Heating device of lining

A heating device and bushing technology, applied in ohmic resistance heating parts and other directions, can solve the problems of inability to complete the assembly process, unsuitable for ultra-long bushings, shrinkage and deformation of apertures, etc., to avoid overheating and uneven heating, and to ensure mechanical Performance, Difficulty Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with embodiment and specific embodiment the present invention will be described in further detail

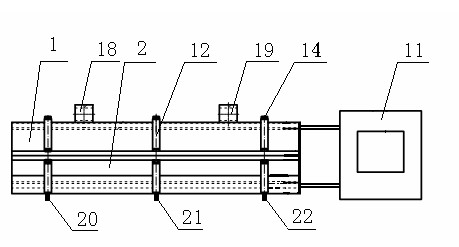

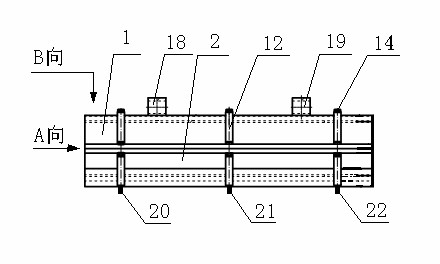

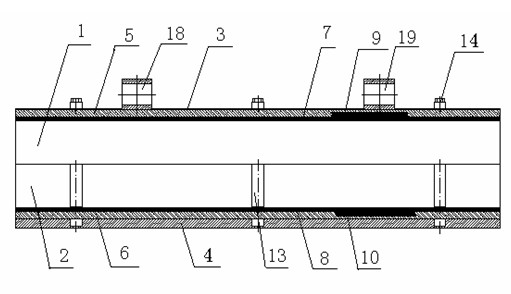

[0035] see figure 1 — Figure 4 , the heating device of a kind of liner of the present invention, comprises heater, thermocouple and control cabinet, and heater is divided into upper heater 1 and lower heater 2, and upper heater 1 is made of housing 3, insulation layer 5, heating belt 7, the insulation layer 5 is set between the inner side of the shell 3 and the heating belt 7; The thermocouples 9 and 10 are respectively arranged in the gaps between the heating belts 7 and 8; the power lines of the heating belts 7 and 8 and the temperature measurement signal lines of the thermocouples 9 and 10 are electrically connected to the control cabinet 11 respectively.

[0036] The upper and lower casings 3 and 4 are made of metal materials, the upper and lower insulation layers 5 and 6 are laid with aluminum silicate fiber insulation materials, and the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com