Rapid rice husk pyrolysis apparatus and matching system thereof

A fast, pyrolysis technology, applied in special forms of dry distillation, petroleum industry, biofuels, etc., can solve the problems that volatile substances cannot be quickly guided away, materials are not heated uniformly, and cracking is not sufficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

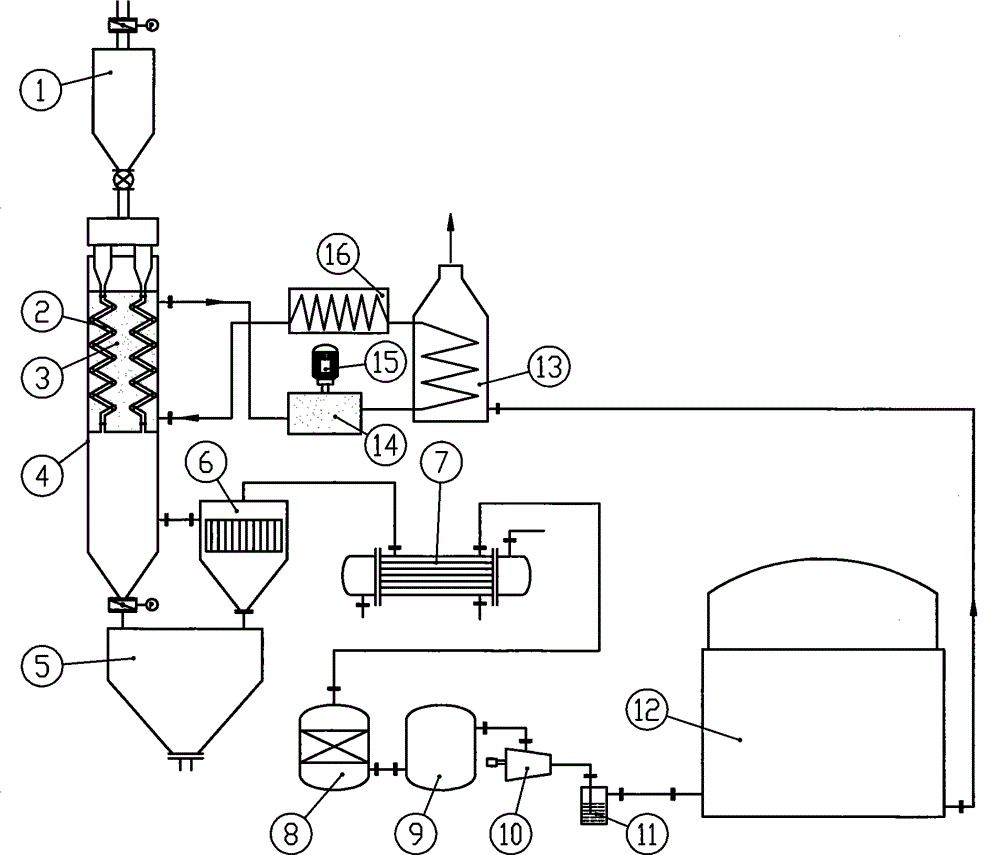

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing 1 .

[0023] As shown in Figure 1, a vacuum feeder (1) is provided on the upper part of the pyrolysis reactor shell made of stainless steel, and the feed port at the upper end is closely connected with the pyrolysis reactor shell (4) to maintain the reactor and the outside Air isolation; the lower part of the pyrolysis reactor shell is closely connected with the silo (5) through the discharge port, and two pneumatic gate valves are respectively set at the upper and lower outlets of the silo (5) to keep the reactor isolated from the outside air. Multiple sets of molten salt heaters (2) are installed vertically inside the reactor, and each set of molten salt heaters (2) is closely arranged and densely distributed inside the reactor; a gas outlet is set on the upper right of the reactor shell, and the outside is sequentially connected with the rotary ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com