Manufacturing method of cold-rolled medium-high carbon alloy structural steel with thickness ranging from 0.1 mm to 0.4 mm

An alloy structural steel and a manufacturing method technology, applied in the field of steel manufacturing, can solve the problems of easy fracture, peeling, incomplete penetration of deformation, poor forming performance of steel strips, etc., and achieve the effects of improving plasticity, reducing quantity and reducing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

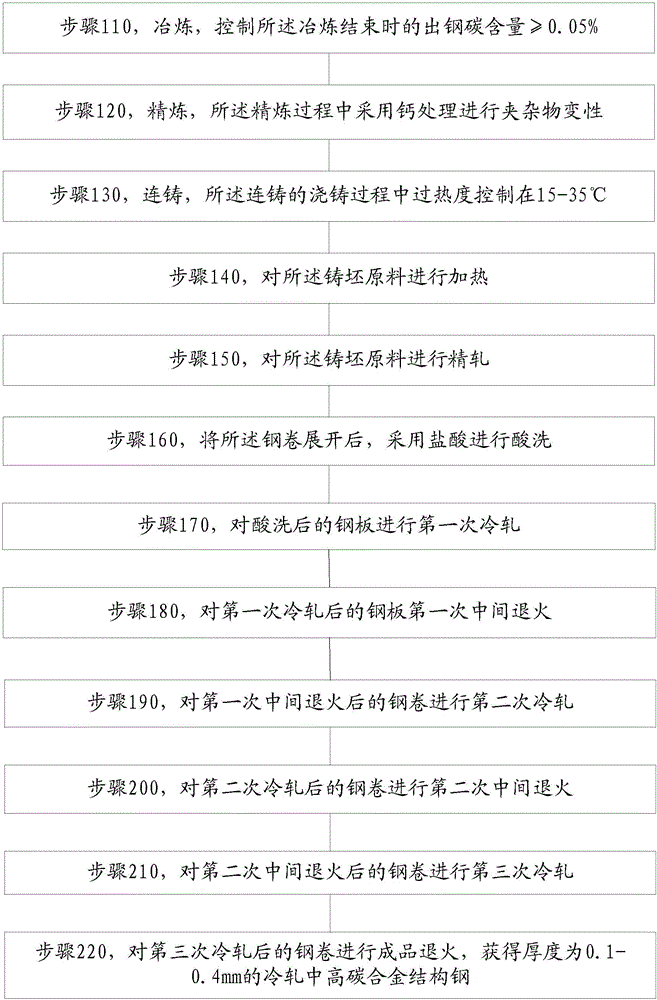

Method used

Image

Examples

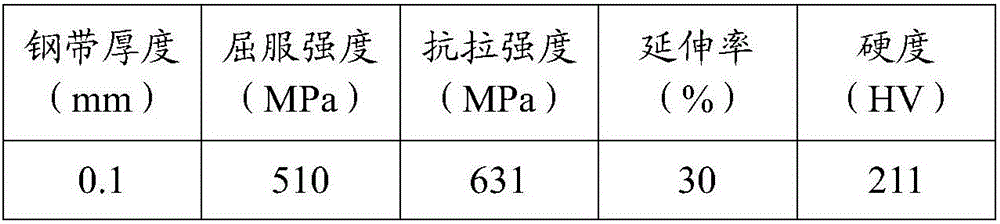

example 1

[0078] The method for manufacturing cold-rolled structural alloy steel 50Cr with a thickness of 0.1 mm described in this example, the chemical composition is C: 0.50wt.%, Si: 0.27wt.%, Mn: 0.60wt.%, Cr: 1.0wt.%, P: 0.012wt.%, S: 0.001wt.%, Alt: 0.021%, and the rest are Fe and unavoidable impurities.

[0079] The thickness of the billet raw material is 55mm, the finish rolling temperature is 920°C, the cold rolling speed after finish rolling is 30°C / s, the coiling temperature is 730°C, and then the steel coil is slowly cooled in the warehouse, and the thickness of the steel coil is 2.0mm .

[0080] The pickling temperature is 85° C., the concentration of the hydrochloric acid is 12%, the iron salt content in the hydrochloric acid is 105 g / l, and the pickling speed is 15 m / min.

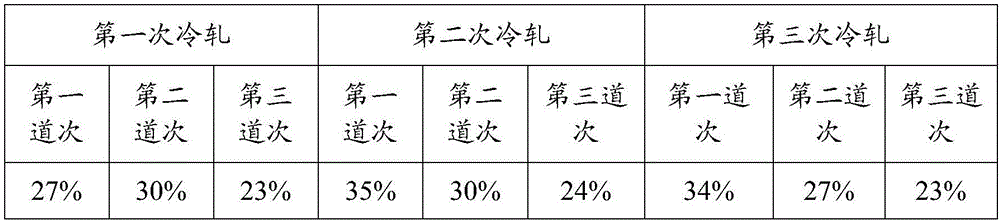

[0081] The distribution of cold rolling passes is shown in Table 1. The surface roughness Ra of the third cold rolling roll is 0.5 μm. The first intermediate annealing, the second intermediate annealin...

example 2

[0089] The manufacturing method of the cold-rolled structural alloy steel 42CrMo4 with a thickness of 0.4mm described in this example, the chemical composition is C: 0.39wt.%, Si: 0.22wt.%, Mn: 0.77wt.%, P: 0.012wt.%, S: 0.003wt.%, Alt: 0.030%, Cr: 1.1%, Mo: 0.17%, and the rest is Fe and unavoidable impurities.

[0090] The thickness of the billet raw material is 90mm, the finish rolling temperature is 860°C, the cold rolling speed after finish rolling is 18°C / s, the coiling temperature is 680°C, and then the steel coil is slowly cooled in the warehouse. The thickness of the steel coil is 2.5mm.

[0091] The pickling temperature is 75° C., the concentration of the hydrochloric acid is 6%, the iron salt content in the hydrochloric acid is 110 g / l, and the pickling speed is 30 m / min.

[0092] The allocation of cold rolling passes is shown in Table 3. After the third cold rolling, the surface roughness Ra of the roll is 0.45 μm. The protective gas used for the first intermediate...

example 3

[0101] The manufacturing method of cold-rolled alloy structural steel 40CrMn with a thickness of 0.2mm described in this example, the chemical composition is C: 0.40wt.%, Si: 0.35wt.%, Mn: 0.90wt.%, P: 0.010wt.%, S: 0.005wt.%, Alt: 0.025%, Cr: 1.0%, and the rest is Fe and unavoidable impurities.

[0102] The thickness of the billet raw material is 150mm, the finish rolling temperature is 912°C, the cold rolling speed after finish rolling is 24°C / s, and the coiling temperature is 700°C, and then the steel coil is slowly cooled in the warehouse, and the thickness of the steel coil is 2.2mm.

[0103] The pickling temperature is 81° C., the concentration of the hydrochloric acid is 11%, the iron salt content in the hydrochloric acid is 95 g / l, and the pickling speed is 21 m / min.

[0104] The distribution of cold rolling passes is shown in Table 5. After the third cold rolling, the surface roughness Ra of the roll is 0.35 μm. The protective gas used for the first intermediate anne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com