Mill construction of overhanging type air inlet ventilation outer wall

A technology for air intake and workshops, which is applied to walls, building components, building structures, etc. It can solve the problems that the upper fixed glass windows are easy to break, the glass is easy to corrode and damage, and the windshield switch is not flexible, so as to achieve the effect of preventing drifting rain Good, beautiful appearance, the effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

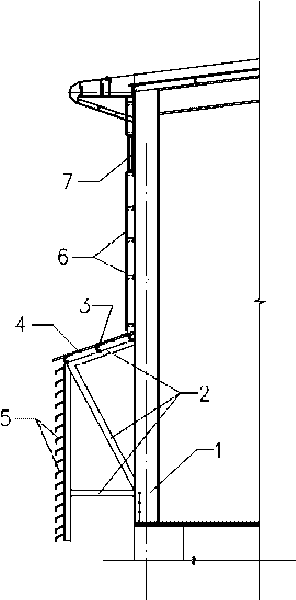

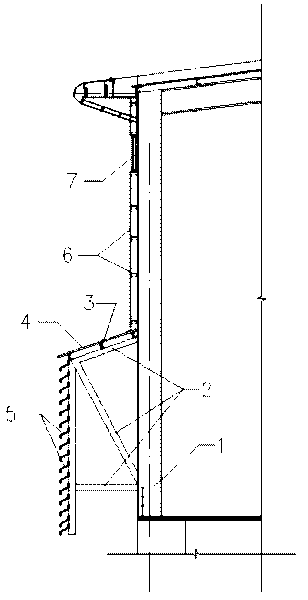

[0010] Embodiments of the present invention: as figure 1 As shown, when the factory building is being built, the factory building column foundation is first made, and then the factory building steel column 1 is fabricated and installed on the factory building column foundation, and the steel beam is connected on the factory building steel column 1, and the roof is laid on the steel beam. The outer wall of the factory building is to install the cantilevered open large air intake steel bracket 2 on the lower part of the outer side of the factory building steel column 1 and below the interface with bolts or welding. The baffle is installed on the top surface, and the baffle is composed of purlins 3 and colored profiled steel plates 4. The purlins 3 are installed with bolts on the top surface of the cantilevered open large air intake steel bracket 2, and then fastened on the purlins 3 Lay the colored profiled steel plate 4, and then install the rainproof louver blade 5 with self-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com