Thermal insulation slurry and novel aqueous carbon nanotube composite thermal insulation coating using thermal insulation slurry and preparation method thereof

A water-based carbon nanotube and carbon nanotube technology, applied in the field of coatings, can solve the problems of low thermal insulation effect and thermal insulation durability of coatings, limited energy saving effect of buildings, poor stain resistance and crack resistance, etc. Solve the effects of low durability, simple and easy-to-obtain construction equipment, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

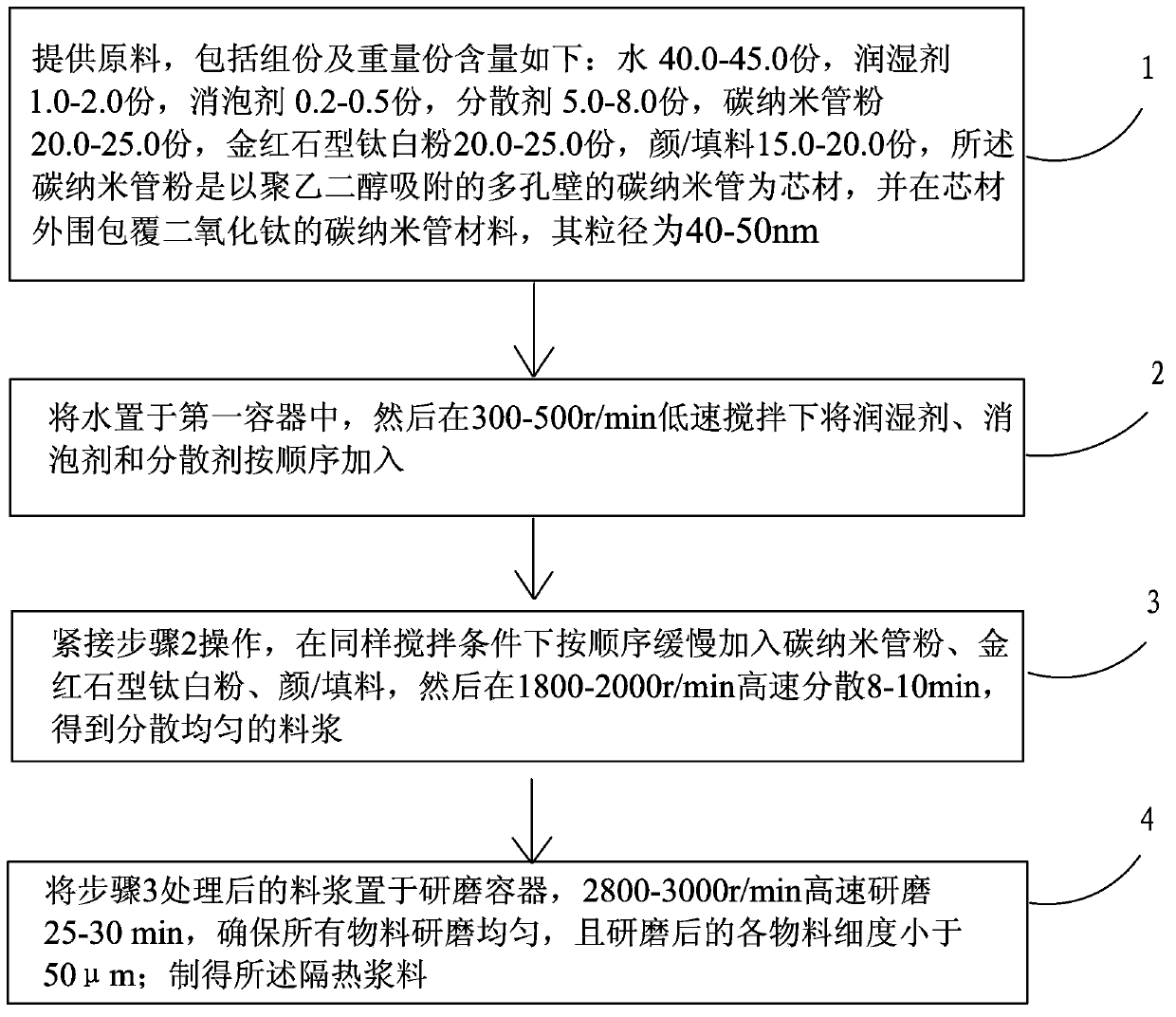

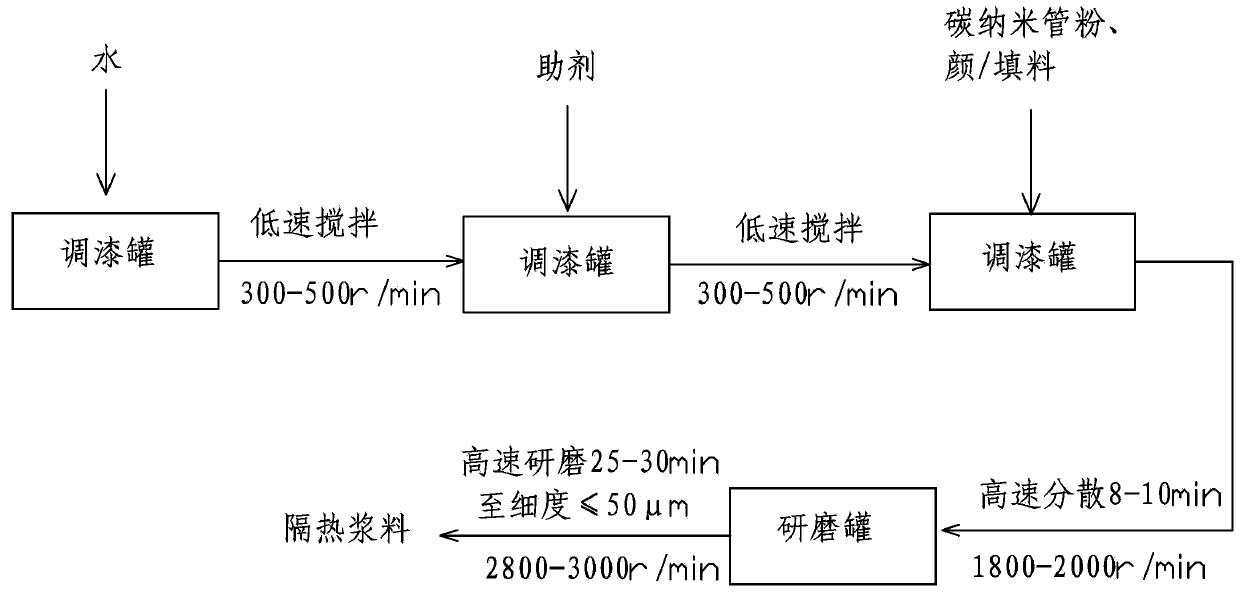

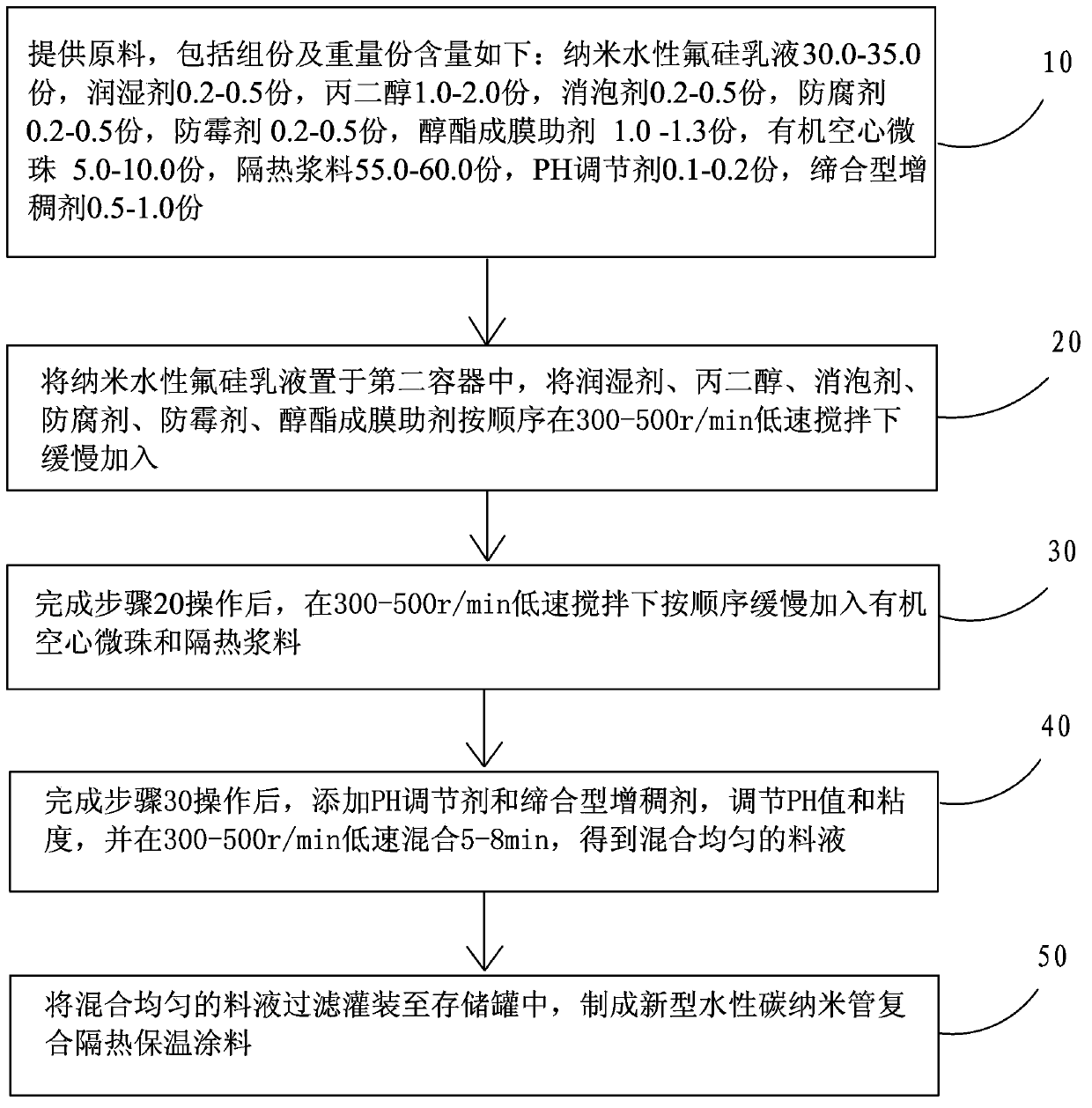

[0043] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0044] The invention provides a thermal insulation slurry, which includes components and parts by weight as follows:

[0045]

[0046] The pigment / filler is one or more commonly used pigments / fillers in the paint field such as calcium carbonate or mica powder, and its specific type can be selected according to requirements.

[0047] The dispersant is an acrylic-polyurethane copolymer dispersant with a macromolecular block structure, and its dispersion efficiency for carbon nanotubes is super strong. The preferred content is 5.0-7.0 parts by weight, and the preferred content is 6.0 parts by weight.

[0048] The wetting agent is an environmentally friendly acetylenic diol wetting agent that does not contain APEO (alkylphenol ethoxylate) and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com