Sports shoes and preparation method thereof

A technology of sports shoes and raw materials, applied in footwear, applications, clothing, etc., can solve the problems of poor thermal insulation effect, poor toughness, heavy quality, etc., and achieve the effect of good aging resistance, good elasticity, toughness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

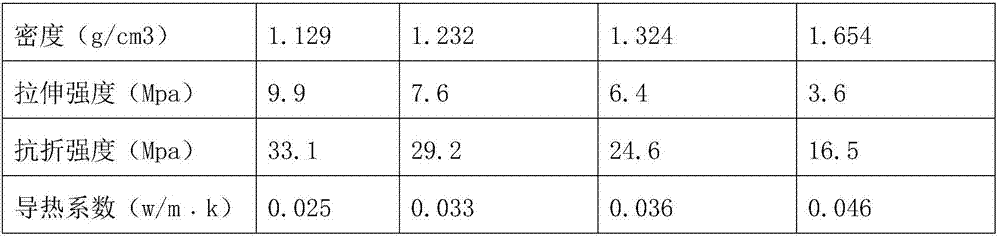

Embodiment 1

[0042] A sports shoe comprising the following raw materials in parts by weight: 265 parts of natural rubber, 150 parts of styrene-butadiene rubber, 75 parts of polyurethane rubber, 650 parts of stone powder, 70 parts of zinc oxide, 4 parts of stearic acid, and 6 parts of sulfur , 12 parts of ointment, 20 parts of floating beads, 28 parts of airgel, 50 parts of polyvinyl formal fiber, 32 parts of aramid fiber, 7 parts of foaming agent, 5 parts of rubber accelerator, and 4 parts of plasticizer 8 parts, 8 parts of light stabilizer, 6 parts of heat stabilizer, 4 parts of lubricant and 6 parts of coupling agent.

[0043] Styrene-butadiene rubber is added to the raw material. Styrene-butadiene rubber has the advantages of good air permeability, bending resistance, high mechanical strength, good vibration isolation and good aging resistance.

[0044] Polyurethane rubber is added to the raw material. Polyurethane rubber has the advantages of high tensile strength, high elongation, goo...

Embodiment 2

[0063] A sports shoe comprising the following raw materials in parts by weight: 250 parts of natural rubber, 100 parts of styrene-butadiene rubber, 50 parts of polyurethane rubber, 600 parts of stone powder, 60 parts of zinc oxide, 3 parts of stearic acid, and 4 parts of sulfur , 10 parts of ointment, 16 parts of floating beads, 16 parts of airgel, 40 parts of polyvinyl formal fiber, 29 parts of aramid fiber, 5 parts of foaming agent, 3 parts of rubber accelerator, and 3 parts of plasticizer parts, 7 parts of light stabilizer, 3 parts of heat stabilizer, 2 parts of lubricant and 4 parts of coupling agent.

[0064] Styrene-butadiene rubber is added to the raw material. Styrene-butadiene rubber has the advantages of good air permeability, bending resistance, high mechanical strength, good vibration isolation and good aging resistance.

[0065] Polyurethane rubber is added to the raw material. Polyurethane rubber has the advantages of high tensile strength, large elongation, good...

Embodiment 3

[0084] A sports shoe comprising the following raw materials in parts by weight: 280 parts of natural rubber, 200 parts of styrene-butadiene rubber, 100 parts of polyurethane rubber, 700 parts of stone powder, 80 parts of zinc oxide, 5 parts of stearic acid, and 8 parts of sulfur , 14 parts of ointment, 24 parts of floating beads, 40 parts of airgel, 60 parts of polyvinyl formal fiber, 35 parts of aramid fiber, 9 parts of foaming agent, 7 parts of rubber accelerator, and 5 parts of plasticizer 9 parts, 9 parts of light stabilizer, 9 parts of heat stabilizer, 6 parts of lubricant and 8 parts of coupling agent.

[0085] Styrene-butadiene rubber is added to the raw material. Styrene-butadiene rubber has the advantages of good air permeability, bending resistance, high mechanical strength, good vibration isolation and good aging resistance.

[0086] Polyurethane rubber is added to the raw material. Polyurethane rubber has the advantages of high tensile strength, large elongation, g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com