Air sealed door for grain depot

A technology of airtight doors and door leaves, which is applied in sealing devices, anti-war damage, etc. It can solve the problems of poor airtightness of warehouse roofs, warehouse walls, doors and windows, and poor heat insulation of warehouse roofs, and achieves light, fast, stable operation and reasonable structure. , Solve the effect of heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

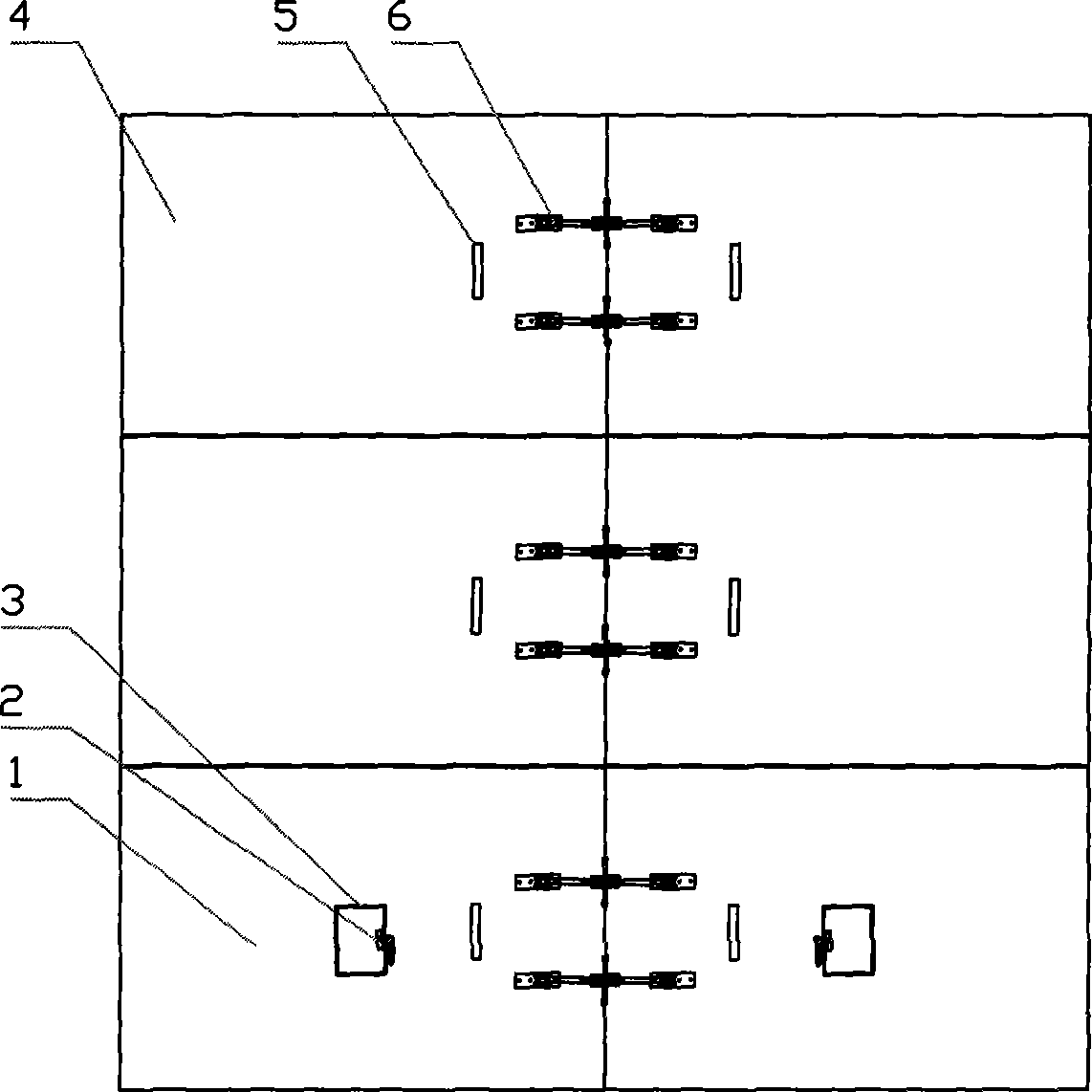

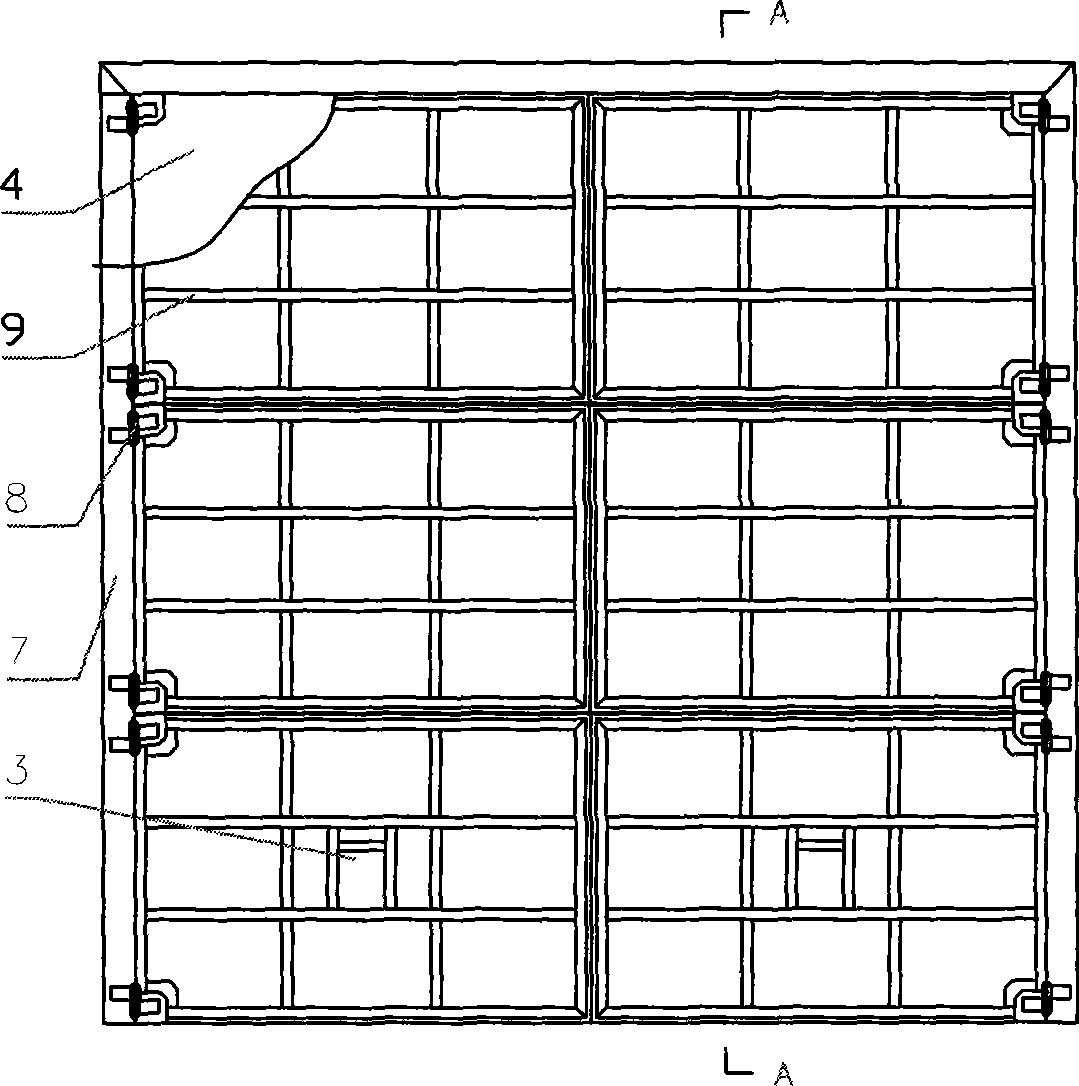

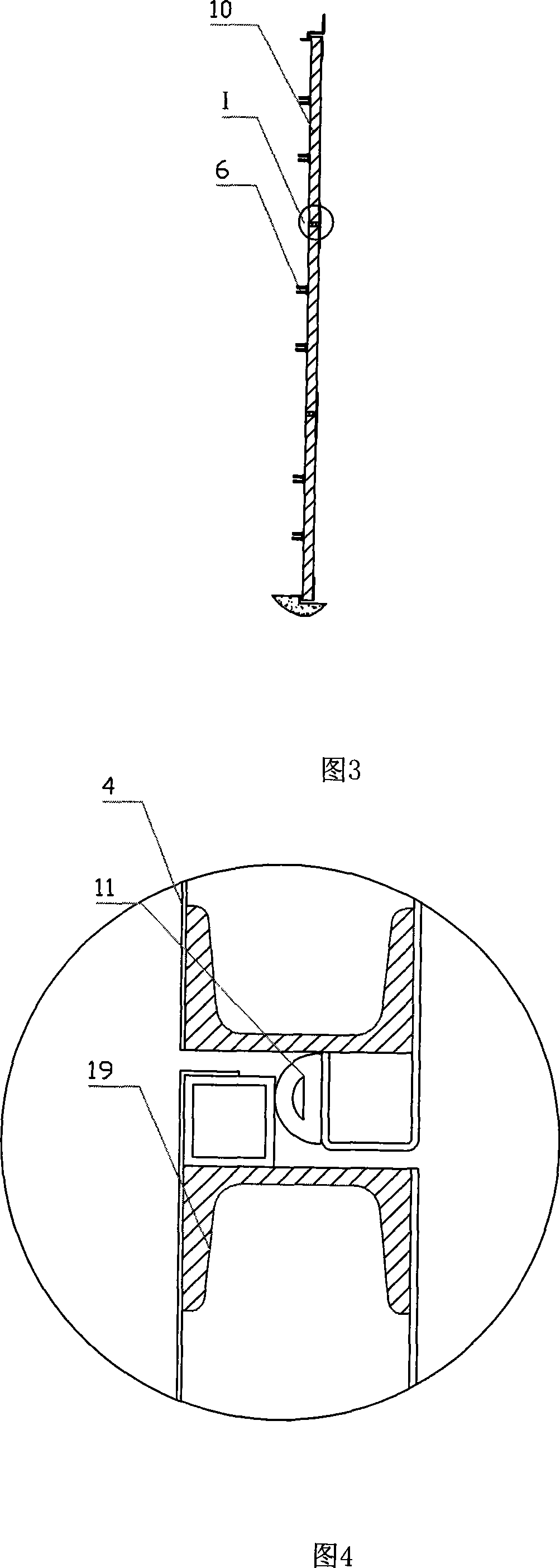

[0023] see Figure 1-10 . The door frame 7 of the present invention is consolidated with the wall as a whole, and it is composed of 6 sides that are not on a plane, wherein the upper and lower door frames consist of 4 sides of the same length, with the opening and closing of the door leaf as the apex, It is an included angle of 138° (130-145° is all acceptable), and the door frame 7 is movably connected with the door leaf through the door hinge 8 .

[0024] After the left and right door leaves are closed, they form an included angle of 138° (130-145° is acceptable). The left and right door leaves are divided into three layers, and are composed of 6 door panels 1 in total. Each door panel 1 is composed of an insulating material 5 in the middle, a door frame 9 evenly distributed, channel steel 19 around, and steel plates 4 on both inner and outer sides. Closed compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com