High temperature and high pressure resistance electromagnetism driving stop valve inner screen outer dissipation heat insulation device

A technology of heat insulation device and high temperature resistance, which is applied in the field of valves and electromagnetic shut-off valves, and can solve the problem of not being able to meet the long-term use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

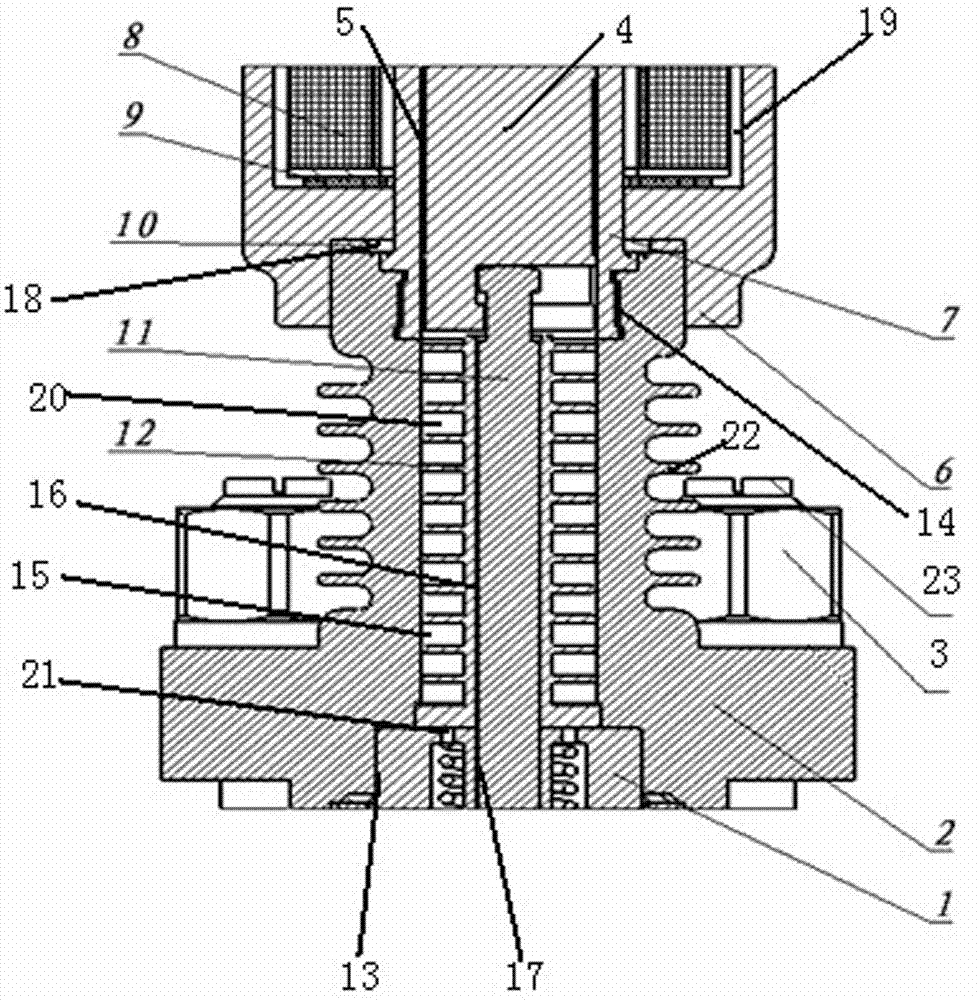

[0046] A high-temperature and high-pressure electromagnetic stop valve inner and outer heat dissipation heat insulation device, including a guide body 1, a valve sleeve 2, a coil outer shell 6, a non-magnetic tube 7, a coil assembly 8, a valve stem 11, a moving magnet 4 and a heat insulation Set of 12, characterized in that:

[0047]The lower end surface of the valve sleeve 2 is provided with a guide body groove 13, the upper end of the valve sleeve 2 is provided with a non-magnetic pipe jack 14 with an internal thread, and the center of the valve sleeve 2 is provided with a through hole 15 for a heat-insulating sleeve. The heat insulation sleeve 12 is installed in the heat insulation sleeve through hole 15, the heat insulation sleeve 12 has a first valve stem through hole 16, the guide body 1 has a second valve stem through hole 17, and the guide body 1 is installed in the guide body concave. In the groove 13, the valve stem 11 is loaded into the first valve stem through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com