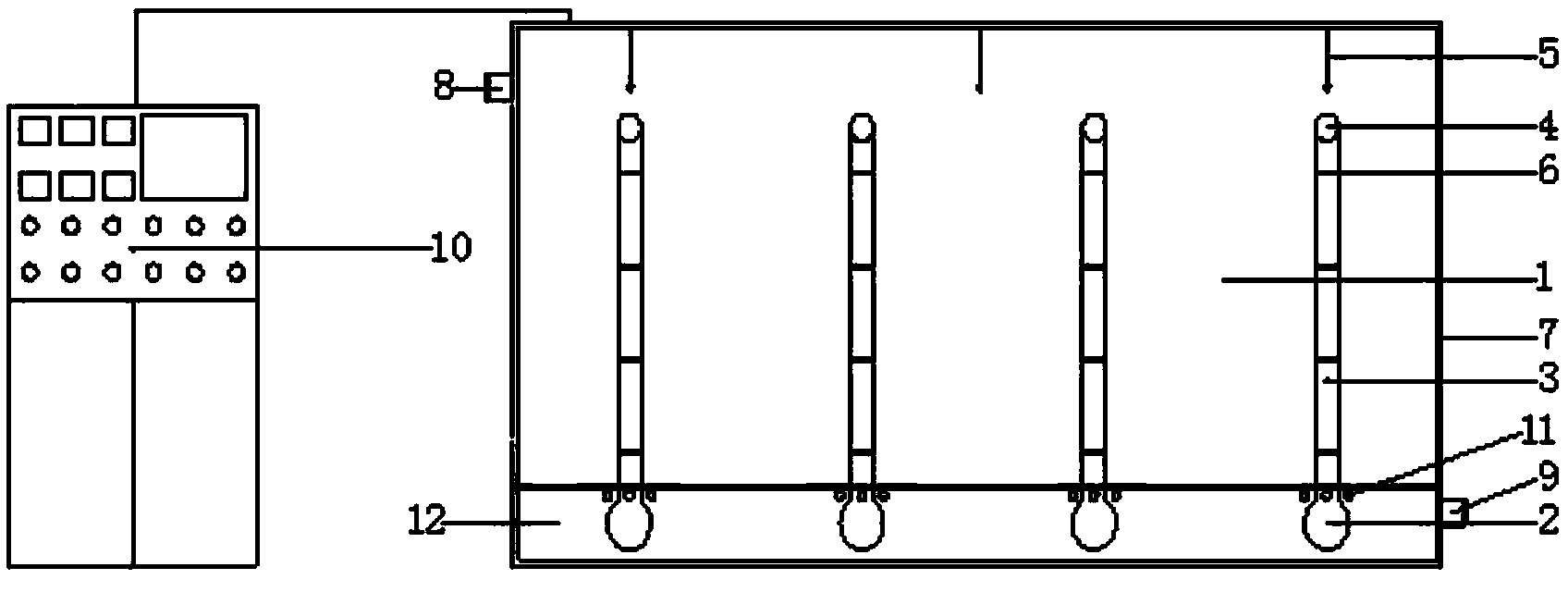

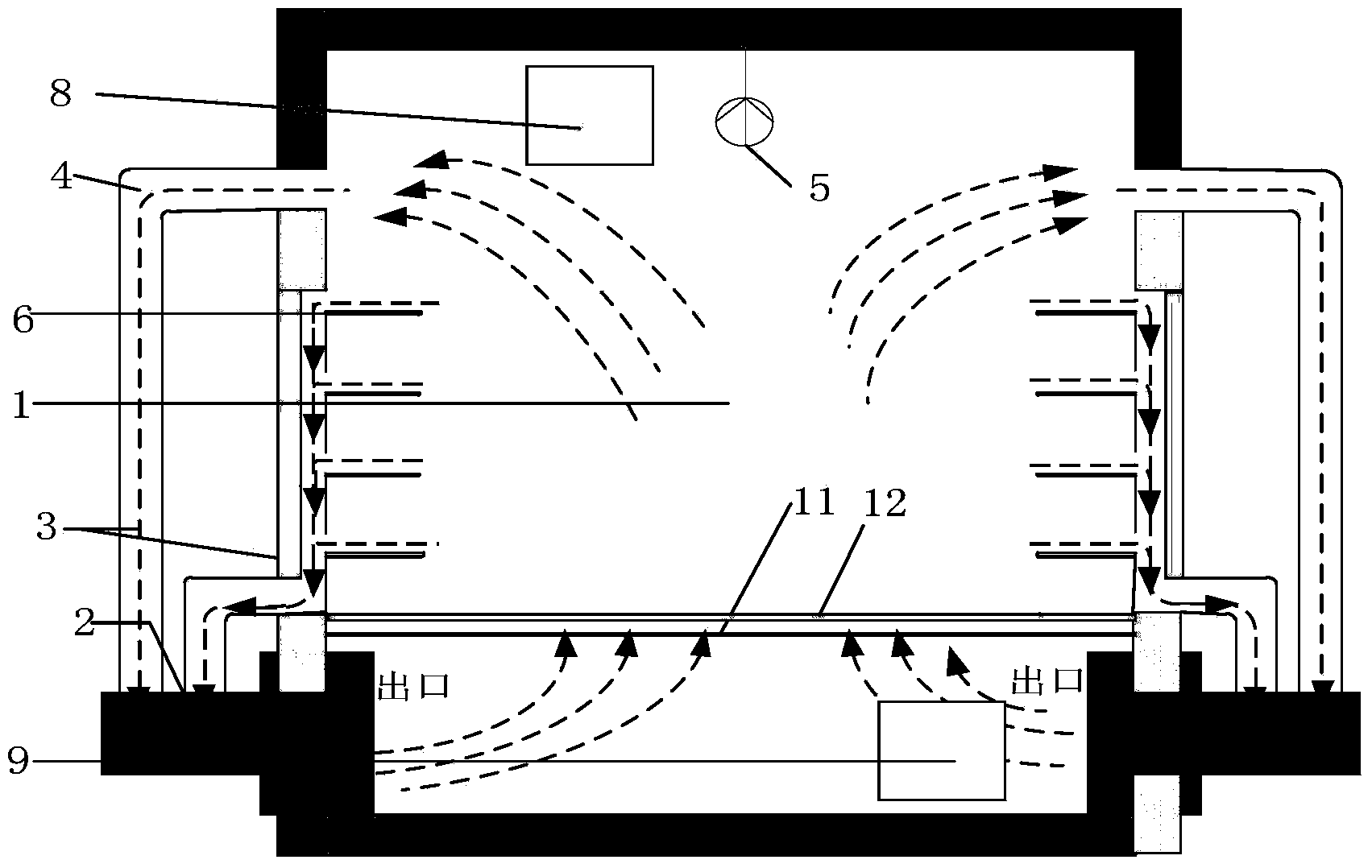

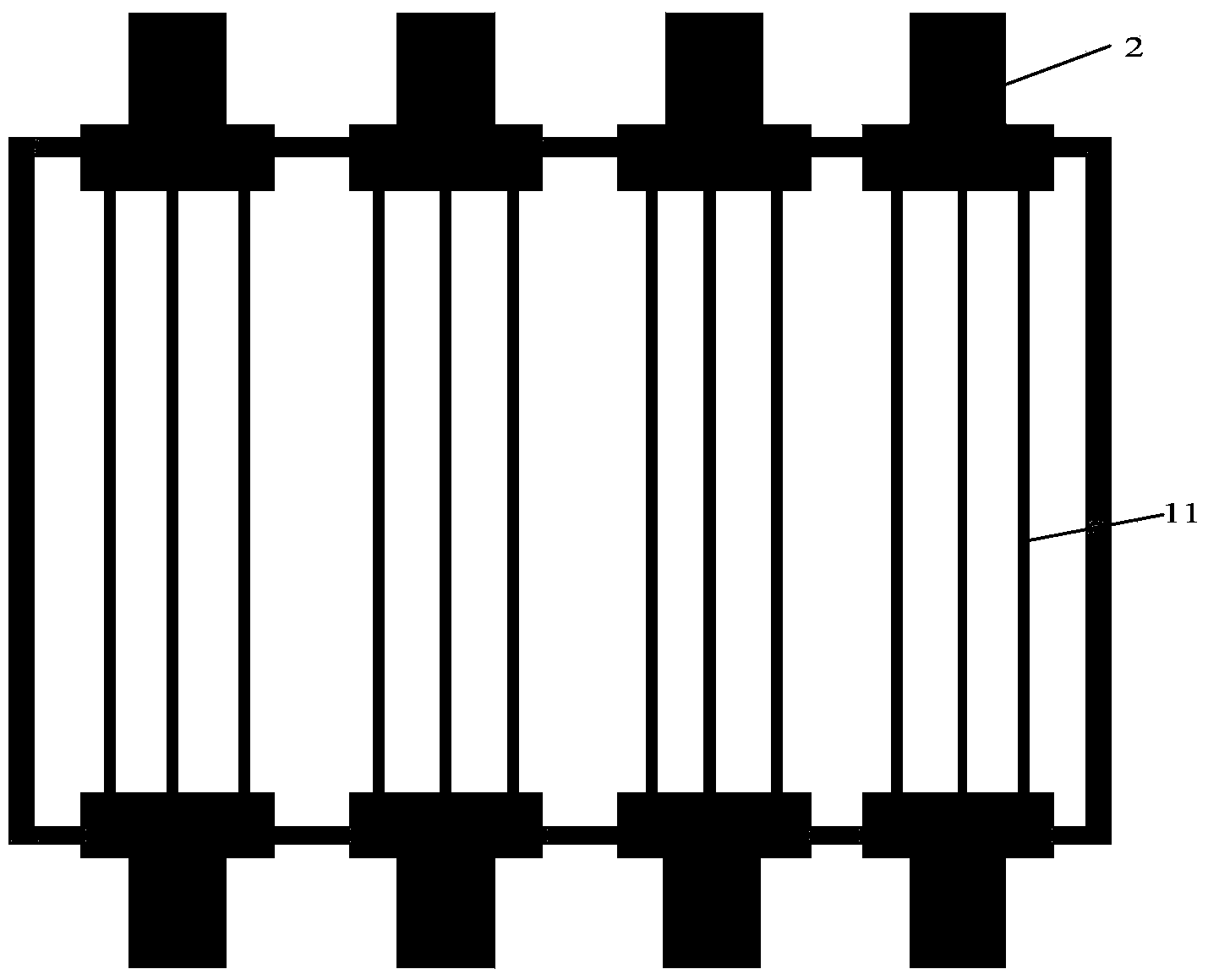

[0016] combine Figure 1~3 , the drying box is mainly composed of box 1, axial flow fan 2, return pipe 3, connecting elbow 4, sensor 5, swing plate 6, door 7, air outlet 8, air inlet 9, control cabinet 10, heating rod 11 , 12 metal sieve plates.

[0017] It works like this:

[0018] One end of the axial flow fan 2 is embedded in the box body 1, and the other end is rotatably connected to the return pipe 3 through the elbow 4, and the other end of the return pipe 3 is connected to the box body 1 through the elbow 4, and each connection part is sealed deal with;

[0019] Install the sensor 5 on the upper part of the box body 1 and connect it tightly;

[0020] Fix the swing plate 5 in the box through the slideway.

[0021] Install a one-way fan blade axial flow fan at the air outlet 8 and the air inlet 9, and fix it.

[0022] Fix the heating rod 11 under the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com