System for processing thin-film material surface using bi-medium to block electric discharge

A thin-film material, barrier discharge technology, applied in electrical components, plasma, etc., can solve the problems of affecting the surface properties of materials, ablation, and large local micro-arc current, and achieve the effect of avoiding uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

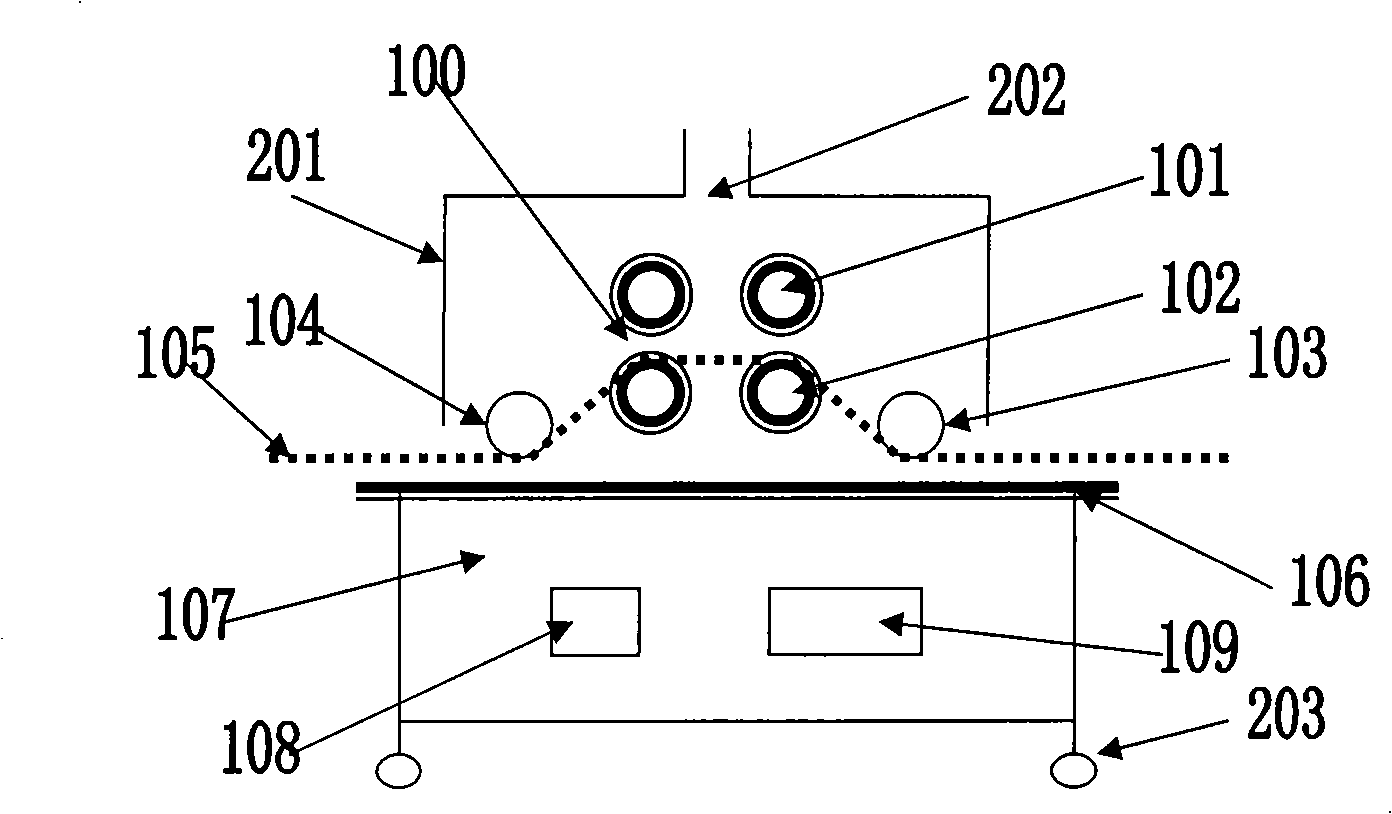

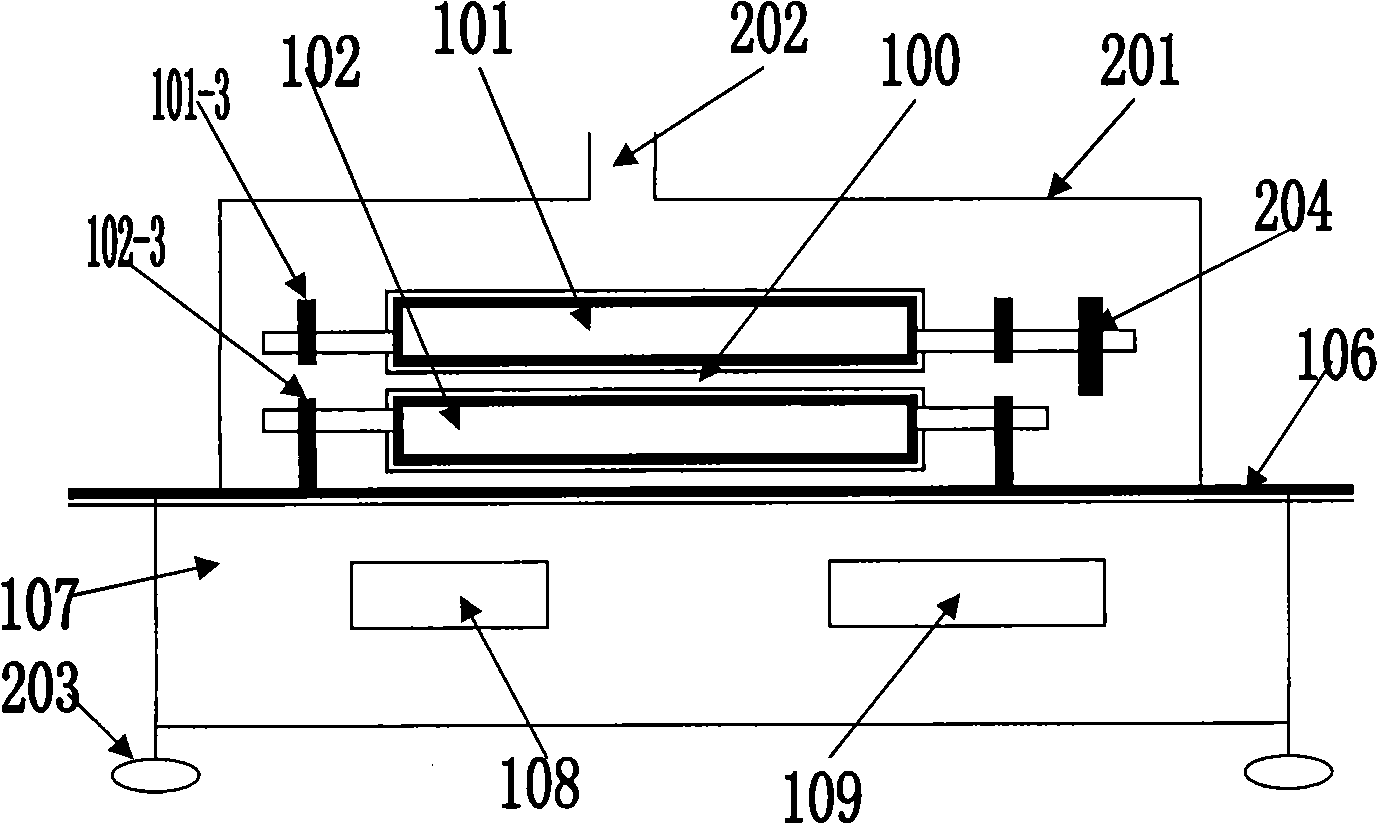

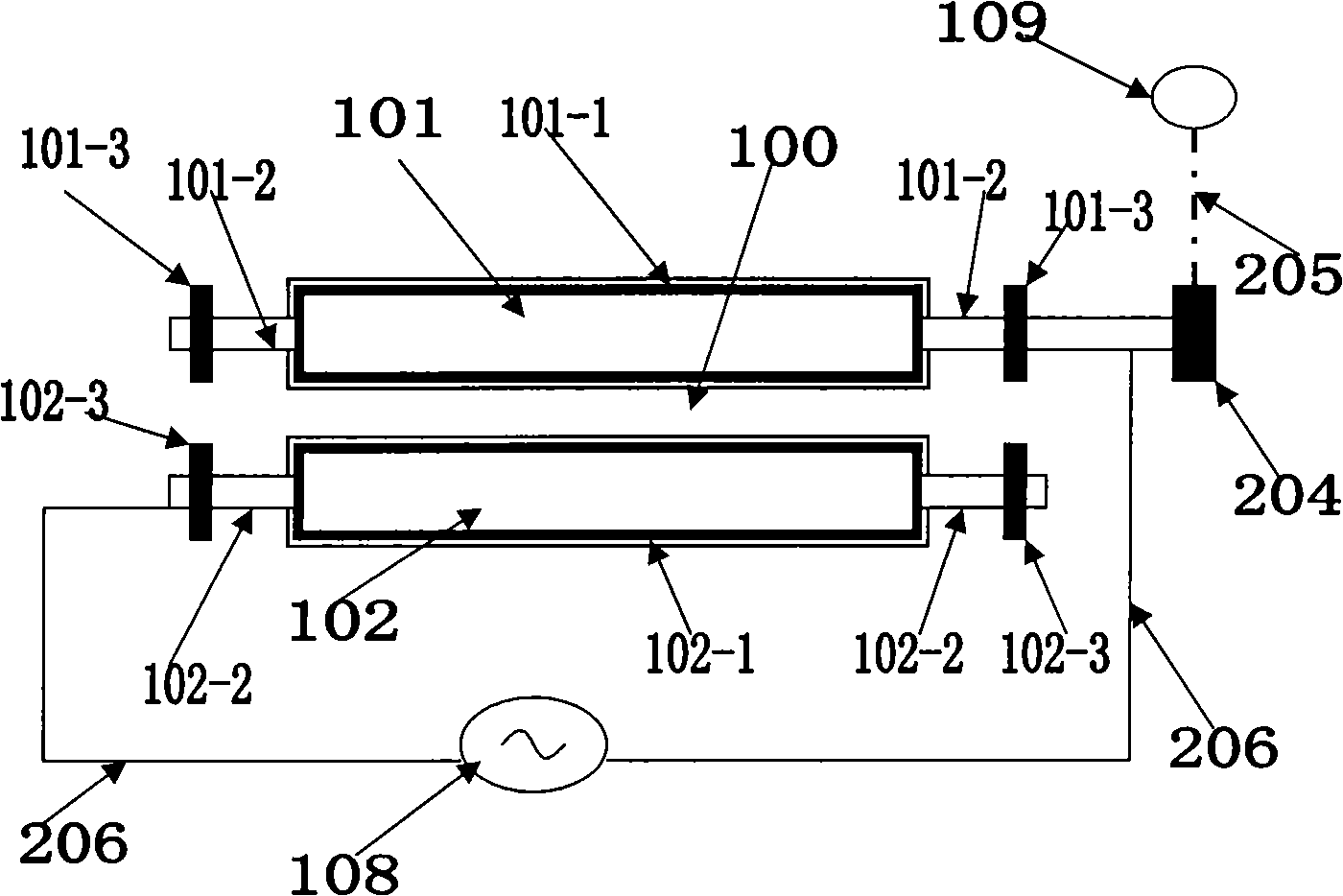

[0017] The present invention will be described in detail below in conjunction with specific embodiments with reference to the accompanying drawings. refer to figure 1 and figure 2 , are respectively the front structure schematic diagram and the side structure schematic diagram of the embodiment of the present invention; as figure 1 and figure 2 As shown, the double-dielectric barrier discharge treatment device for the surface of thin film materials includes a housing 107 for installing a high-frequency and high-voltage power supply 108. On the upper panel 106 of the housing, there are multiple groups of parallel glass tubes or ceramic tubes. The upper metal tube electrode 101 and the lower metal tube electrode 102 with the same gap between them, wherein the upper metal tube electrode 101 is driven by a motor 109 to rotate, and the lower metal tube electrode 102 is driven by the film material 105 to form a rotation. When the film material 105 passes through the upper and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com