Intermediate wave infrared and pulse vacuum draying integrated device of granulate prepared food and using method thereof

A technology of short-wave infrared and food conditioning, which is applied in the directions of drying solid materials, heating to dry solid materials, and non-heating to dry solid materials, etc. It can solve the problems of weak penetration, long drying time, and poor drying uniformity. Easy to operate, high drying efficiency, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

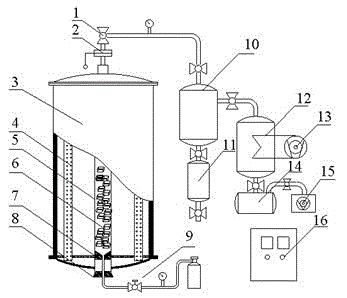

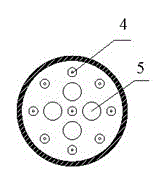

[0028] Embodiment 1, medium and short wave infrared pulse vacuum uniform drying method of potato particles

[0029] Clean the fresh potatoes and cut them into 5mm-10mm cubes. Put 200g of potato granules into a microwave oven and blanch for 2 minutes at a microwave power of 800W. After blanching, take out the potato granules, and use a cooling fan to remove the moisture attached to the surface. Turn on the refrigerator 13, and when the temperature of the cooler 12 reaches 10°C, put the gas distributor 7 and the drying pipe plug 8 into the drying pipe 5 from the lower part of the drying pipe 5, open the feed valve 1 and the baffle valve 2, and put the microwave The potato particles after blanching and cooling are put into the drying pipe 5, the feed valve 1 and the damper valve 2 are closed, and the water ring vacuum pump 15 is turned on. The power supply of the short-wave infrared emission tube 4 and the gas flow regulating valve 9, and the power of the medium-short wave infra...

Embodiment 2

[0030] Embodiment 2, medium and short-wave infrared pulse vacuum uniform drying method of mushroom particles

[0031] Clean the fresh shiitake mushrooms and cut them into cubes of 5mm-10mm. Turn on the refrigerator 13, and when the temperature of the cooler 12 reaches 10°C, put the gas distributor 7 and the drying pipe plug 8 into the drying pipe 5 from the bottom of the drying pipe 5, open the feed valve 1 and the baffle valve 2, and put the shiitake mushrooms Put the particles into the drying tube 5, close the feed valve 1 and the baffle valve 2, turn on the water ring vacuum pump 15, and the pressure in the short-wave infrared heating cavity 3 and the drying tube 5 reaches 15kPa, and turn on the power supply of the medium-short wave infrared emitting tube 4 And gas flow regulator 9. The power of medium and short-wave infrared emission tube 4 is automatically adjusted according to the set temperature of the granular material. The maximum temperature of the granular material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com