Polyurethane composition for wood-like spraying all-water foaming system as well as preparation method and equipment

A technology of all-water foaming and polyurethane, which is applied in polyurea/polyurethane coatings, coatings, chemical/physical/physicochemical fixed reactors, etc., and can solve problems that cannot meet market demand, coating texture is not clear, and spraying performance Poor and other problems, to achieve the effect of large-scale popularization and application, little change in production process, and solution to foam brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

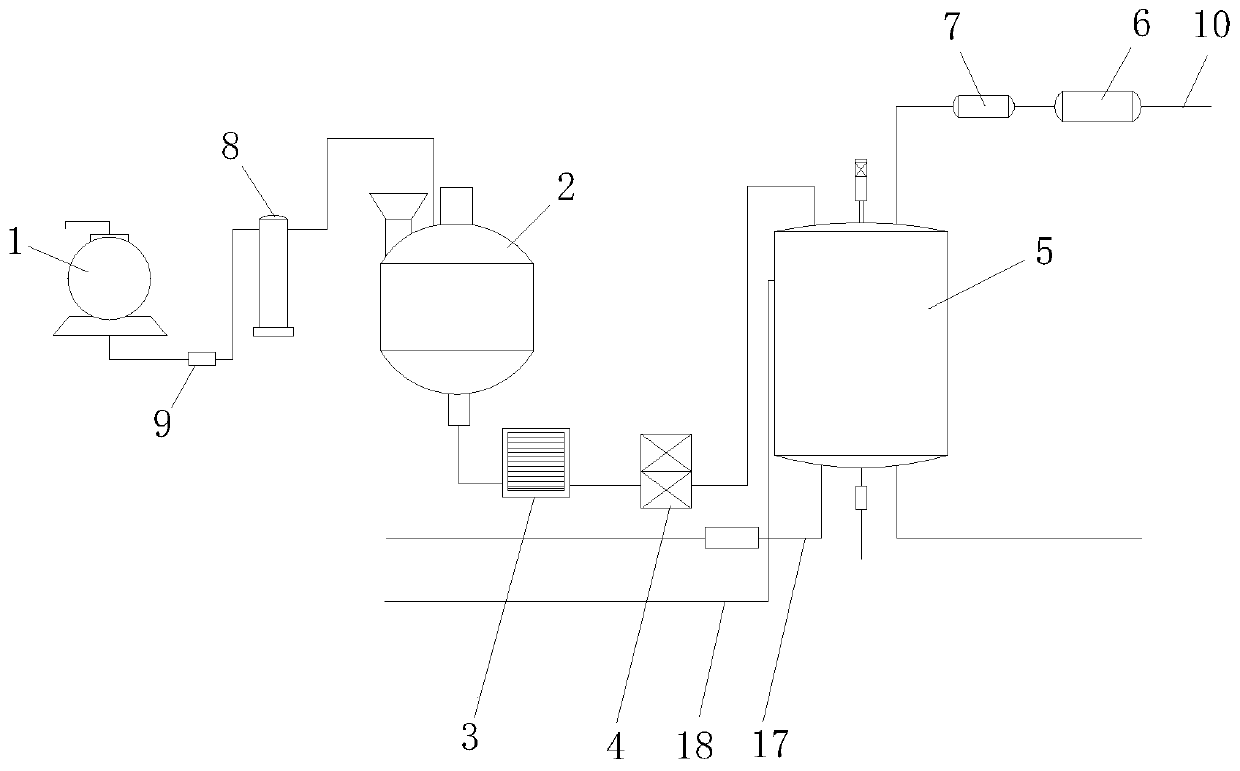

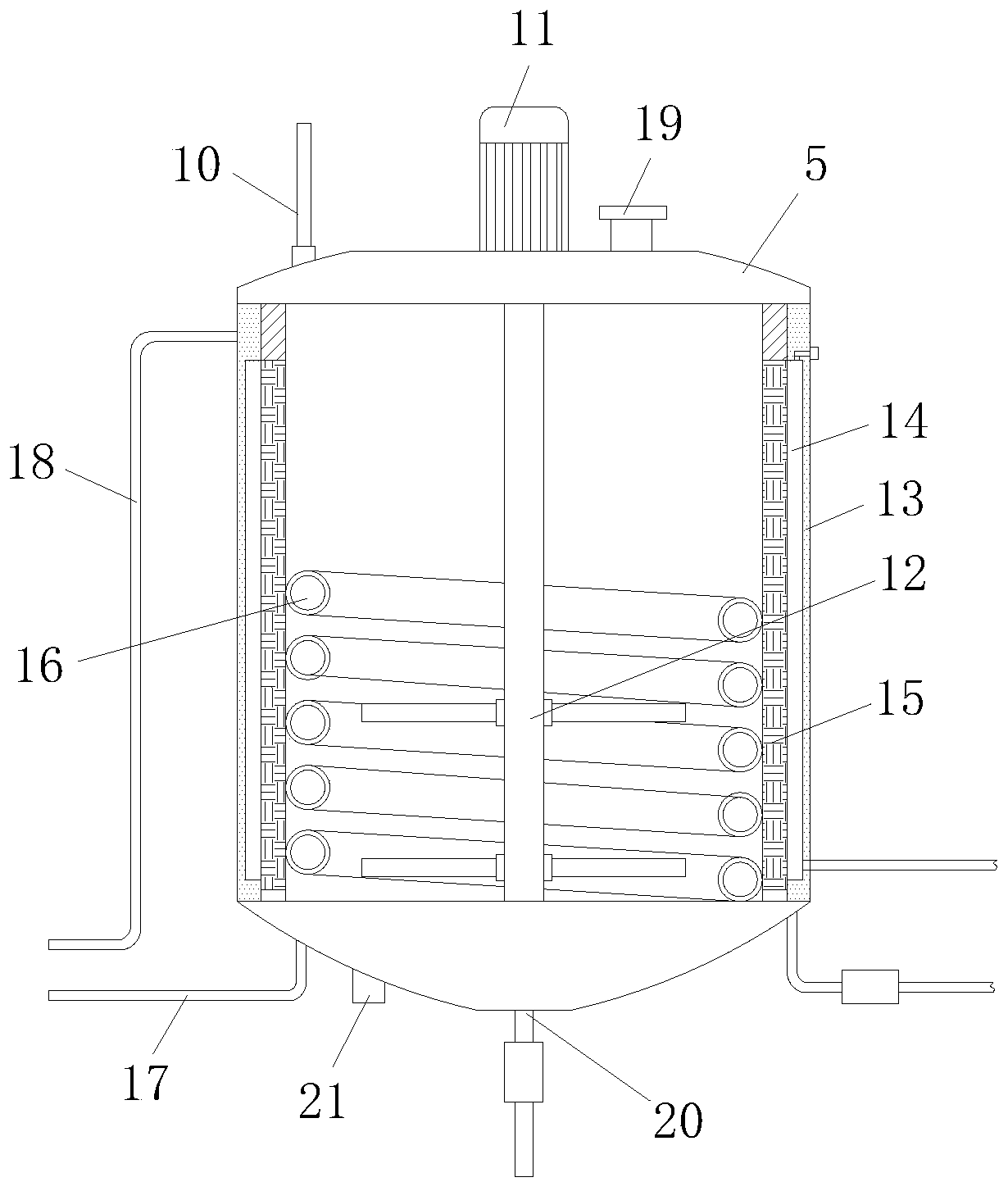

[0037] see Figure 1-3 , the polyurethane composition that the present invention is used for imitation wood spraying all-water foaming system, polyurethane composition is prepared by the component of following parts by weight:

[0038] Polyether: 85 parts; Polyester: 15 parts; Crosslinking agent: 3-5 parts; Catalyst: 1-5 parts; Foam stabilizer: 2-5 parts; Water: 1-1.5 parts.

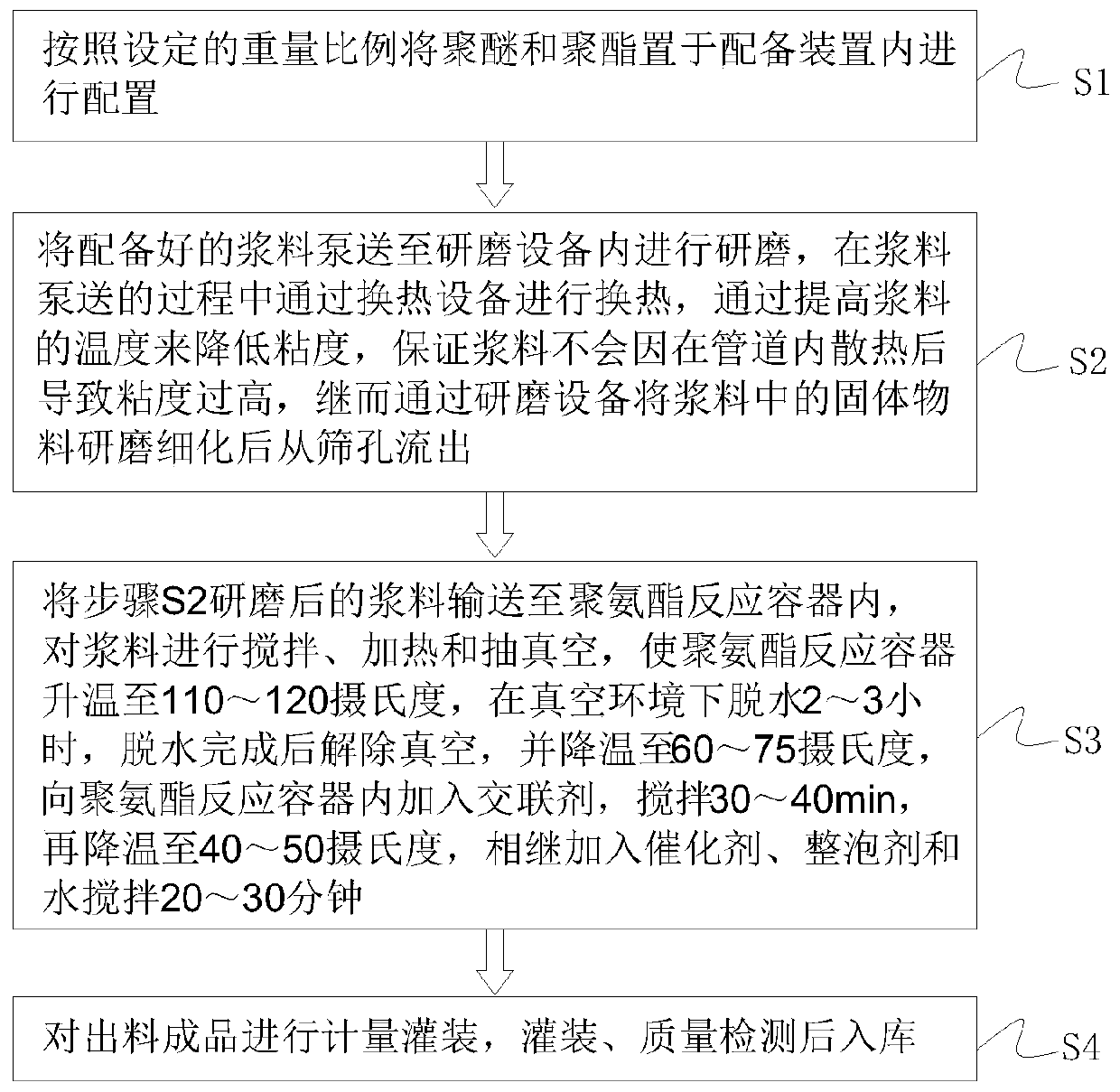

[0039] The present invention also provides the above-mentioned preparation method for the polyurethane composition of imitation wood spraying all-water foaming system, comprises the following steps:

[0040] S1. Raw material configuration: according to the set weight ratio, polyether and polyester are placed in the equipment for configuration;

[0041] S2. Heat exchange and grinding: Pump the prepared slurry to the grinding equipment for grinding. During the slurry pumping process, heat exchange is performed through the heat exchange equipment, and the viscosity is reduced by increasing the temperature ...

Embodiment 2

[0060] The polyurethane composition, preparation method and equipment for wood-like spraying all-water foaming system provided in this embodiment are basically the same as in Example 1, except that:

[0061] In this embodiment, the polyurethane composition used for imitation wood spraying all-water foaming system is specifically prepared from the following components by weight:

[0062] Polyether: 60 parts; polyester: 15 parts; crosslinking agent: 3-5 parts; catalyst: 3-5 parts; foam regulator: 5-7 parts; water: 5-10 parts.

Embodiment 3

[0064] The polyurethane composition, preparation method and equipment for imitation wood spraying all-water foaming system provided by this embodiment are basically the same as embodiment 1 and embodiment 2, and its difference is:

[0065] Polyether: 60 parts; Polyester: 15 parts; Crosslinking agent: 1-3 parts; Catalyst: 2-4 parts; Foam stabilizer: 3-6 parts; Water: 4-8 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com